A preparation method of biofunctional coating on the surface of pure magnesium with low corrosion rate

It is a technology of biological functionalization and corrosion rate, which can be used in coatings, metal material coating processes, tissue regeneration and other directions. The effect of convenience and low preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

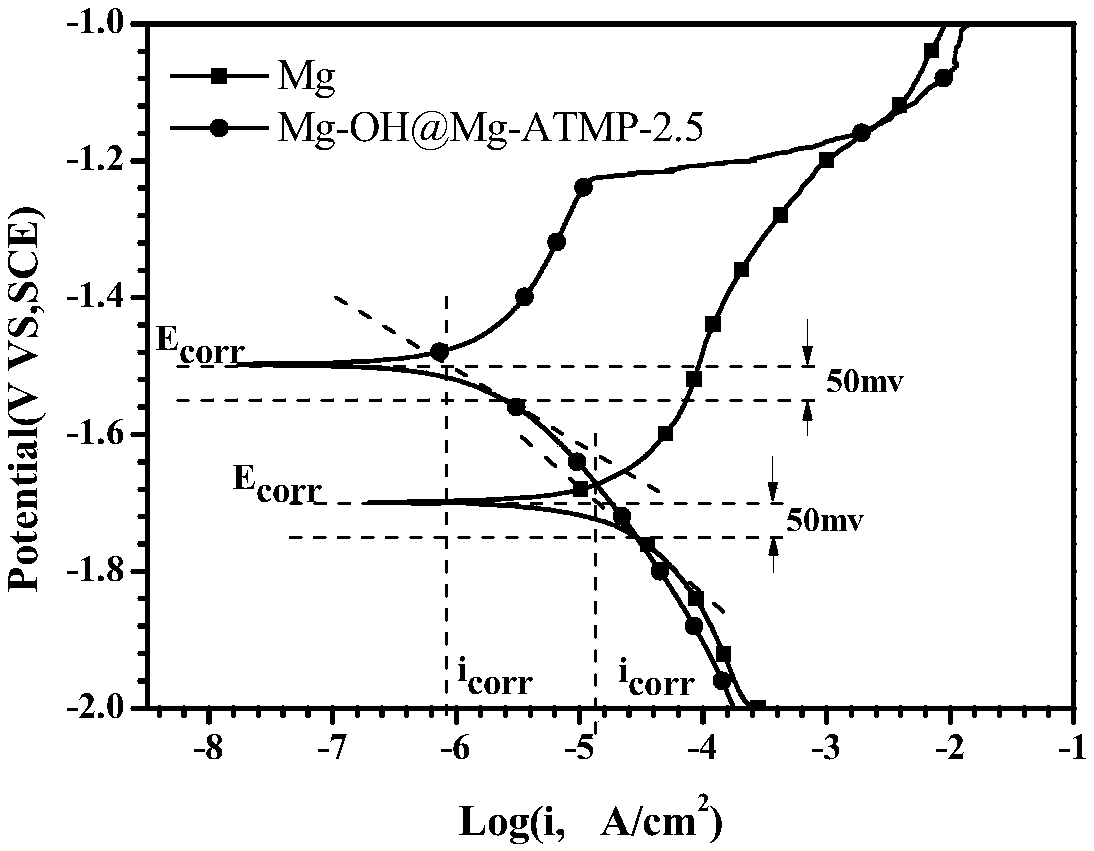

Embodiment 1

[0022] A method for preparing a biofunctional coating on the surface of pure magnesium with low corrosion rate, the steps are:

[0023] A, the NaOH solution of 1mol / L is joined in the aminotrimethylene phosphonic acid solution that concentration is 2.5mmol / L, obtains the modified solution that pH value is 7;

[0024] B, soaking pure magnesium in a NaOH solution with a temperature of 60°C and a concentration of 3mol / L for 24 hours to obtain alkali-activated pure magnesium;

[0025] C. Soak the pure magnesium after alkali activation in the modified solution of step A, heat up to 60°C, and keep it warm for 12 hours; obtain pure magnesium with an aminotrimethylene phosphonic acid coating on the surface;

[0026] D, put the pure magnesium with aminotrimethylene phosphonic acid coating on the surface prepared in step C into a magnesium sulfate solution with a concentration of 0.5mol / L and soak for 2 hours to obtain a layer of corrosion rate on the surface of pure magnesium Biofunct...

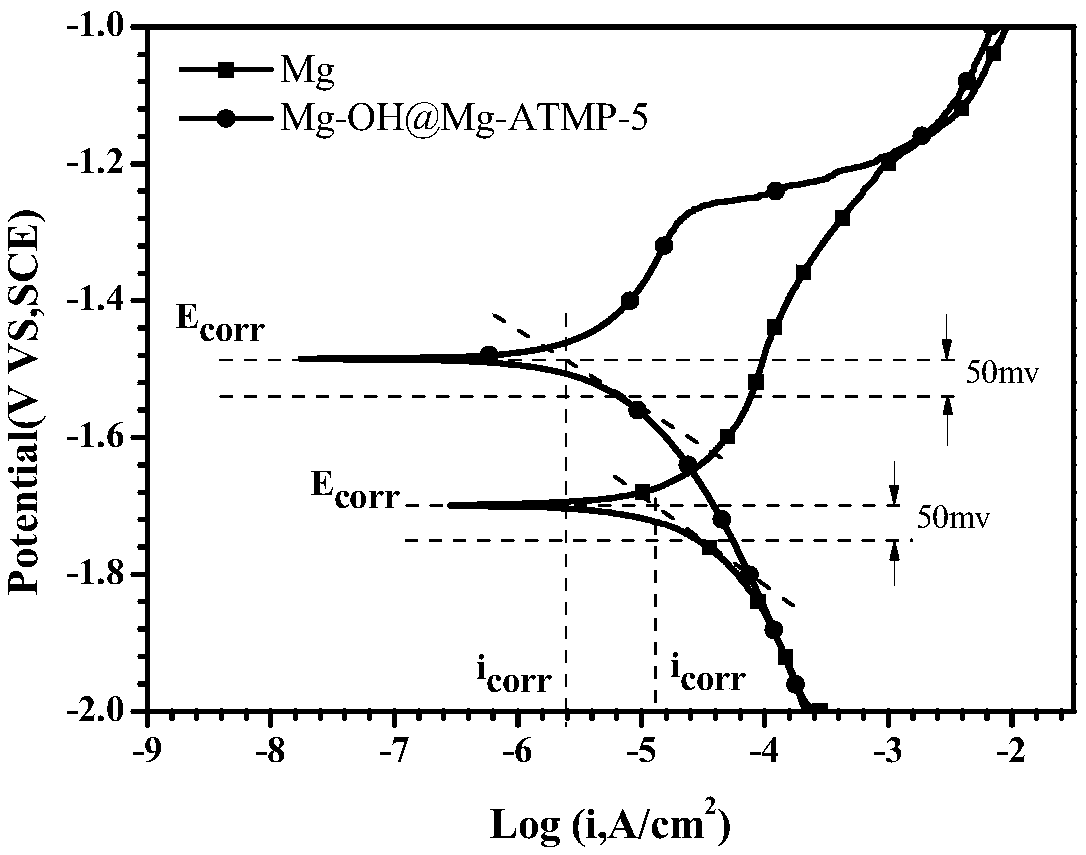

Embodiment 2

[0030] A method for preparing a biofunctional coating on the surface of pure magnesium with low corrosion rate, the steps are:

[0031] A, the NaOH solution of 1mol / L is joined in the aminotrimethylene phosphonic acid solution that concentration is 5mmol / L, obtains the modified solution that pH is 9;

[0032] B, soaking pure magnesium in a NaOH solution with a temperature of 65°C and a concentration of 3mol / L for 18 hours to obtain alkali-activated pure magnesium;

[0033] C. Soak the pure magnesium after alkali activation in the modified solution, heat up to 80° C., and keep it warm for 17 hours; obtain pure magnesium with an aminotrimethylene phosphonic acid coating on the surface;

[0034] D, put the pure magnesium with aminotrimethylene phosphonic acid coating on the surface prepared in step C into a magnesium sulfate solution with a concentration of 0.5mol / L and soak for 1.5 hours, and obtain a layer of corrosion rate on the surface of pure magnesium Biofunctionalized co...

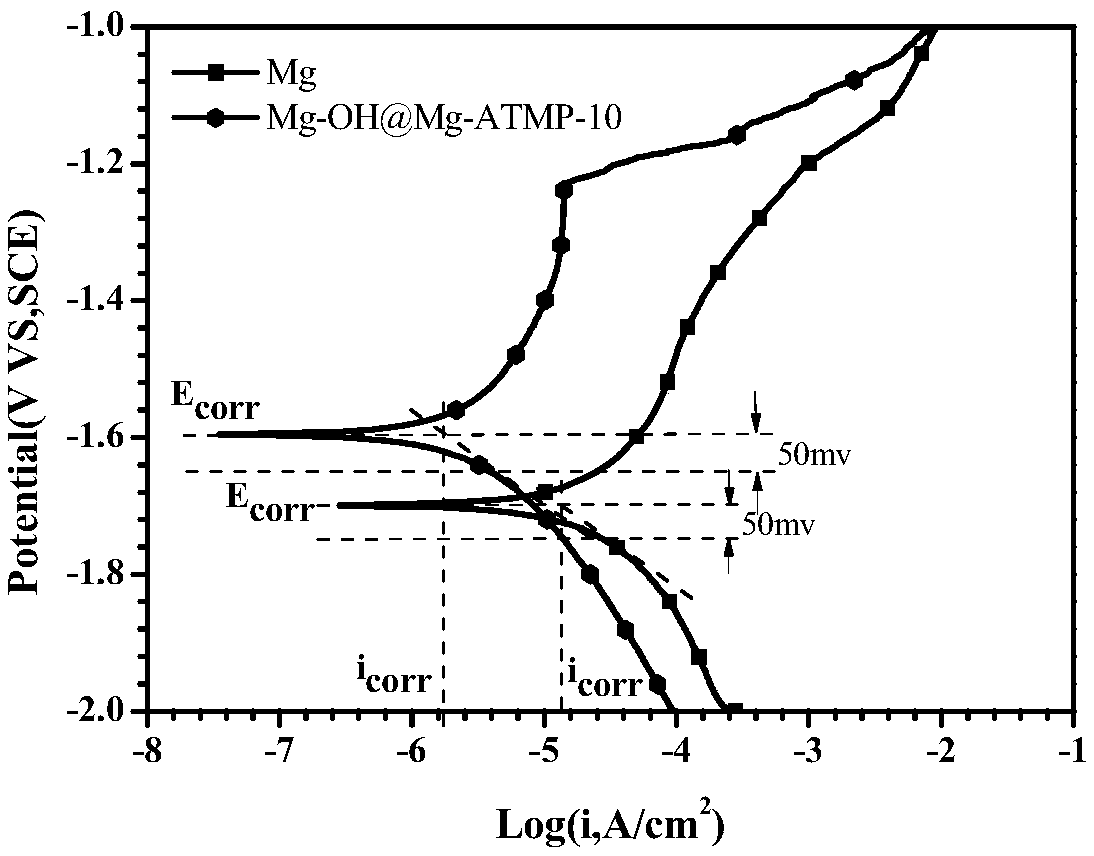

Embodiment 3

[0038] A method for preparing a biofunctional coating on the surface of pure magnesium with low corrosion rate, the steps are:

[0039] A, the NaOH solution of 1mol / L is joined in the aminotrimethylene phosphonic acid solution that concentration is 10mmol / L, obtains the modified solution that pH is 5;

[0040] B, soaking pure magnesium in a NaOH solution with a temperature of 55°C and a concentration of 3mol / L for 12 hours to obtain alkali-activated pure magnesium;

[0041] C. Soak the pure magnesium after alkali activation in the modified solution, heat up to 50° C., and keep it warm for 24 hours; obtain pure magnesium with an aminotrimethylene phosphonic acid coating on the surface;

[0042] D, put the pure magnesium with aminotrimethylene phosphonic acid coating on the surface prepared in step C into a magnesium sulfate solution with a concentration of 0.5mol / L and soak for 1 hour to obtain a layer of corrosion rate on the surface of pure magnesium Biofunctionalized coatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com