Multi-rubber rotary body casting, multi-rubber rotary body and casting mold for casting multi-rubber rotary body casting

A rotary body and multi-channel technology, applied in the direction of casting molds, casting mold components, manufacturing tools, etc., can solve problems such as hole deformation, unsatisfactory results, small valve core holes, etc., achieve simple structure, and solve shrinkage defects , design reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

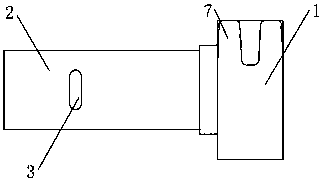

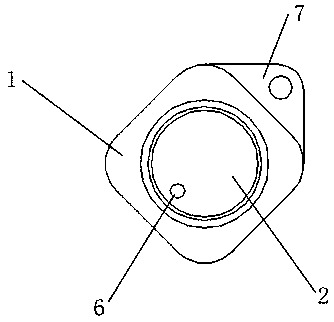

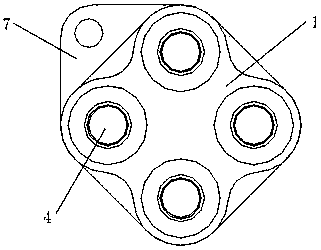

[0021] Such as Figure 1-4 , a multi-channel rotary casting, which includes a base 1 and a base 2, the base 1 is in the shape of a cube, the base 2 is a second-order column, and the second step of the base 2 is connected to one end of the base 1; the base 2 Four oil outlets 3 are evenly arranged around the second stage of the second stage, and the four oil outlets 3 are distributed along the axial direction of the base 2; the other end surface of the base 1 is evenly provided with four oil inlets 4; the oil inlets 4. The oil outlets 3 are in one-to-one correspondence and are respectively connected through the flow channel holes 5 provided in the rotary casting; one end of the rotary casting is provided with a riser 6; during pouring, the shrinkage cavity of the casting is solved by gravity feeding Shrinkage defects; one side of the base 1 is provided with arc-shaped ears 7; the technical parameters of the rotary casting are as follows: material QT450-10, tensile strength singl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com