Side-form hoisting type road wrecker

A technology for wreckers and roads, which is applied in the field of wreckers, can solve problems such as high cost, long operation time, and long time for wreckers, and achieve the effects of convenient operation and use, reasonable structural design, and high operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

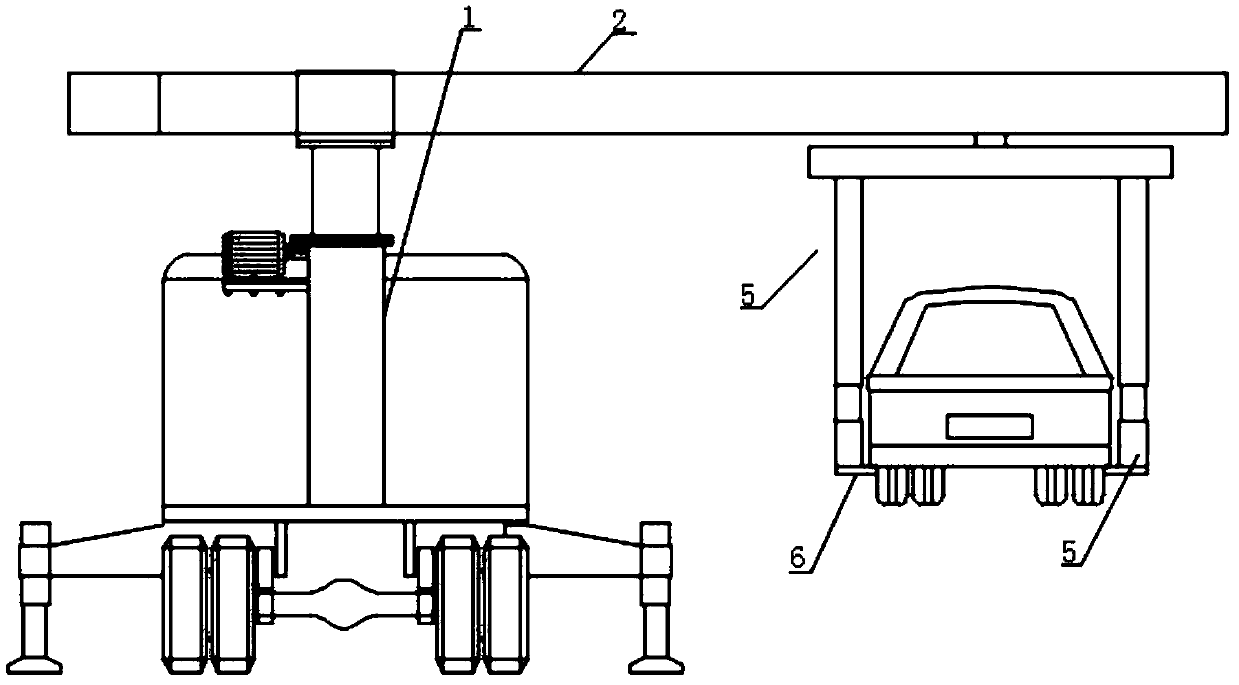

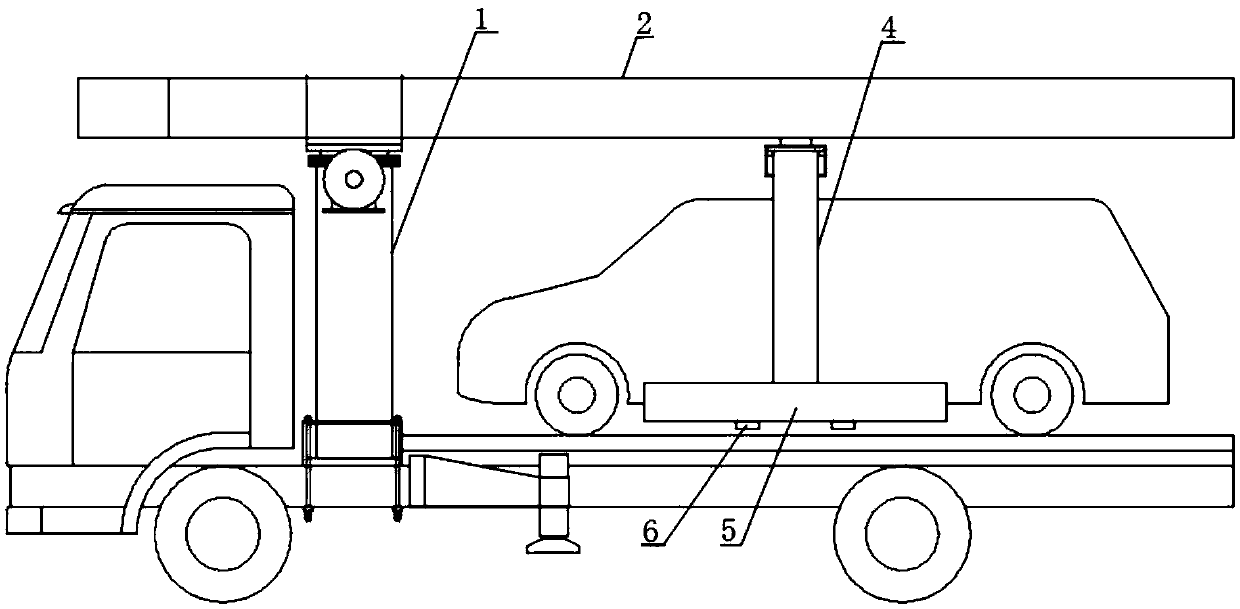

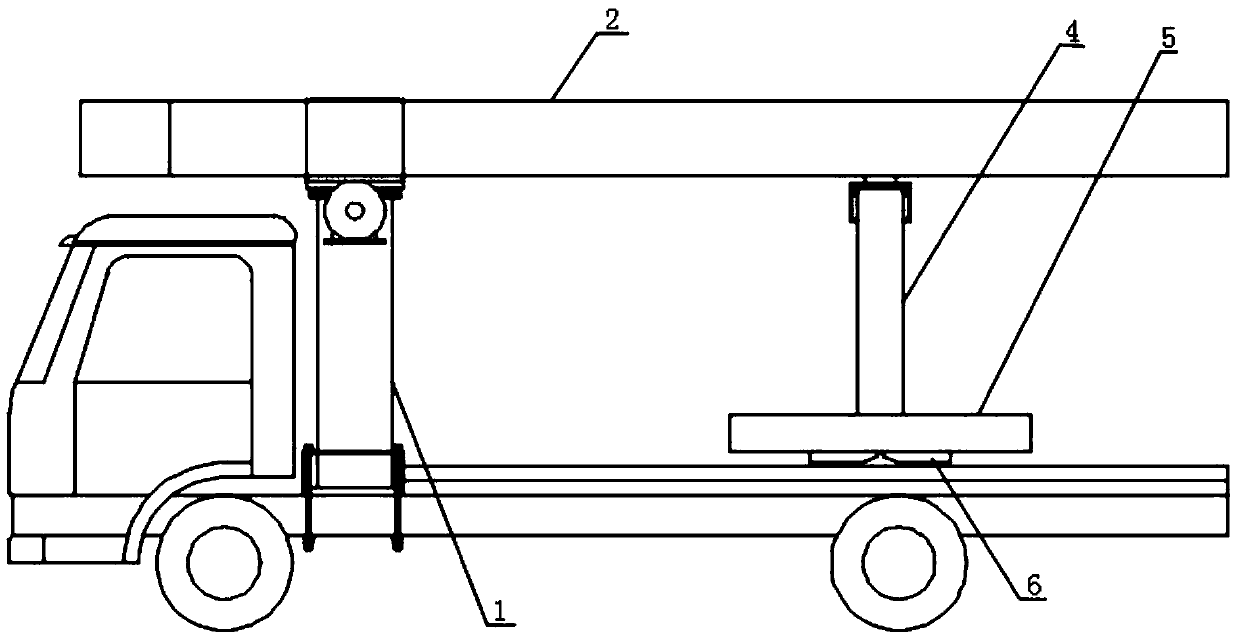

[0044] Example: such as figure 1 , 2 , 3, 4, 10, and 11, the present embodiment provides a side fork hoisting road wrecker vehicle, the side fork hoisting road wrecker vehicle uses a second-class automobile chassis as a carrier, and includes a lifting type slewing bearing 1, which is installed On the front girder of the above-mentioned second-class automobile chassis; track arm 2, which is horizontally assembled above the above-mentioned lifting slewing bearing 1, the above-mentioned track arm 2 is linear, and a track cavity is opened at its lower end along its length direction. The above-mentioned lifting slewing bearing 1 can drive the above-mentioned track arm 2 to rotate horizontally and lift; the fork frame operation regulator 3 is assembled in the above-mentioned track cavity, and is connected to the first telescopic mechanism 21 installed in the above-mentioned track cavity. The first telescopic mechanism 21 can drive the above-mentioned fork frame operation controller...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com