Casting method of body casting of centrifugal air compressor

A centrifugal air compressor and air compressor technology, applied in the direction of casting molding equipment, casting molds, casting mold components, etc., can solve problems such as uneven wall thickness, difficulty in solidification and feeding of castings, complex structure, etc., and achieve heat dissipation , Excellent appearance quality, avoid brush marks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

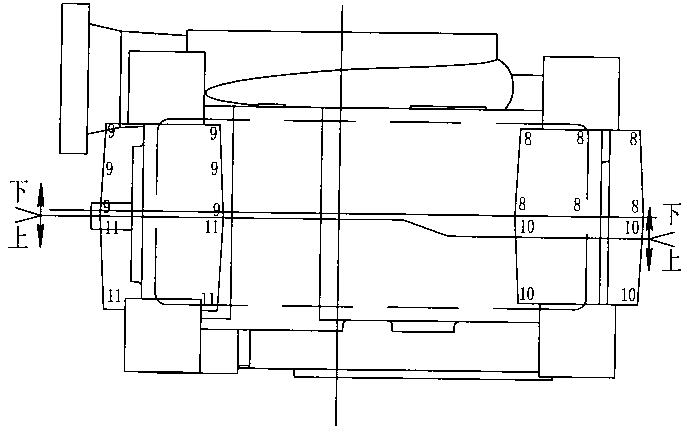

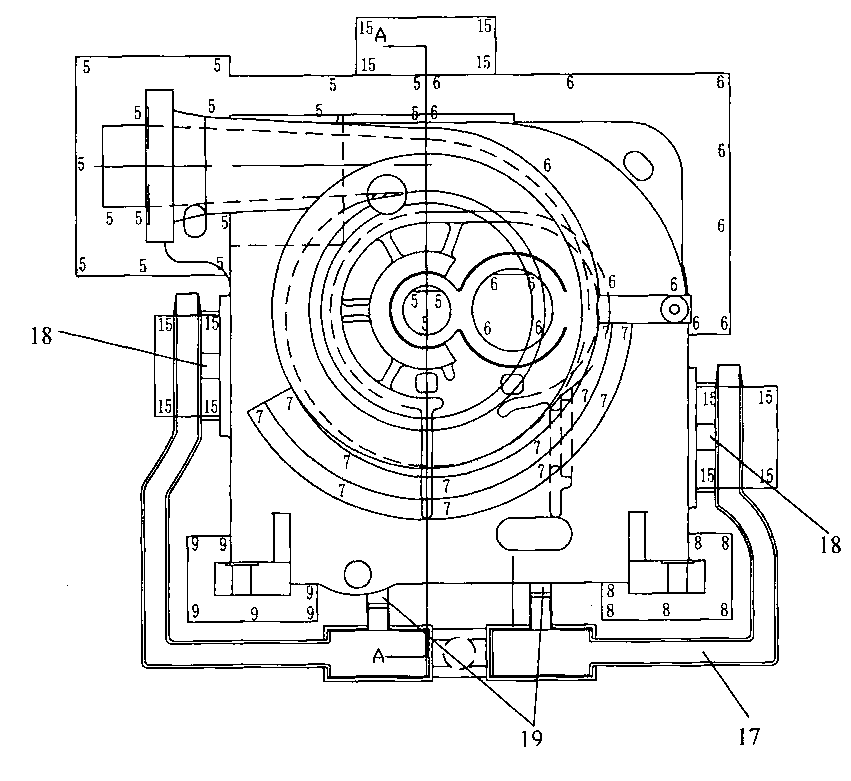

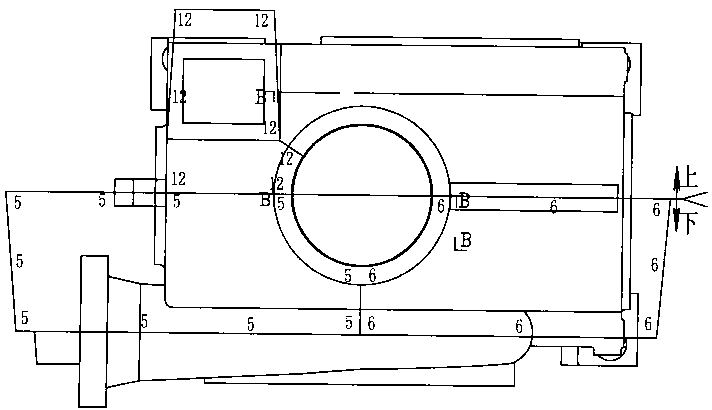

[0027] see Figure 1 to Figure 6 , the present invention relates to a casting method for centrifugal air compressor body castings used in large-scale venues in the air-conditioning industry, comprising the following steps:

[0028] 1. Sand mixing, molding and core making

[0029] Air-conditioning centrifugal air compressor body castings use an automatic sand mixer to mix furan resin no-hardening sand before modeling and manufacturing 1~15# sand cores. Place insulation riser 21 and exhaust piece at the specified position of the upper mold before molding, then carry out sand filling, compaction, mold removal, mold repair, and carry out brushing and surface drying treatment. Then manufacture fifteen sand cores 1 to 15 of 1 to 15#, and place them for later use after brushing the paint and drying the surface.

[0030] 2. Fit

[0031] Put 1#~15# sand cores 1~15 into the upper and lower sand molds in sequence, and place two pieces of ceramic filter nets in the filter; after blowin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com