Coarse spinner with yarn tension detection function

A yarn tension, roving frame technology, applied in textile and papermaking, sustainable manufacturing/processing, climate sustainability, etc., can solve the problems of unstable performance, high failure rate, complex structure, etc., to achieve stable performance, failure Low rate and stable elongation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

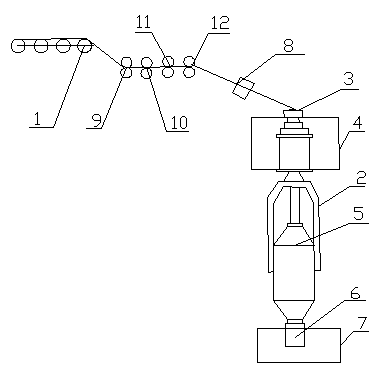

[0010] The present invention will be further described below in conjunction with the accompanying drawings.

[0011] Such as figure 1 As shown, it includes a feeding device, a drafting mechanism, a twisting mechanism and a winding mechanism. The feeding device is formed by connecting a group of guide rollers 1, and the drafting mechanism is formed by connecting a group of rollers. The twisting mechanism includes a flyer 2, a false twister 3, and an upper rib 4, and the winding mechanism includes a bobbin 5, a bobbin gear 6, and a lower rib 7, and the bobbin 5 is connected with the bobbin gear 6, The bobbin gear 6 is installed on the lower dragon rib 7, and at least three tension sensors 8 are also arranged between the drafting mechanism and the twisting mechanism for online detection of the roving tension. The drafting mechanism includes a back roller 9, three Roller 10, second roller 11, front roller 12, the tension sensor 8 is placed between the front roller 12 and the fals...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com