Large-section high-strength high-toughness spheroidal graphite cast iron profile and preparation method thereof

A nodular cast iron, high-strength technology, applied in the direction of improving process efficiency and reducing gas emissions, can solve problems such as graphite deformity, spheroidization and inoculation decline, and casting performance degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

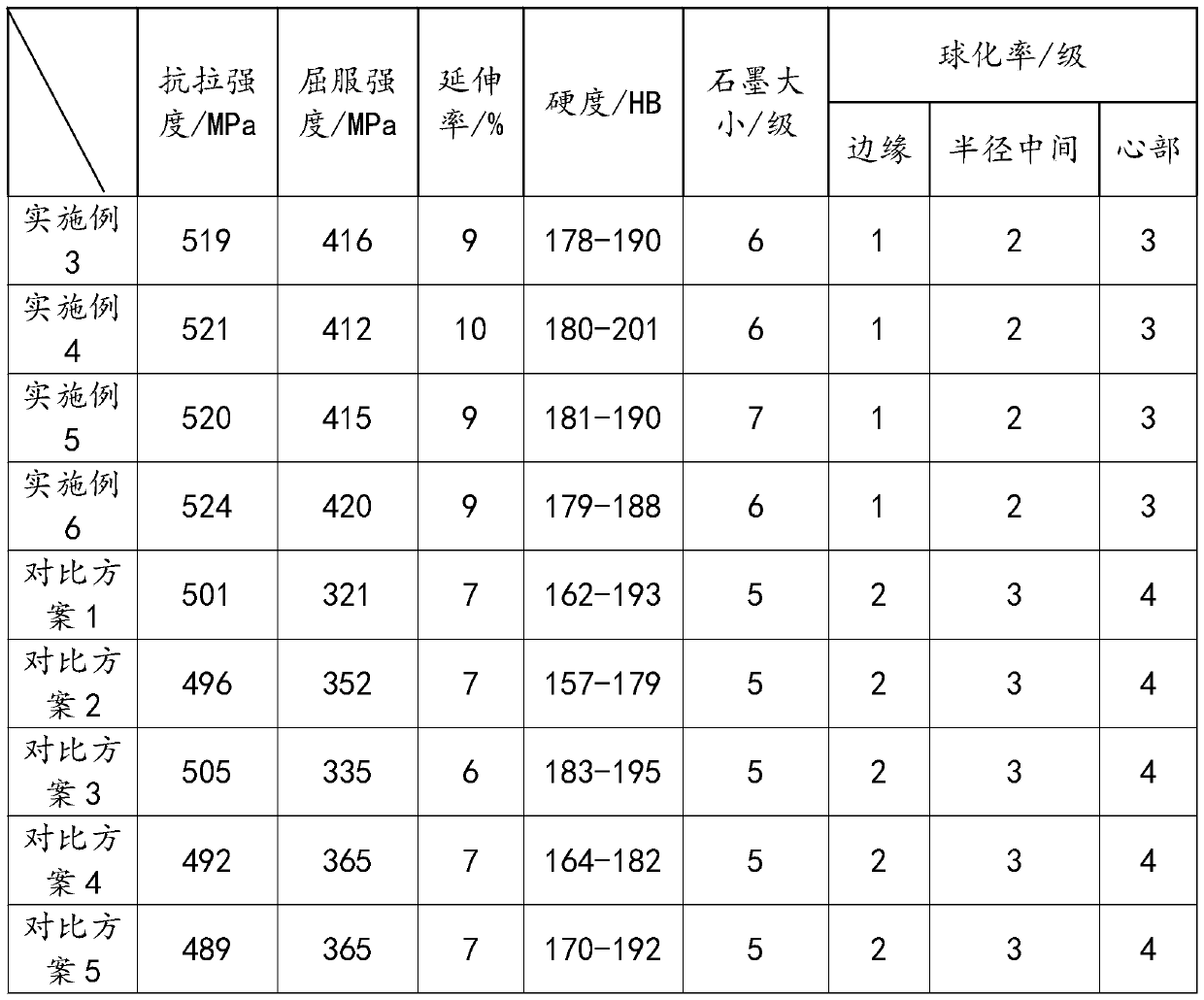

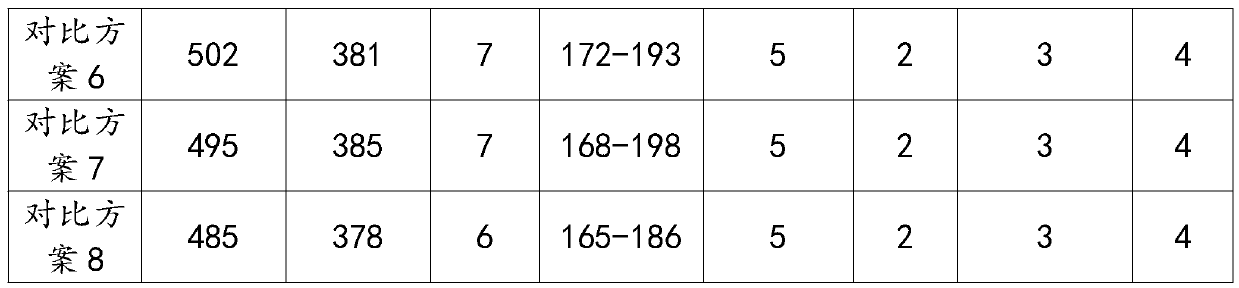

Examples

Embodiment 1

[0026] A large-section, high-strength, high-toughness ductile iron profile, which is made of QT500-7 material The profile is prepared from the following elements according to the mass percentage: carbon: 3.48%, silicon: 2.65%, manganese: 0.37%, magnesium: 0.048%, phosphorus 0.035%, sulfur: 0.01%, and the rest is iron. By adopting the above technical scheme, the obtained large-section ductile iron profile has good graphite shape, high graphite roundness, fine graphite, high graphite spheroidization rate, and the obtained large-section ductile iron profile has high strength and good toughness.

Embodiment 2

[0028] A method for preparing a large-section, high-strength, and high-toughness ductile iron profile, specifically comprising the following steps:

[0029] (1) Furnace preparation. After the combination of water-cooled graphite crystallizer and continuous casting and drawing holding furnace is installed, use natural gas to bake the continuous casting and drawing holding furnace. The baking time is 3-5 hours. Continuous casting before production The temperature in the holding furnace for drawing is 500-600°C;

[0030] (2) Ingredients, the above metal materials will be calculated and weighed with pig iron, scrap steel, recycled material, recarburizer, ferrosilicon block and ferromanganese according to the following target values: carbon: 3.55%-3.65%, silicon: 1.3%-1.4% , Manganese: 0.32%-0.42%, wherein the amount of pig iron selected is 50%-55% of the total mass of ingredients, and the amount of scrap steel selected is 30%-35% of the total mass of ingredients;

[0031] (3) Sme...

Embodiment 3

[0037] A method for preparing a large-section, high-strength, and high-toughness ductile iron profile, specifically comprising the following steps:

[0038] (1) Furnace preparation. After the combination of water-cooled graphite crystallizer and continuous casting and drawing holding furnace is installed, use natural gas to bake the continuous casting and drawing holding furnace. The baking time is 4 hours. Continuous casting and drawing before production The temperature in the holding furnace is 600°C;

[0039] (2) Batching, pig iron, steel scrap, furnace charge, recarburizer, ferrosilicon block and ferromanganese are calculated and weighed according to the following target values: carbon: 3.55%, silicon: 1.4%, manganese: 0.35%, wherein The selected amount of pig iron is 50% of the total mass of ingredients, and the selected amount of scrap steel is 35% of the total mass of ingredients;

[0040] (3) Smelting, using medium-frequency induction furnace for smelting, put the wei...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com