Preparation method of copper-silver alloy wire

A copper-silver alloy and wire technology, applied in the direction of manufacturing tools, heat treatment equipment, furnaces, etc., can solve the problems of reducing the electrical conductivity of the matrix, increasing the content of solute atoms, and reducing the electrical conductivity of materials, so as to improve electrical conductivity, improve mechanical properties, Achieve the effect of alloy strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

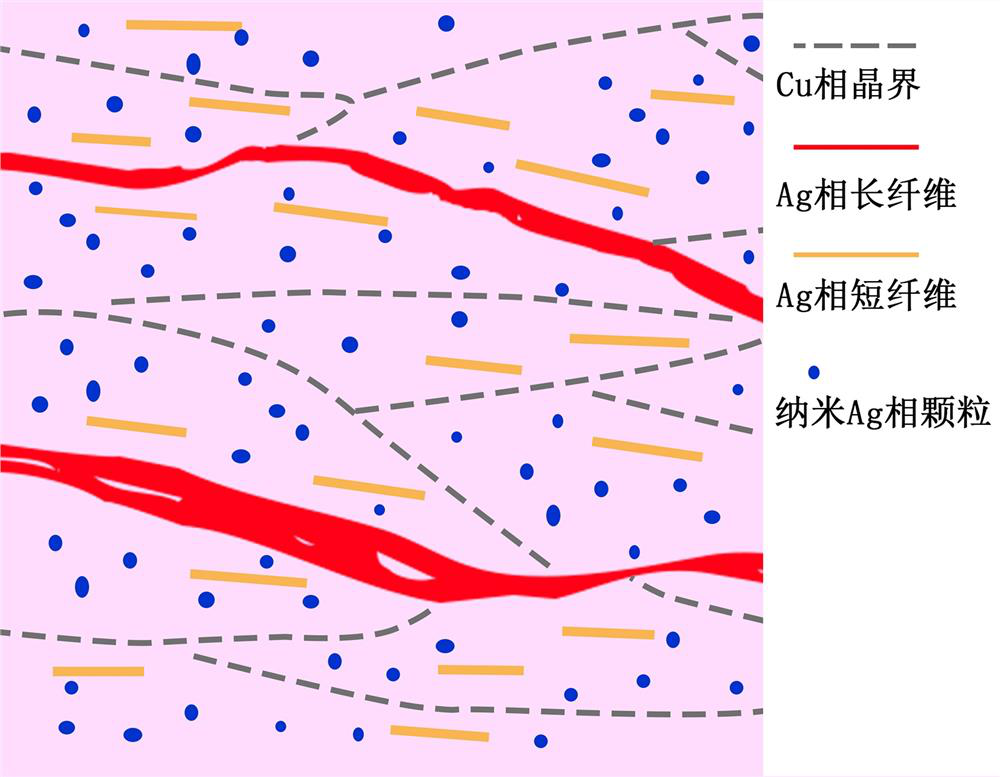

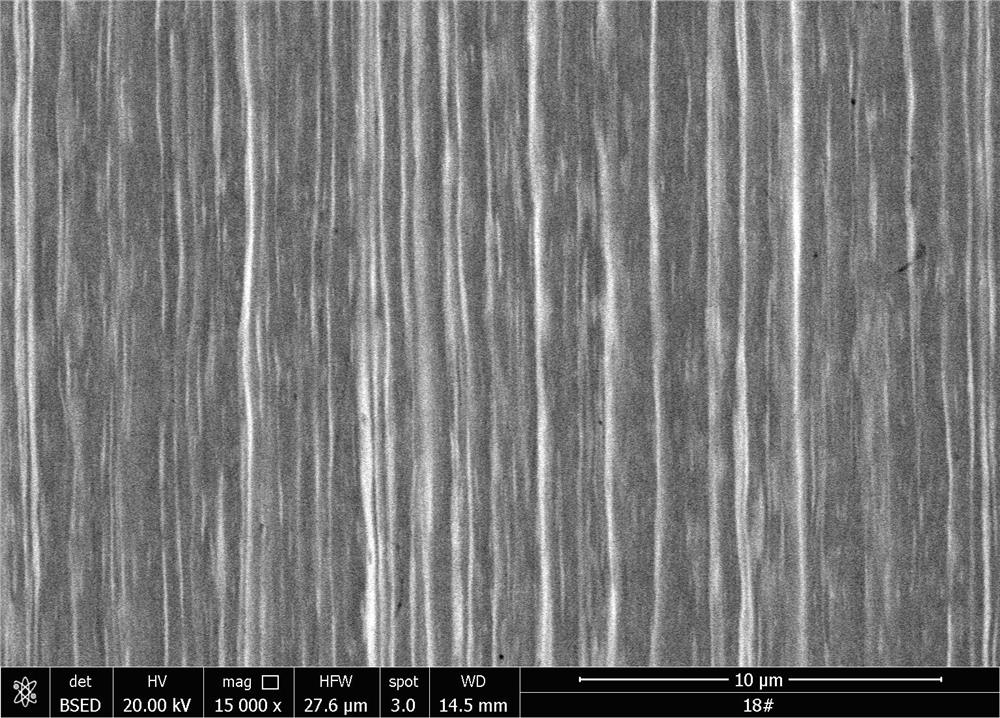

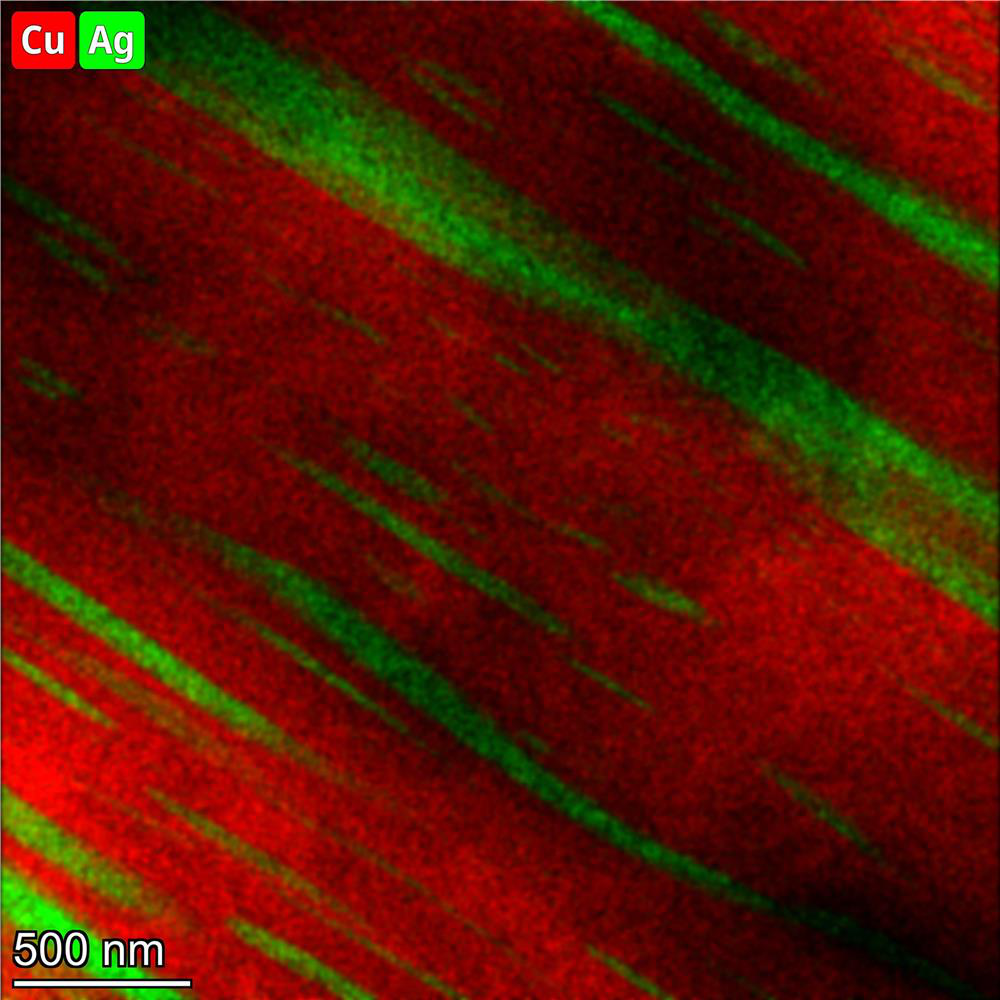

[0057] A high-strength and high-conductivity copper-silver alloy material, its composition includes Cu, Ag, Sc, La elements and unavoidable impurities, and the mass ratio of each composition is as follows: Ag element is 20 wt.%, La element is 0.02wt .%, the Sc element is 0.03 wt.%, the total mass of unavoidable impurities is 0.05 wt.%, the balance is copper, and the mass ratio of Sc to La is 1.5. The preparation method of above-mentioned copper-silver alloy, its concrete processing step comprises:

[0058] Step 1, according to the above-mentioned component ratio, put pure copper, pure silver, pure scandium with a mass purity of 99.95%, and a copper-lanthanum master alloy with a mass fraction of lanthanum of 10wt.% into a graphite crucible, and put it into a vacuum induction melting inside the furnace. First, control the vacuum degree in the vacuum induction melting furnace at 8.0×10 -2 Below Pa; then pass argon into the melting furnace. Under the protection of argon atmosph...

Embodiment 2

[0070] A high-strength and high-conductivity copper-silver alloy material, its composition includes Cu, Ag, Sc, La elements and unavoidable impurities, and the mass ratio of each composition is as follows: Ag element is 24 wt.%, La element is 0.12wt .%, the Sc element is 0.1 wt.%, the total mass of unavoidable impurities is 0.05 wt.%, the balance is copper, and the mass ratio of Sc to La is 0.83. The preparation method of above-mentioned copper-silver alloy, its concrete processing step comprises:

[0071] Step 1, according to the above-mentioned component ratio, put pure copper, pure silver, pure scandium with a mass purity of 99.95%, and a copper-lanthanum master alloy with a mass fraction of lanthanum of 10wt.% into a graphite crucible, and put it into a vacuum induction melting inside the furnace. First, control the vacuum degree in the vacuum induction melting furnace at 8.0×10 -2 Below Pa; then pass argon into the melting furnace. Under the protection of argon atmosph...

Embodiment 3

[0083] A high-strength and high-conductivity copper-silver alloy material, its composition includes Cu, Ag, Sc, La elements and unavoidable impurities, and the mass ratio of each composition is as follows: Ag element is 25 wt.%, La element is 0.1wt .%, the Sc element is 0.05 wt.%, the total mass of unavoidable impurities is 0.05 wt.%, the balance is copper, and the mass ratio of Sc to La is 0.5. The preparation method of above-mentioned copper-silver alloy, its concrete processing step comprises:

[0084] Step 1, according to the above-mentioned component ratio, put pure copper, pure silver, pure scandium with a mass purity of 99.95%, and a copper-lanthanum master alloy with a mass fraction of lanthanum of 10wt.% into a graphite crucible, and put it into a vacuum induction melting inside the furnace. First, control the vacuum degree in the vacuum induction melting furnace at 8.0×10 -2 Below Pa; then pass argon into the smelting furnace. Under the protection of argon atmosph...

PUM

| Property | Measurement | Unit |

|---|---|---|

| lattice constant | aaaaa | aaaaa |

| lattice constant | aaaaa | aaaaa |

| lattice constant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com