Method for eliminating casting shrinkage cavity defect by using petroleum coke carburant

A carburant and petroleum coke technology, which is applied in the field of metal smelting, can solve problems such as shrinkage cavities, hinder free carbon spheroidization, and shrinkage porosity, and achieve the effects of reducing waste of raw materials, reducing production costs, and preventing spheroidization decline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

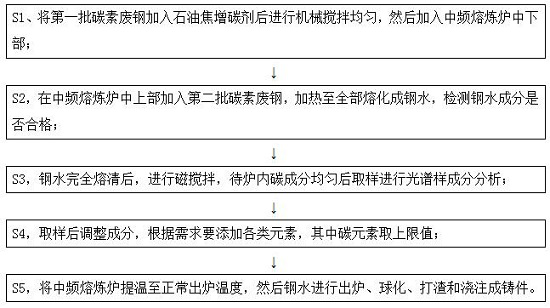

[0026] A kind of method utilizing petroleum coke carburant to eliminate casting shrinkage cavity defect, comprises the steps:

[0027] The weight ratio of the first batch of carbon scrap steel to the second batch of carbon scrap steel is 4:6. Add the first batch of carbon scrap steel to the petroleum coke recarburizer and stir it evenly, then add it to the middle and lower part of the intermediate frequency melting furnace for intermediate frequency melting The temperature of the furnace is controlled at 600°C. The level of carbon content has a very important influence on the strength, hardness and plasticity of the casting. In order to ensure that the casting has sufficient strength and hardness, the molten steel must contain a considerable amount of carbon. Therefore, petroleum coke carbon The additive amount accounts for 1.8% of the total amount of molten steel to ensure the carbon content, so that the cast iron graphite has a good shape, uniform distribution, and moderate s...

Embodiment 2

[0029] A kind of method utilizing petroleum coke carburant to eliminate casting shrinkage cavity defect, comprises the steps:

[0030] The weight ratio of the first batch of carbon scrap steel to the second batch of carbon scrap steel is 4:6. Add the first batch of carbon scrap steel to the petroleum coke recarburizer and stir it evenly, then add it to the middle and lower part of the intermediate frequency melting furnace for intermediate frequency melting The temperature of the furnace is controlled at 700°C. The carbon content has a very important influence on the strength, hardness and plasticity of the casting. In order to ensure that the casting has sufficient strength and hardness, the molten steel must contain a considerable amount of carbon. Therefore, petroleum coke carbon The additive amount accounts for 1.9% of the total amount of molten steel to ensure the carbon content, so that the cast iron graphite has a good shape, uniform distribution, and moderate size. Gra...

Embodiment 3

[0032] A kind of method utilizing petroleum coke carburant to eliminate casting shrinkage cavity defect, comprises the steps:

[0033] The weight ratio of the first batch of carbon scrap steel to the second batch of carbon scrap steel is 4:6. Add the first batch of carbon scrap steel to the petroleum coke recarburizer and stir it evenly, then add it to the middle and lower part of the intermediate frequency melting furnace for intermediate frequency melting The temperature of the furnace is controlled at 800°C. The level of carbon content has a very important influence on the strength, hardness and plasticity of the casting. In order to ensure that the casting has sufficient strength and hardness, the molten steel must contain a considerable amount of carbon. Therefore, petroleum coke carbon The additive amount accounts for 2.1% of the total amount of molten steel to ensure the carbon content, so that the graphite shape of cast iron is good, the distribution is uniform, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com