Casting method for protecting thin-wall casting from local isolated hot spot shrinkage

A thin-walled casting, isolated technology, used in casting molding equipment, casting molds, casting mold components, etc., can solve the problems of bosses unable to take riser feeding, cooling water chilling, casting leakage, etc., to improve the working environment. conditions, improve production efficiency, and reduce labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawing.

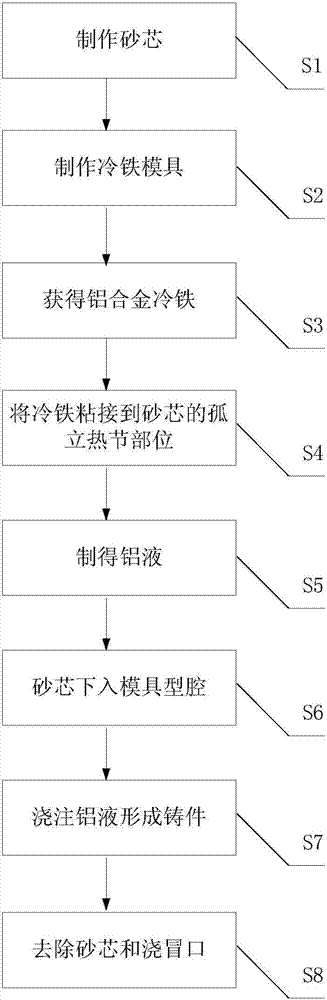

[0024] see figure 2 , Figure 3 and Figure 4 , the thin-walled casting of the present invention prevents the casting method of local isolated thermal shrinkage porosity, comprising the following steps:

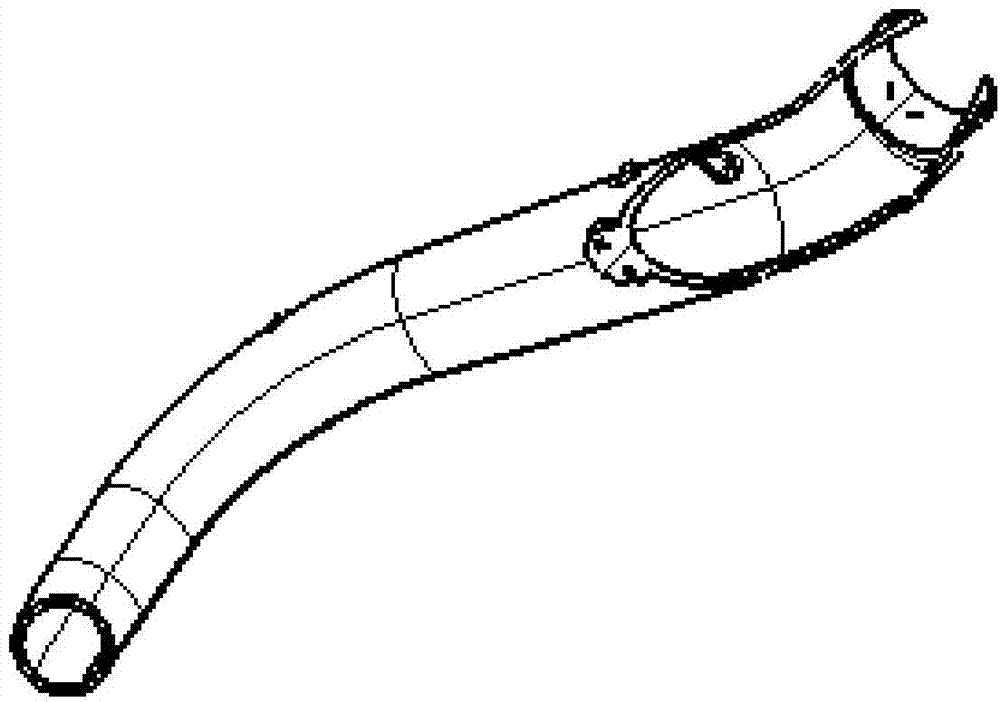

[0025] Step S1, making sand cores for casting thin-walled castings; in this embodiment, the thin-walled castings use intercooling tubes as an example, such as figure 1 shown;

[0026] Step S2, making a corresponding cold iron mold according to the shape of the isolated heat joint of the thin-walled casting;

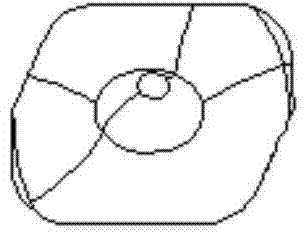

[0027] Step S3, using the chilled iron mold to obtain an aluminum alloy chilled iron that fits the isolated hot spot of the thin-walled casting, such as Figure 3a , Figure 3b and shown in Figure 3C; and, the volume of the aluminum alloy chiller is greater than or equal to 3 times that of the isolated hot joint part of the thin-walled casting, because the larger...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com