Production method of colorful natural cellulose membranes

A technology of natural cellulose and production method, which is applied in the production field of colored natural cellulose film, can solve the problems of easy fading and unstable color, and achieve the effects of good transparency, saving heating steam, and small difference between thickness and width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

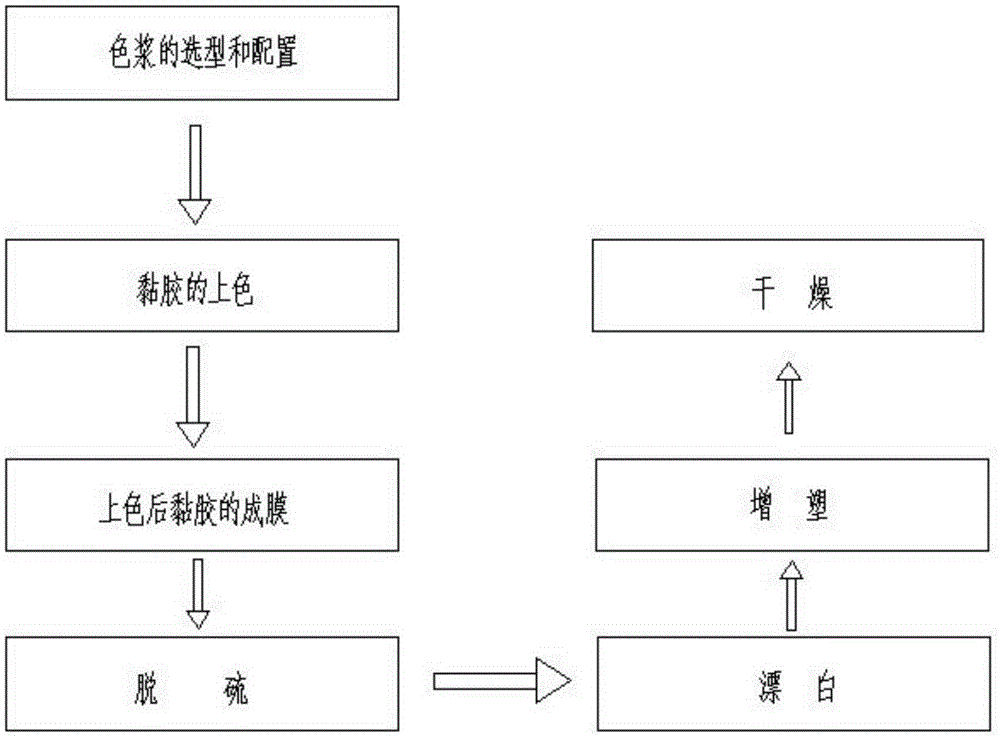

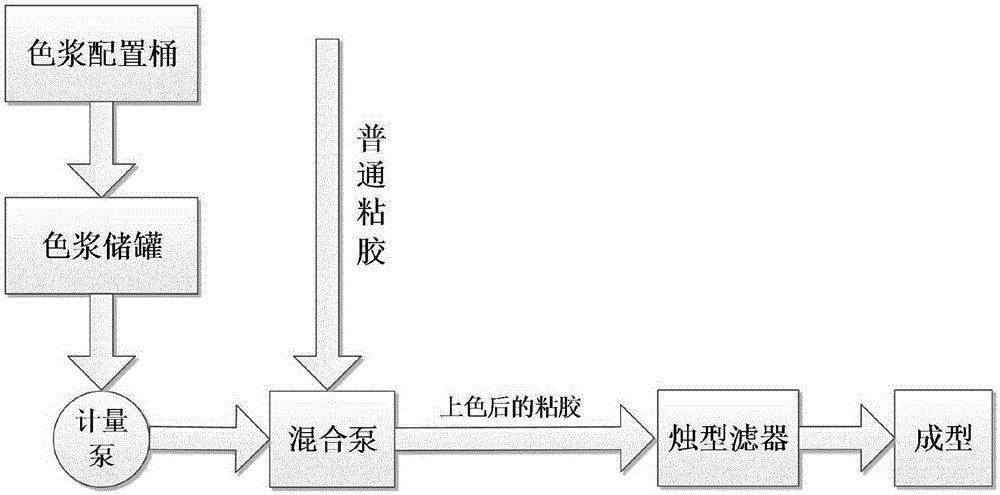

[0048] The production method of colored natural cellulose film comprises the steps:

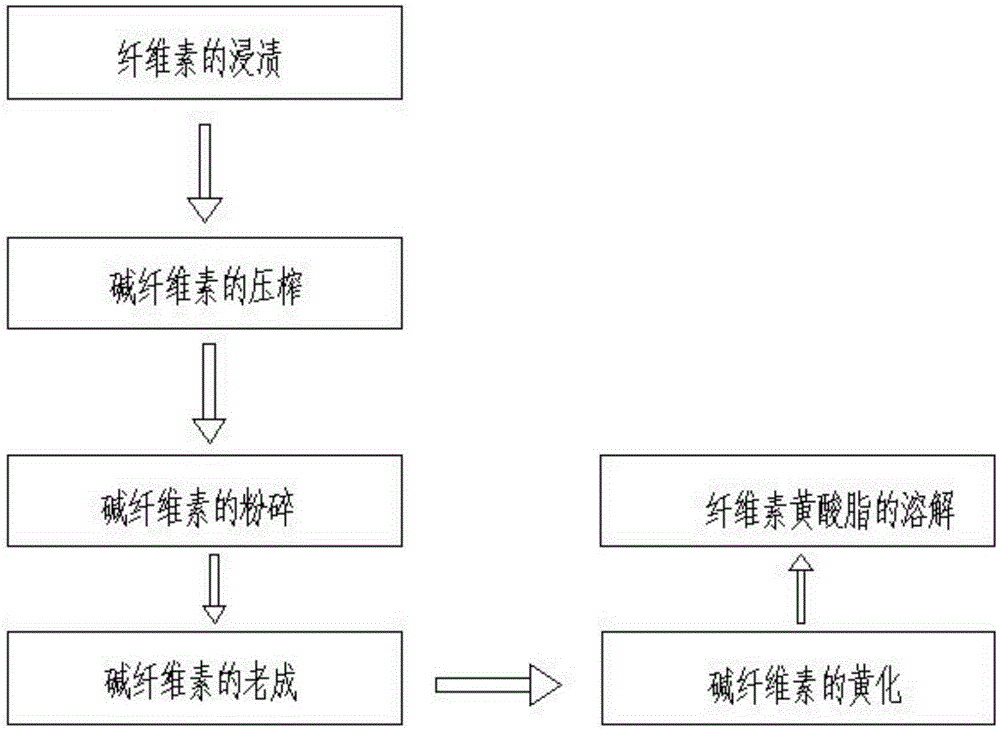

[0049] a, the preparation of cellulose viscose

[0050] (1) Impregnation of cellulose

[0051] Pulp (cotton pulp, wood pulp mixed in proportion) is put into the sodium hydroxide aqueous solution of percentage concentration 15%~18%, soaks for 10 minutes~20 minutes at 55 ℃~65 ℃, obtains the alkali cellulose dipping solution;

[0052] (2) Squeeze of alkali cellulose

[0053] Squeeze and separate excess lye in the soaking liquid to obtain pressed alkali cellulose;

[0054] (3) Grinding of alkali cellulose

[0055] crushing the pressed alkali cellulose to obtain the crushed alkali cellulose;

[0056] (4) The aging of alkali cellulose

[0057] Aging the crushed alkali cellulose at 55°C to 80°C for 2 hours to 4 hours to obtain aged alkali cellulose;

[0058] (5) Yellowing of alkali cellulose

[0059] Soak the aged alkali cellulose in an aqueous sodium hydroxide solution with a mass percentag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com