Patents

Literature

57results about How to "Elongation stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Tension control system and method for planetary gear structure tension roller type evener

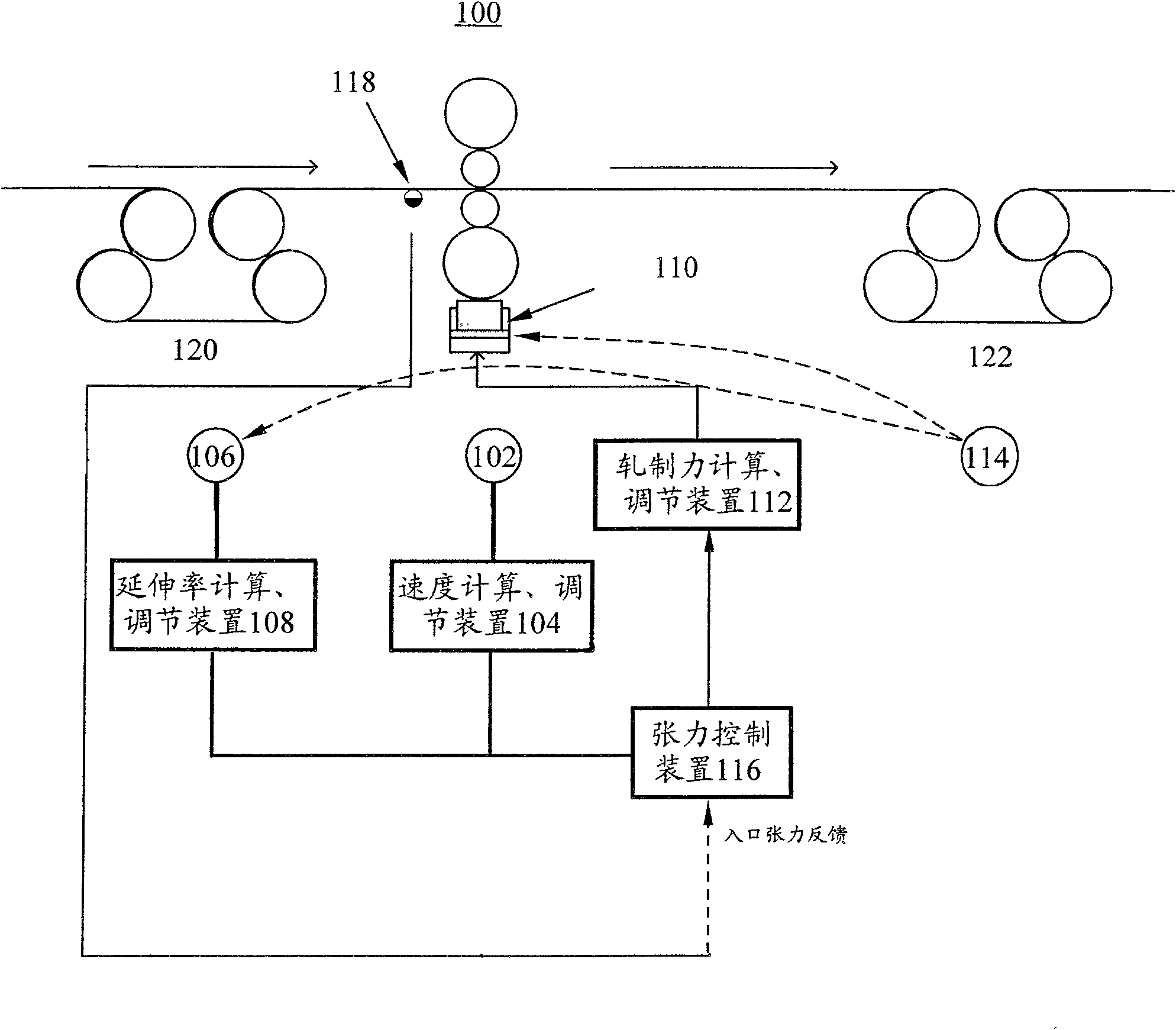

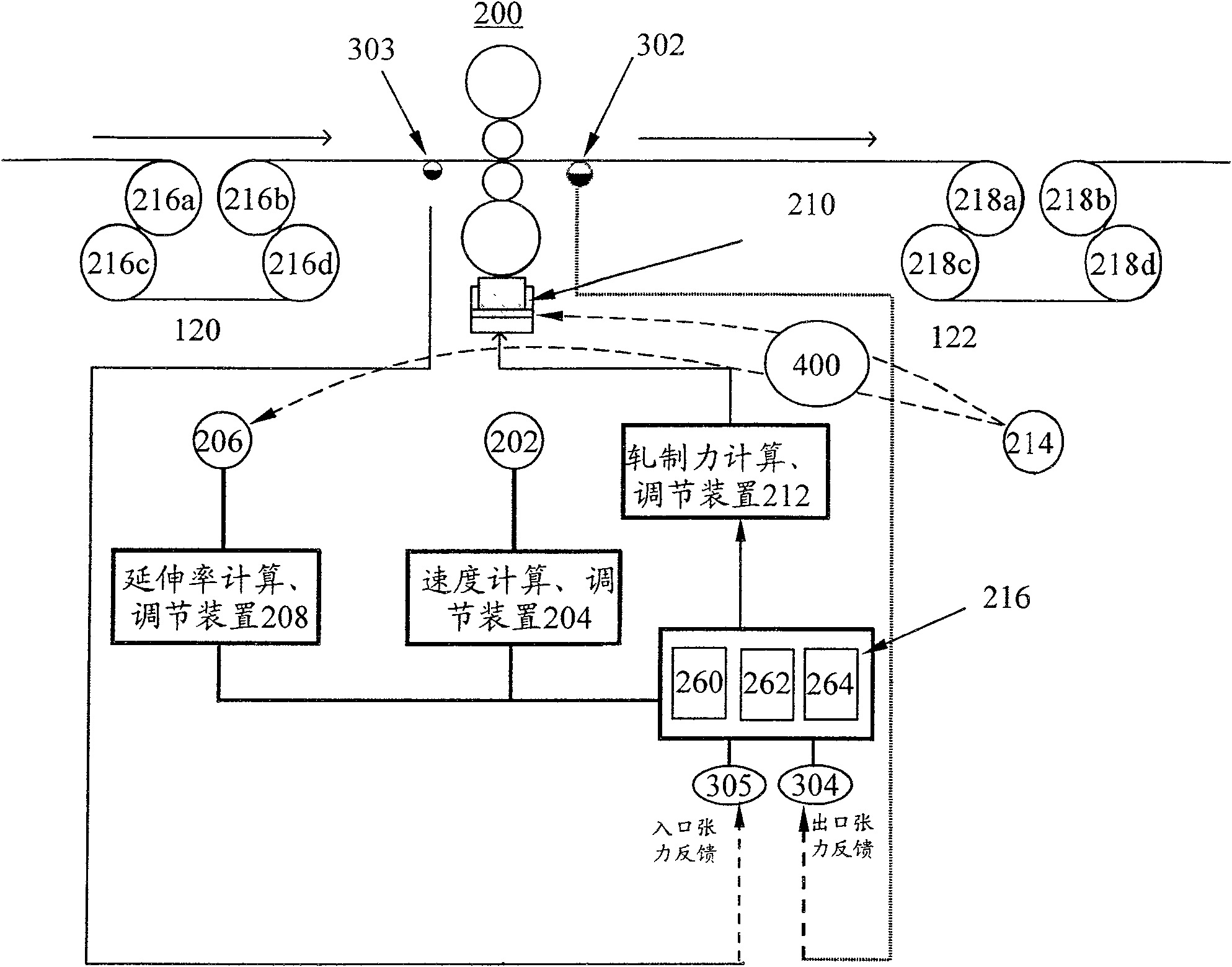

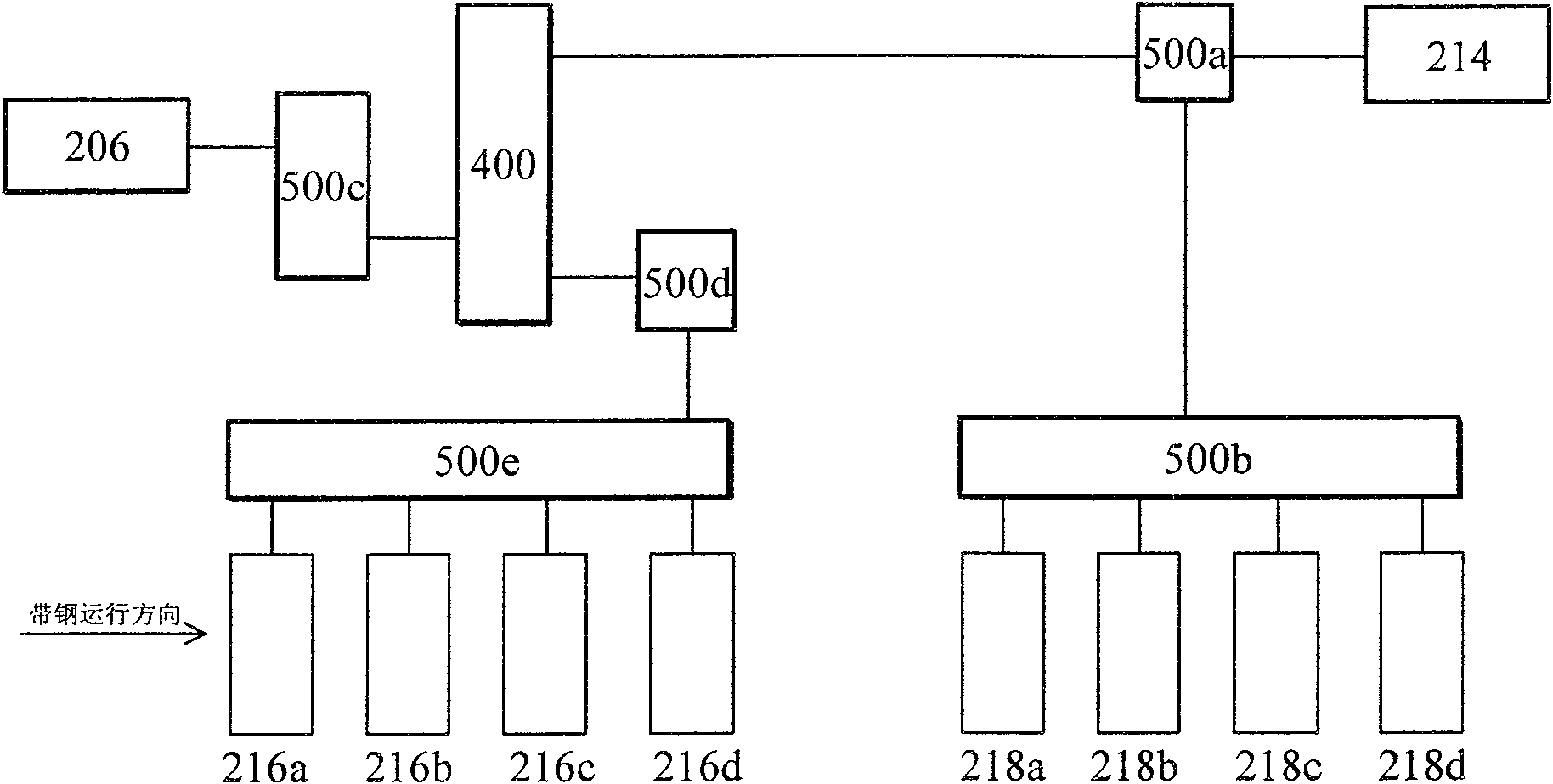

ActiveCN101168172AElongation stabilityRoll force/gap control deviceTension/compression control deviceControl systemEngineering

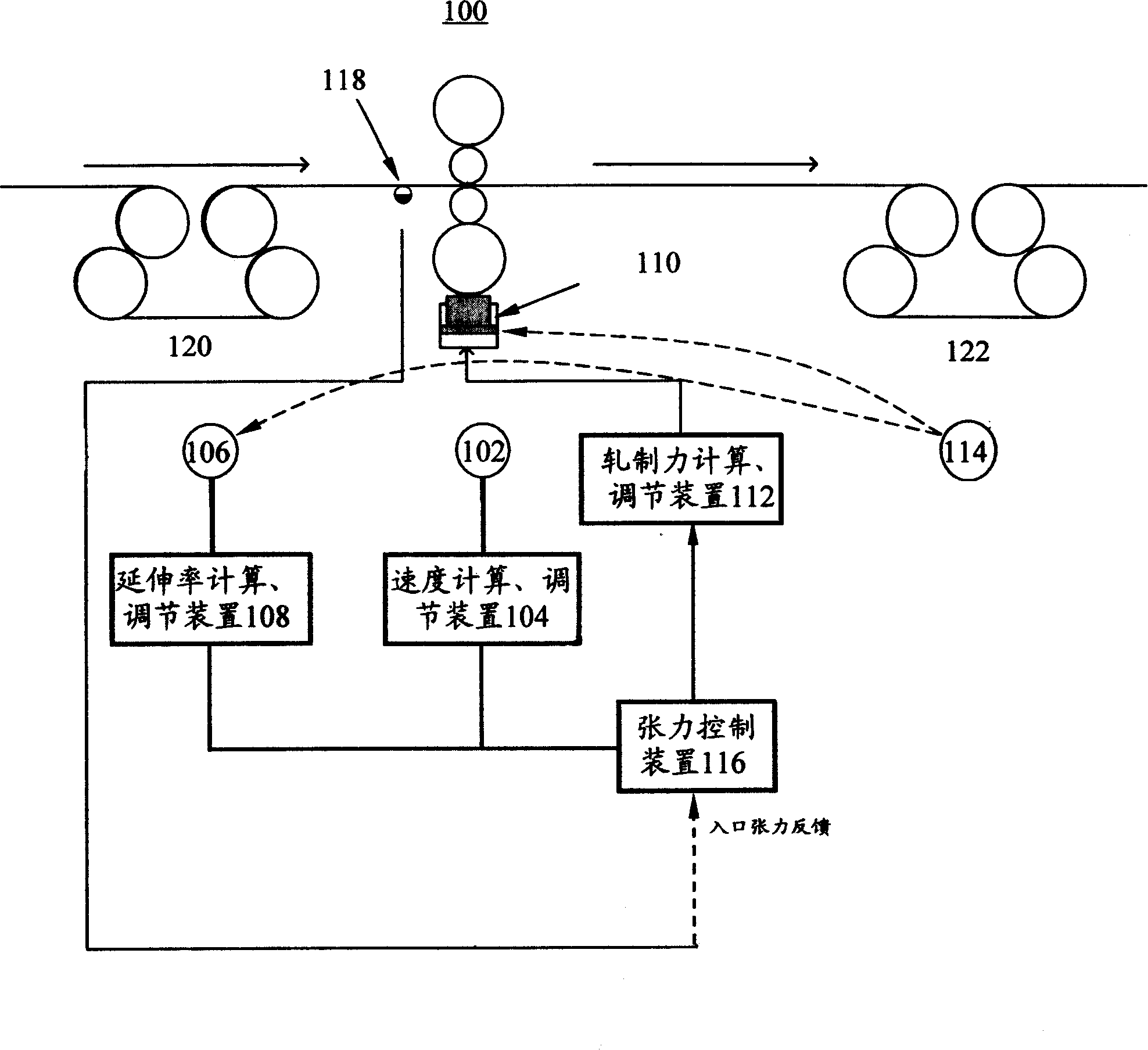

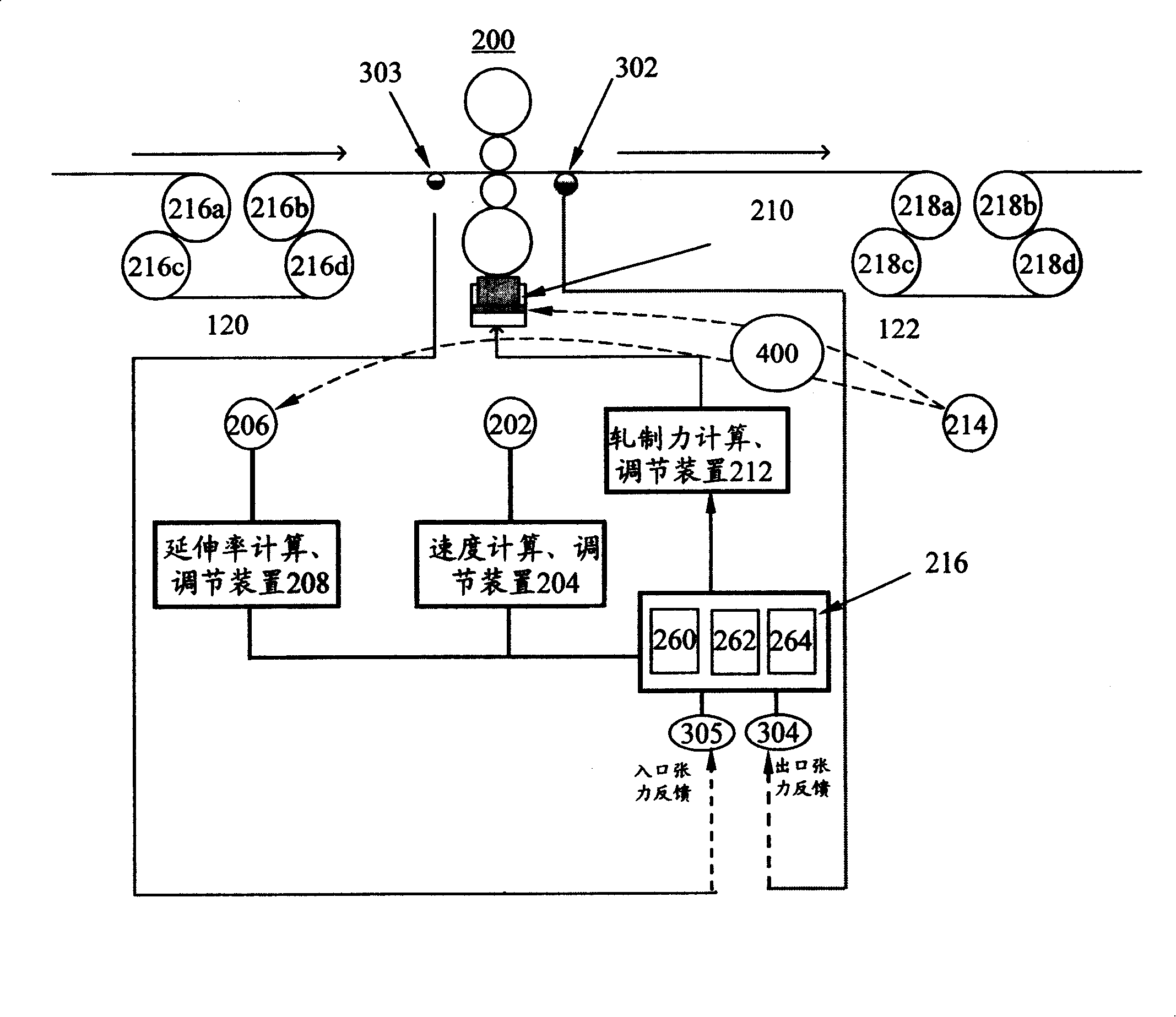

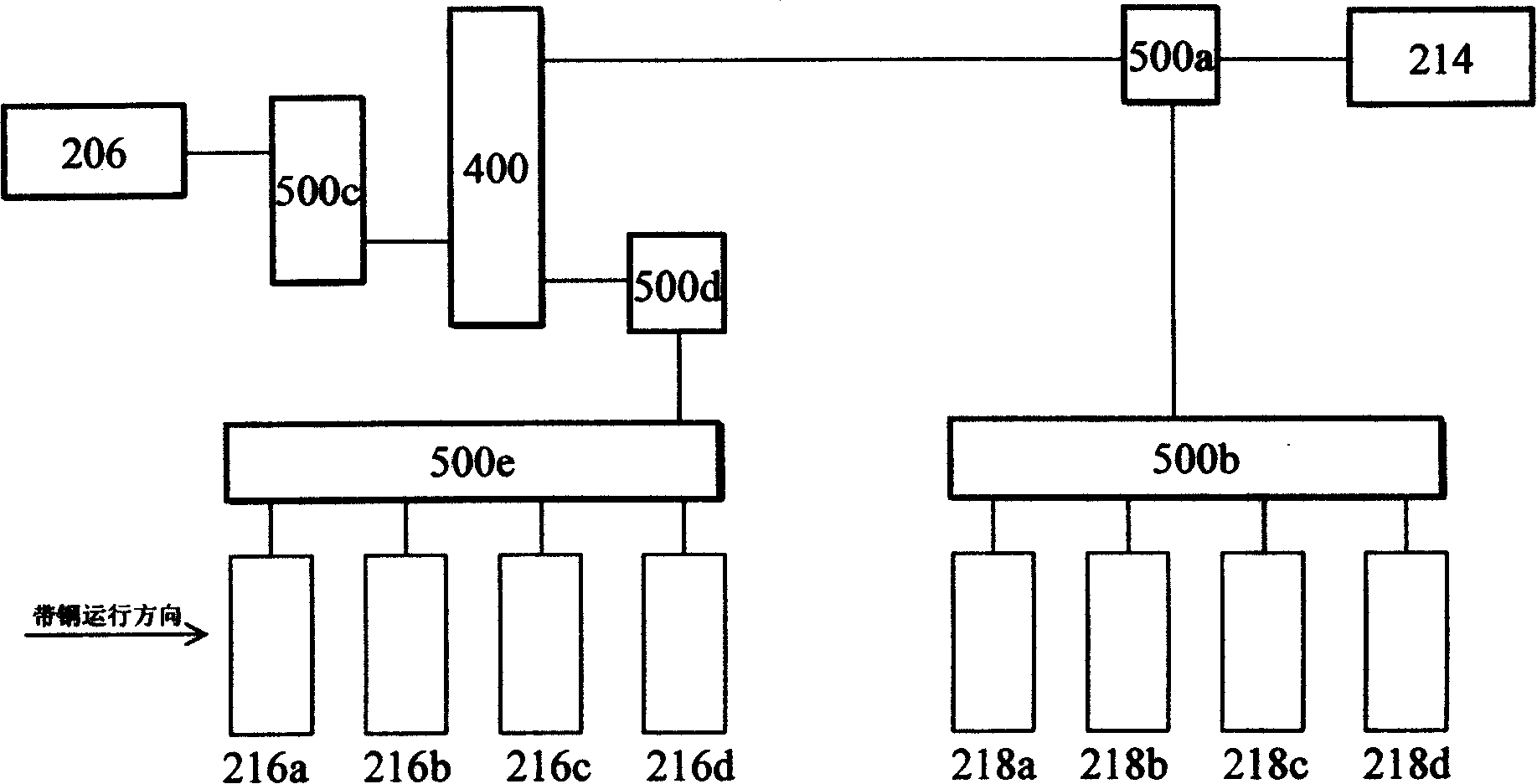

The invention discloses a tension control system of an epicyclic gear tension roll leveler, which comprises an inlet pull tension gage and an inlet tension feedback device, an outlet pull tension gage which is provided in the outlet of the leveler for measuring the strip tension in the outlet, an outlet tension feedback device for feedback the strip tension in the outlet which measuring by the outlet pull tension gage, a tension control device for receive the strip tension in the outlet which is feedback from the outlet tension feedback device. The roll-force, the elongation and the speed of the leveler can be definite by the association of strip tension in the inlet and outlet. The three key parameters comprises the roll-force, the elongation and the speed of epicyclic gear tension roll leveler, the coordinate cooperated controlled can be constructed among the three key parameters. According to the addition of tension in outlet with the outlet pull tension gage by the technical scheme of the invention, meanwhile the stable elongation, roll-force and tension control can be realized, and the order of stable strip steel property and shape can be achieved.

Owner:BAOSHAN IRON & STEEL CO LTD

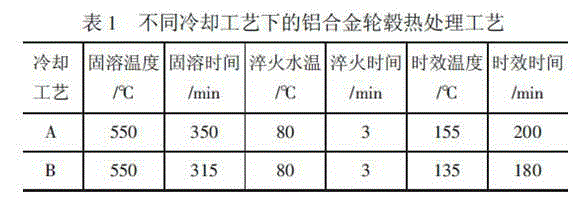

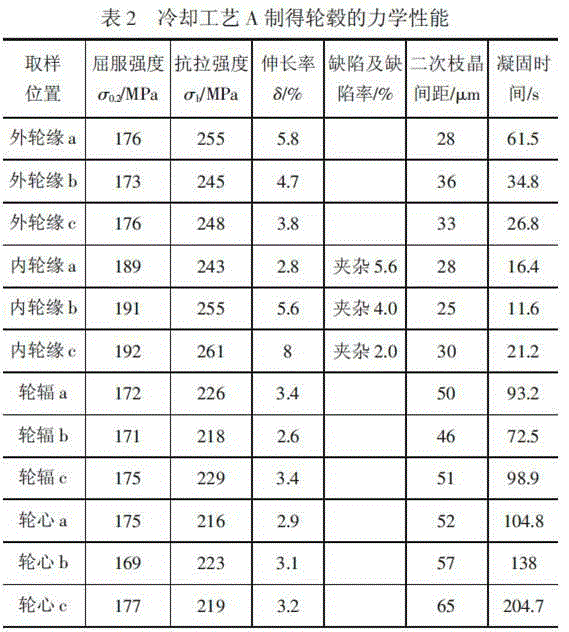

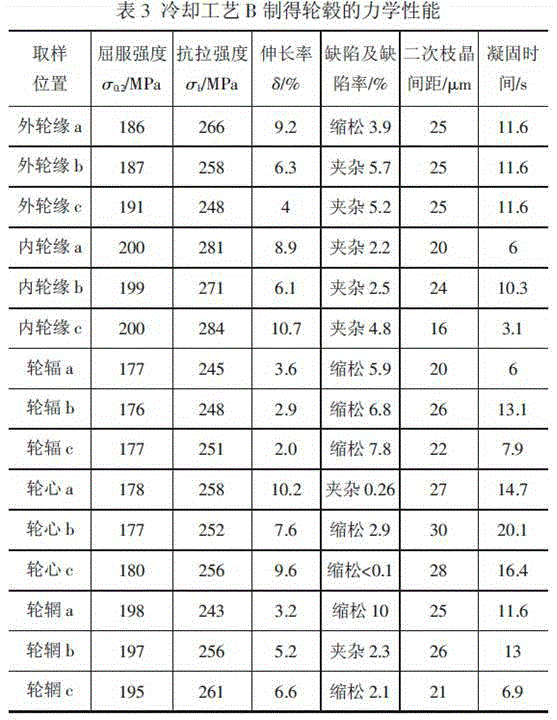

High effective heat treatment method for wheel hub founded at low pressure from high performance A356 alloy

This invention relates to a method for thermal treatment of high-efficiency and high-performance low-pressure die casting A356 alloy wheel. The method comprises: performing solid solution treatment at 535-545 deg.C for 5-7 h, quenching, performing low-temperature pre-aging treatment, and then performing aging treatment at 175-185 deg.C for 3-5 h immediately. The method has such advantages as shortened solid solution treatment time, shortened aging treatment time, high strength of low-pressure die casting A356 alloy wheel, shortened thermal treatment period, increased production efficiency, and improved mechanical properties of low-pressure die casting A356 alloy wheel.

Owner:ZHENGZHOU UNIV

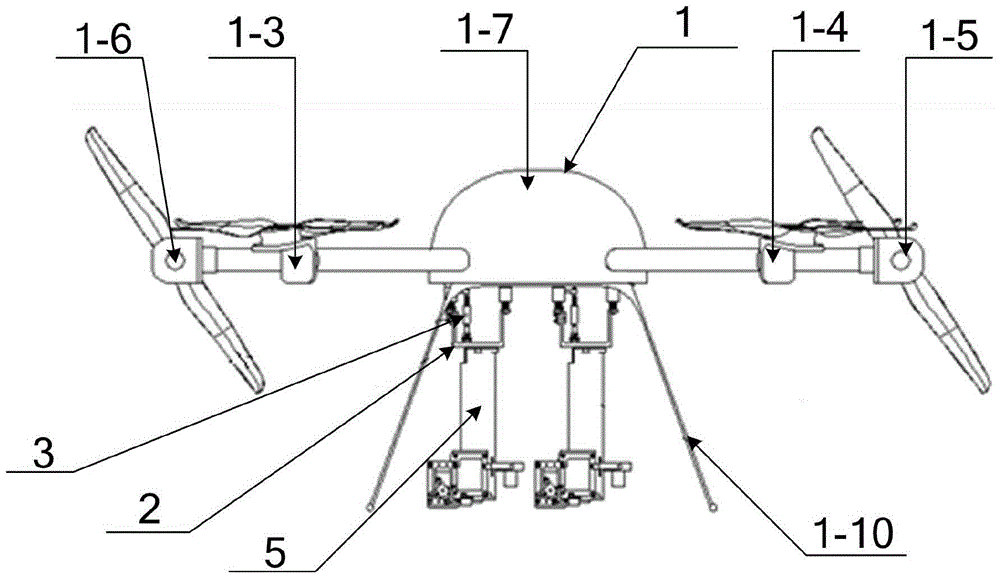

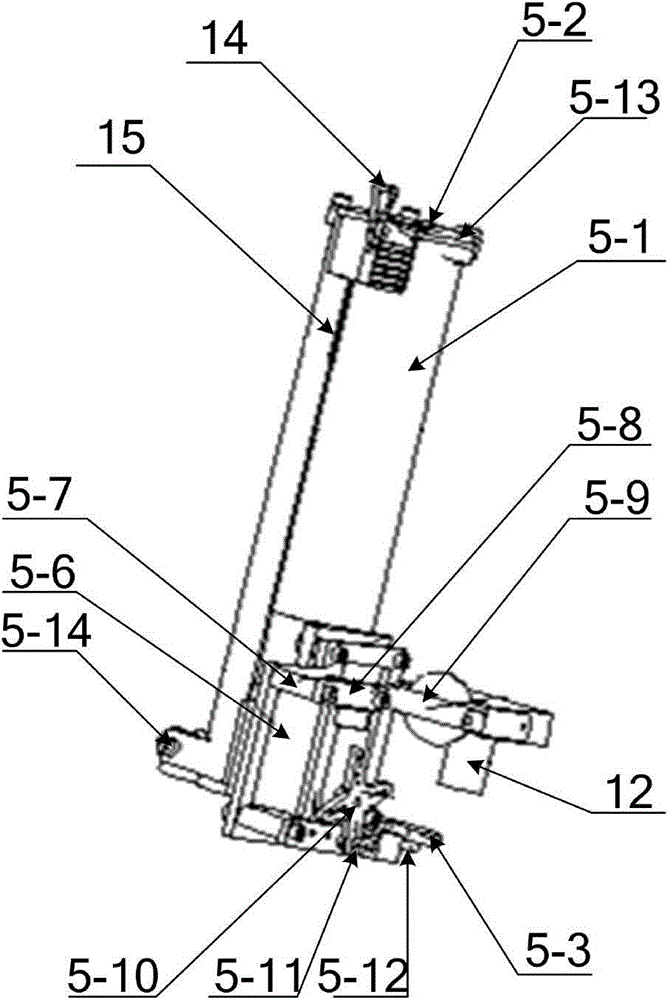

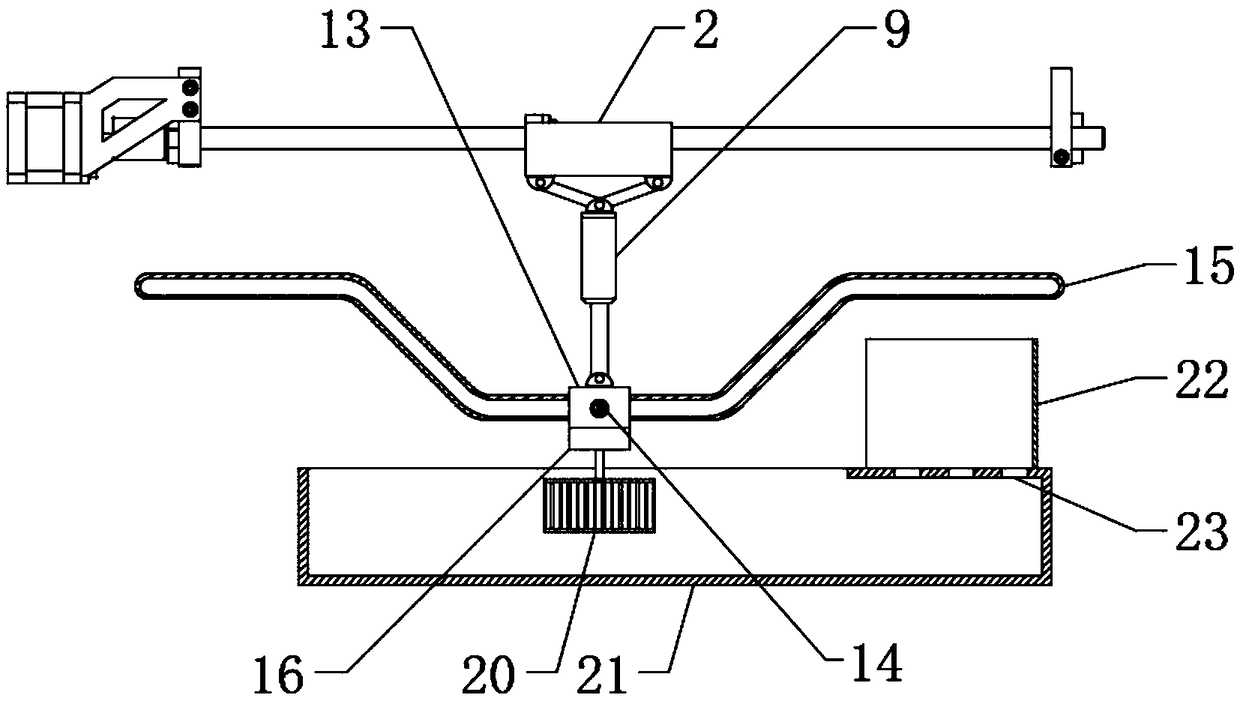

Automatic dispenser for air-based tear gas bomb

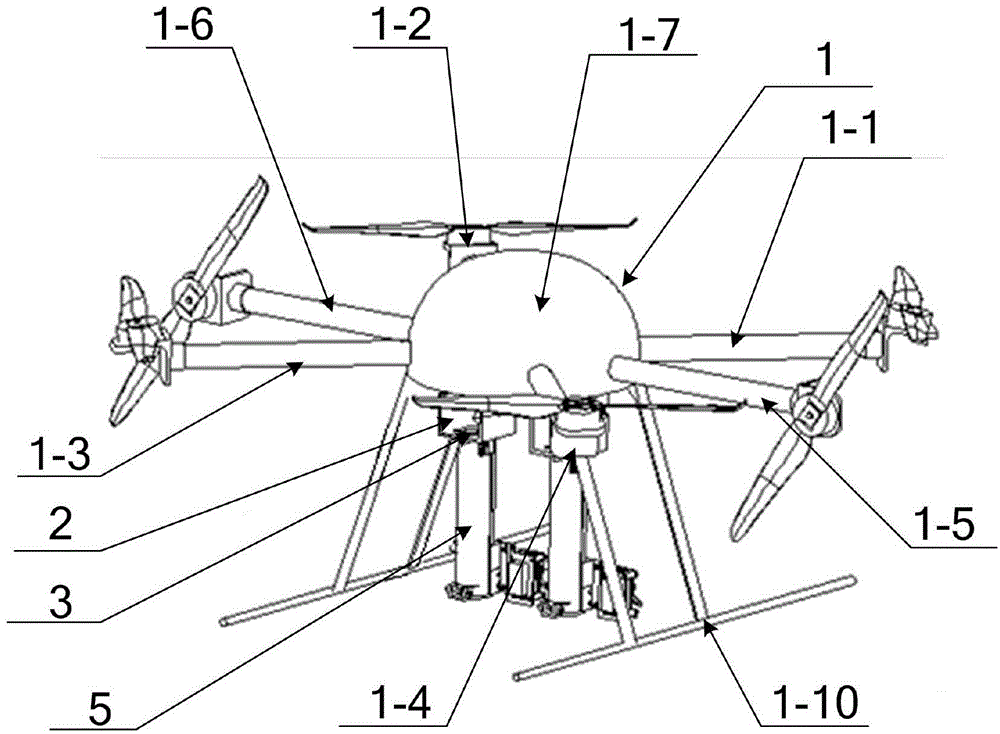

InactiveCN104527979ASimple structureEasy to operateAircraft componentsRotocraftHand heldData transmission

The invention discloses an automatic dispenser for air-based tear gas bomb and relates to the technical field of security and protection. The automatic dispenser for the air-based tear gas bomb solves the problems that the existing rifle-hand tear gas bomb dispensing is incapable of precisely shooting to an appointed position and not obvious in subduing effect. The automatic dispenser comprises a multi-rotor aircraft, a connecting platform, a pull ring fixing fine-adjustment mechanism, a gas bomb, a gas dispensing mechanism, a main control board, a data transmission module, a power supply module, a Beidou satellite locating system, an air pressure gauge, a hand-held ground controller, a camera and a damper; the gas dispensing mechanism is fixed on the multi-rotor aircraft through the connecting platform, and the connecting platform is connected with the bottom of the multi-rotor aircraft through the damper. The automatic dispenser for the air-based tear gas bomb realizes to automatically dispense tear gas at some part in the air; the automatic dispenser for the air-based tear gas bomb is simple in structure, convenient to operate and strong in practicability.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

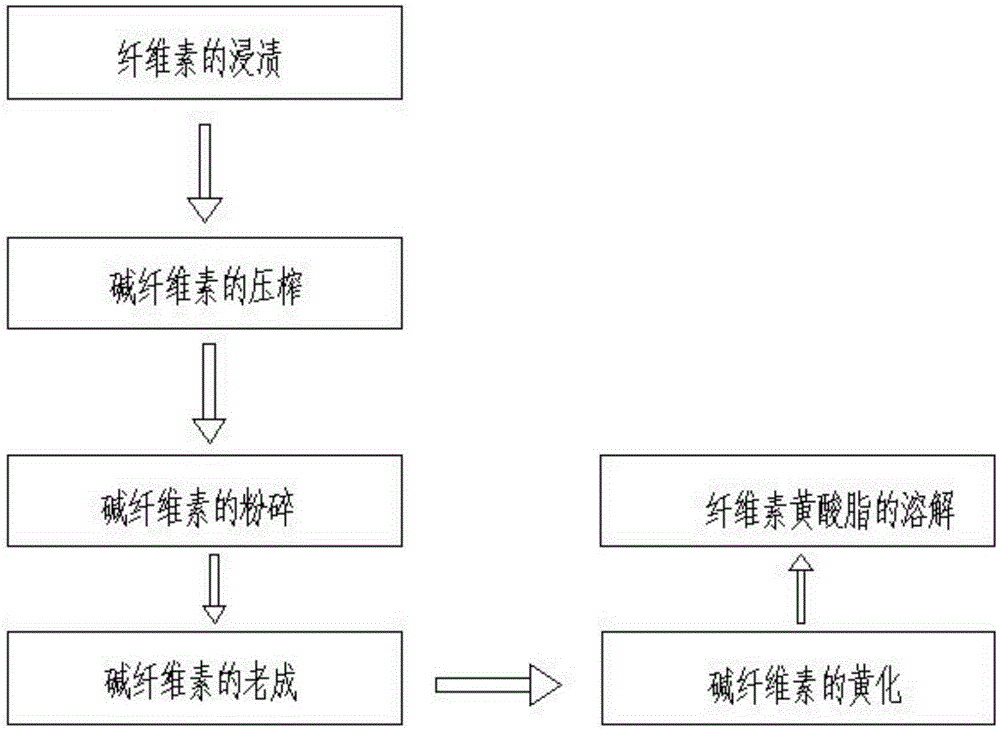

Production method of natural cellulose membrane

The invention discloses a production method of natural cellulose membranes, comprising the following steps: (a) immersion; (b) squeezing; (c) grinding; (d) maturing; (e) etiolation; (f) solution; (g) film formation; (h) desulfuration; (i) bleaching; (j) plastification; and (k) drying. The production method has the advantages of mild reaction condition, short spacings among the prepared natural cellulose membranes, stable expansion rate and tensile strength, proper stiffness and flexibility, better colour and luster, good transparence, high hygiene property, and the like, improves the surface property of paper through the plastification, in particular enhances the smoothness of paper surfaces, improves the printability, reduces the deformability of paper and the moisture absorption, thereby reaching the new requirement of modern printing and packaging.

Owner:绍兴柯德新材料股份有限公司

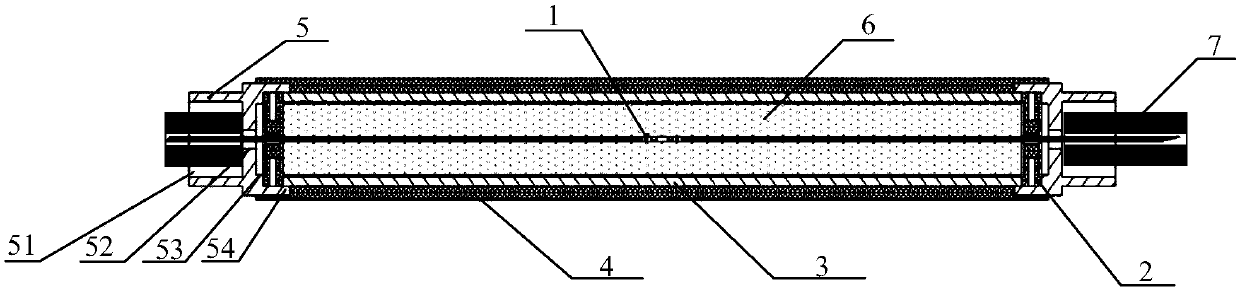

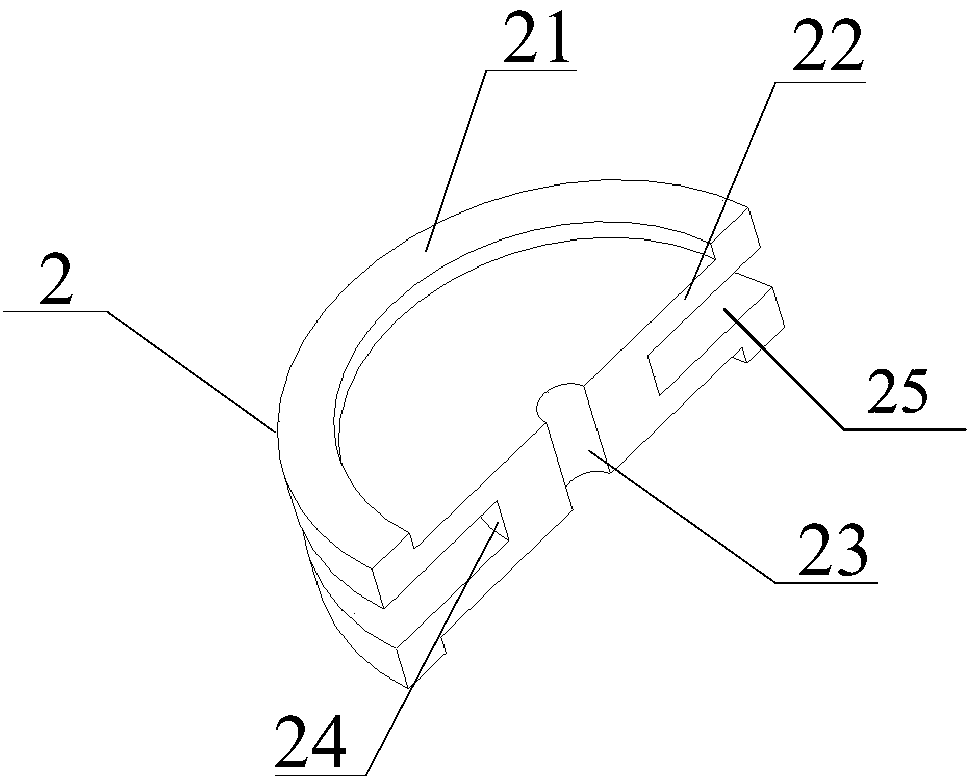

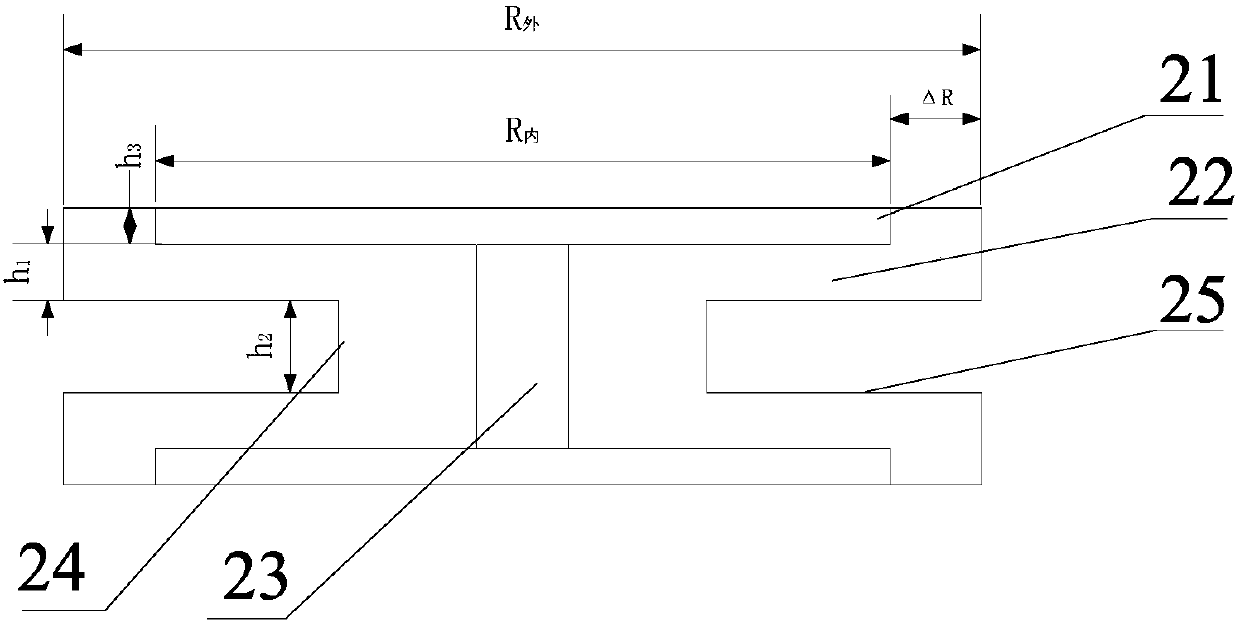

Fiber laser hydrophone and manufacturing method thereof

ActiveCN107631790AElongation stabilityHelp pick upSubsonic/sonic/ultrasonic wave measurementUsing wave/particle radiation meansEngineeringFiber gratings

The invention relates to a fiber laser hydrophone. The fiber laser hydrophone comprises a fiber containing an active fiber grating, two elastic films, a cylinder, an end head and a sheath, wherein theelastic films comprise upper films, lower films and supporting columns, the elastic films are provided with through fiber holes, the through fiber holes are through holes penetrating through the upper films, the lower films and the supporting columns, and the two elastic films are respectively connected with two ends of the cylinder. The two elastic films are added to the fiber laser hydrophone,structures of the elastic films are specially designed, low frequency sound signals can be better picked up, absorption capability of energy generated because of acceleration is stronger, kinetic energy generated because of acceleration can be more effectively consumed, inhibition of acceleration response is facilitated, fine linear demands for the fiber laser hydrophone in practical application are adapted, on the condition that low frequency high sensitivity is guaranteed, the diameter is reduced, the fiber laser hydrophone can be better applied to a super-fine hydrophone array system, and the fiber laser hydrophone is suitable for micro underground mobile platforms.

Owner:BEIJING INST OF AEROSPACE CONTROL DEVICES

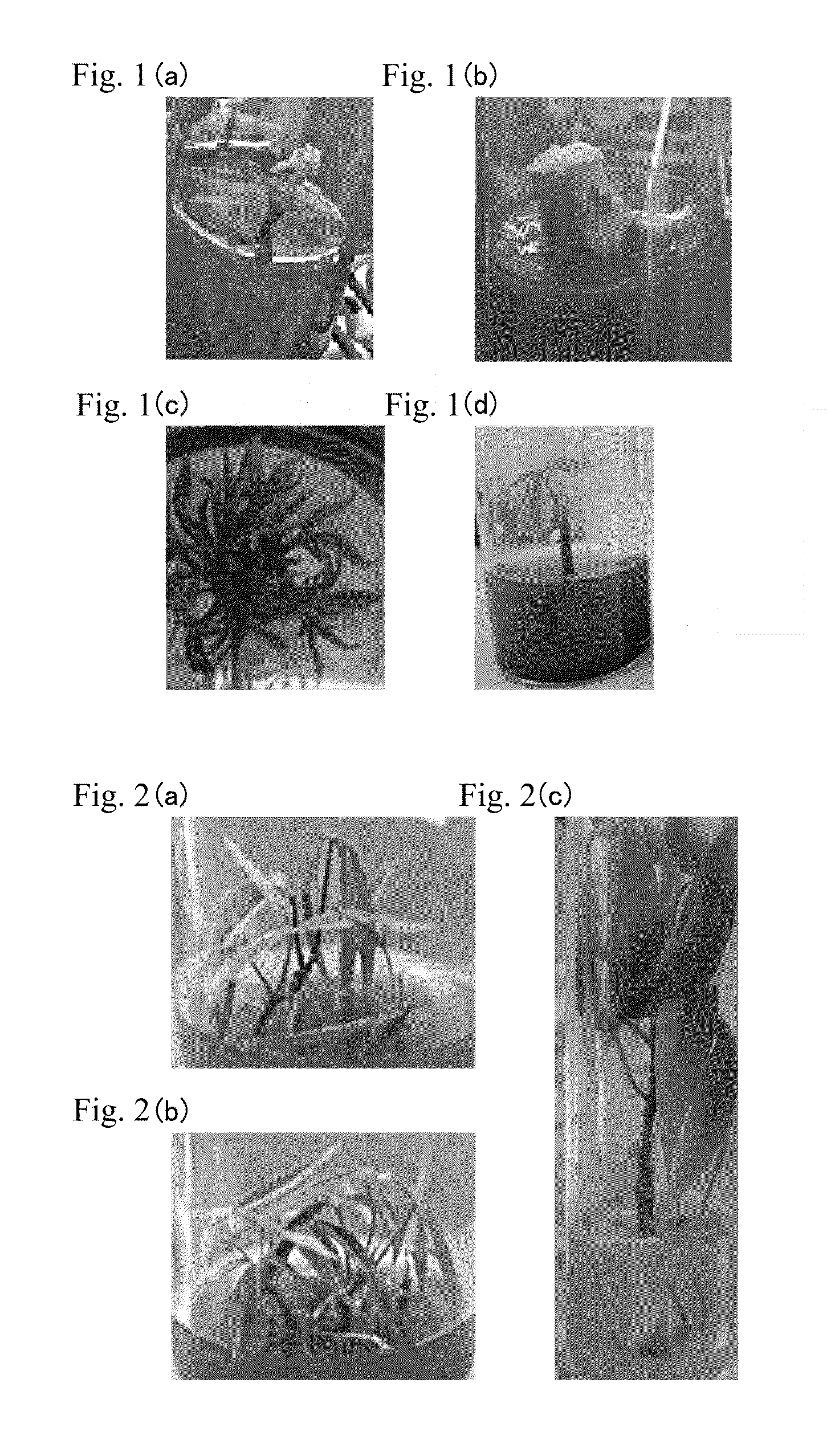

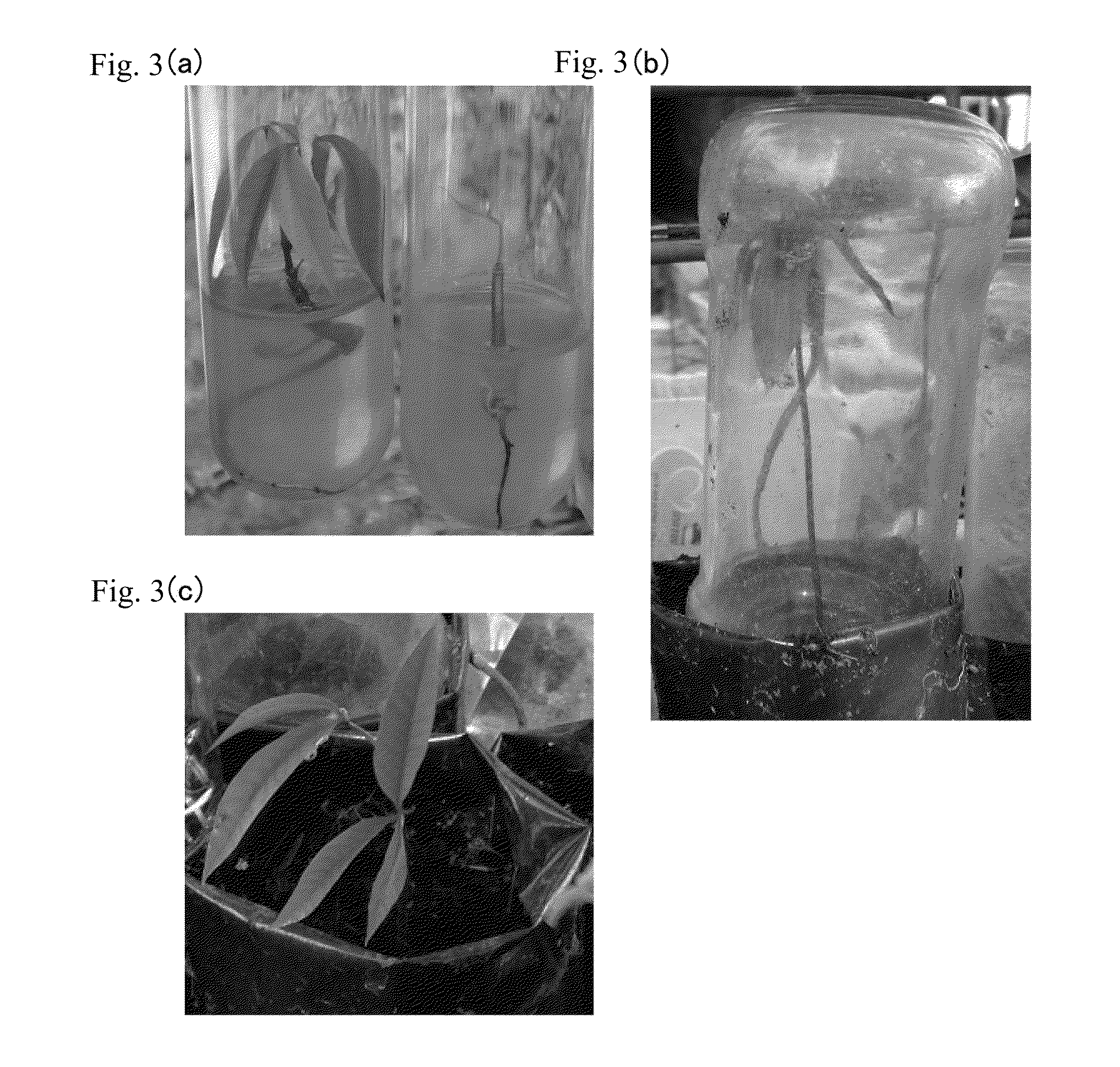

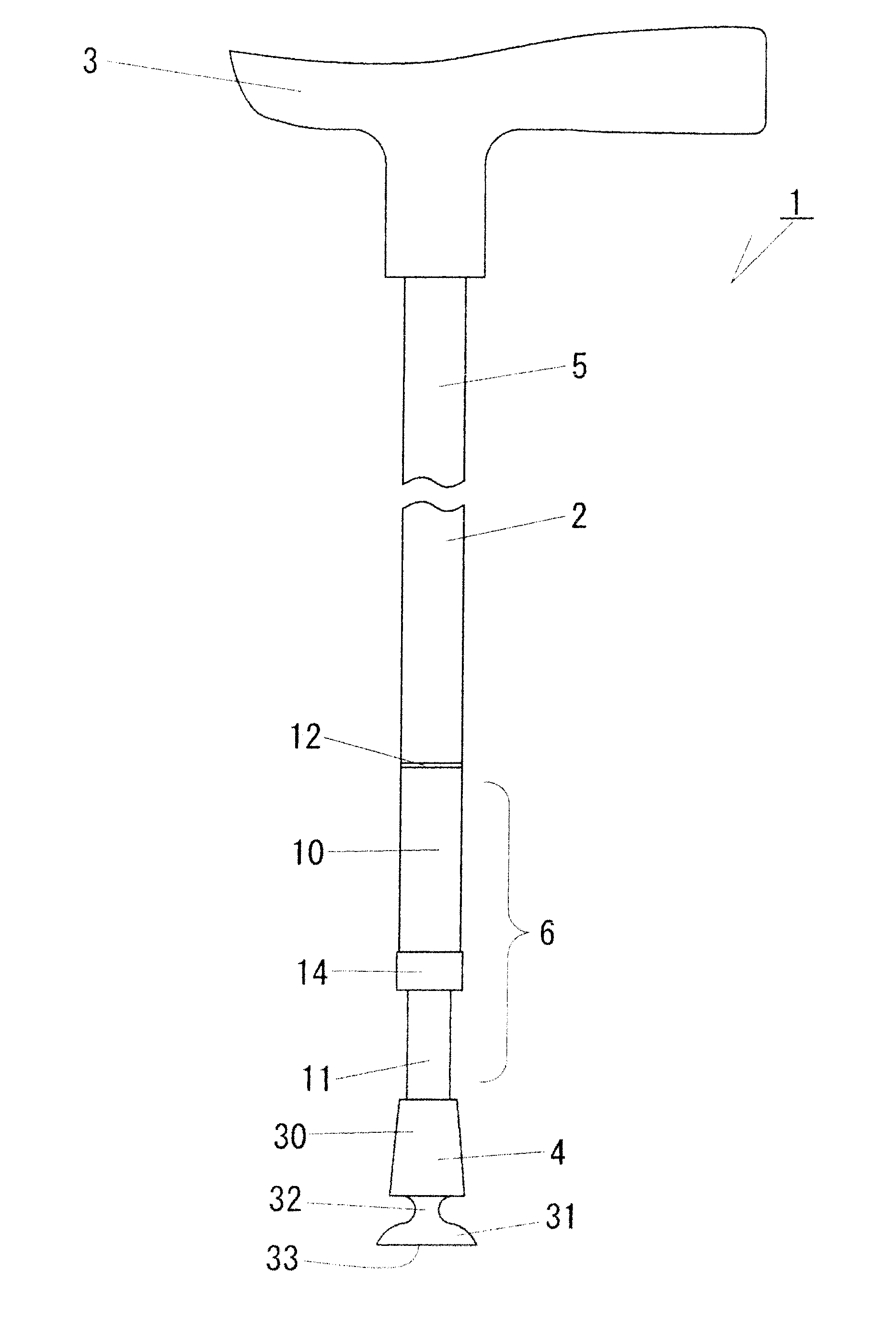

Method of regenerating rubber tree, method of propagating rubber tree, method of inducing shoot, method of elongating shoot, method of rooting shoot, and method of acclimatizing young plant

InactiveUS20160219801A1Stably regenerateSmooth transmissionCultivating equipmentsHorticulture methodsGrowth plantAxillary bud

Provided are a method of regenerating a rubber tree that can stably regenerate the rubber tree from a tissue including a node, axillary bud or apical bud derived from a mature rubber tree, a young rubber tree, or a plantlet of a rubber tree; and a method of propagating a rubber tree that can stably acquire large numbers of clone seedlings of the rubber tree. Included is a method of regenerating a rubber tree including an induction step of culturing a tissue including a node, axillary bud or apical bud of a rubber tree in an induction medium containing a plant growth hormone and a carbon source to form a shoot.

Owner:SUMITOMO RUBBER IND LTD

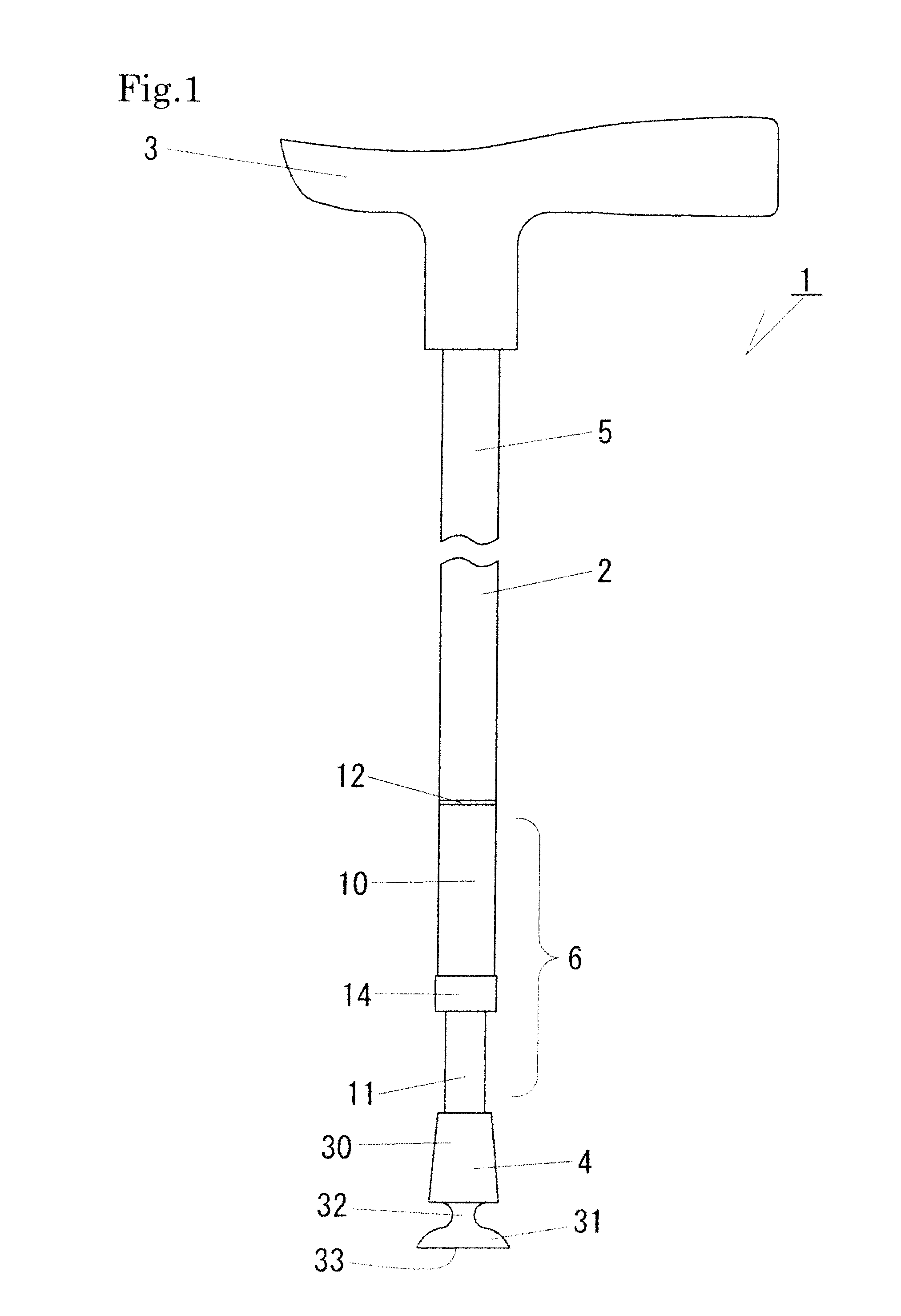

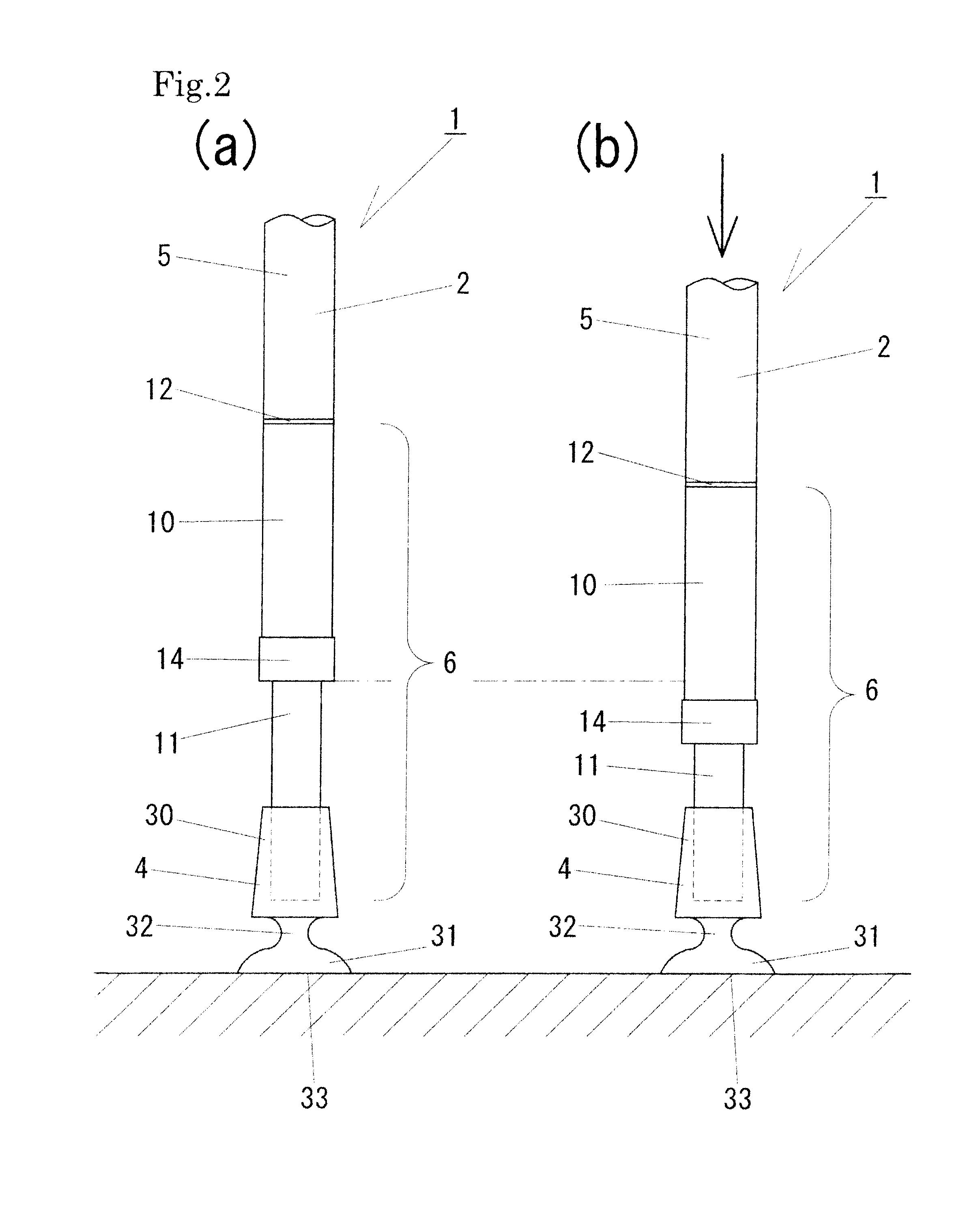

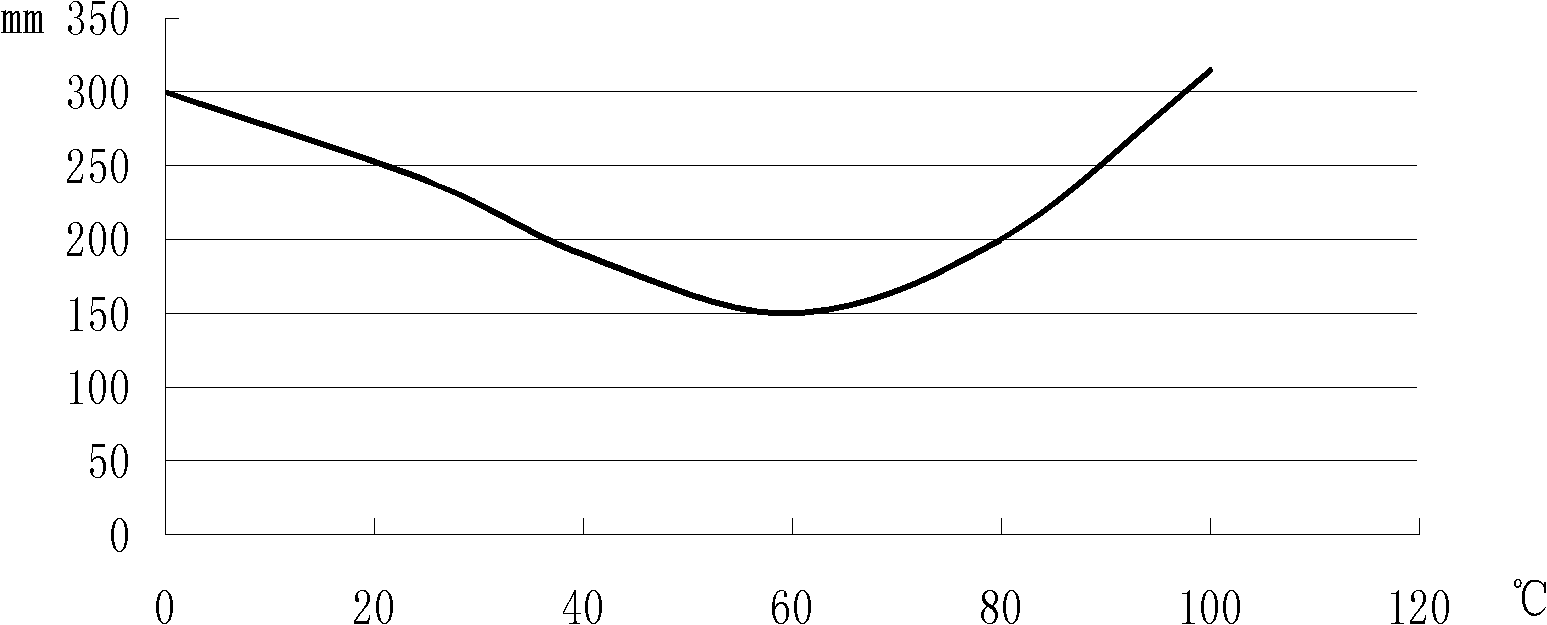

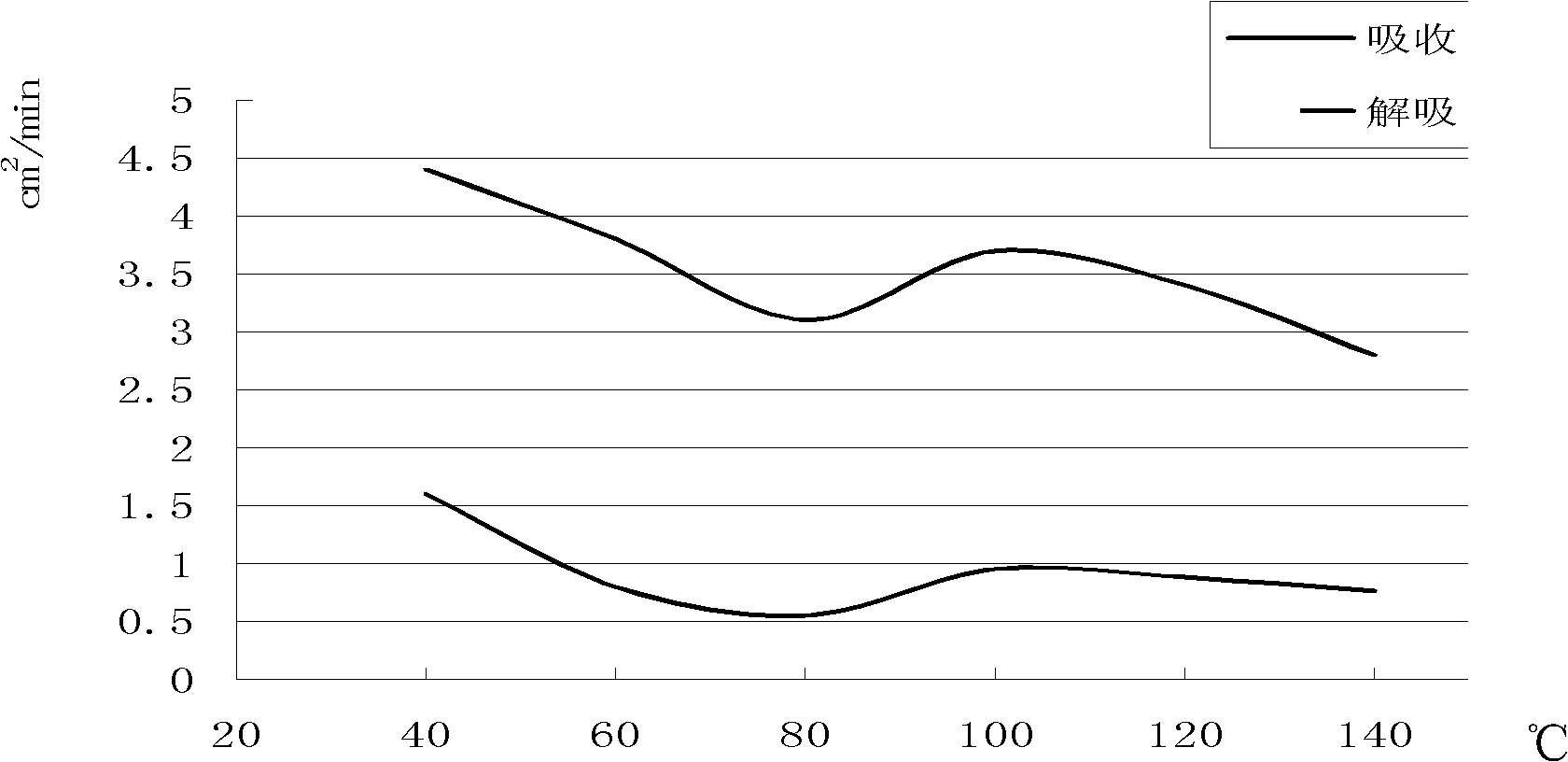

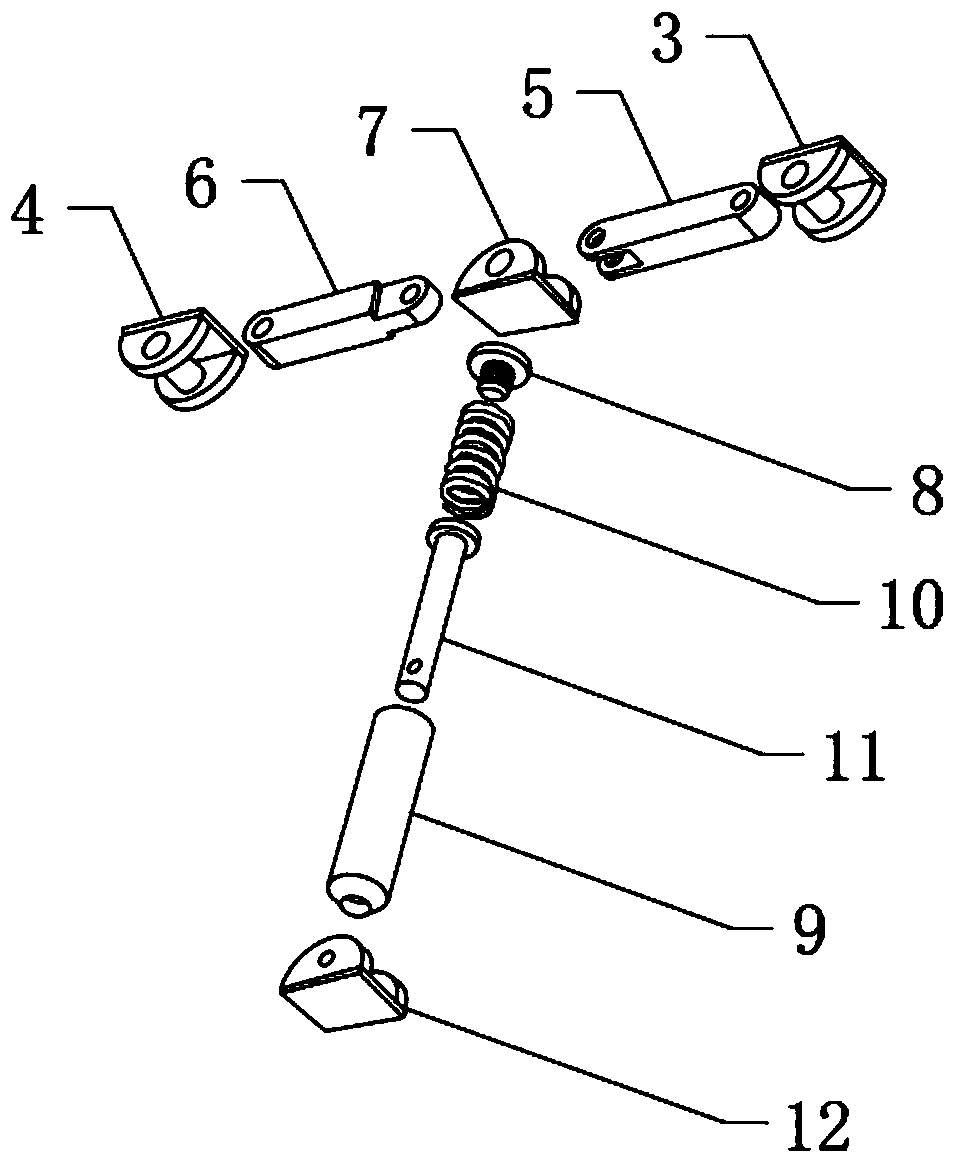

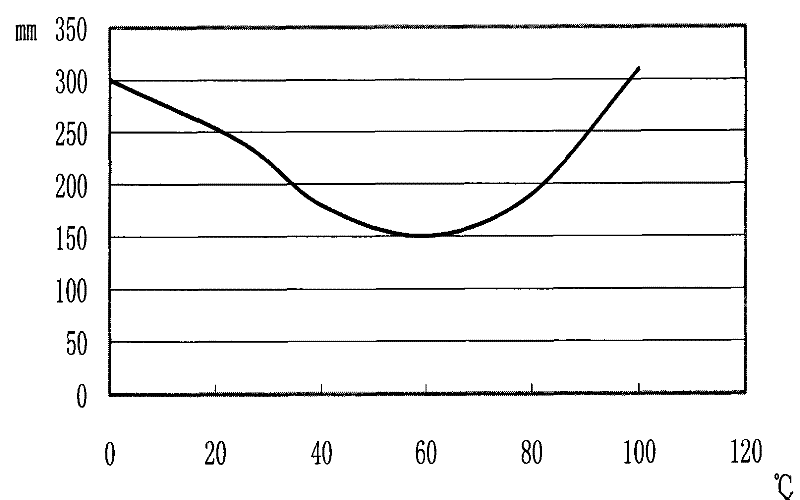

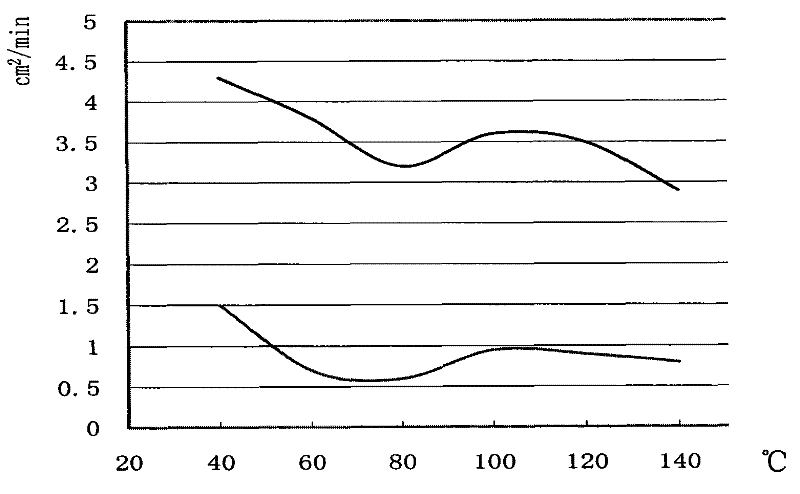

Stick

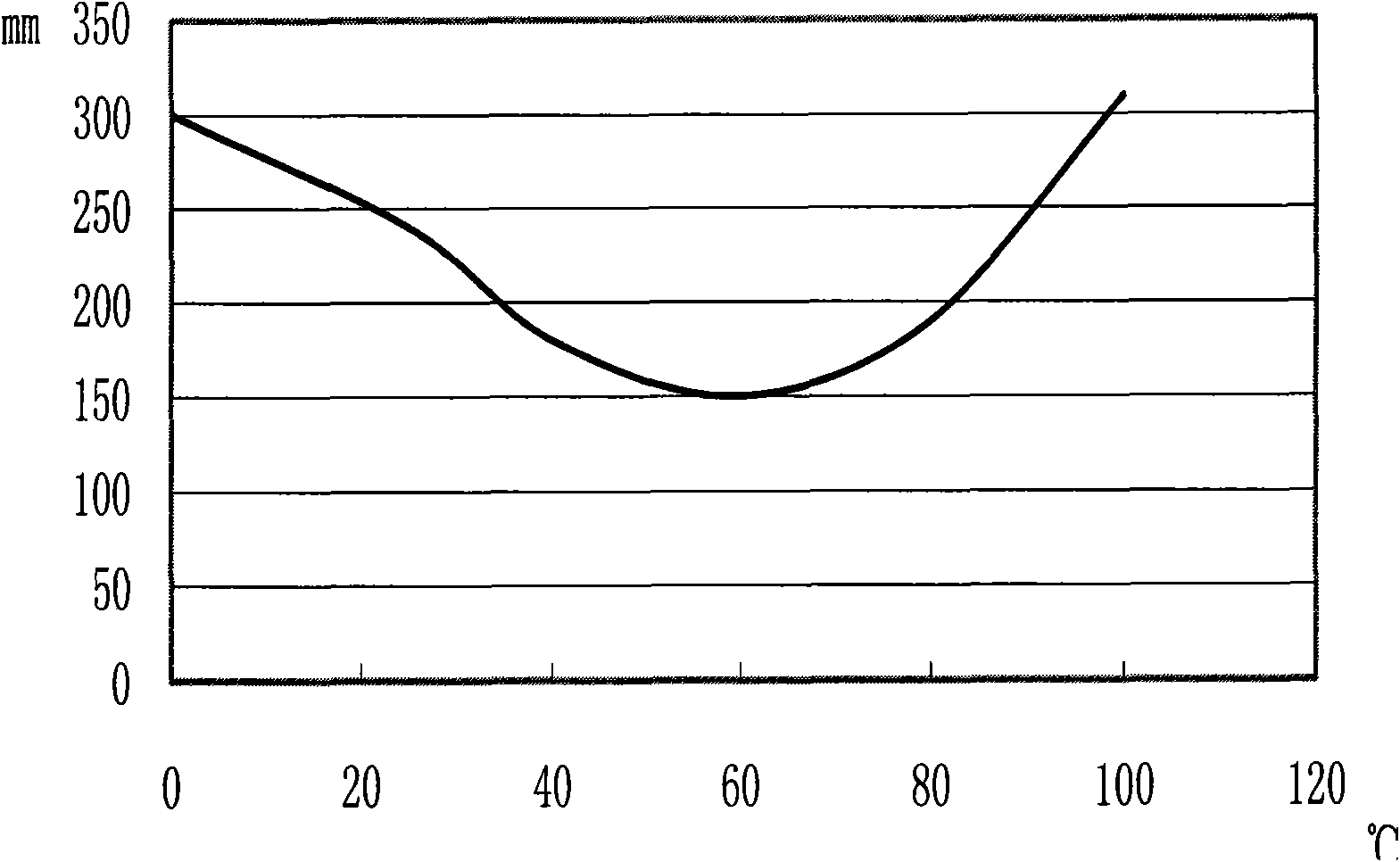

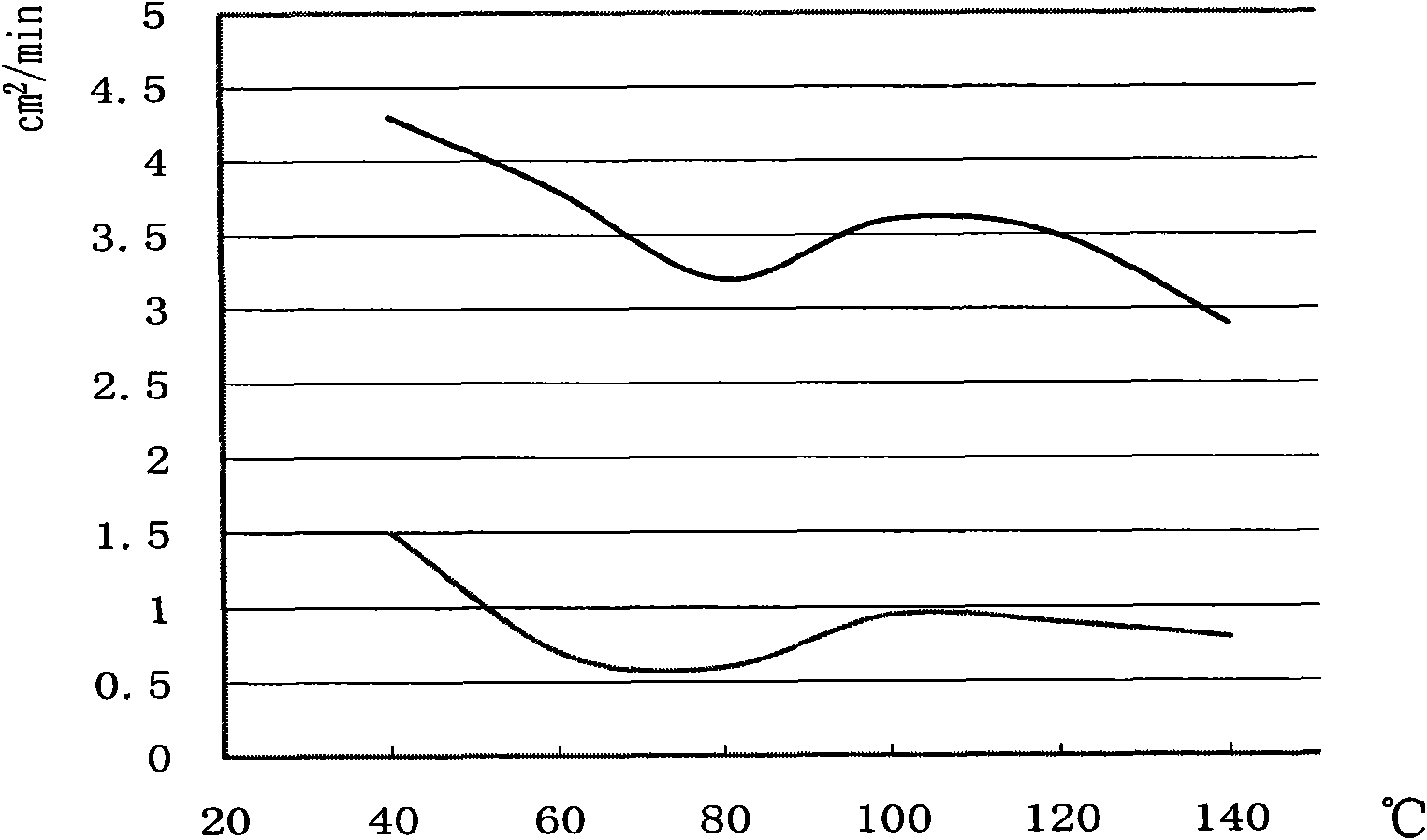

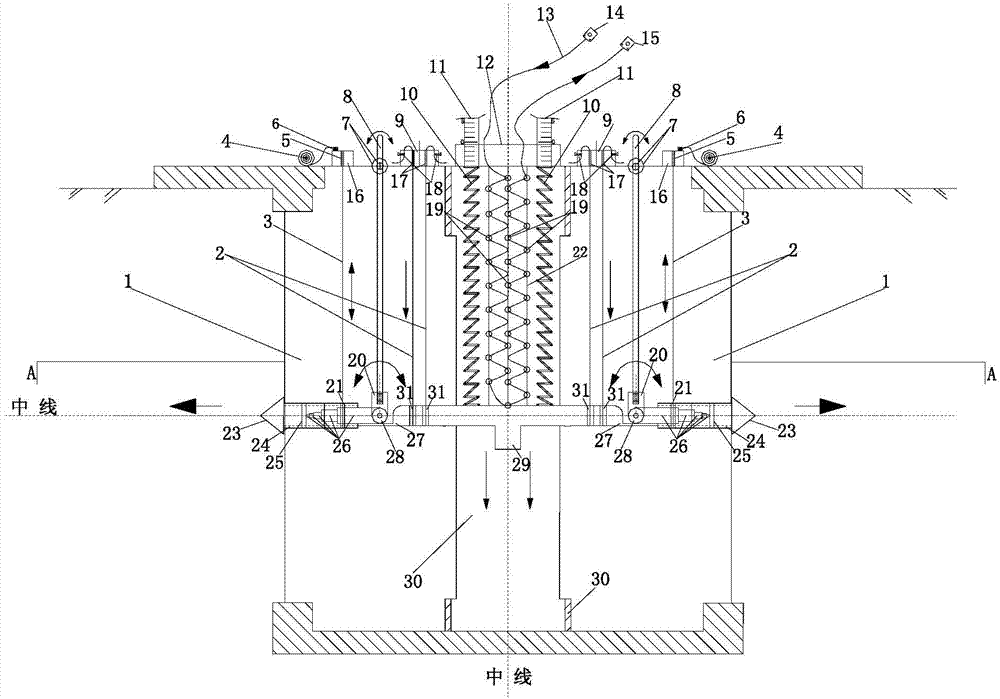

InactiveUS20120160286A1Securely holdPromote absorptionWalking sticksSnowboard bindingsCoil springSnubber

A stick that is excellent in shock absorption and is also excellent in stability is provided.A stick body is provided with a telescopic extension pipe formed by fitting an outer tube and an inner tube together in a nesting manner. Inside the extension pipe, a velocity-dependent damper that damps the relative sliding movement between the outer tube and the inner tube, and a compression coil spring that concentrically fits onto the damper and urges the extension pipe so as to be extended are connected in parallel. According to such a stick, the shock transmitted to the hand can be mitigated as the compression coil spring contracts upon landing. Also, since the damper suppresses unwanted vibration of the extension pipe, the length of the stick quickly becomes stable after landing, allowing the user to keep stable balance with the stick.

Owner:NCC CO LTD

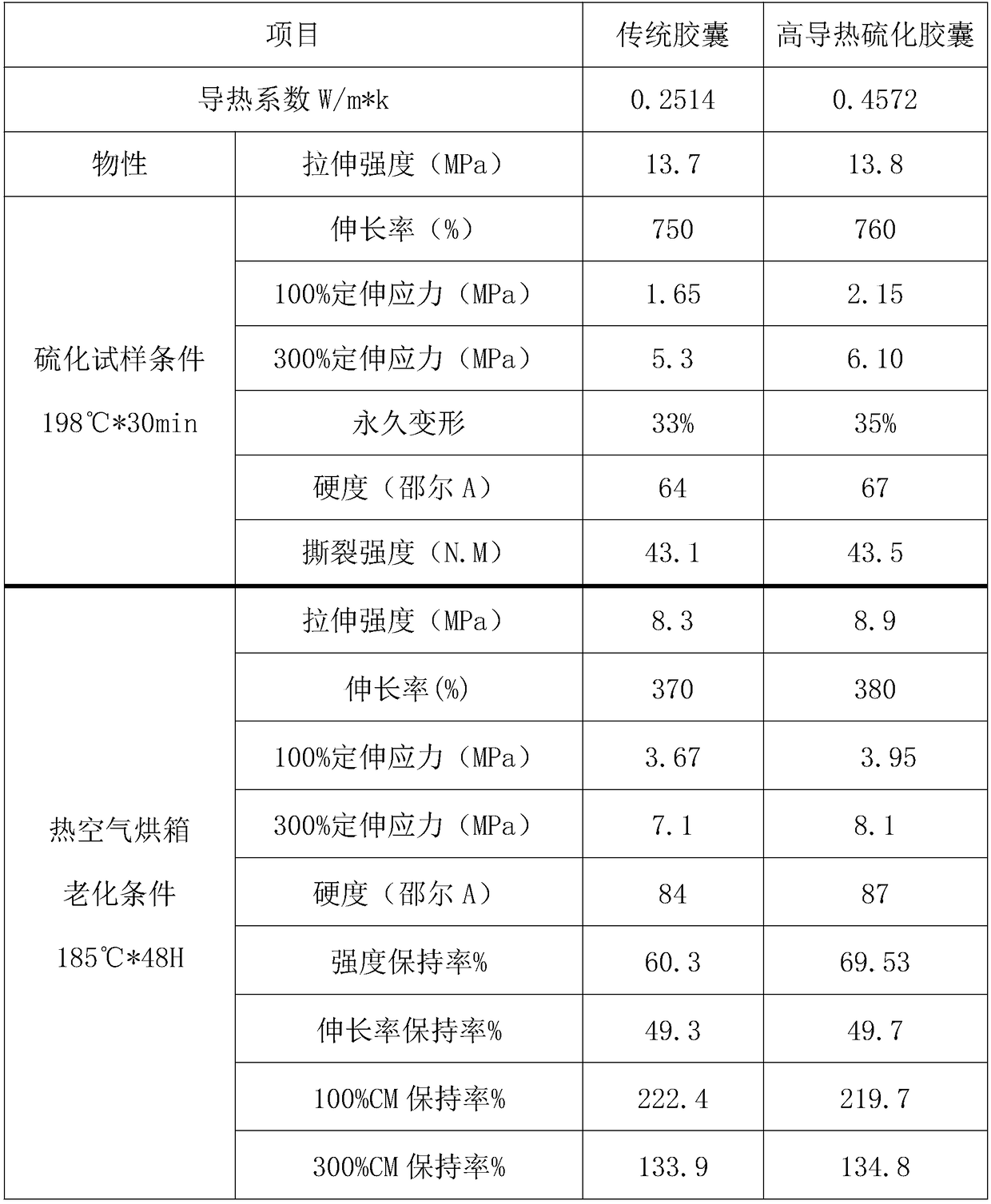

Preparation method of high-heat-conductivity type tire vulcanization capsule

The invention discloses a preparation method of a high-heat-conductivity type tire vulcanization capsule. The preparation method of the high-heat-conductivity type tire vulcanization capsule belongs to the technical field of tires, and comprises the following steps of (1) compounding the components according to the matching ratio: 95 parts of butyl rubber, 4 to 5 parts of chloroprene rubber, 15 to20 parts of N375 carbon black, 35 to 45 parts of acetylene black, 7 to 15 parts of graphene, 7 to 10 parts of alkane oil, 0.5 to 1.5 parts of stearic acid, 5 to 7 parts of zinc oxide, and 8 to 10 parts of resin; (2) primarily mixing; (3) filtering rubber; (4) secondarily mixing; (5) forming; (6) vulcanizing; (7) polishing; and (8) inspecting a finished product. According to the preparation methodof the high-heat-conductivity type tire vulcanization capsule provided by the invention, on the basis of ensuring the stability of various physical and mechanical properties, a heat conductivity coefficient is further improved, so that the aims of saving energy and reducing cost are achieved.

Owner:YONGYI RUBBER CO LTD

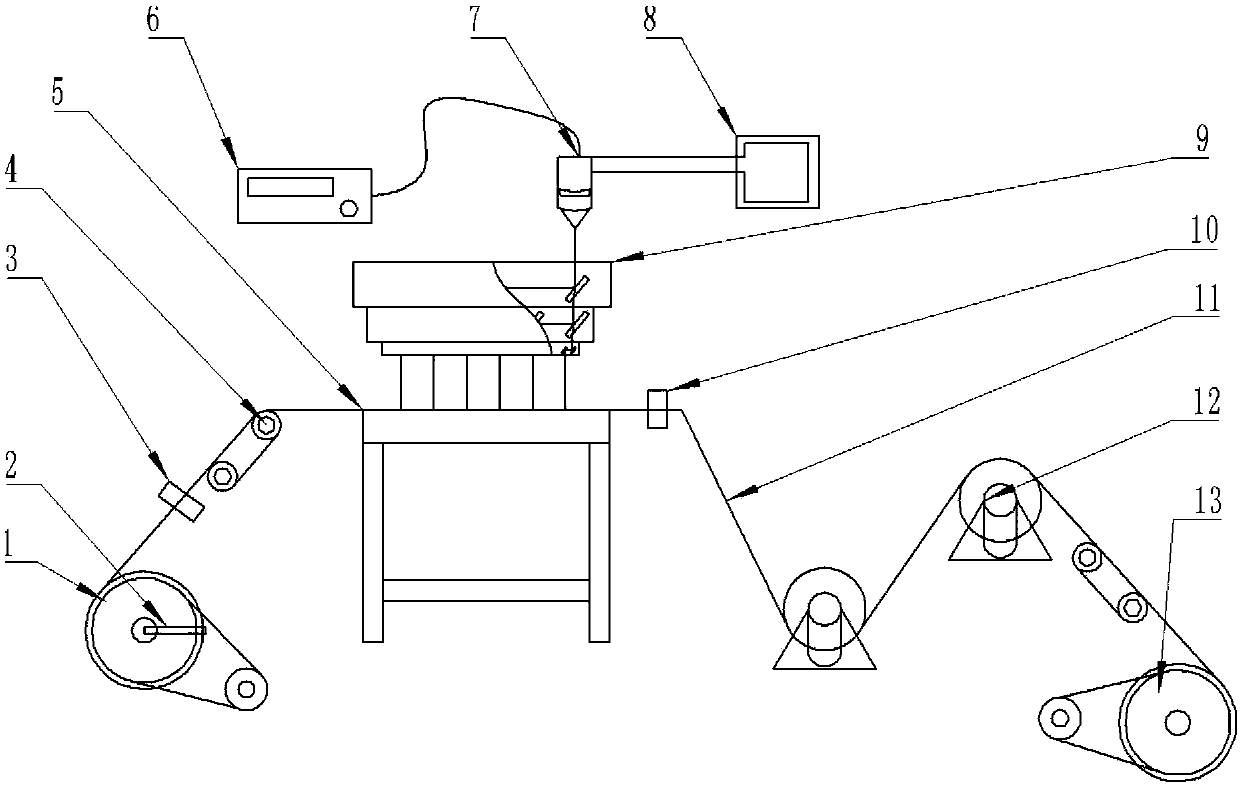

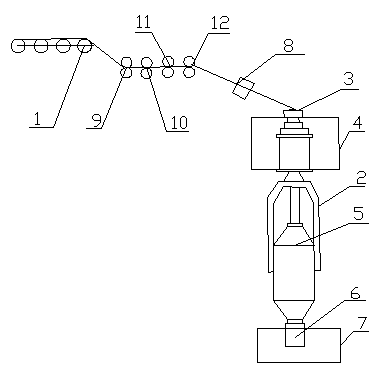

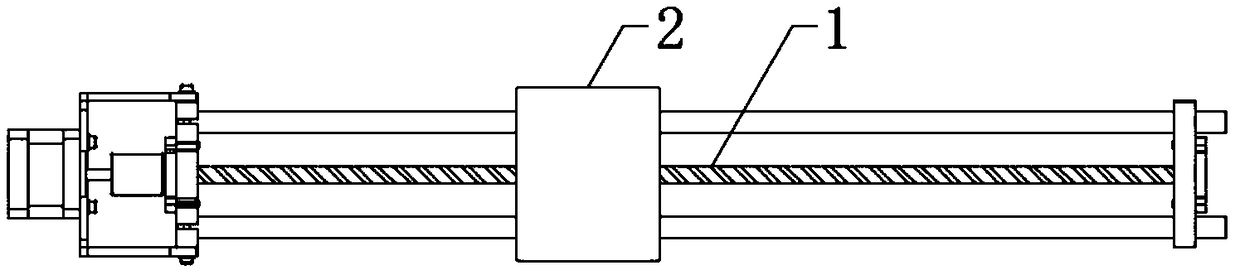

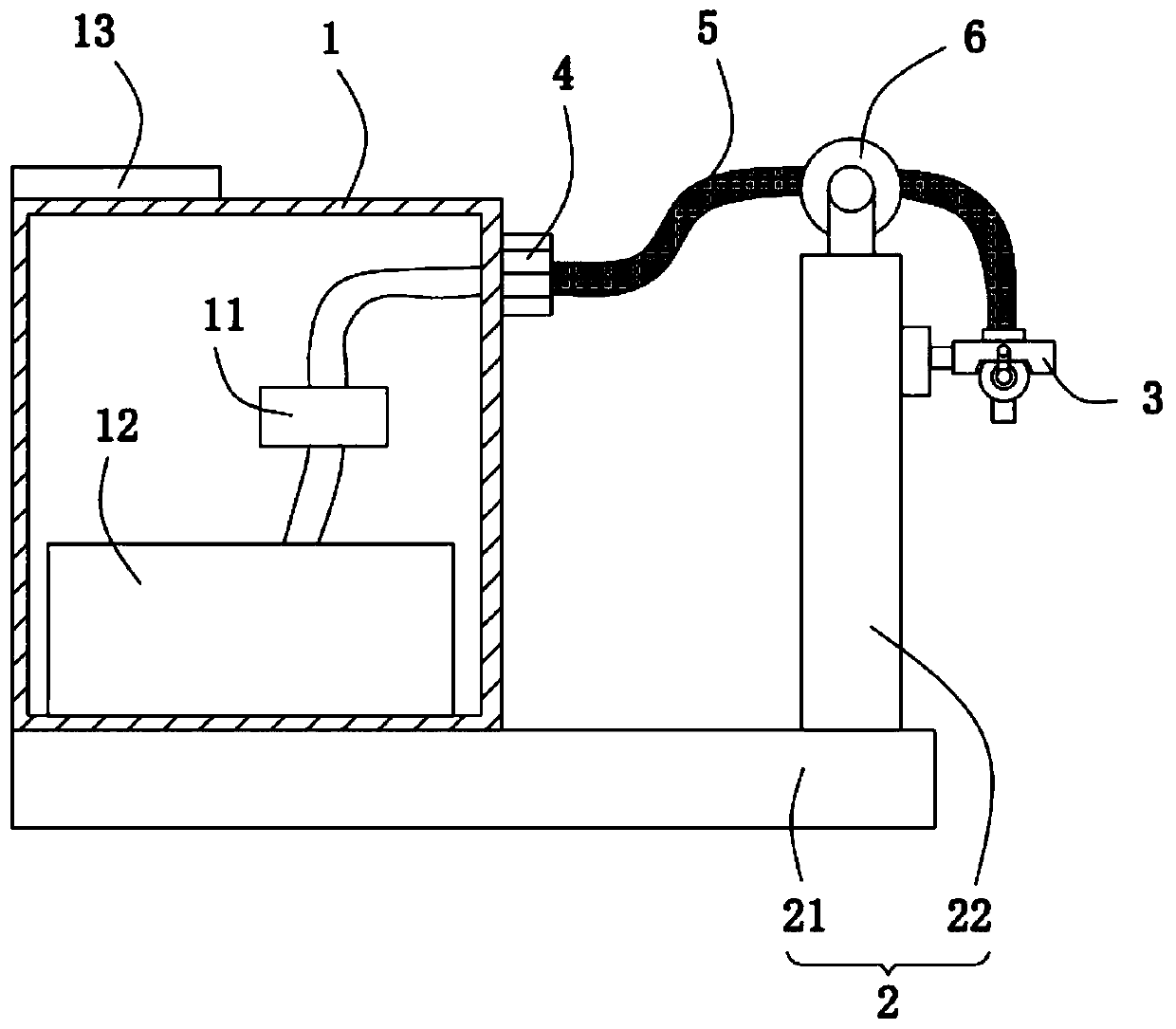

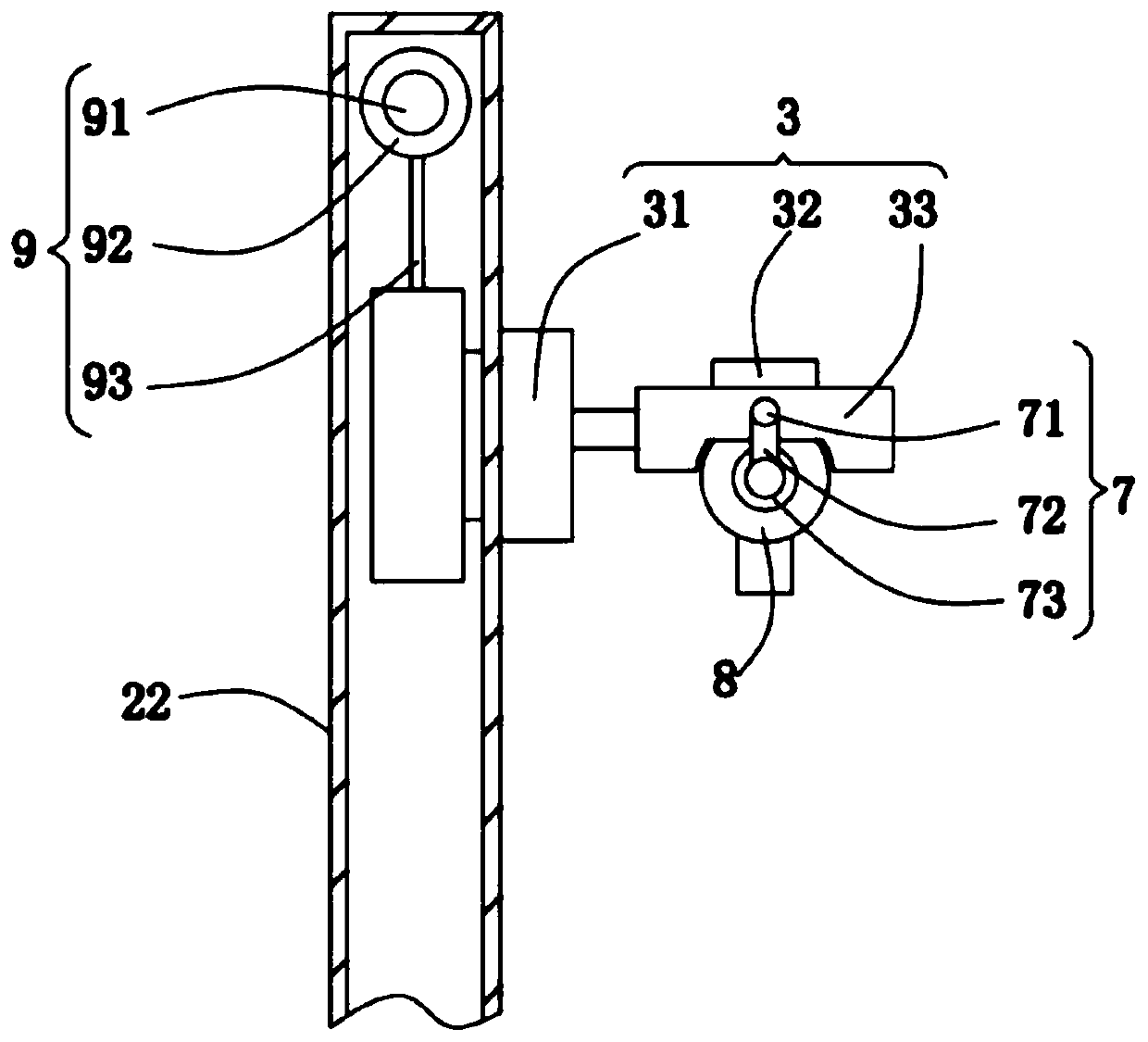

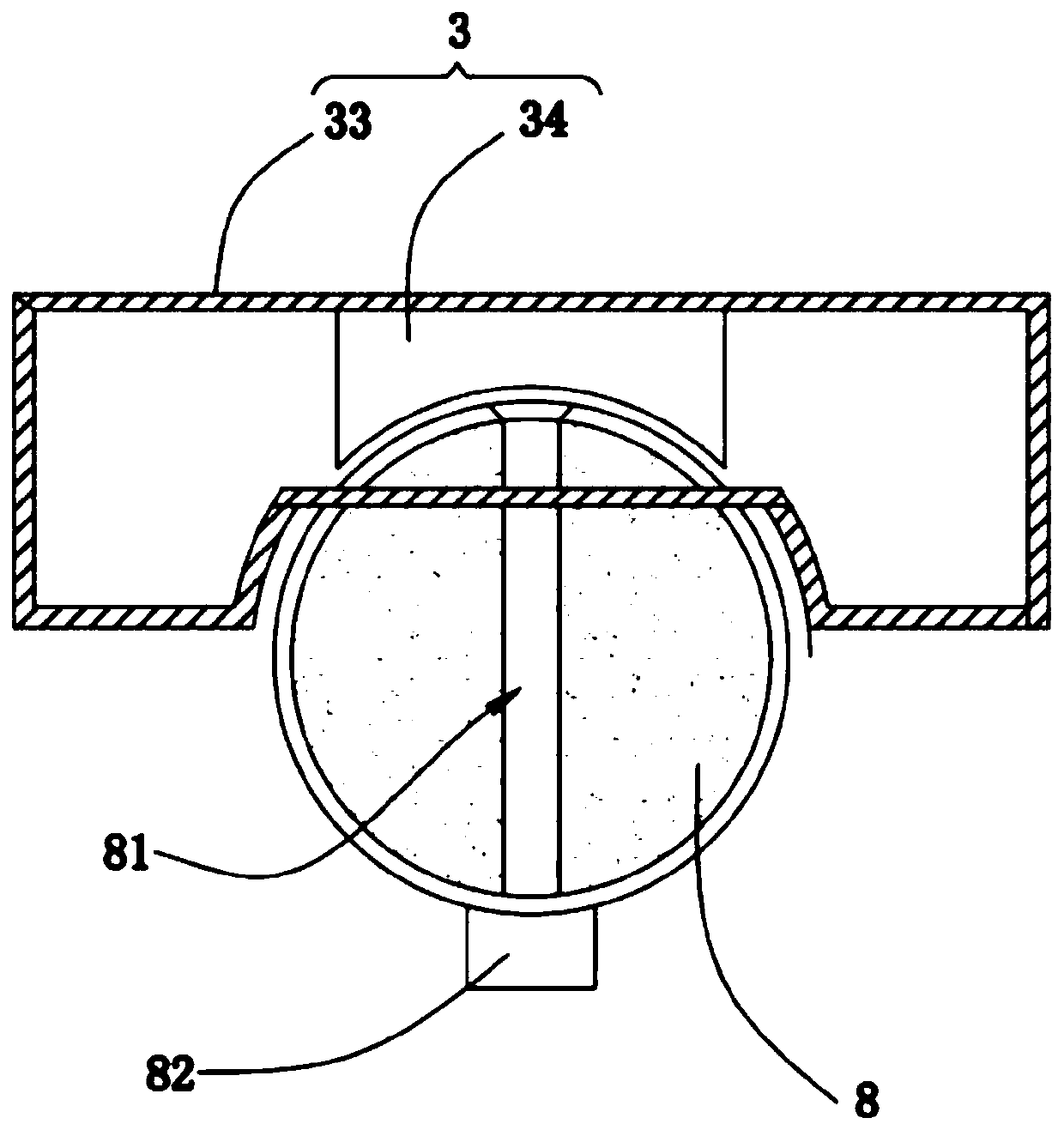

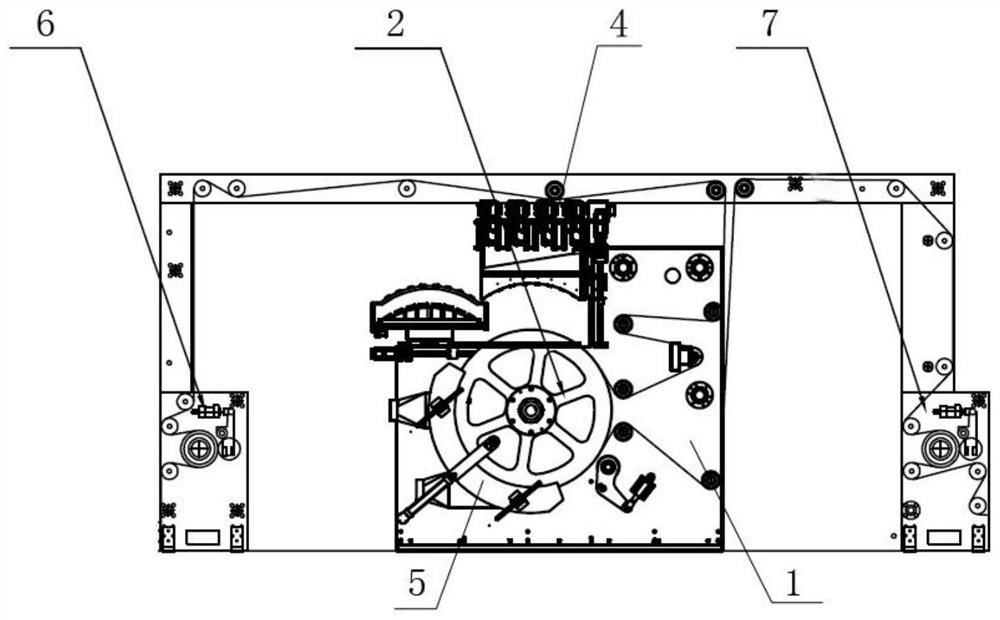

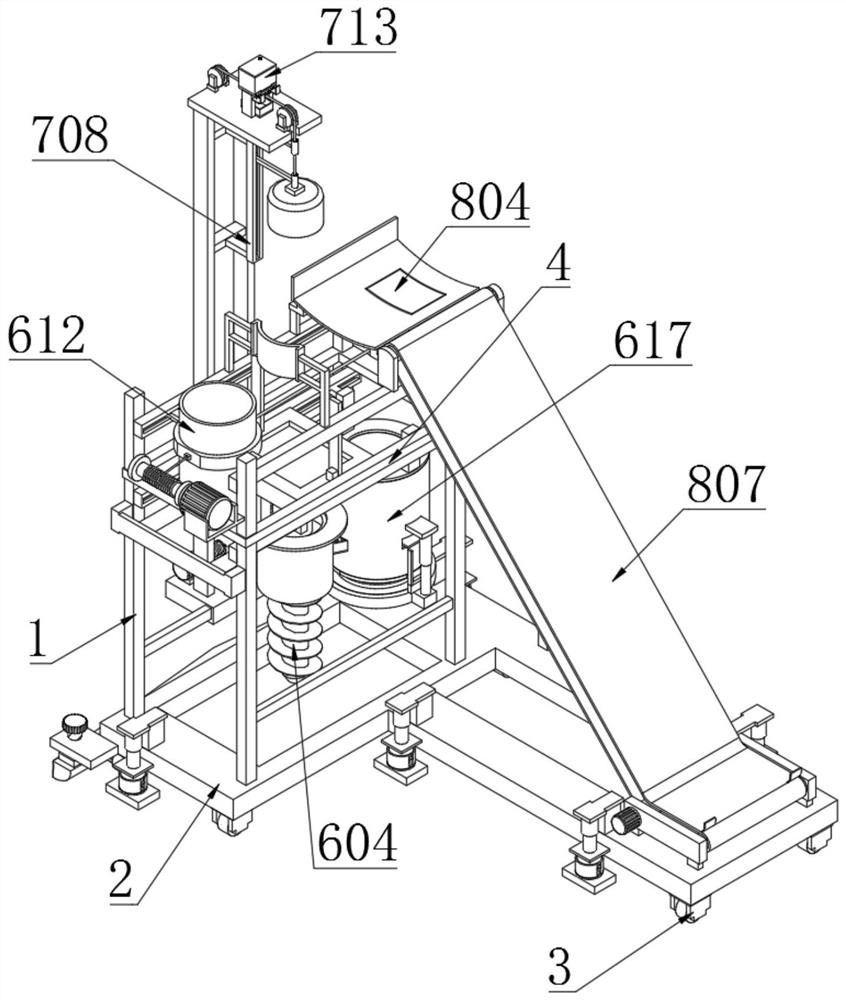

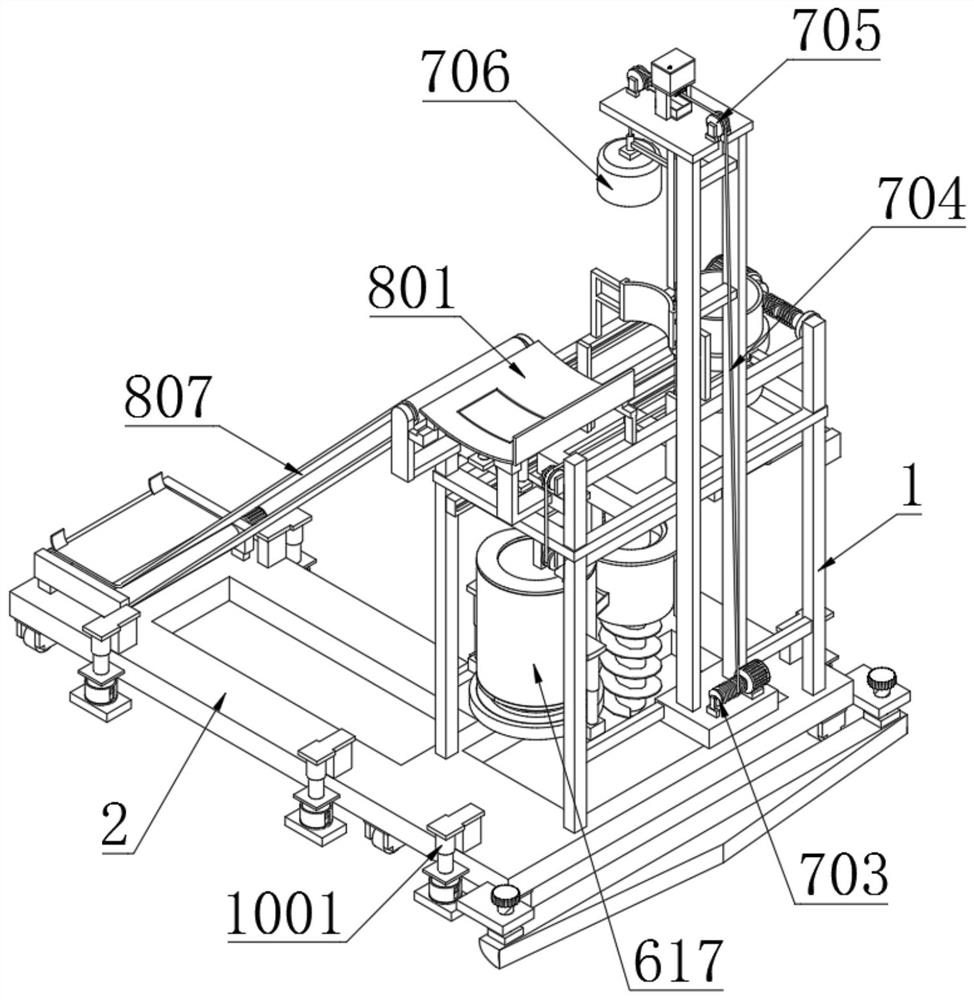

Device for machining copper foil hole through laser

InactiveCN108044242AElongation stabilityStable spacingWelding/soldering/cutting articlesLaser beam welding apparatusPunchingControl system

The invention discloses a device for machining a copper foil hole through a laser. The device for machining the copper foil hole through the laser comprises a control system, a laser device and a motion system. The control system is used for controlling the motion system to work. The motion system is used for driving copper foil to pass through a laser punching point of the laser device. The motion system comprises a copper foil conveying mechanism and a supporting frame. The top of the supporting frame is provided with a punching worktable. The copper foil conveying mechanism is used for making the copper foil sequentially pass through the punching worktable. The device for machining the copper foil hole through the laser further comprises a tension sensor. The tension sensor is used fordetecting the tension on the copper foil in the conveying process of the copper foil, and the data output end of the tension sensor is connected with the signal input end of the control system. The control system controls a working state of the copper foil conveying mechanism according to tension data obtained by the tension sensor. The device for machining the copper foil hole through the laser is used for conducting laser punching machining on the copper foil, and the obtained hole in the copper foil can be made to have higher position precision.

Owner:CHINA SOUTH IND GRP AUTOMATION RES INST

Ship plate steel with thickness not greater than 100mm and yield strength of 390MPa and preparation method

The invention discloses ship plate steel with thickness not greater than 100mm and yield strength of 390MPa and a preparation method. The ship plate steel comprises C, Si, Mn, P, S, Nb, V, Al, Ti, Mo,Cr, Cu, Ni, and the balance Fe and impurities. The preparation method comprises the following steps: heating a continuous casting slab which comprises the same components with the ship plate steel; the continuous casting slab is sequentially processed by cooling through first laminar flow, air cooling and cooling through second laminar flow after being subjected to two-section type rolling; thenthe continuous casting slab is cooled through air until room temperature is reached, thus obtaining the ship plate steel. The ship plate steel has the obvious advantages that the thickness of the shipplate steel is not greater than 100mm; the yield strength is 390MPa; the low-temperature toughness is outstanding; in addition, the component design is simple; the welding performance and the corrosion resistance are outstanding; the comprehensive mechanical property is high.

Owner:NANJING IRON & STEEL CO LTD

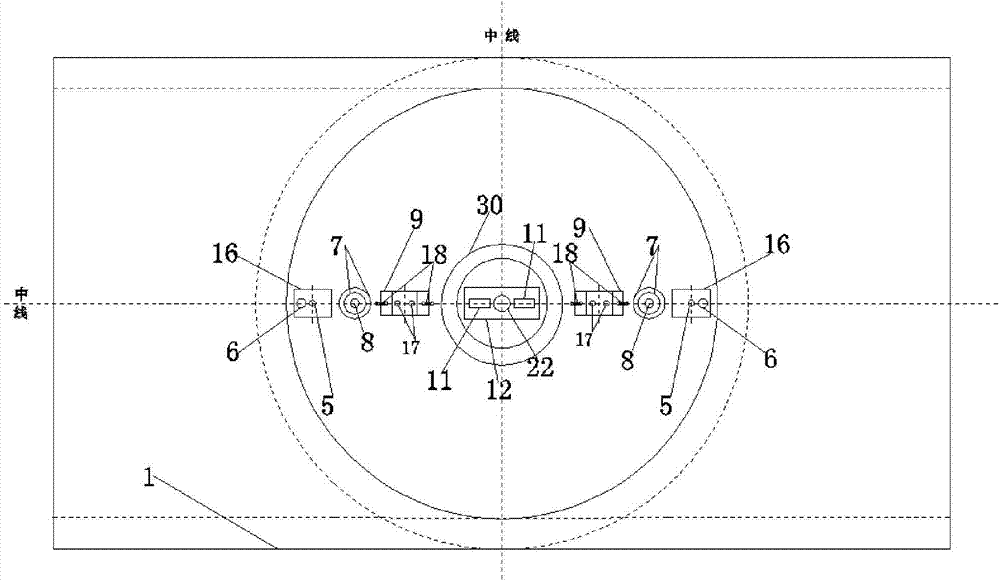

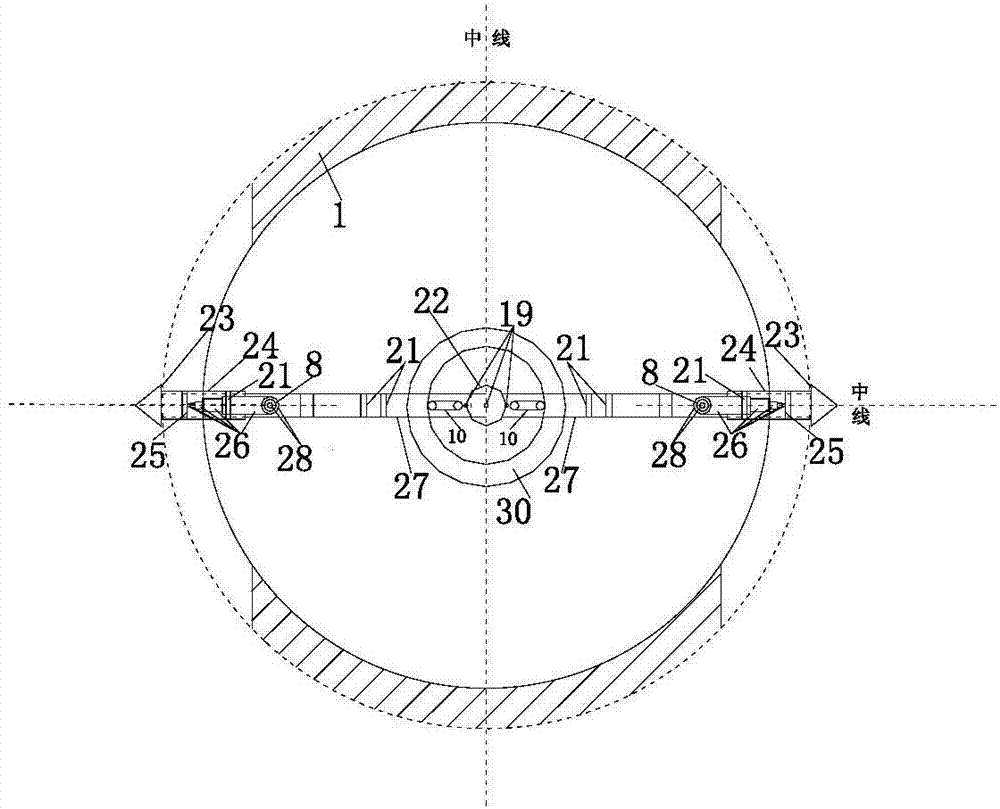

Device and method for monitoring differential settlement in portfolio for soil-stone combined region with hydraulic structure

ActiveCN104501772AEasy to disassembleFlexible liftingHeight/levelling measurementHydraulic structureRepeatability

The invention discloses a device and a method for monitoring differential settlement in portfolio for a soil-stone combined region with a hydraulic structure. The device comprises a bottom-through shaft and an inner carrying tube positioned inside the bottom-through shaft, wherein a displacement station is arranged in the inner carrying tube; drill driving devices are symmetrically arranged on two sides of the displacement station, and are connected with conical drills; the drill driving devices on two sides are respectively connected with lifting devices which are used for promoting motion of the drill driving devices; correcting devices which are used for correcting level of the displacement station are symmetrically arranged at two ends of the displacement station; the middle part of the displacement station is connected with one end of a group of symmetrically arranged springs, and the other end of each spring is hinged with a vertical measuring tape; an optical fiber hanging drum is arranged between two springs, and is filled with a corrugated loop optical fiber; and an optical fiber buckle is arranged on the corrugated loop optical fiber. The device has the advantages of use repeatability, convenience in assembly, real-time detection and maintenance and the like, and has the characteristics of distribution type, micro-macro structure, real-time performance, high adaptability to complex environment and the like.

Owner:HOHAI UNIV

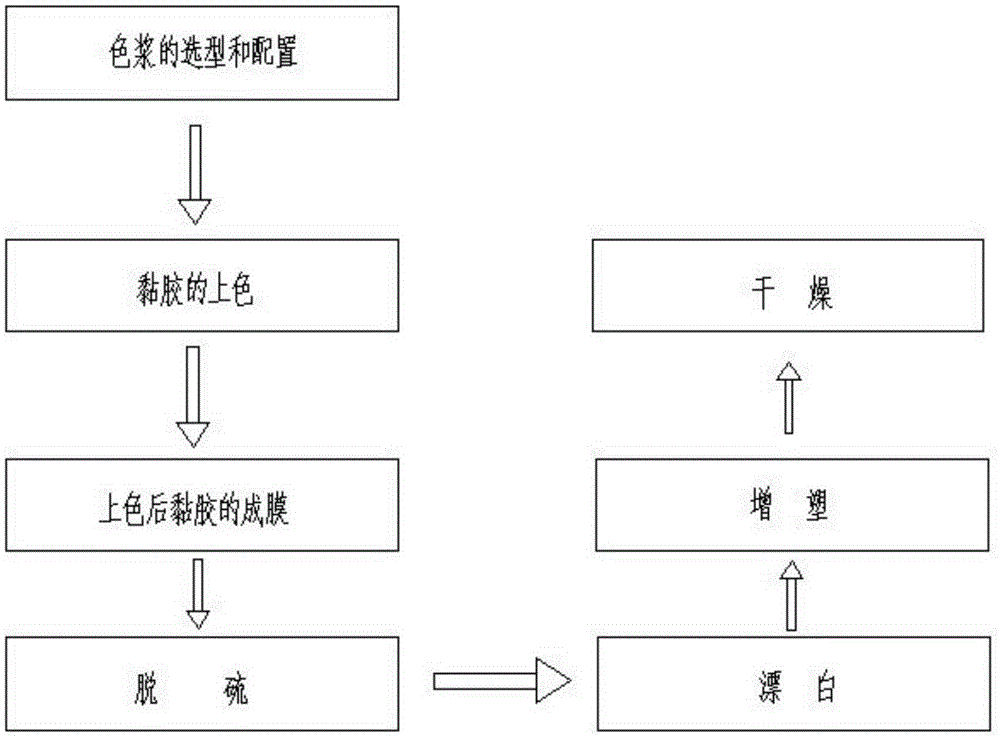

Production method of preservative natural cellulose membrane

ActiveCN102154812AMild reaction conditionsEasy to controlConjugated cellulose/protein artificial filamentsBleaching apparatusCelluloseChitin formation

The invention discloses a production method of a preservative natural cellulose membrane. The method comprises the following steps: a-(1) soaking, a-(2) squeezing, a-(3) crushing, a-(4) maturing, a-(5) yellowing and a-(6) dissolving the cellulose; b-(1) soaking, b-(2) squeezing, b-(3) crushing, b-(4) yellowing and b-(5) dissolving chitin; c-(1) mixing viscose; c-(2) forming a membrane; and c-(3) desulphurizing, c-(4) bleaching, c-(5) plasticizing and c-(6) drying the membrane. The reaction conditions of the method disclosed by the invention are mild; and the prepared preservative natural cellulose membrane has small space, stable elongation rate and tensile strength, proper stiffness and flexibility, relatively good color and luster and transparency, high hygiene property, antibacterial and bacteriostatic characteristics and the like.

Owner:绍兴柯德新材料股份有限公司

Fire-prevention and flame-retardant aramid fiber yarn and preparation method thereof

The invention provides a fire-prevention and flame-retardant armid fiber yarn. The armid fiber yarn comprises the following components by weight ratio: 93% of polyisophthaloyl metaphenylene diamine fiber, 5% of poly-p-phenylene terephthamide and 2% of carbon-guiding fiber. The invention also provides a preparation method of the fire-prevention and flame-retardant fiber yarn. The preparation method comprises the steps of a. raw material preparation, b. blowing process, c. cotton carding process, d. drawing and doubling process, e. spinning process and f. post processing process. The fire-prevention and flame-retardant aramid fiber yarn has the beneficial effects that the yarn levelness is uniform, the strength is strong, the yarn hairness and the yarn fault are few, the flame retardant property is good, the aramid fiber yarn has good radiation resisting property, acid resisting property, alkali resisting property and other various chemical properties, cannot be softened and melted under high temperature due to high temperature resistance, and is stable in prolongation due to good mechanical property so as to be completely suitable for fire-prevention and flame-retardant requirements of spaceflight, military use and civil use.

Owner:PINGHU RISHU TEXTILE

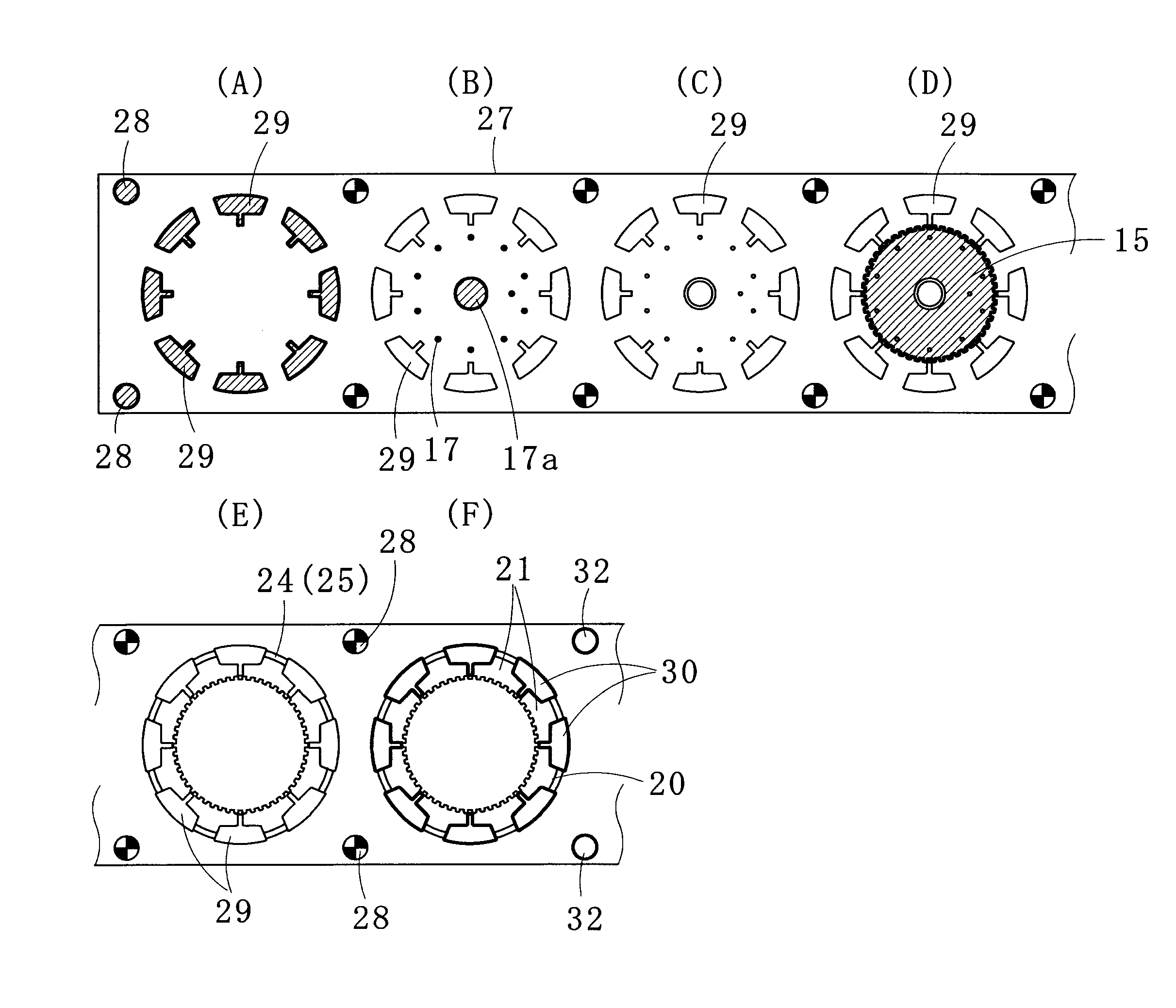

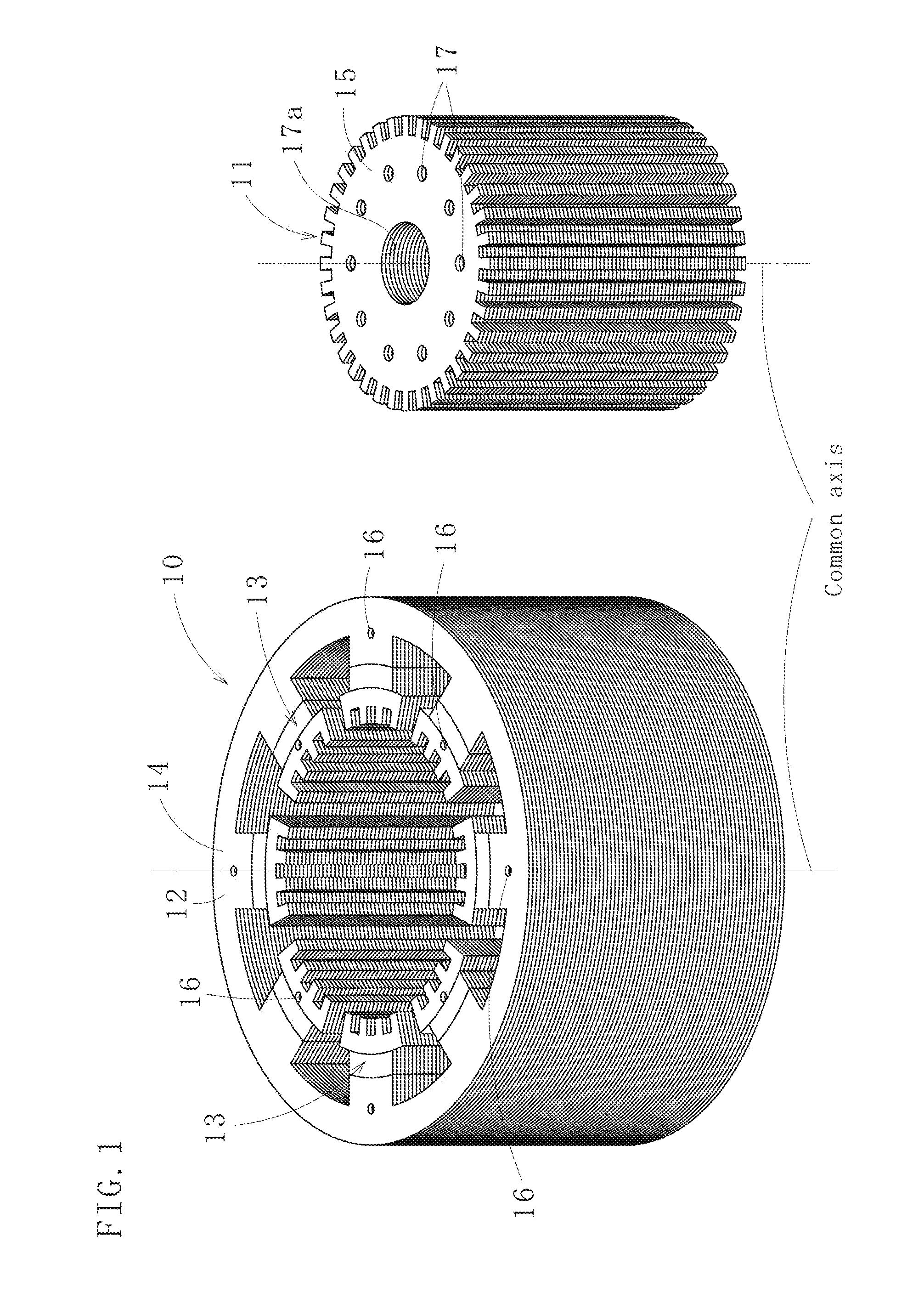

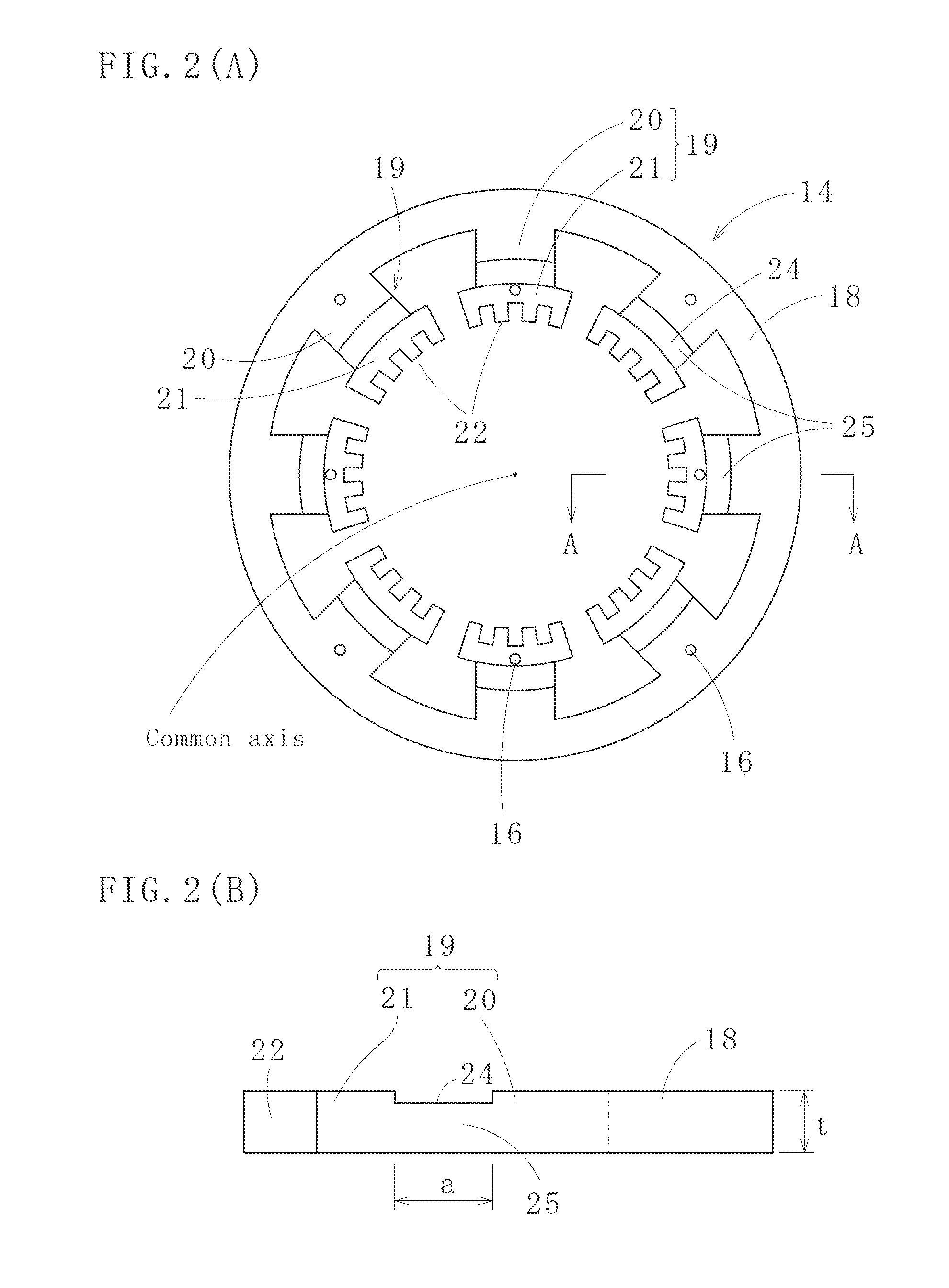

Method for manufacturing laminated core

ActiveUS8286331B2Elongation stabilityHigh dimensional accuracyMagnetic circuitOther manufacturing equipments/toolsMagnetic polesElectrical and Electronics engineering

A method for manufacturing a laminated core includes (1) blanking a rotor core sheet 15 and a stator core sheet 14 from a thin strip material 27 and (2) laminating the stator core sheet 14 inside a die. The stator core sheet 14 includes a ring-shaped yoke piece 18 and plural magnetic pole pieces 19 integrally connecting to a radially inside of the yoke piece 18. Each of the magnetic pole pieces 19 includes a magnetic pole shaft piece 20 and a magnetic pole tooth piece 21. The magnetic pole pieces 19 are formed by blanking preparatory slots 29; coining a part or a whole of the magnetic pole shaft pieces 20 to elongate the same in a radially inward direction; and thereafter, blanking the finishing slots 30 and shaping the magnetic pole tooth pieces 21.

Owner:MITSUI HIGH TEC INC

Economical type duplex stainless steel with phase change plastification effect

The invention relates to an economic type duplex stainless steel with a phase change plastification effect, belonging to the technical field of steel and iron alloy materials. The economical type duplex stainless steel comprises the following components in percentage by weight: not more than 0.03 percent of C, not more than 0.03 percent of S, not more than 0.03 percent of P, 19.0-21.0 percent of Cr, 8-12 percent of Mn, 0.1-0.5 percent of Ni, 0.15-0.35 percent of N, not more than 1.0 percent of Si, 0.001-0.01 percent of B, 0.005-0.20 percent of rare earth Ce or Y and the balance of Fe. A conventional melting process method is adopted and comprehensive ingredients are melted, are poured and formed, and are subjected to solution treatment, thus obtaining the economical type duplex stainless steel with quite good phase change plastification effect and elongation.

Owner:TAIZHOU XINLONGXIANG METAL PROD

Coarse spinner with yarn tension detection function

InactiveCN103510219AElongation stabilityImprove performanceTextile/flexible product manufactureTextiles and paperBobbinKeel

The invention relates to coarse spinners, in particular to a coarse spinner with a yarn tension detection function. The coarse spinner with the yarn tension detection function comprises a feeding device, a drafting mechanism, a twisting mechanism and a winding mechanism. The feeding device is formed by a set of guide bar rollers in a connection mode, the drafting mechanism is formed by a set of rollers in a connection mode, the twisting mechanism comprises a flyer, a false twister and an upper keel, the winding mechanism comprises a bobbin, a bobbin gear and a lower keel, the bobbin is connected to the bobbin gear, and the bobbin gear is mounted on the lower keel. The coarse spinner with the yarn tension detection function is characterized in that at least three tension sensors used for detecting yarn tension on line are further arranged between the drafting mechanism and the twisting mechanism. The coarse spinner with the yarn tension detection function can detect the yarn tension on line, and further controls the speed ratio of a main motor and a variable frequency motor, the purpose of adjusting the tension of coarse yarn is achieved, and the coarse spinner with the yarn tension detection function is simple in structural design and easy to achieve.

Owner:WUJIANG JINZHEN SEWING MACHINE

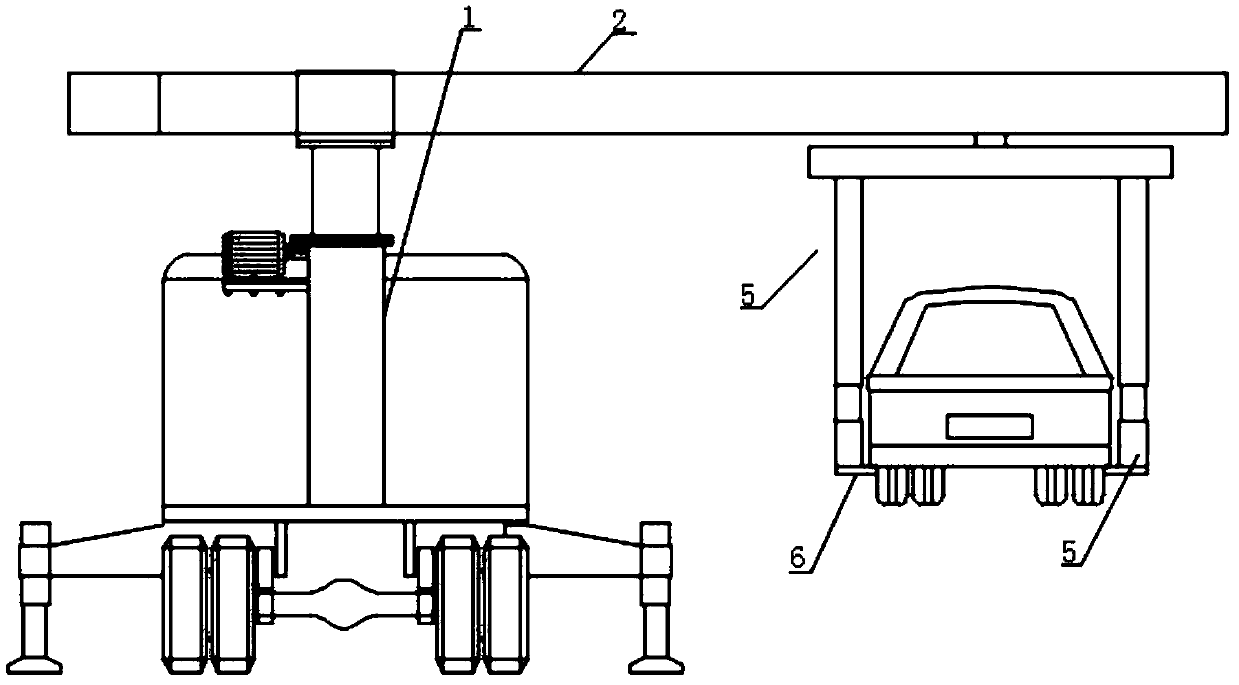

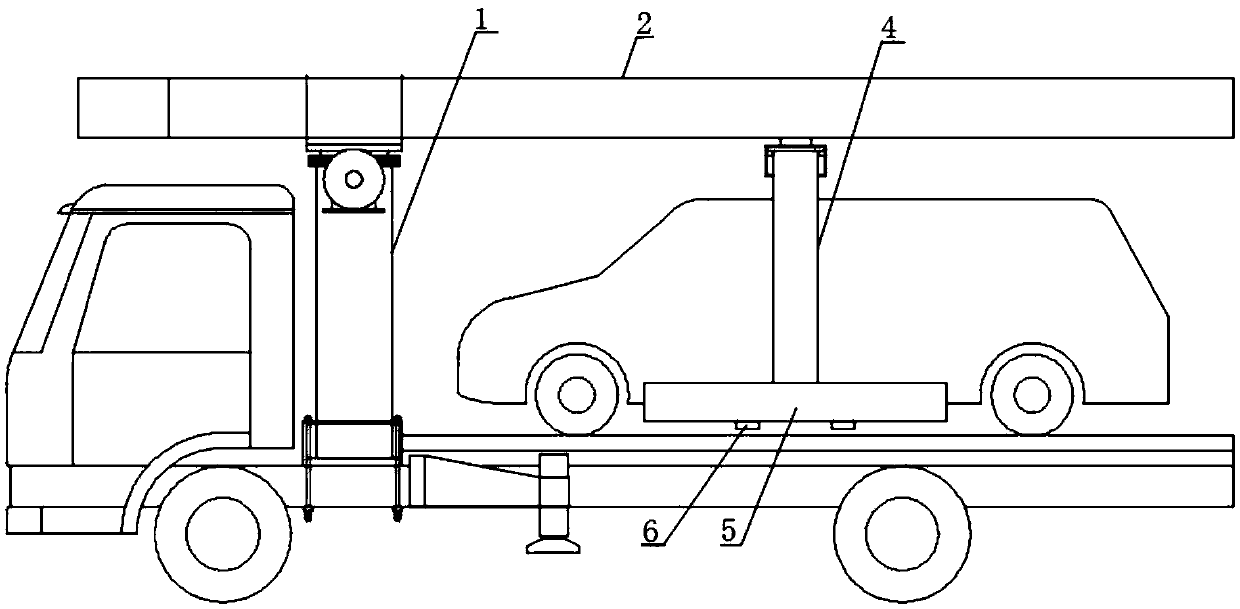

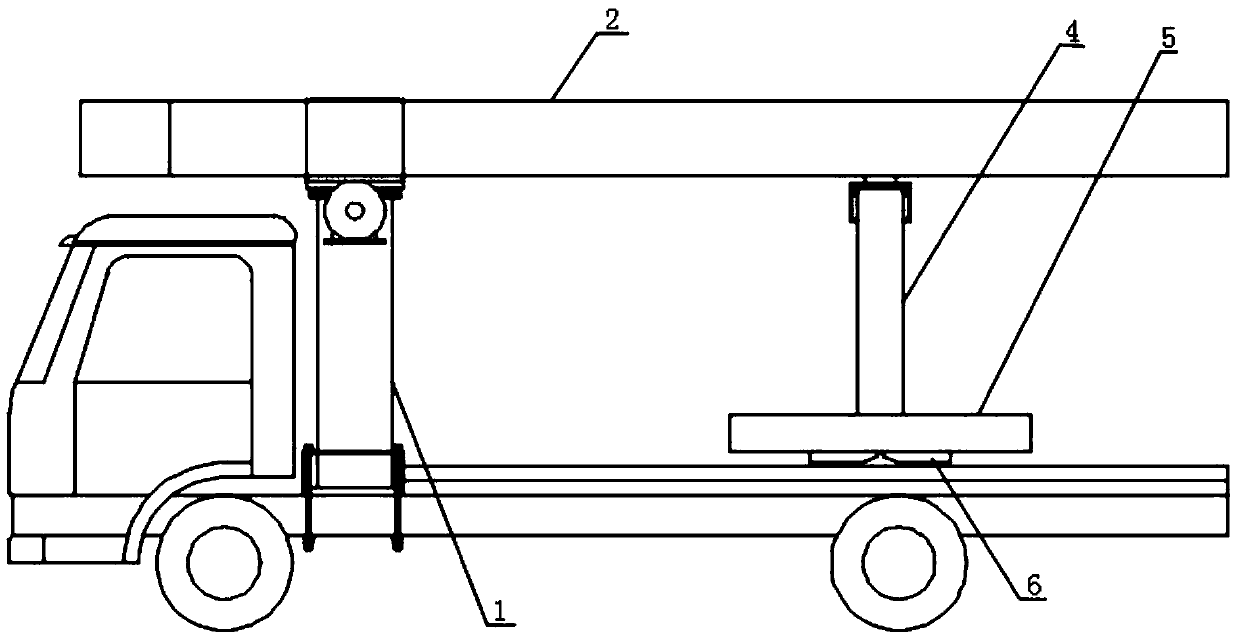

Side-form hoisting type road wrecker

ActiveCN109677316AReasonable structural designEasy to useSalvaging damaged vehiclesSlewing bearingControl theory

The invention relates to a side-form hoisting type road wrecker. The road wrecker comprises a lifting type slewing bearing, a track arm, a cargo fork frame regulation controller, a cargo fork frame and at least two cargo forks, wherein the lifting type slewing bearing is mounted on a big arm at the front end of a second-class automobile chassis; the track arm is horizontally assembled above the lifting type slewing bearing and is of a linear type, and a track cavity is formed in the lower end of the track arm; the cargo fork frame regulation controller is assembled into the track cavity and isin transmission connection with a first telescopic mechanism; the cargo fork frame is arranged below the cargo fork frame regulation controller and is connected with the cargo fork frame regulation controller, the cargo fork frame comprises two telescopic arms which are vertically arranged at intervals, and cargo fork beams are respectively fixed at the lower ends of the two telescopic arms; andthe cargo forks are uniformly distributed below the two cargo fork beams and are respectively connected with rotation systems on the corresponding cargo fork beams. The side-form hoisting type road wrecker has the advantages that the structural design is reasonable, the operation and the use are convenient, vehicles or barriers can be hoisted, transferred and loaded at any angles, the diversifiedfunctions are realized, and the wrecker has multiple functions and is high in working efficiency and relatively strong in practicability.

Owner:HUBEI PIONEER SPECIAL AUTOMOBILE

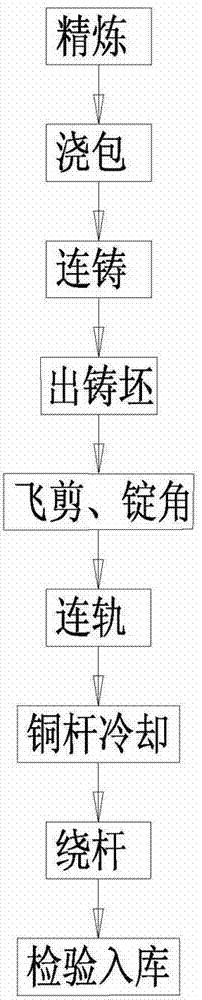

Continuous casting and rolling production technique for copper rods

The invention discloses a continuous casting and rolling production technique for copper rods. The production technique comprises the following steps: A) a plurality of pieces of waste red copper are added in an open hearth for refining; B) qualified copper liquid after refining is discharged out, and flows in a casting ladle through a flowing groove; in the casting process, the temperature of copper water in the casting ladle is 1,110-1,130 DEG C, and the oxygen content is 140-160 PPM; C) the copper liquid in the casting ladle passes through a gate; a stainless steel casting nozzle is continuously and evenly introduced in a crystallization recess of a casting wheel, and is strongly cooled by cooling water for crystallizing; crystals are increased continuously along with the rotation of the casting wheel; D) casting blanks are separated from the casting wheel; E) the unqualified casting blanks are cut off by flying scissors; two acute angles at the upper parts of the casting blanks are removed; F) the casting blocks enter a rolling machine to be rolled into the copper rods; G) oxidization layers on the surfaces of the rolled copper rods are removed through a cleaning and cooling pipe; the temperature is reduced below 80 DEG C; H) the cleaning and cooling pipe is dried through a compressed air spray nozzle, and is conveyed to a rod winder by a clamping roller for rod winding . The production technique can produce the copper rods by using the plurality of pieces of waste copper; the produced copper rods have good quality.

Owner:肇庆市弘达实业有限公司

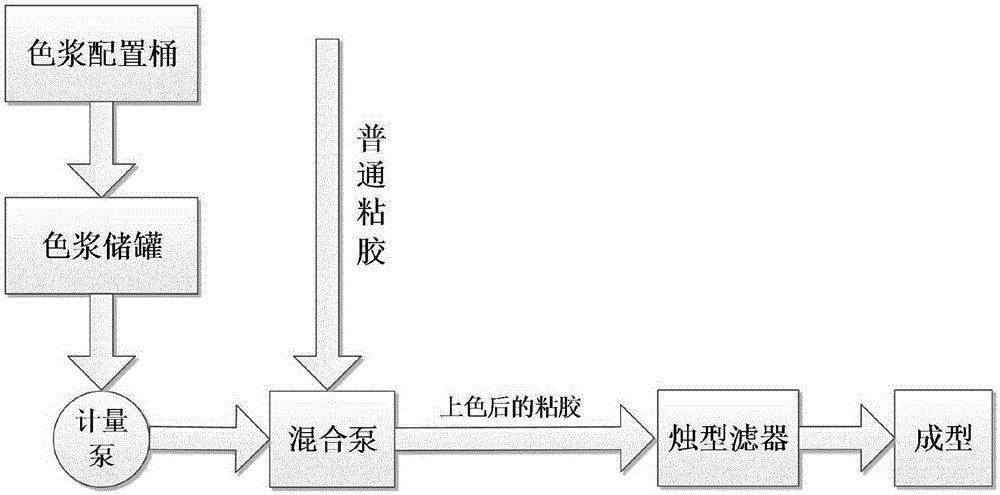

Method for producing heavy-denier mucilage glue flat yarn

ActiveCN103603066ASpeed up the molding processHigh strengthFilament manufactureArtificial filament washing/dryingYarnCandle

The invention relates to a method for producing heavy-denier mucilage glue flat yarn. The method includes the steps that mucilage glue is pumped into a candle type filter through a metering pump to be filtered, the filtered mucilage glue enters a yarn spraying nozzle through a goose neck to be sprayed into yarn, sprayed yarn enters a primary coagulating bath groove to undergo primary solidification forming, then, the yarn is guided to a secondary solidification forming groove through a yarn guiding mechanism to undergo secondary solidification forming, the yarn enters a washing groove to undergo primary washing after the secondary solidification forming is conducted, the yarn is laid on a conveying net of a united refiner in parallel to undergo regeneration, washing, desulfuration, blanching, pH value adjustment, oiling and drying after the primary washing is conducted, finally, the yarn is formed to be in a cylinder shape or a strand shape, and carbon disulfide is recycled in the primary solidification forming process and the secondary solidification forming process of the yarn. The carbon disulfide is recycled, the strength and the elongation of the heavy-denier mucilage glue flat yarn produced through the process completely meet the requirements, and the method is quite beneficial for development of downstream markets.

Owner:YIBIN GRACE +2

Production method of colorful natural cellulose membranes

InactiveCN105696305ASmall thickness differenceStable elongationMonocomponent cellulose artificial filamentDry-cleaning apparatus for textilesCelluloseSulfur

The invention discloses a production method of colorful natural cellulose membranes. The production method comprises the steps of cellulose dipping, alkali cellulose squeezing, alkali cellulose smashing, alkali cellulose aging, alkali cellulose yellowing, cellulose sulphonate dissolving, color paste type selecting and matching, coloring viscose preparing, viscose film forming after coloring, sulfur removing, bleaching, softness improving and drying. According to the method, the reaction condition is mild, viscose with different properties can be colored, the difference between widths of the colorful natural cellulose membranes is small, elongation and the tensile strength are stable, and the membranes have the advantages of having suitable stiffness and softness and good color and transparency, being high in hygiene level, and resisting and inhibiting the bacteria.

Owner:SHAOXING CHUNMING NATURAL CELLULOSE MEMBRANE CO LTD

Anti-rust processing device after hardware workpiece ultrasonic cleaning

The invention discloses an anti-rust processing device after hardware workpiece ultrasonic cleaning. The anti-rust processing device comprises an oil immersing groove, and a ball screw, a sliding railand a material cage which are hung above the oil immersing groove. A nut of the ball screw is fixedly connected with an upper base block. The bottom of the upper base block is fixedly connected witha first hinging supporting seat and a second hinging supporting seat. A first connecting rod and a second connecting rod are respectively hinged to the first hinging supporting seat and the second hinging supporting seat. The first connecting rod and the second connecting rod are hinged to a third hinging supporting seat. The third hinging supporting seat is fixedly connected with a fastening piece. The fastening piece is connected with a sleeve in a threaded mode. The sleeve is internally provided with an elastic element. The elastic element abuts against a sleeving rod. The sleeving rod penetrates through the sleeve, and is hinged to a fourth hinging supporting seat. The fourth hinging supporting seat is fixedly connected with a lower base block. The anti-rust processing device moves inthe direction of the sliding rail by the lower base block, and immersing and taking out operation is well conducted. The material cage is driven to rotate by driving a stepping motor, and spin-dryingis well achieved. Traditional manual oil immersing and spin-drying procedures are replaced, and mechanical and automatic operation is achieved.

Owner:深圳市博思创环保设备有限公司

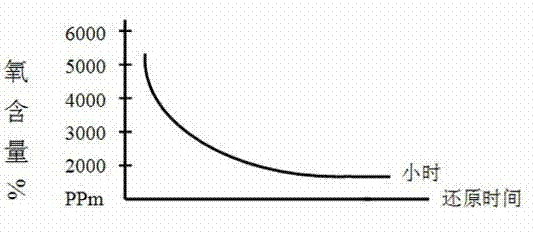

Continuous casting and continuous rolling production process for low-oxygen copper rod

InactiveCN108624763AHigh elongationImprove quality and efficiencyRotary drum furnacesCrucible furnacesWinding machineIngot

The invention discloses a continuous casting and continuous rolling production process for a low-oxygen copper rod. The continuous casting and continuous rolling production process for the low-oxygencopper rod comprises the following steps: smelting: putting an electrolytic copper raw material into a reflecting melting furnace and melting into a copper liquid; performing heat-preserving treatment: conveying the copper liquid into a heat-preserving furnace and heating the heat-preserving furnace; performing continuous casting treatment: conveying the copper liquid into a continuous casting machine and casting the copper liquid into a copper ingot; coating the surface of the copper ingot with one layer of anti-oxidation lubricating oil rapidly and uniformly; rolling the copper ingot into acopper rod by a continuous rolling machine; enabling the rolled copper rod through a cleaning cooling pipeline and reducing the temperature to be below 80 DEG C; scrubbing the anti-oxidation lubricating oil on the surface of the copper rod and waxing the surface; conveying the copper rod to a rod winding machine and winding; and packaging and inspecting, delivering by a travelling crane, weighingand putting into storage. The extension rate of the produced low-oxygen copper rod is increased, the resistivity is reduced, the extension rate and the resistivity are stable, and the quality and theproduction efficiency of products are improved.

Owner:安徽润藤电缆材料科技有限公司

Tension control system and method for planetary gear structure tension roller type evener

ActiveCN100584476CElongation stabilityRoll force/gap control deviceTension/compression control deviceControl systemEngineering

The invention discloses a tension control system of an epicyclic gear tension roll leveler, which comprises an inlet pull tension gage and an inlet tension feedback device, an outlet pull tension gage which is provided in the outlet of the leveler for measuring the strip tension in the outlet, an outlet tension feedback device for feedback the strip tension in the outlet which measuring by the outlet pull tension gage, a tension control device for receive the strip tension in the outlet which is feedback from the outlet tension feedback device. The roll-force, the elongation and the speed of the leveler can be definite by the association of strip tension in the inlet and outlet. The three key parameters comprises the roll-force, the elongation and the speed of epicyclic gear tension roll leveler, the coordinate cooperated controlled can be constructed among the three key parameters. According to the addition of tension in outlet with the outlet pull tension gage by the technical scheme of the invention, meanwhile the stable elongation, roll-force and tension control can be realized, and the order of stable strip steel property and shape can be achieved.

Owner:BAOSHAN IRON & STEEL CO LTD

Gas detection device for environment detection

InactiveCN111381006AMeet the needs of fertilization and sprayingRetract automaticallyWithdrawing sample devicesGas analyser construction detailsSoil scienceAir pump

The invention relates to the technical field of gas detection, and particularly relates to a gas detection device for environment detection. The gas detection device comprises a gas detection box, a supporting mechanism, a gas extraction mechanism, a gas extraction pump, a gas conveying pipe, a conveying mechanism, a swing mechanism, a gas extraction head and a lifting mechanism. According to thegas detection device provided by the invention for environment detection, the lifting mechanism can drive the gas extraction mechanism to move up and down along a sliding plate, so that the fertilization and spraying requirements of crops with different heights are met, and the application range of the device is wider; through the conveying mechanism, the gas conveying pipe can be automatically retracted while stably extending, and the gas conveying pipe is prevented from being wound with equipment and crops; and the swing mechanism can drive the gas extraction head to swing back and forth along the conveying block, so that the gas extraction range is wider, and the gas extraction efficiency is improved.

Owner:江苏华睿巨辉环境检测有限公司

Production method of natural cellulose membrane

ActiveCN101628986BSmall difference between film websElongation stabilityCelluloseMoisture absorption

The invention discloses a production method of natural cellulose membranes, comprising the following steps: (a) immersion; (b) squeezing; (c) grinding; (d) maturing; (e) etiolation; (f) solution; (g) film formation; (h) desulfuration; (i) bleaching; (j) plastification; and (k) drying. The production method has the advantages of mild reaction condition, short spacings among the prepared natural cellulose membranes, stable expansion rate and tensile strength, proper stiffness and flexibility, better colour and luster, good transparence, high hygiene property, and the like, improves the surface property of paper through the plastification, in particular enhances the smoothness of paper surfaces, improves the printability, reduces the deformability of paper and the moisture absorption, thereby reaching the new requirement of modern printing and packaging.

Owner:绍兴柯德新材料有限公司

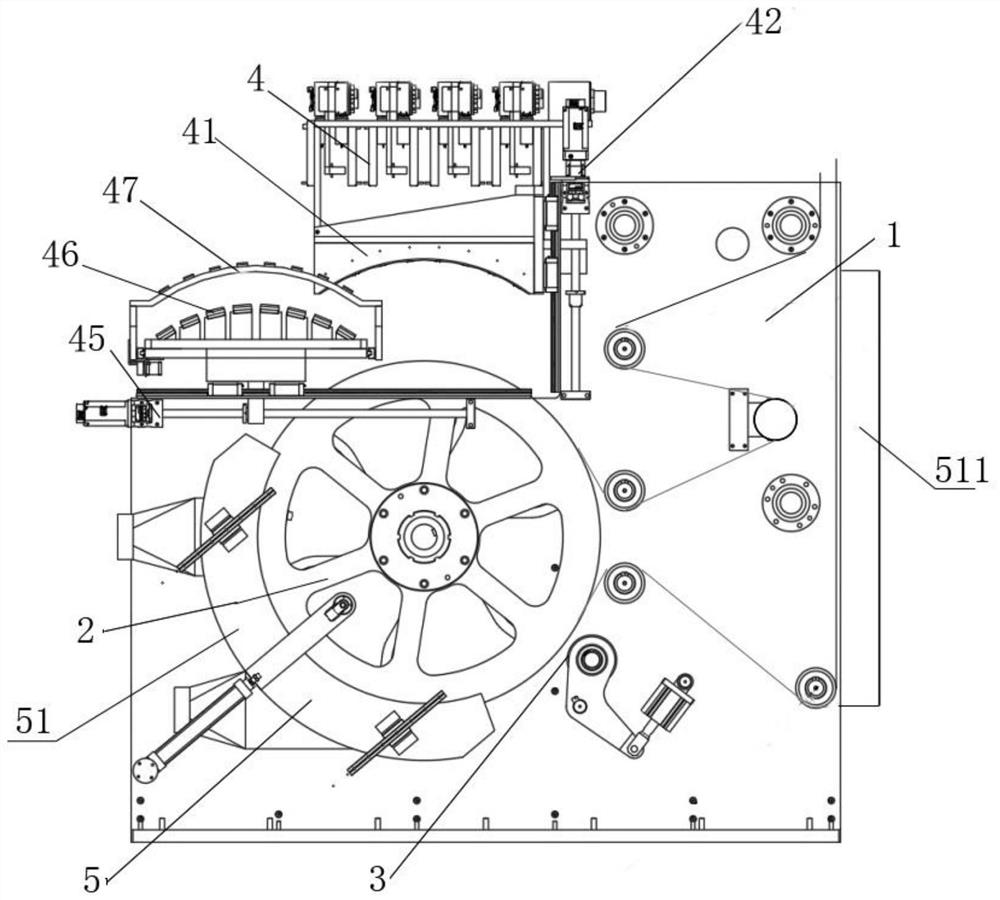

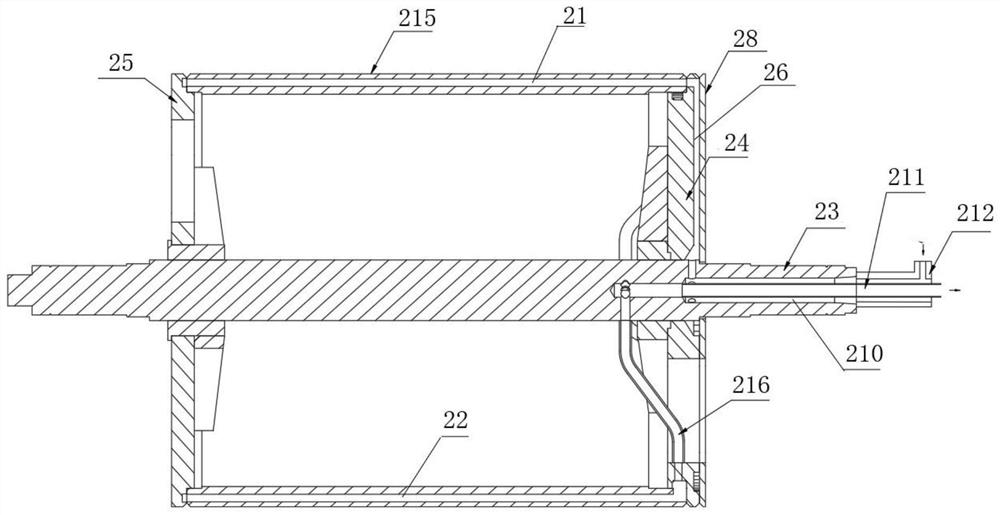

High-speed wide full-color water-based ink-jet printing mechanism for reel base material

PendingCN112810314AAchieve stabilityImprove printing effectInking apparatusPower drive mechanismsEngineeringPrinting press

The invention belongs to the technical field of printing equipment, and particularly relates to a high-speed wide full-color water-based ink-jet printing mechanism for a reel base material. The high-speed wide full-color water-based ink-jet printing mechanism comprises a rack, a jet printing cylinder and a compression roller are rotationally mounted on the rack, a jet printing assembly is arranged on the rack and located above the jet printing cylinder, and a drying device is arranged on the rack. According to the high-speed wide full-color water-based ink-jet printing mechanism for the reel base material, the jet printing cylinder is adopted for conveying the base material, stability is improved, the width of the base material can exceed 1 m, the conveying speed of the base material is high and exceeds 100 m / min, a cooling structure is arranged in the jet printing cylinder and is used in cooperation with the drying device, the temperature of the surface of the jet printing cylinder and the temperature of the base material of the jet printing cylinder are kept constant, the elongation of the base material is stable, and four-color or multi-color unbiased registration based on the water-based ink is achieved.

Owner:潍坊彩鸿数码科技有限公司

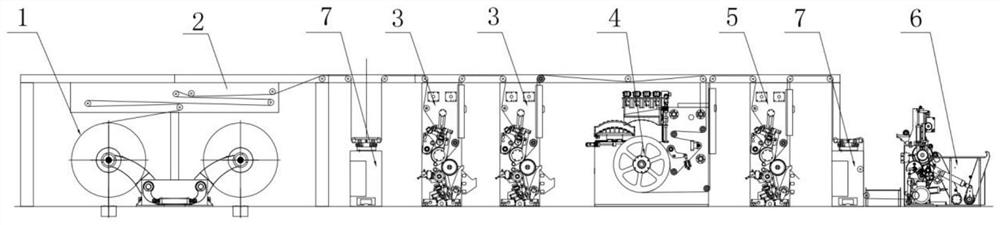

Composite printing machine

PendingCN112829468AImprove stabilityGood stability, good printing accuracyOther printing apparatusColor printingDigital printing

The invention belongs to the technical field of printing, and particularly relates to a composite printing machine. The machine comprises an unwinding unit, a base material receiving unit, a unit printing mechanism, a digital printing mechanism, a unit gloss oil applying mechanism and a winding unit which are sequentially arranged. The digital printing mechanism comprises a jet printing rack, a jet printing roller and a pressing roller are rotatably mounted on the jet printing rack, and a jet printing assembly is arranged at the position, located above the jet printing roller, of the jet printing rack. According to the composite printing machine, spot color printing is conducted on a printing base material through the unit printing mechanism, digital printing is conducted on the printing base material through the digital printing mechanism, the printing base material is wound around the jet printing roller for ink jet printing in the digital printing process, and the printing base material is good in conveying stability and high in printing precision and is matched with the unit printing mechanism to achieve complementary advantages; and wide-width high-speed full-color printing of the printing base material is achieved, the width of the base material can exceed 1 m, and the conveying speed of the base material is high and exceeds 100 m / min.

Owner:潍坊彩鸿数码科技有限公司

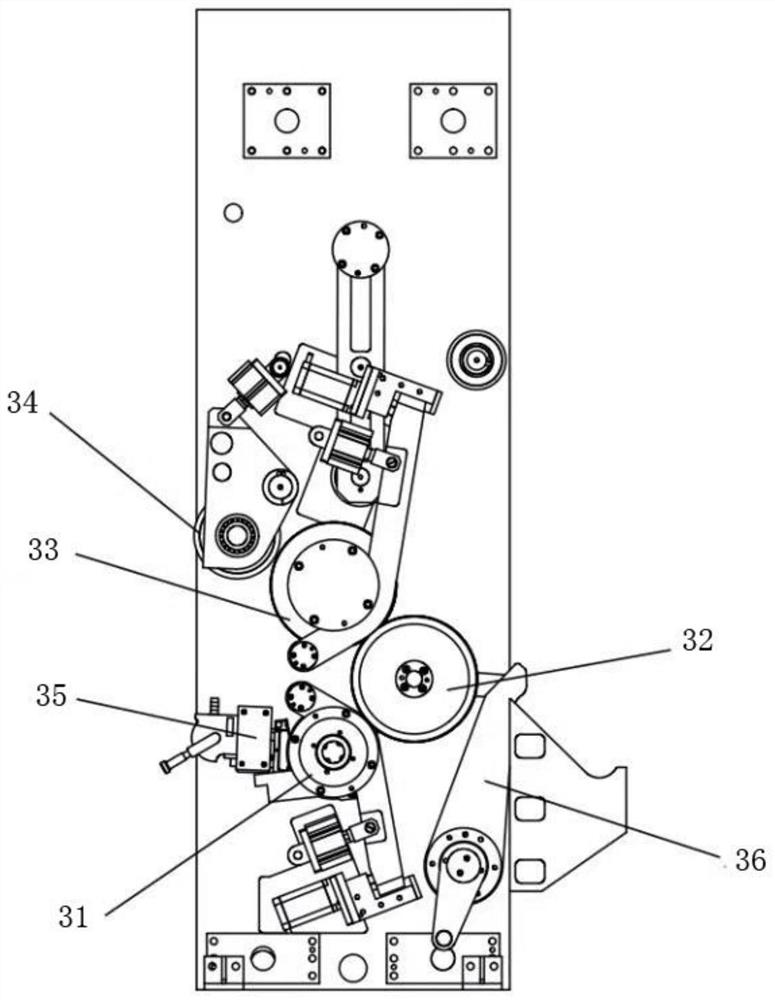

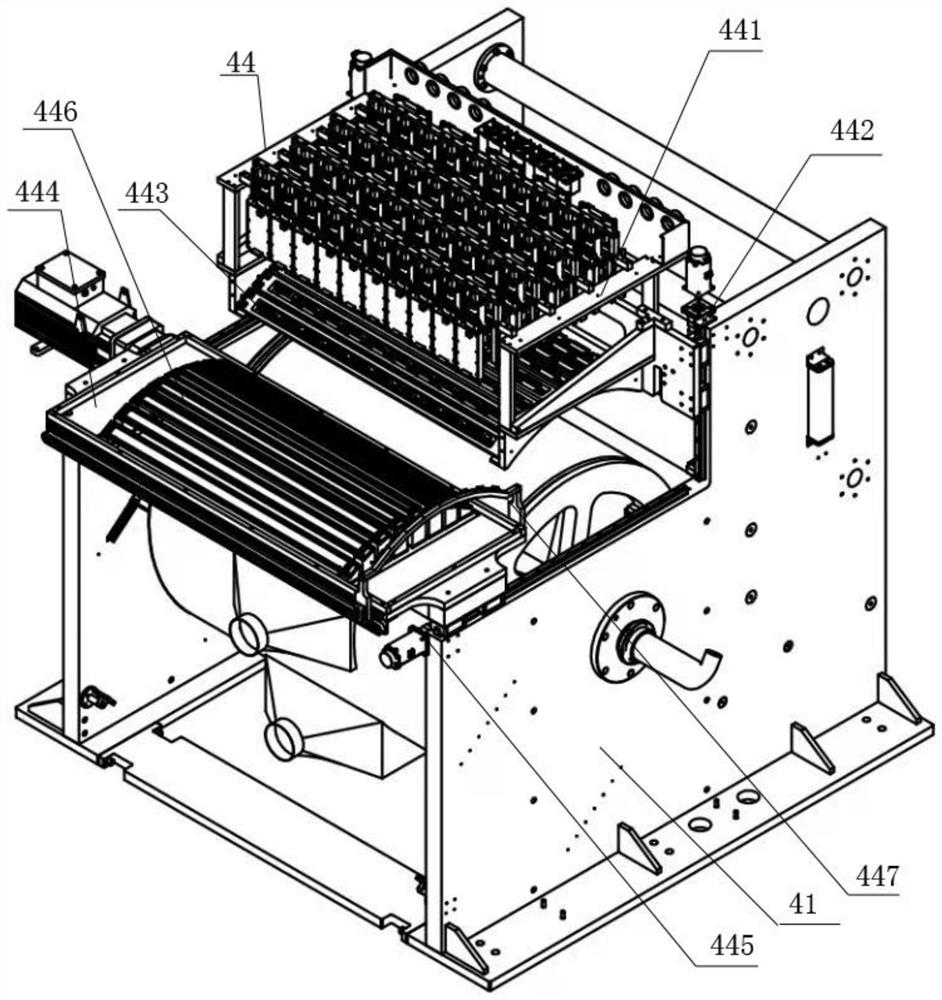

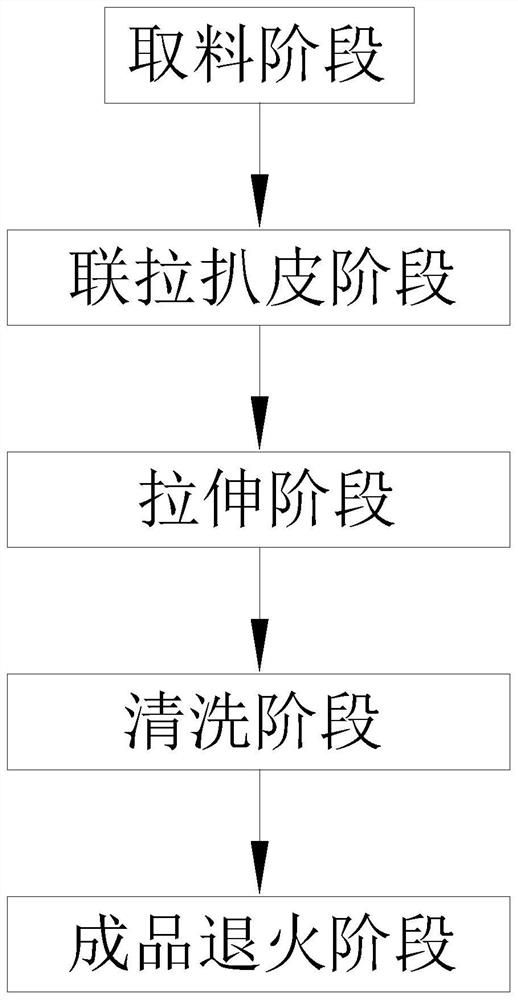

Preparation method of high-strength super-long cupronickel alloy capillary tube

The invention relates to the technical field of non-ferrous metal processing, in particular to a preparation method of a high-strength super-long cupronickel alloy capillary tube, which comprises a material preparation stage, a joint pulling and scalping stage, a stretching stage, a cleaning stage and a finished product annealing stage, and solves the problems of low efficiency, long period and easiness in environmental pollution during production of the existing cupronickel alloy capillary tube. By utilizing the new production method, the production efficiency of the cupronickel alloy tube is improved, the productivity is improved, meanwhile, the steps of intermediate annealing and acid pickling in the capillary tube production process are not needed, and the environmental pollution is reduced while the energy consumption is reduced.

Owner:上海海亮铜业有限公司 +1

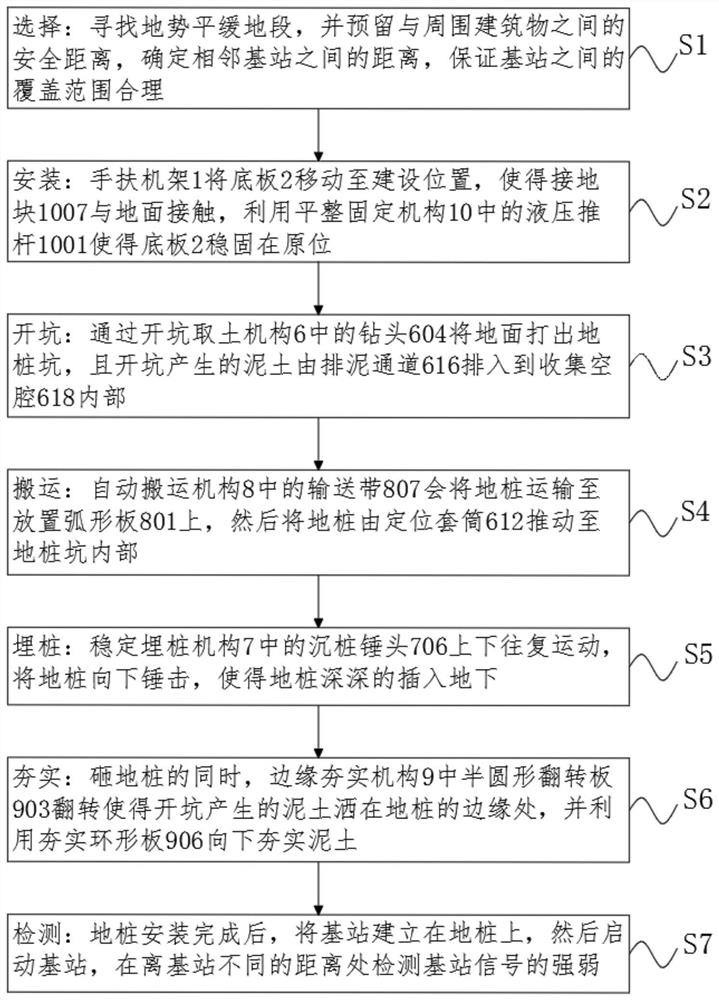

Selection and layout method for base station construction

ActiveCN112267462AEasy to installWind evenlyDrill bitsVibration suppression adjustmentsStructural engineeringDrill bit

The invention discloses a selection and layout method for base station construction. The method comprises the following steps of S1, selection, wherein a section with gentle terrain is searched, a safe distance between the section and a surrounding building is reserved, the distance between adjacent base stations is determined, and it is ensured that the coverage area between the base stations isreasonable; S2, mounting, wherein a bottom plate is moved to a construction position by holding a rack, a grounding block is enabled to be in contact with the ground, and the bottom plate is stabilized at an original position by utilizing a hydraulic push rod in a leveling fixing mechanism; S3, pit digging, wherein the ground is dug out of ground pile pits through a drill bit in a pit digging andsoil taking mechanism, and soil generated by pit digging is discharged into a collecting cavity through a soil discharging channel; and S4, carrying, wherein a conveying belt in an automatic carryingmechanism can convey ground piles to a placement arc-shaped plate, and the ground piles are pushed into the ground pile pits through a positioning sleeve. A pile sinking hammerhead moves up and down repeatedly, the ground piles placed into the ground pile pits are hit into the ground, and the situation that the base station construction is unqualified due to the fact that subsequent base stationscannot be fixed due to instability of the ground piles is avoided.

Owner:山西信息规划设计院有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com