Insulating riser and manufacture method thereof

A technology of thermal insulation riser and thermal insulation layer, which is applied in the field of alloy casting, can solve the problems of flexibility and adaptability limitation of thermal insulation riser sleeve, feeding resistance and other problems, and achieve the effect of convenient and quick maintenance, loose solution and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

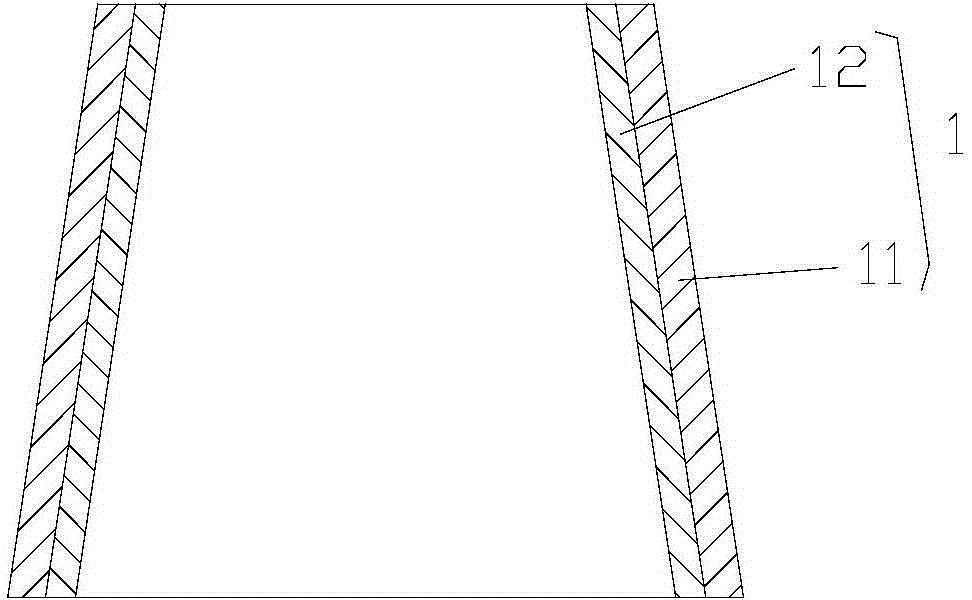

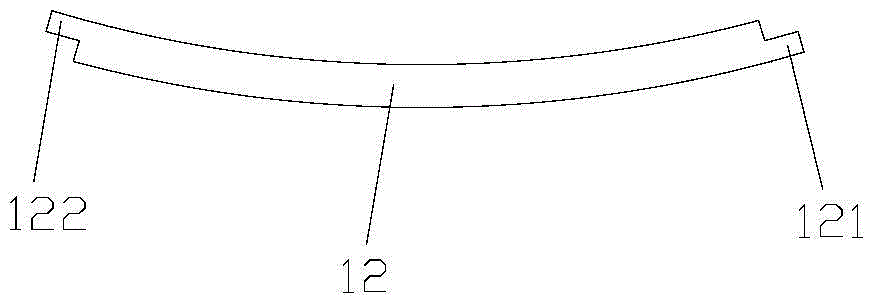

[0028] Wherein the raw materials of the heating sheet 12 include by weight: hollow microspheres: 30 parts, aluminum powder: 10 parts, ferric oxide: 5 parts, magnesium powder: 20 parts, charcoal powder: 40 parts, potassium permanganate: 5 parts share.

Embodiment 2

[0030] Wherein the raw material of heating sheet 12 comprises by weight: hollow microspheres: 50 parts, aluminum powder: 20 parts, ferric oxide: 15 parts, magnesium powder: 40 parts, charcoal powder: 60 parts, potassium permanganate: 15 parts share.

Embodiment 3

[0032] Wherein the raw material of heating sheet 12 comprises by weight: hollow microspheres: 38 parts, aluminum powder: 17 parts, ferric oxide: 10 parts, magnesium powder: 25 parts, charcoal powder: 53 parts, potassium permanganate: 5 parts share.

[0033] Example 3

[0034] Wherein the raw materials of the heating sheet 12 include by weight: hollow microspheres: 42 parts, aluminum powder: 18 parts, ferric oxide: 12 parts, magnesium powder: 30 parts, charcoal powder: 55 parts, potassium permanganate: 8 parts share.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com