Device for machining copper foil hole through laser

A laser processing and laser drilling technology, which is applied in laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of high loss of drill bits, difficulty in chip removal, and inability to achieve high-efficiency processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

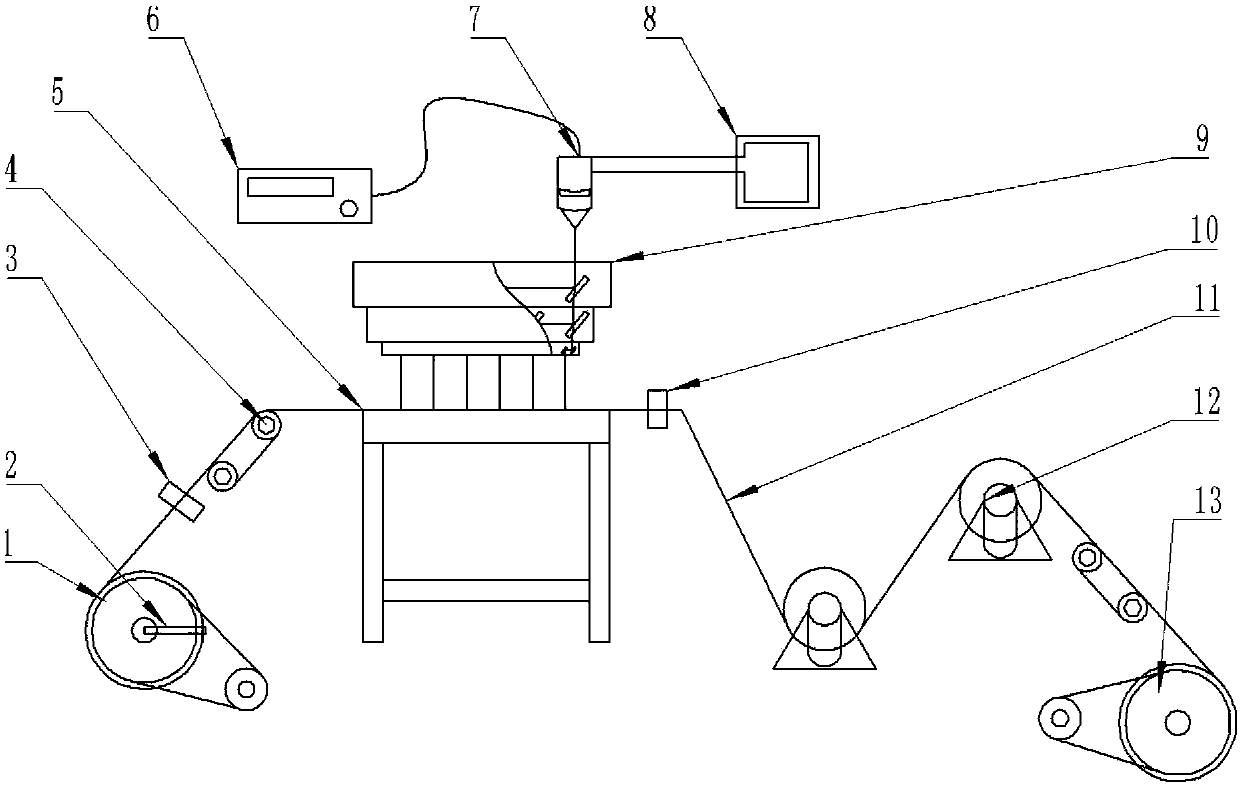

[0036] Such as figure 1 As shown, a device for laser processing copper foil holes, including a control system, a laser 6 and a motion system;

[0037] The control system is used to control the motion system to work;

[0038] The motion system is used to drive the copper foil through the laser drilling point of the laser 6;

[0039] The motion system includes a copper foil transmission mechanism and a support frame 5, the top of the support frame 5 is provided with a punching table, and the copper foil transmission mechanism is used to make the copper foil pass through the punching table in sequence;

[0040] Also includes a tension sensor 10, the tension sensor 10 is used to detect the tension on the copper foil during the copper foil transfer process, and the data output end of the tension sensor 10 is connected with the signal input end of the control system, and the control system is based on the tension obtained by the tension sensor 10 The data controls the working stat...

Embodiment 2

[0044] Such as figure 1 As shown, this embodiment is further limited on the basis of Embodiment 1: As a specific implementation of the copper foil transmission mechanism, the copper foil transmission mechanism includes a winding wheel 1 and an unwinding wheel 13;

[0045] The winding wheel 1 is used for winding the laser-perforated copper foil, and the winding wheel 1 is also connected with a driving device for driving the winding wheel 1 to rotate;

[0046] The unwinding wheel 13 is used to fix the copper foil roll to be released;

[0047] It also includes a tension wheel 12, and also includes a position adjustment device or a damping device, and the wheel surface of the tension wheel 12 serves as a constraint surface for the copper foil movement path during the copper foil transfer process;

[0048] The position adjusting device is connected with the tension wheel 12, and is used to change the position of the tension wheel 12 wheel surface in space;

[0049] The damping de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com