Formula of rubber for valve seat, preparation method for rubber, and valve seat

A formula and rubber technology, applied in the direction of valve devices, mechanical equipment, engine components, etc., can solve problems such as product failure, achieve the effect of improving antibacterial effect, improving food safety, and increasing content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The structure of the present invention will be described in detail below in conjunction with the accompanying drawings.

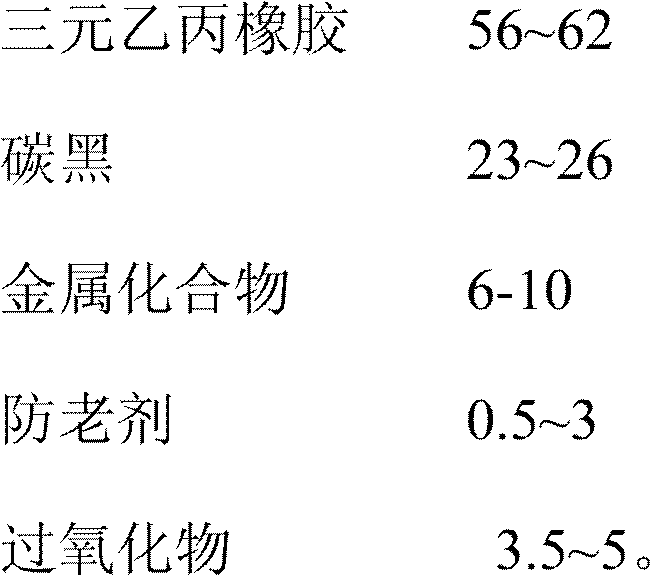

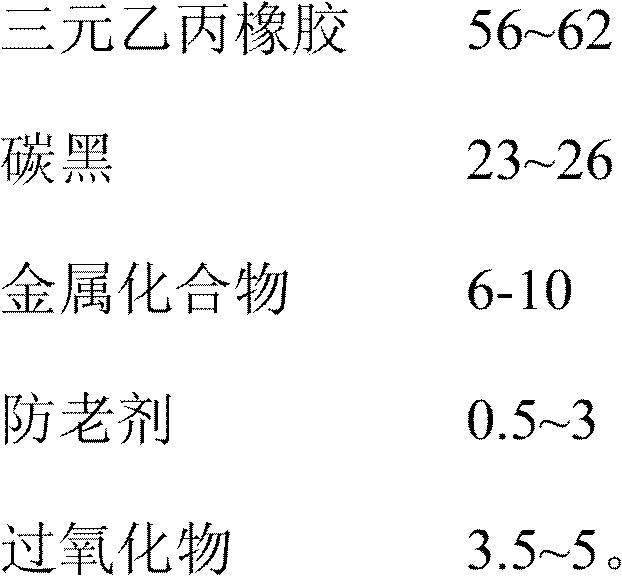

[0021] The following table is specific examples and main performance indicators, wherein the content in the examples is weight percent.

[0022] material name

[0023] In the five tests of the BS6920 standard, the samples prepared in the above four examples were far less than the standard requirements, especially the antibacterial effect was improved by about 70% compared with the formula in 2006, which improved the scope of product use and broadened the company's commodity items. Only tap water valve seat products have brought huge benefits to the company, while maintaining the basic conditions of human existence and improving food safety.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com