Production technology of low-alloy high-strength cast iron piston

A low-alloy high-strength, cast-iron piston technology, applied in metal processing equipment, molds, mold components, etc., can solve problems such as slow solidification, substandard metallographic and hardness, and poor exhaust.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

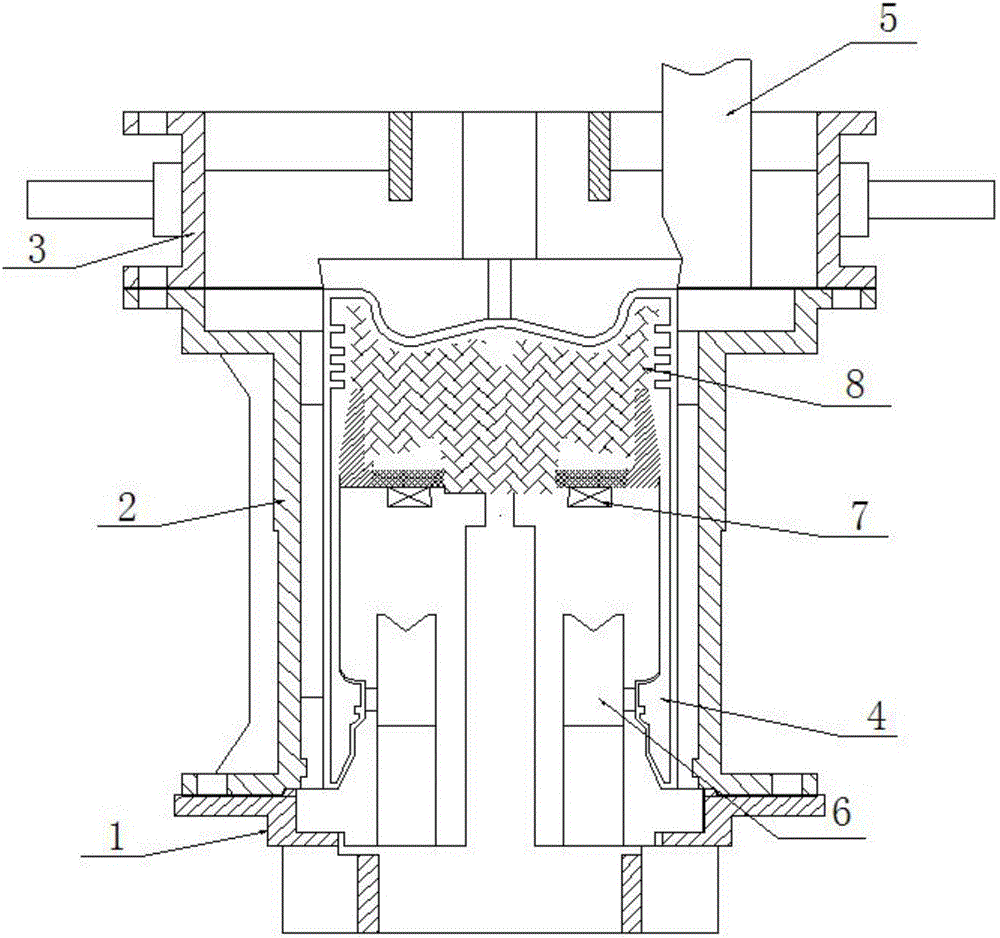

[0013] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

[0014] Such as figure 1 As shown, a production process of low-alloy high-strength cast iron pistons, the production tooling used includes bottom box 1, middle box 2 and cover box 3 from bottom to top, and bottom box 1, middle box 2 and cover box 3 are surrounded by a An internal cavity, the piston casting 4 is placed in the internal cavity with one end of the combustion chamber of the piston casting 4 facing upwards, and a top riser 5 is arranged on the cover box 3, and the position of the top riser 5 corresponds to the outer ring of the piston casting 4 The outer ring groove is fed through the top riser 5 to prevent shrinkage and porosity.

[0015] A dark riser 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com