Slow-wire-walking electrospark wire-electrode cutting copper alloy electrode wire and manufacture method thereof

A technology of electric discharge wire and electrode wire, which is applied in the direction of electrode manufacturing, electric processing equipment, metal processing equipment, etc., to achieve the effects of good conductivity, improved corrosion resistance, and reduced production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

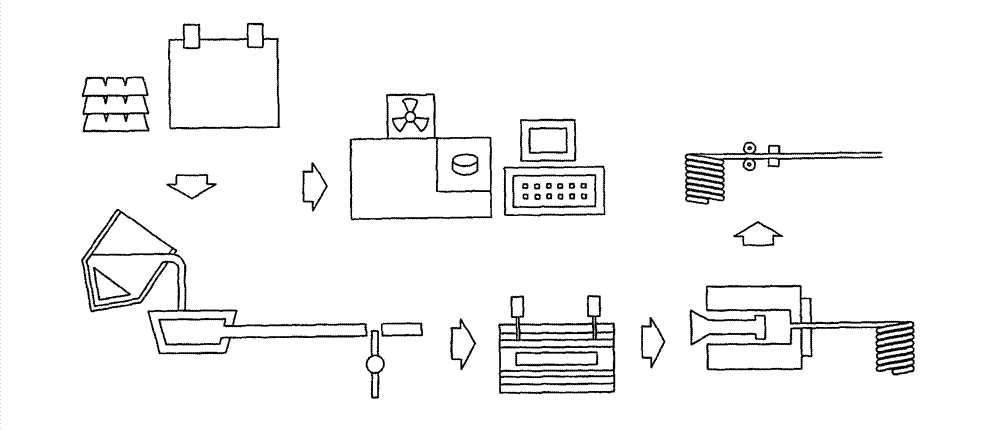

Method used

Image

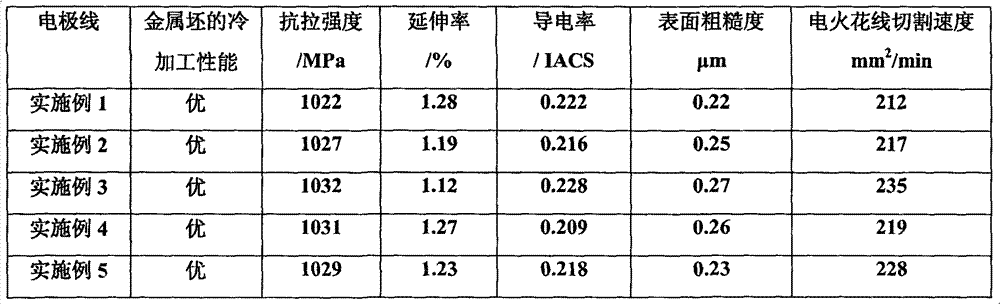

Examples

Embodiment 1

[0023] Prepare a total of 100Kg of alloy raw materials (high-purity raw materials that can be block or powder) according to the following quality, wherein, Al: 32.0Kg; Zn: 10.0Kg; Ni: 3.0Kg; Mg: 0.20Kg; W: 0.20Kg; and the balance of Cu;

[0024] Put the prepared alloy raw material into an induction melting furnace to melt it, the melting temperature is 1100°C, and the holding time is 100 minutes;

[0025] The molten alloy liquid is introduced into the horizontal continuous casting furnace, and the alloy wire billet is prepared by the continuous casting method. The inlet water temperature is 5-30°C, the temperature difference between the inlet and outlet water is 5-15°C, and the continuous casting speed is 1200mm / min;

[0026] The prepared alloy billet is subjected to multi-channel cold drawing and online annealing, the annealing temperature is 600°C, the annealing time is 50 seconds; and the stress relief annealing before the finished product is carried out, the annealing tem...

Embodiment 2

[0029] Prepare a total of 100Kg of alloy raw materials (high-purity raw materials that can be block or powder) according to the following quality, wherein, Al: 32.0Kg; Zn: 10.0Kg; Ni: 3.0Kg; Mg: 0.20Kg; W: 0.20Kg; and the balance of Cu;

[0030] Put the prepared alloy raw material into an induction melting furnace to melt it, the melting temperature is 1100°C, and the holding time is 100 minutes;

[0031] The molten alloy liquid is introduced into the horizontal continuous casting furnace, and the alloy wire billet is prepared by the continuous casting method. The inlet water temperature is 5-30°C, the temperature difference between the inlet and outlet water is 5-15°C, and the continuous casting speed is 1200mm / min;

[0032] The prepared alloy billet is subjected to multi-channel cold drawing and online annealing, the annealing temperature is 600°C, the annealing time is 50 seconds; and the stress relief annealing before the finished product is carried out, the annealing tem...

Embodiment 3

[0035] Prepare a total of 100Kg of alloy raw materials (high-purity raw materials that can be block or powder) according to the following quality, wherein, Al: 36.0Kg; Zn: 12.0Kg; Ni: 5.0Kg; Mg: 0.80Kg; W: 0.80Kg; and the balance of Cu;

[0036] Put the prepared alloy raw material into an induction melting furnace to melt it, the melting temperature is 1100°C, and the holding time is 100 minutes;

[0037] The molten alloy liquid is introduced into the horizontal continuous casting furnace, and the alloy wire billet is prepared by the continuous casting method. The inlet water temperature is 5-30°C, the temperature difference between the inlet and outlet water is 5-15°C, and the continuous casting speed is 1200mm / min;

[0038] The prepared alloy billet is subjected to multi-channel cold drawing and online annealing, the annealing temperature is 600°C, the annealing time is 25 seconds; and the stress relief annealing before the finished product is carried out, the annealing tem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com