An integrated forming equipment and method for thin-walled parts of aluminum matrix composite materials

A technology of aluminum-based composite materials and forming equipment, which is applied in the field of composite material forming casting, can solve problems such as complex aluminum-based composite materials, pores, inclusions, many cold barriers, and thin-walled parts are difficult to form, so as to achieve stable casting quality and easy Promotes and prevents the effect of shrinkage and porosity defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are only used to illustrate the present invention, but not to limit the scope of the present invention.

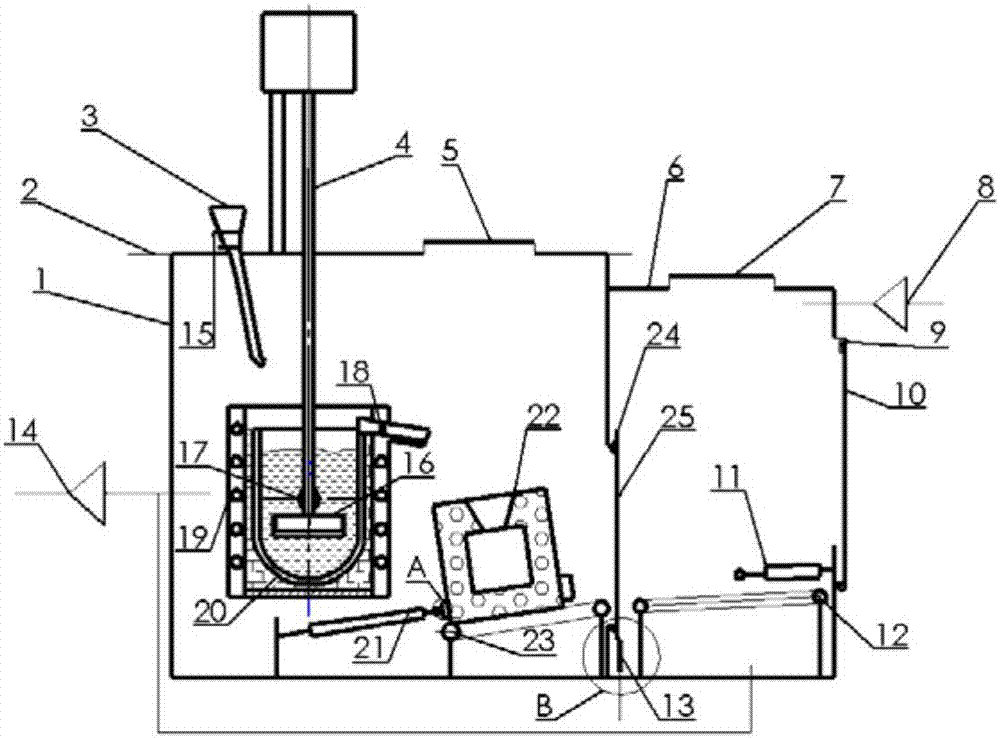

[0038] Such as figure 1 As shown, this embodiment describes an integrated forming equipment for complex and thin-walled aluminum alloy composite materials, which includes: aluminum alloy preparation-casting tank 1 and pressurized tank 6 .

[0039] The upper part of the preparation-casting tank 1 is isolated from the outside by a sealing cover 2 , on which a feeding barrel 3 , a feeding-stirrer 4 and a first observation window 5 are arranged. The feeding barrel 3 has two built-in layers, the upper layer is equipped with modifier and refiner, and the lower layer is equipped with SiCp powder. The feeding speed is controlled by two ball valves 15 respectively, and it is completely is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com