Preparation method of low-corrosion-rate bio-functionalized coating for pure magnesium surface

It is a technology of biological functionalization and corrosion rate, which can be used in coatings, metal material coating processes, tissue regeneration and other directions. The effect of convenience and low preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

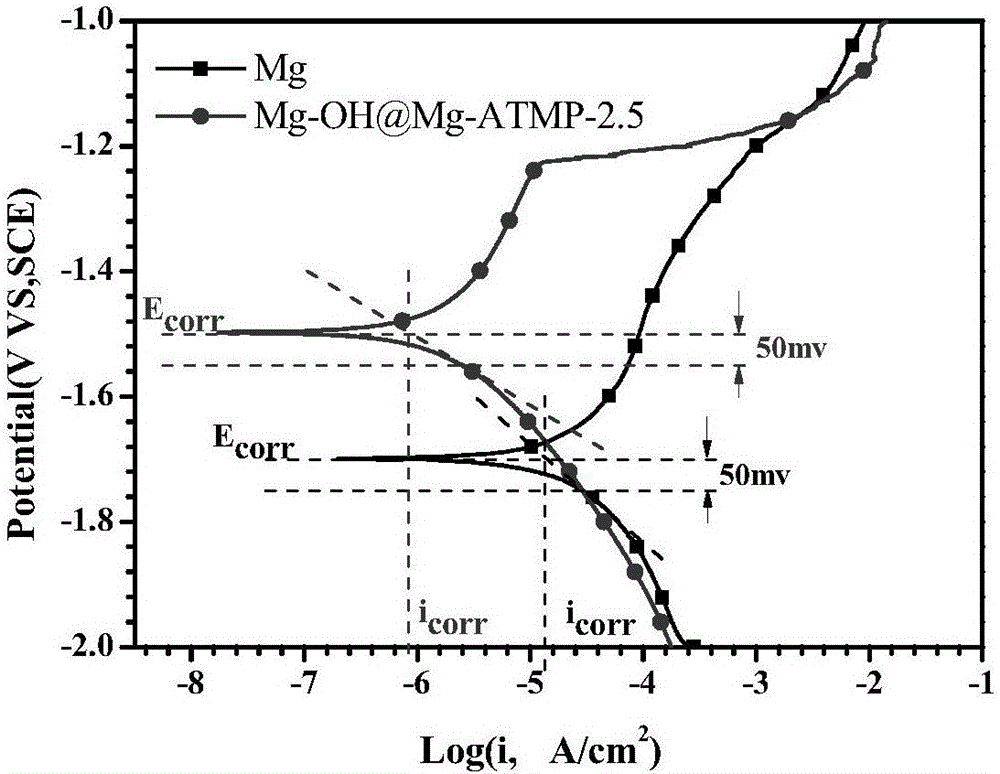

Embodiment 1

[0022] A kind of preparation method of pure magnesium surface biological functionalization coating with low corrosion rate, and its steps are:

[0023] A, adding the NaOH solution of 1mol / L to the aminotrimethylidene phosphonic acid solution with a concentration of 2.5mmol / L to obtain a modified solution with a pH value of 7;

[0024] B. Soak pure magnesium in a NaOH solution with a temperature of 60° C. and a concentration of 3 mol / L for 24 hours to obtain alkali-activated pure magnesium;

[0025] C, soak the pure magnesium after alkali activation in the modification solution of A step, be warmed up to 60 ℃, be incubated for 12 hours; Obtain the pure magnesium with aminotrimethylene phosphonic acid coating on the surface;

[0026] D, the pure magnesium with aminotrimethylene phosphonic acid coating on the surface prepared in step C is put into a magnesium sulfate solution with a concentration of 0.5mol / L and soaked for 2 hours, namely, a layer of corrosion rate is obtained on...

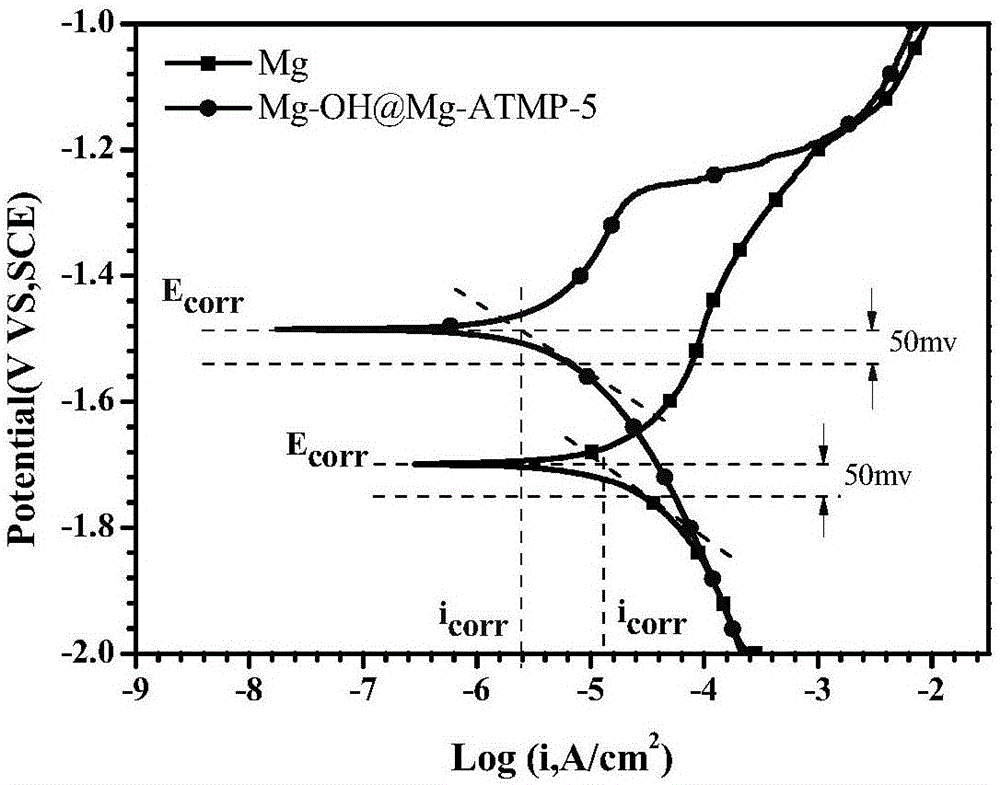

Embodiment 2

[0030] A kind of preparation method of pure magnesium surface biological functionalization coating with low corrosion rate, and its steps are:

[0031] A, adding the NaOH solution of 1mol / L to the aminotrimethylidene phosphonic acid solution with a concentration of 5mmol / L to obtain a modified solution with a pH value of 9;

[0032] B. Soak pure magnesium in a NaOH solution with a temperature of 65°C and a concentration of 3 mol / L for 18 hours to obtain alkali-activated pure magnesium;

[0033] C, soak the pure magnesium after alkali activation in the modification solution, heat up to 80 ℃, and keep the temperature for 17 hours; obtain the pure magnesium with aminotrimethyleneidene phosphonic acid coating on the surface;

[0034] D. The pure magnesium with aminotrimethylene phosphonic acid coating on the surface prepared in step C is put into a magnesium sulfate solution with a concentration of 0.5mol / L and soaked for 1.5 hours, that is, a layer of corrosion rate is obtained o...

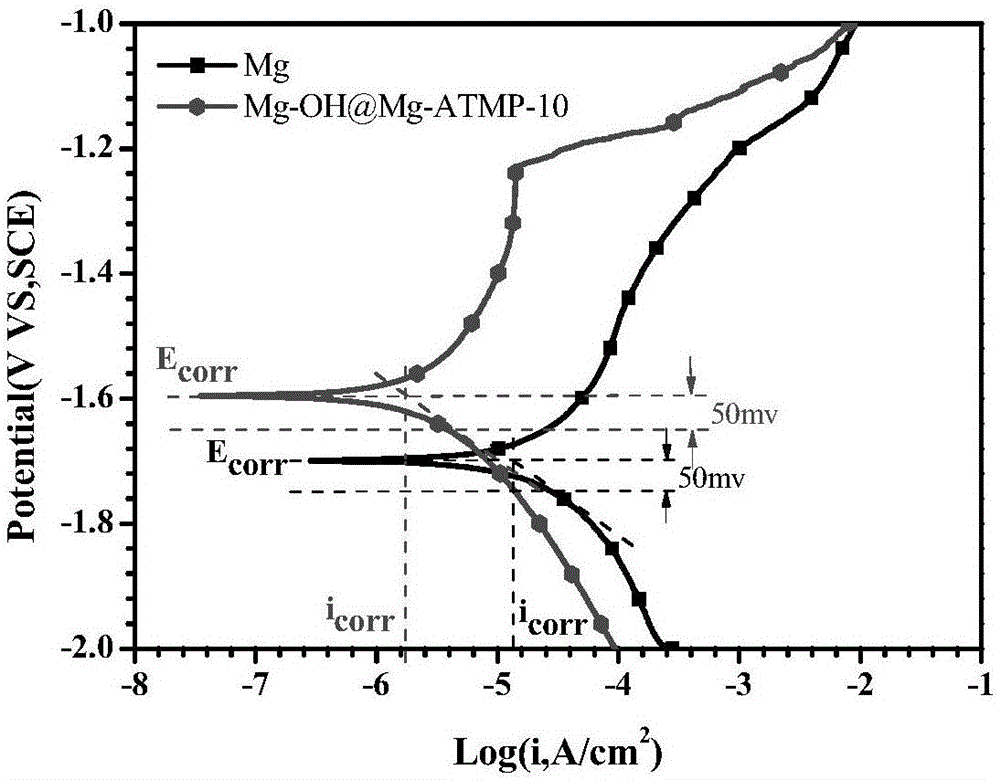

Embodiment 3

[0038] A kind of preparation method of pure magnesium surface biological functionalization coating with low corrosion rate, and its steps are:

[0039] A, adding the NaOH solution of 1 mol / L to the aminotrimethylidene phosphonic acid solution with a concentration of 10 mmol / L to obtain a modified solution with a pH value of 5;

[0040] B. Soak pure magnesium in a NaOH solution with a temperature of 55°C and a concentration of 3 mol / L for 12 hours to obtain alkali-activated pure magnesium;

[0041] C, soak the pure magnesium after alkali activation in the modification solution, heat up to 50 ℃, and keep the temperature for 24 hours; obtain the pure magnesium with aminotrimethyleneidene phosphonic acid coating on the surface;

[0042] D, the pure magnesium with aminotrimethylene phosphonic acid coating on the surface obtained in step C is put into a magnesium sulfate solution with a concentration of 0.5mol / L and soaked for 1 hour, that is, a layer of corrosion rate is obtained o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Self-corrosion potential | aaaaa | aaaaa |

| Self-corrosion potential | aaaaa | aaaaa |

| Self-corrosion potential | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com