Washing method of capsule beverage machine

A beverage machine and capsule technology, which is applied to cleaning methods and utensils, chemical instruments and methods, cleaning hollow objects, etc., can solve the problems of inability to adjust the amount of cleaning water and cleaning mode, waste water resources, etc., to achieve convenient use and ensure cleaning effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

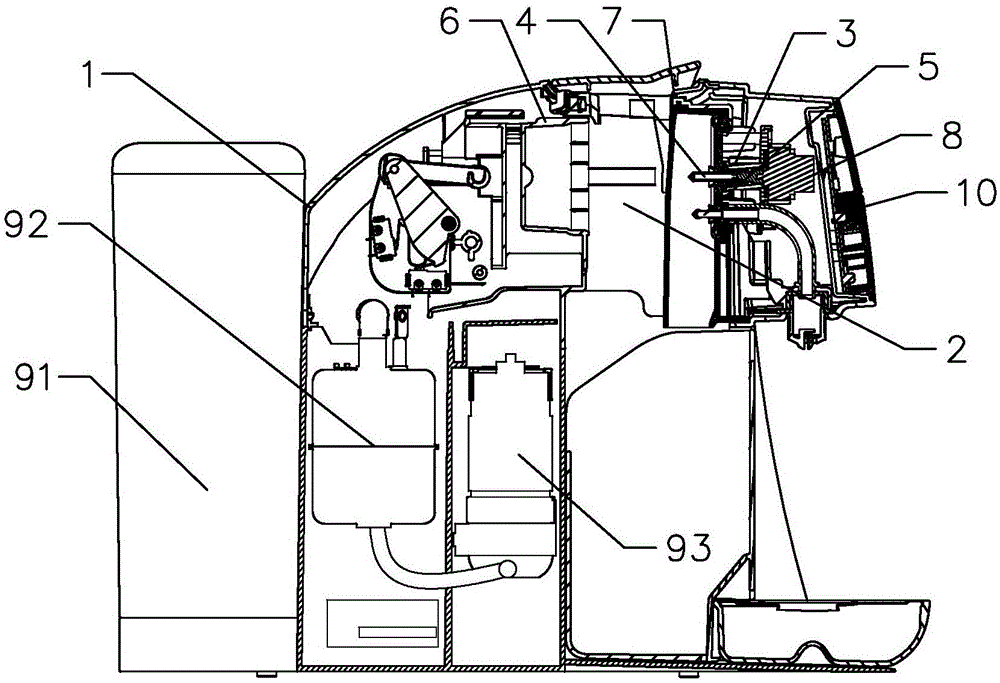

[0033] Such as figure 1 As shown, the present invention provides a capsule beverage machine, including a machine base 1, a brewing chamber 2 and a control panel (not shown in the figure) located in the machine base 1, a brewing head 3, a water inlet puncture needle 4, a water outlet The puncture needle 5, the liquid supply mechanism that provides the liquid to the brewing head 3, the brewing cup 6 for accommodating the capsule, and the identification device 7 for identifying the capsule, the liquid supply mechanism includes a water tank 91, a boiler 92 and a water pump 93, and the brewing cup 6 can be relatively The brewing head 3 is reciprocating, the water inlet needle 4 and the water outlet needle 5 are arranged horizontally and located on one side of the brewing head 3, the water inlet needle 4 is higher than the water outlet needle 5, and the capsule is put into the capsule beverage machine from the inlet. The brewing cup 6 moves towards the direction of the brewing head ...

Embodiment 2

[0047] The difference between this embodiment and the first embodiment is that the cleaning method further includes a step of shutting down the machine.

[0048] The cleaning method of the capsule beverage machine in this embodiment is as follows, specifically taking coffee beverage capsules as an example for a specific description:

[0049] Recognition step: the recognition device 7 recognizes that the capsules are coffee drink capsules, that is, in the water-saving cleaning mode, and transmits the recognized data to the control board for storage.

[0050] Cleaning steps: After the beverage machine finishes brewing beverages, the user manipulates the operation panel and selects the cleaning function. The control panel controls the capsule beverage machine to follow the water-saving cleaning mode. Specifically, the brewing cup is retracted and the brewing head is separated at a certain interval. The water pump uses 50% power to introduce a certain amount of water from the wate...

Embodiment 3

[0056] The difference between this embodiment and the first embodiment is that the cleaning mode is different, that is, the normal cleaning mode.

[0057] The cleaning method of the capsule beverage machine in this embodiment is as follows, specifically taking soy milk beverage capsules as an example for a specific description:

[0058] Recognition step: the recognition device 7 recognizes that the capsule is a soymilk drink capsule, that is, according to the conventional cleaning mode, and transmits the recognized data to the control board for storage.

[0059] Cleaning steps: After the beverage machine completes the brewing of beverages, the user manipulates the operation panel and selects the cleaning function, and the control panel controls the capsule beverage machine to follow the normal cleaning mode. Specifically, the brewing cup retreats and the brewing head is separated and separated by a certain distance To form an opening, the water pump introduces a certain amount...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com