7XXX aluminum alloy

A technology of aluminum alloy and composition, which is applied in the field of alloys, can solve problems such as difficult extrusion of aluminum alloy profiles, low decorative aesthetics, and unstable oxide film, so as to improve the quality and strength of anodic oxide films, and the oxide films are delicate and beautiful Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The invention discloses a 7XXX series aluminum alloy, which is named as 7A07 aluminum alloy. The content (percentage by weight) of each element in the aluminum alloy of the present invention is: zinc content is 6.60%-7.60%, magnesium content is 1.25%-1.80%, copper content is 0.18%-0.44%, silicon content≤0.06%, iron Content ≤0.16%, manganese content ≤0.03%, chromium content ≤0.03%, gallium content ≤0.02%, vanadium content ≤0.02%, titanium content ≤0.03%, zirconium content ≤0.02%, sum of manganese plus chromium ≤0.03%; The individual content of impurity elements is ≤0.03%, the total content of other impurity elements is ≤0.10%, and the balance is aluminum.

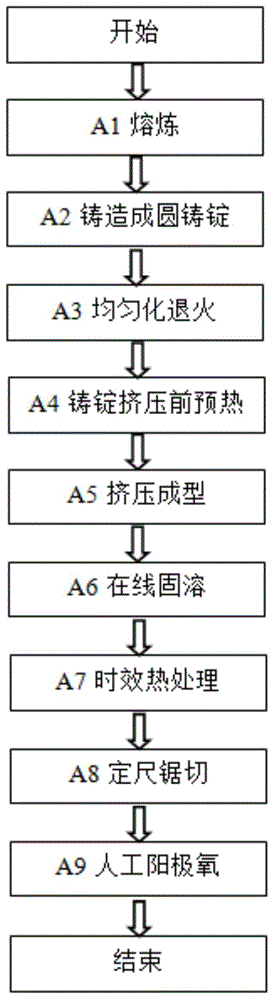

[0023] Using the above-mentioned aluminum alloy composition, extruded profiles are produced. The profile processing sequence is A1 smelting→A2 casting into a round ingot→A3 homogenizing annealing→A4 ingot preheating before extrusion→A5 extrusion molding→A6 online solid solution→A7 aging heat treatment→A8 sawing to le...

Embodiment 2

[0039] In this embodiment, the content (percentage by weight) of each element of the 7XXX aluminum alloy is: zinc content 6.6%, magnesium content 1.25%, copper content 0.18%, silicon content ≤ 0.06%, iron content ≤ 0.16%, manganese content ≤0.03%, chromium content ≤0.03%, gallium content ≤0.02%, vanadium content ≤0.02%, titanium content ≤0.03%, zirconium content ≤0.02%, the sum of manganese and chromium ≤0.03%; the individual content of other impurity elements ≤0.03 %, the sum of the remaining impurity elements is ≤0.10%, and the balance is aluminum.

[0040] Using the above-mentioned aluminum alloy composition, extruded profiles are produced. The profile processing sequence is A1 smelting→A2 casting into a round ingot→A3 homogenizing annealing→A4 ingot preheating before extrusion→A5 extrusion molding→A6 online solid solution→A7 aging heat treatment→A8 sawing to length→A9 manual Anodized surface treatment. After the above-mentioned processing and manufacturing of aluminum al...

Embodiment 3

[0042] In this embodiment, the content (percentage by weight) of each element of the 7XXX aluminum alloy is: zinc content 7.00%, magnesium content 1.40%, copper content 0.30%, silicon content ≤ 0.06%, iron content ≤ 0.16%, manganese content ≤0.03%, chromium content ≤0.03%, gallium content ≤0.02%, vanadium content ≤0.02%, titanium content ≤0.03%, zirconium content ≤0.02%, the sum of manganese and chromium ≤0.03%; the individual content of other impurity elements ≤0.03 %, the sum of the remaining impurity elements is ≤0.10%, and the balance is aluminum.

[0043] Using the above-mentioned aluminum alloy composition, extruded profiles are produced. The profile processing sequence is A1 smelting→A2 casting into a round ingot→A3 homogenizing annealing→A4 ingot preheating before extrusion→A5 extrusion molding→A6 online solid solution→A7 aging heat treatment→A8 sawing to length→A9 manual Anodized surface treatment. After the above-mentioned processing and manufacturing of aluminum a...

PUM

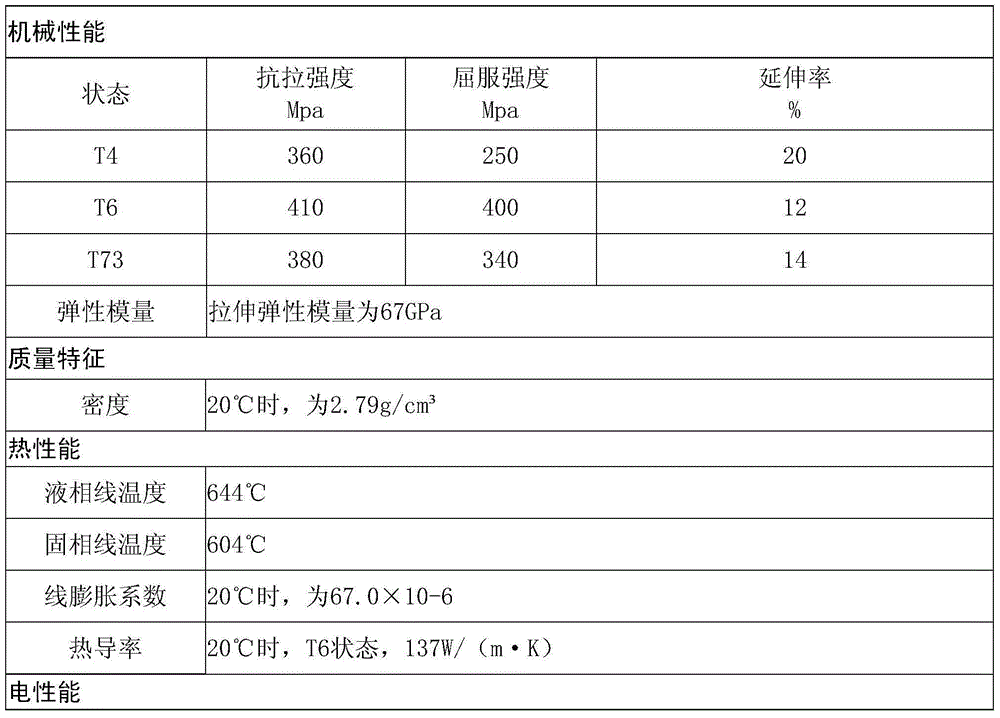

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com