Thermal insulation metal material

A heat-insulating metal material and heat-insulating material technology, applied in the field of metal alloy materials, can solve the problems of strong corrosiveness and irritation, safety hazards of smelting equipment and operators, and achieve less shrinkage defects, slow atomic diffusion, The effect of preventing metal corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

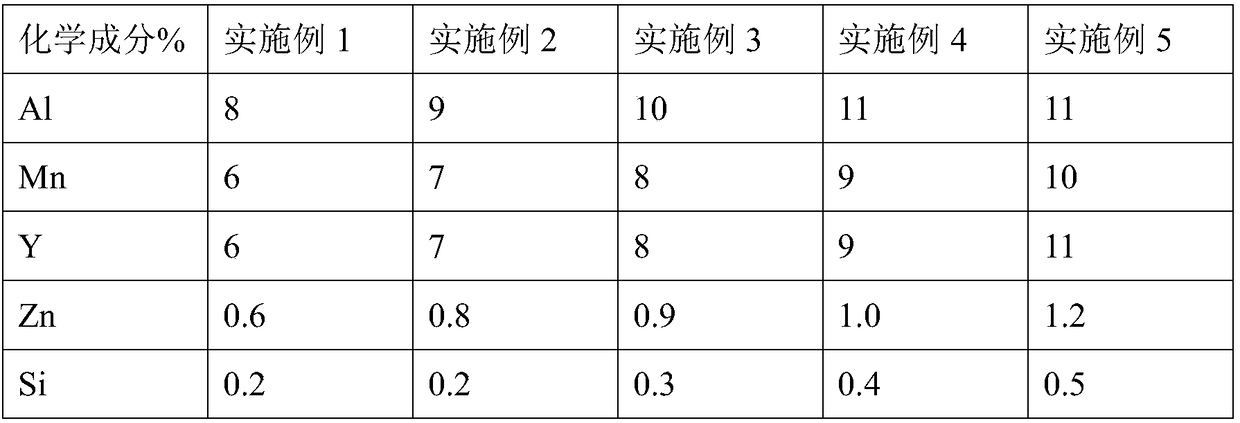

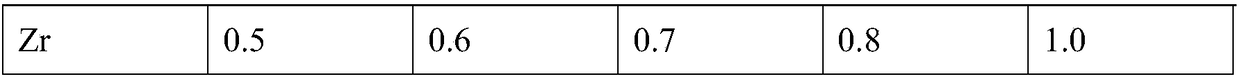

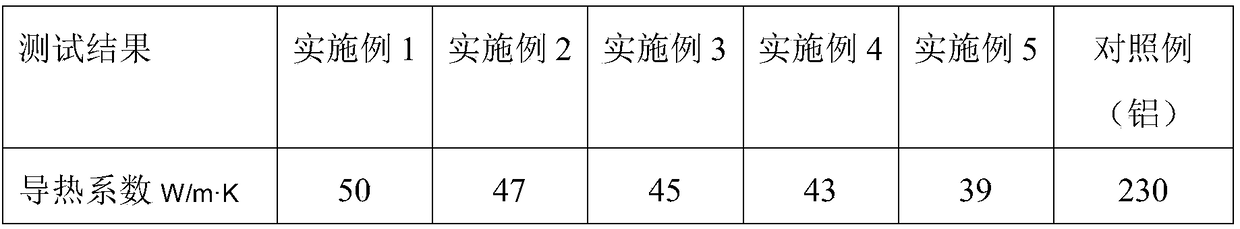

Embodiment 1

[0027] This embodiment provides a heat-insulating metal material, which is composed of a metal material and a heat-insulating material, wherein the weight percentage of the chemical composition of the metal material is: Al 8%, Mn 6%, Y 6%, Zn 0.6%, Si 0.2%, Zr 0.5%, and the balance is Mg. The thermal insulation material is ceramics, and the components of the ceramics are as follows by weight: 40 parts of kaolin, 25 parts of potassium feldspar, 18 parts of quartz, 10 parts of clay, and 1 part of talc. Its structure is three layers, the thickness of the upper metal layer is 5mm, the thickness of the middle insulation layer is 5mm, and the thickness of the lower metal layer is 5mm.

[0028] A heat-insulating metal material realized in this example includes the following steps:

[0029] Step 1, the magnesium alloy that Mg, Al, Zn, Si etc. are formed is in solvent capping agent SF 6 Under protection, the temperature rises and melts into a liquid;

[0030] Step 2. Add Y, Zr and M...

Embodiment 2

[0034]This embodiment provides a heat-insulating metal material, which is composed of a metal material and a heat-insulating material, wherein the weight percentage of the chemical composition of the metal material is: Al 9%, Mn 7%, Y 7%, Zn 0.8%, Si 0.2%, Zr 0.6%, and the balance is Mg. The thermal insulation material is ceramics, and the components of the ceramics are as follows by weight: 41 parts of kaolin, 27 parts of potassium feldspar, 18 parts of quartz, 10 parts of clay, and 1 part of talc. Its structure is three layers, the thickness of the upper metal layer is 9mm, the thickness of the middle insulation layer is 6mm, and the thickness of the lower metal layer is 9mm.

[0035] A heat-insulating metal material realized in this example includes the following steps:

[0036] Step 1, the magnesium alloy that Mg, Al, Zn, Si etc. are formed is in solvent capping agent SF 6 Under protection, the temperature rises and melts into a liquid;

[0037] Step 2. Add Y, Zr and Mn...

Embodiment 3

[0041] This embodiment provides a heat-insulating metal material, which is composed of a metal material and a heat-insulating material, wherein the weight percentage of the chemical composition of the metal material is: Al 10%, Mn 8%, Y 8%, Zn 0.9%, Si 0.3%, Zr 0.7%, and the balance is Mg. The thermal insulation material is ceramics, and the components of the ceramics are as follows by weight ratio: 42 parts of kaolin, 28 parts of potassium feldspar, 19 parts of quartz, 11 parts of clay, and 2 parts of talc. Its structure is three layers, the thickness of the upper metal layer is 13mm, the thickness of the middle insulation layer is 7mm, and the thickness of the lower metal layer is 13mm.

[0042] A heat-insulating metal material realized in this example includes the following steps:

[0043] Step 1, the magnesium alloy that Mg, Al, Zn, Si etc. are formed is in solvent capping agent SF 6 Under protection, the temperature rises and melts into a liquid;

[0044] Step 2. Add Y...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com