Preparation method of high-heat-conductivity type tire vulcanization capsule

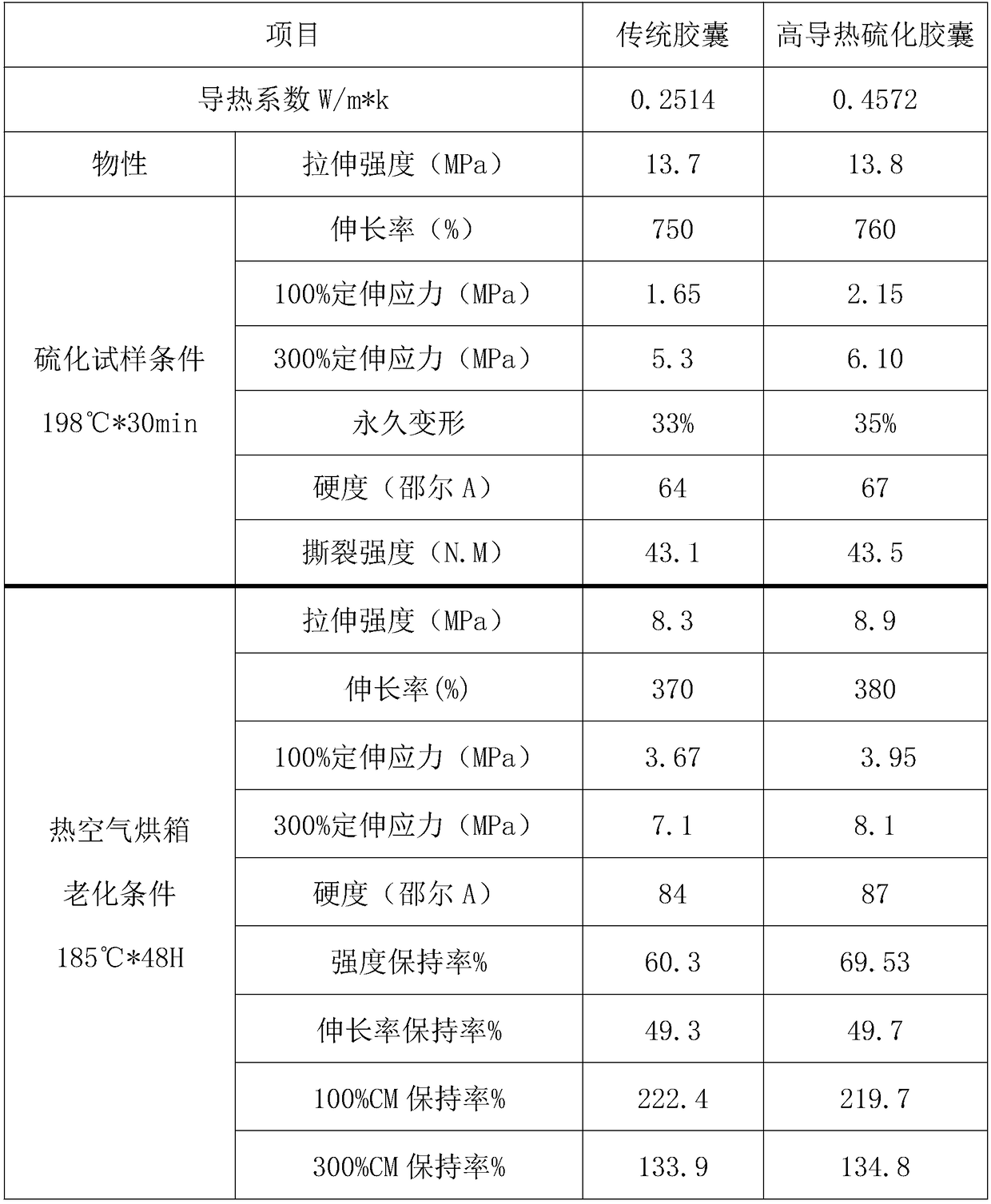

A technology of tire vulcanization and high thermal conductivity, which is applied in the field of tire manufacturing, which can solve the problems of insufficient thermal conductivity, shorten mixing time, reduce tires, etc., achieve stable physical and mechanical performance indicators, shorten mixing time, and improve uniformity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] [S-X-1] Embodiment 1, a preparation method of a high thermal conductivity tire curing bladder, adopts the following process steps:

[0034] The first step, batching, weighs various raw materials with an electronic scale, selects 95 parts of butyl rubber, 5 parts of neoprene rubber, 14 parts of N375 carbon black, 32 parts of acetylene carbon black, 5.5 parts of graphene, and 8.2 parts of alkane oil 1.2 parts of stearic acid, 5 parts of zinc oxide, 8 parts of resin;

[0035] Step 2, one-stage mixing, using the internal mixing center for mixing, the feeding order is butyl rubber, neoprene → stearic acid → graphene → 1 / 2N375 carbon black, 1 / 2 acetylene carbon black → 1 / 2N375 carbon Black, 1 / 2 acetylene carbon black → alkane oil → debinding, the debinding temperature is controlled between 140-150°C, the pressure is 4.5-6Pa, the speed is 35-50 rpm, and the time is 240 seconds. The rubber is pounded on the rubber mixing machine to dissipate heat, and the lower piece of rubber i...

Embodiment 2

[0042] [S-X-2] Embodiment 2 A method for preparing a high thermal conductivity tire curing bladder, using the following process steps:

[0043] Step 1, ingredients, weigh various raw materials with electronic scales, select 98 parts of butyl rubber, 4 parts of neoprene rubber, 16 parts of N375 carbon black, 35 parts of acetylene carbon black, 9 parts of graphene, and 8 parts of alkane oil 1.5 parts of stearic acid, 6 parts of zinc oxide, 9 parts of resin;

[0044] Step 2, one-stage mixing, using the internal mixing center for mixing, the feeding sequence is butyl rubber, neoprene → stearic acid → graphene → 1 / 2 carbon black (N375 carbon black, acetylene carbon black) → 1 / 2 2 Carbon black (N375 carbon black, acetylene carbon black) → alkane oil → debinding, the debinding temperature is controlled between 140-150°C, the pressure is 4.5-6Pa, the speed is 35-50 rpm, and the time is 240 seconds. After mixing The obtained mixed rubber is dissipated on the rubber mixer, and then the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com