Fiber laser hydrophone and manufacturing method thereof

A fiber laser and hydrophone technology, applied in instruments, measuring devices, measuring ultrasonic/sonic/infrasonic waves, etc., can solve problems such as reducing the diameter of hydrophones, achieve small mechanical impedance, strong absorption capacity, and enhanced stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

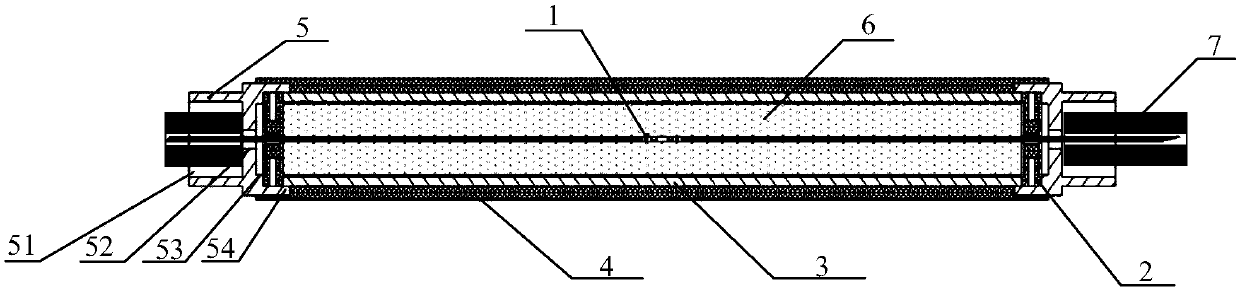

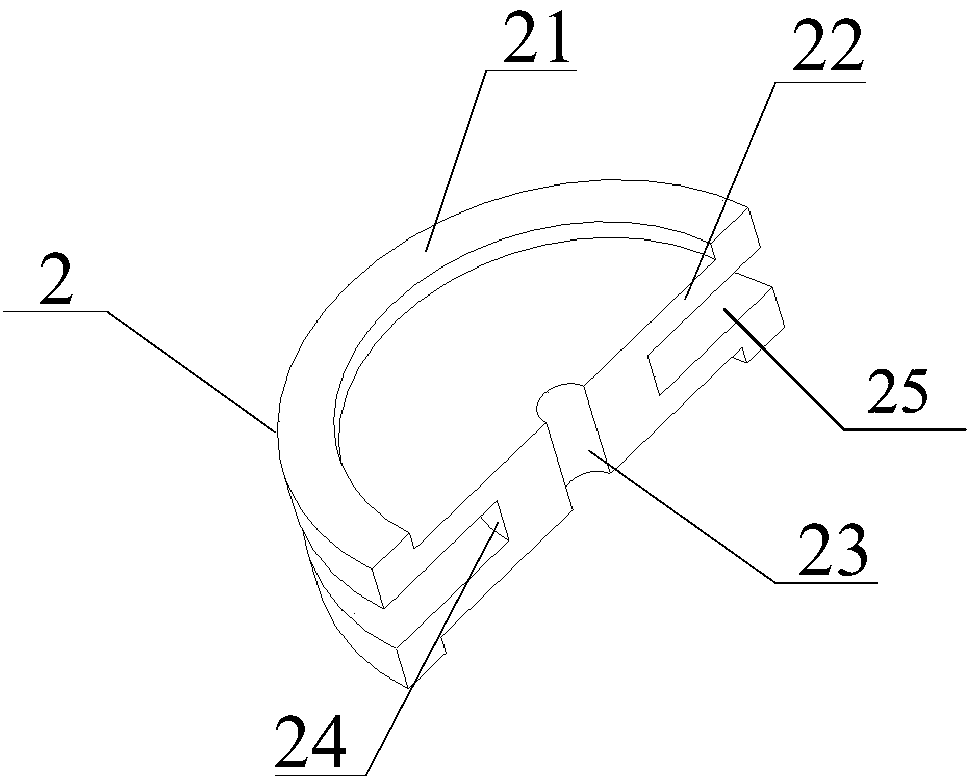

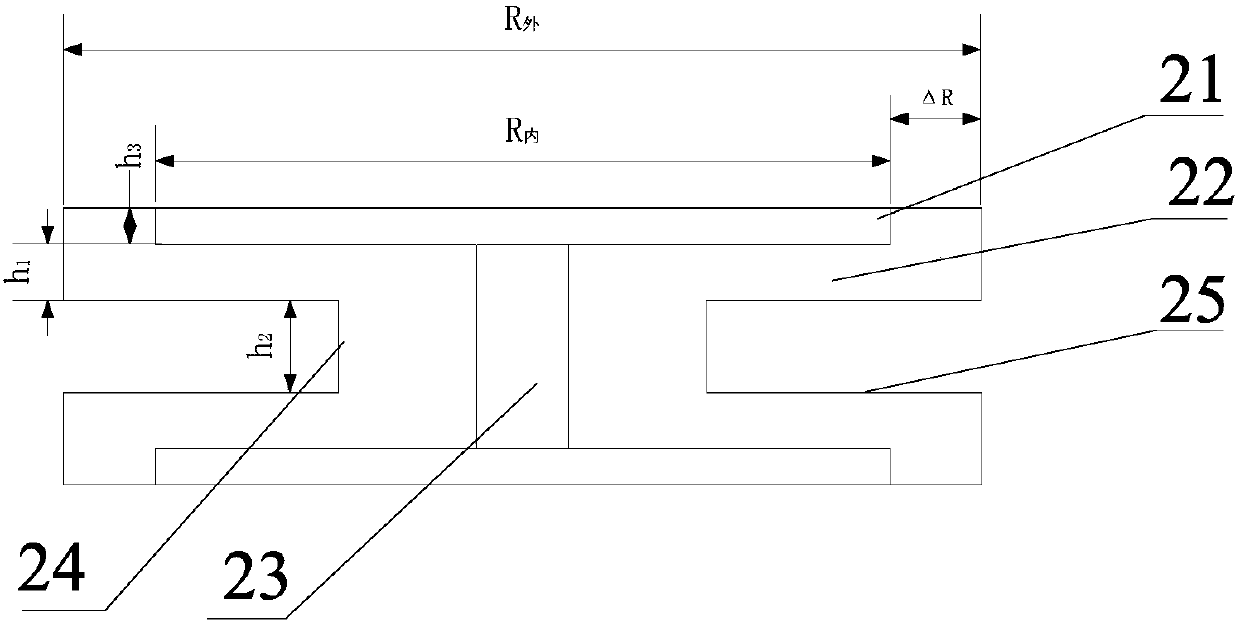

[0040] like figure 1 Shown is a schematic cross-sectional view of the ultra-fine fiber laser hydrophone of the present invention, as can be seen from the figure, the ultra-fine fiber laser hydrophone of the present invention includes an optical fiber 1, two elastic diaphragms 2, a cylinder body, a terminal 5 and a sheath 7. like figure 2Shown is the schematic diagram of the I-shaped diaphragm of the ultra-fine fiber laser hydrophone of the present invention. It can be seen from the figure that the elastic diaphragm 2 includes an upper diaphragm 22, a lower diaphragm 25 and a support column 24, wherein the support column 24 is located on the upper diaphragm. 22 and the lower diaphragm 25, and the upper diaphragm 22 and the lower diaphragm 25 are connected as one. A fiber hole 23 is provided on the elastic diaphragm 2, and the fiber hole 23 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com