Method for refining grains of large medium high alloy steel forgings

A technology for large-scale forgings and high-alloy steel, applied in heat treatment equipment, heat treatment process control, manufacturing tools, etc., can solve problems such as coarse grains and mixed grains, and unstable grain refinement effect of large forgings, and achieve simple and easy operation process line, reduce energy and time cost consumption, and reduce the effect of tissue inheritance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

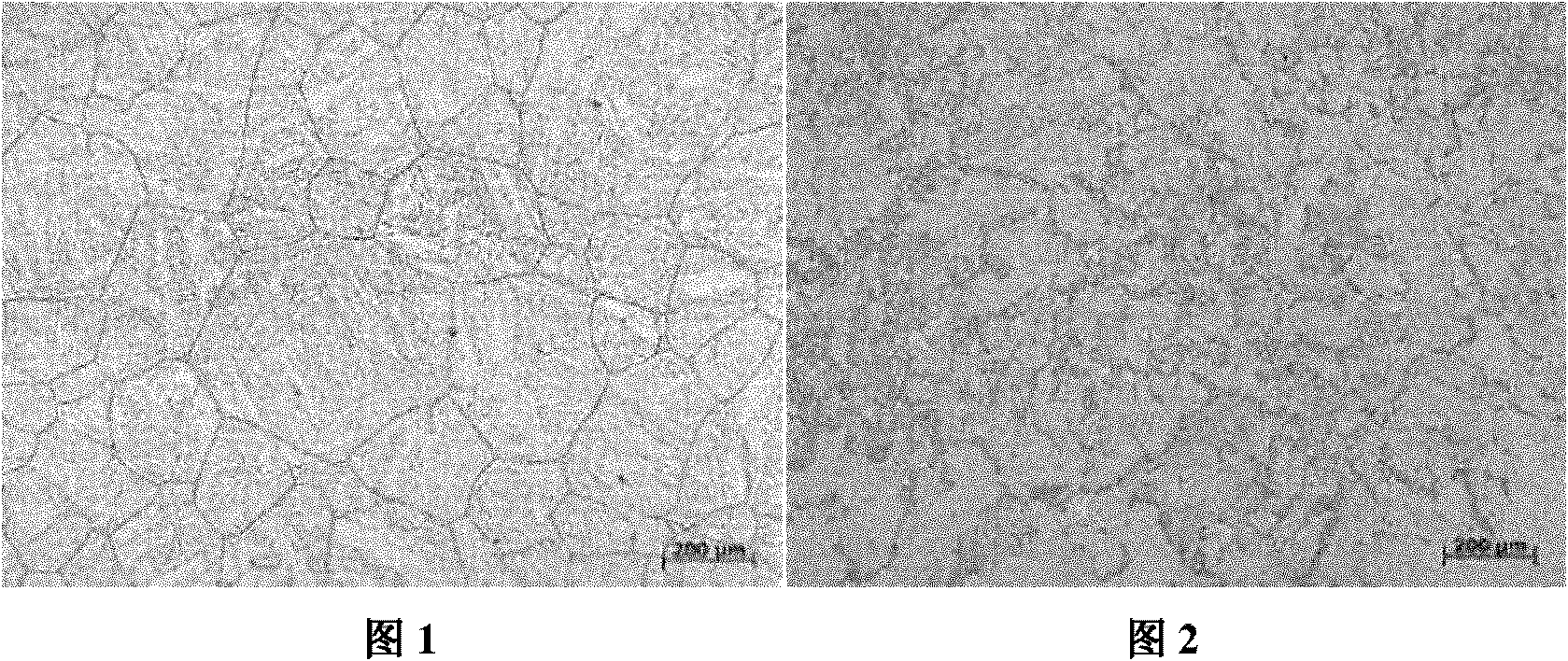

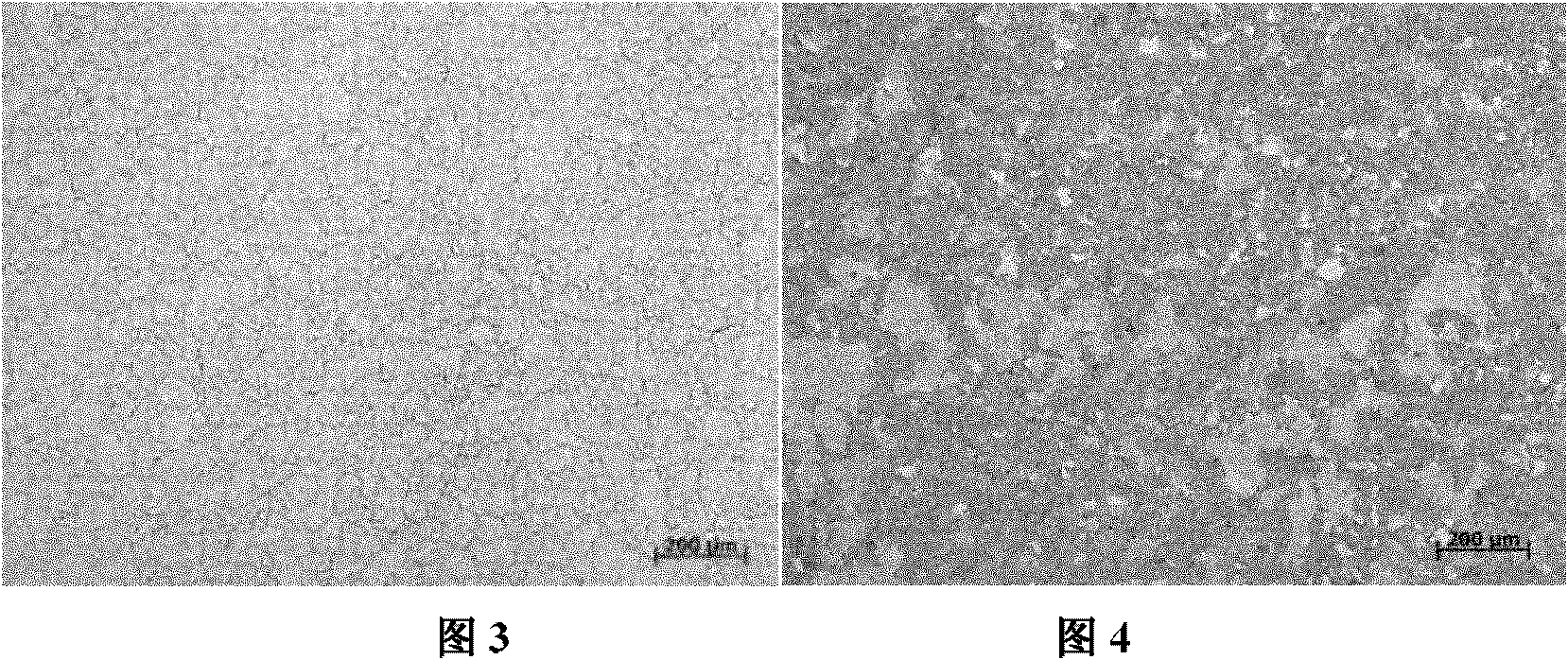

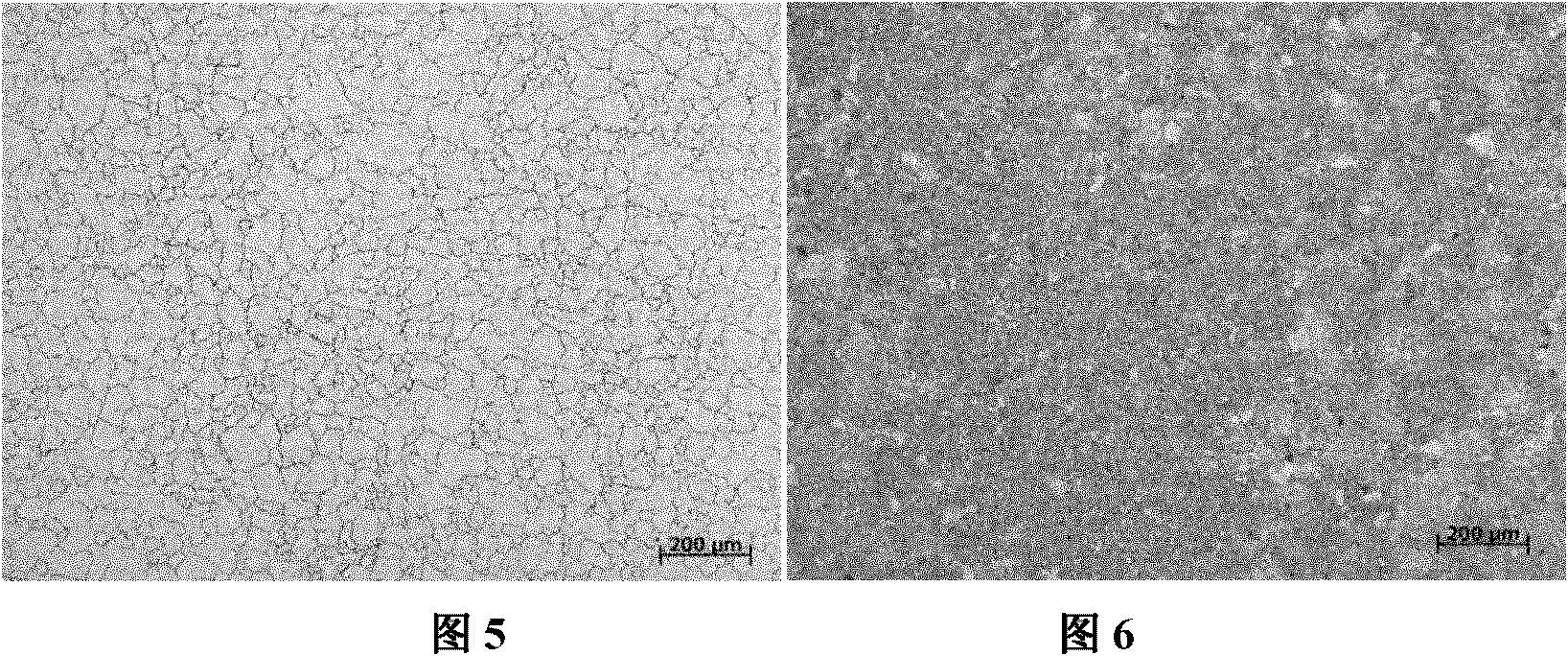

[0032] The test adopts 30Cr2Ni4MoV steel commonly used in large forgings of low-pressure rotors, and its original grain size is about ASTM No.1.0 grade, see figure 1 As shown, its chemical composition is shown in Table 1, and the test material was processed into a 15mm×15mm×15mm sample. Firstly, heat the sample from room temperature to 840°C at a heating rate of 30°C / h and keep it warm for 3 hours; then cool the sample at a rate of 50°C / h to the pearlite transition nose temperature of 600°C and keep it warm for 120 hours to form a certain amount of Pearlite structure distributed in a network (such as figure 2 shown), so as to eliminate tissue genetics, and then cool to room temperature; then, heat the sample to 870°C at a heating rate of 30°C / h, and keep it for 3h to make the austenitization uniform, and the austenitization recrystallization is fine crystallization, then cooled to room temperature, the grain size see image 3 shown. The test results show that this method m...

Embodiment 2

[0036] The test adopts 30Cr2Ni4MoV steel commonly used in large forgings of low-pressure rotors, and its original grain size is about ASTM No.1.0 grade, see figure 1 As shown, its chemical composition is shown in Table 1, and the test material was processed into a 15mm×15mm×15mm sample. First, heat the sample from room temperature to 840°C at a heating rate of 30°C / h, and keep it warm for 3 hours; then cool the sample at a rate of 50°C / h to the pearlite transition nose temperature of 600°C, and keep it warm for 240 hours to form a certain amount of Pearlite structure distributed in a network (such as Figure 4 shown), so as to eliminate tissue genetics, and then cool to room temperature; then, heat the sample to 870°C at a heating rate of 30°C / h, and keep it for 3h to make the austenitization uniform, and the austenitization recrystallization is fine crystallization, then cooled to room temperature, the grain size see Figure 5 shown. The test results show that this method ...

Embodiment 3

[0038] The test adopts 30Cr2Ni4MoV steel commonly used in large forgings of low-pressure rotors, and its original grain size is about ASTM No.1.0 grade, see figure 1 As shown, its chemical composition is shown in Table 1, and the test material was processed into a 15mm×15mm×15mm sample. First, heat the sample from room temperature to 840°C at a heating rate of 30°C / h and keep it warm for 3 hours; then cool the sample at a rate of 50°C / h to the pearlite transition nose temperature of 600°C and keep it warm for 360 hours to generate a certain amount of Pearlite structure distributed in a network (such as Figure 6 shown), so as to eliminate tissue genetics, and then cool to room temperature; then, heat the sample to 870°C at a heating rate of 30°C / h, and keep it for 3h to make the austenitization uniform, and the austenitization recrystallization is fine crystallization, then cooled to room temperature, the grain size see Figure 7 shown. The test results show that this metho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com