Lithium battery spherical positive electrode material with lithium fluoride coating layer and preparation method

A positive electrode material and coating layer technology, which is applied in the field of lithium battery spherical positive electrode materials and preparation, can solve the problems of transition metal element dissolution and poor control of spheroidization, and achieve the effect of reducing production costs and improving cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] A preparation method of a lithium battery spherical positive electrode material with a lithium fluoride coating, comprising the steps of:

[0047] Step 1. Add nickel sulfate, cobalt sulfate, and manganese sulfate in order of molar ratio (50:20:30) into excess deionized water to form a mixed solution, slowly add ammonia solution to the mixed solution to adjust the pH of the solution to 11, and keep mechanical stirring After the reaction is complete, the solid is washed after filtration, and dried in a vacuum oven at 78°C to obtain NCM precursor powder;

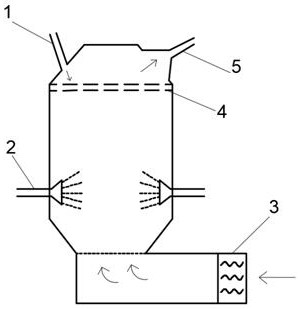

[0048] Step 2. Disperse NCM precursor powder and lithium carbonate in deionized water, add a small amount of magnesium lithium silicate, heat and stir in a water bath at 45°C for 30min, filter and separate, place in a vacuum furnace and pre-fire at 220°C for 2h form a powder, after which, as attached figure 1 As shown, the powder is transported from the high-pressure nozzle 2 to the fluidized bed cavity at a temperature...

Embodiment 2

[0051] A preparation method of a lithium battery spherical positive electrode material with a lithium fluoride coating, comprising the steps of:

[0052] Step 1. Add nickel sulfate, cobalt sulfate, and manganese sulfate in order of molar ratio (55:25:35) into excess deionized water to form a mixed solution, slowly add ammonia solution to the mixed solution to adjust the pH of the solution to 12, and keep mechanical stirring To complete the reaction, after filtering, the solid matter was washed and dried in a vacuum oven at 83°C to obtain NCM precursor powder;

[0053] Step 2. Disperse NCM precursor powder and lithium carbonate in deionized water, add a small amount of magnesium lithium silicate, heat and stir in a water bath at 50°C for 30min, filter and separate, place in a vacuum furnace and pre-fire at 300°C for 1h form a powder, after which, as attached figure 1 As shown, the powder is transported from the high-pressure nozzle 2 to the fluidized bed cavity at a temperatur...

Embodiment 3

[0055] A preparation method of a lithium battery spherical positive electrode material with a lithium fluoride coating, comprising the steps of:

[0056] Step 1. Add nickel sulfate, cobalt sulfate, and manganese sulfate in order of molar ratio (52:20:30) into excess deionized water to form a mixed solution, slowly add ammonia solution to the mixed solution to adjust the pH of the solution to 12, and keep mechanical stirring After complete reaction, the solid matter was washed after filtration, and dried in a vacuum oven at 80°C to obtain NCM precursor powder;

[0057] Step 2. Disperse NCM precursor powder and lithium carbonate in deionized water, add a small amount of magnesium lithium silicate, heat and stir in a water bath at 50°C for 30min, filter and separate, place in a vacuum furnace and pre-fire at 250°C for 2h form a powder, after which, as attached figure 1 As shown, the powder is transported from the high-pressure nozzle 2 to the fluidized bed cavity at a temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com