Wide and thick steel plate for normalized and rolled fine-grain pressure-welded steel tube and preparation method thereof

A technology of normalizing rolling and pressure welding, which is applied in the field of wide and thick steel plates for normalizing rolled fine-grained pressure welded steel pipes and its preparation, can solve the problems of less attention to microstructure and mechanical properties, and achieve the elimination of The effect of off-line normalizing heat treatment, improving production efficiency and reducing production energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

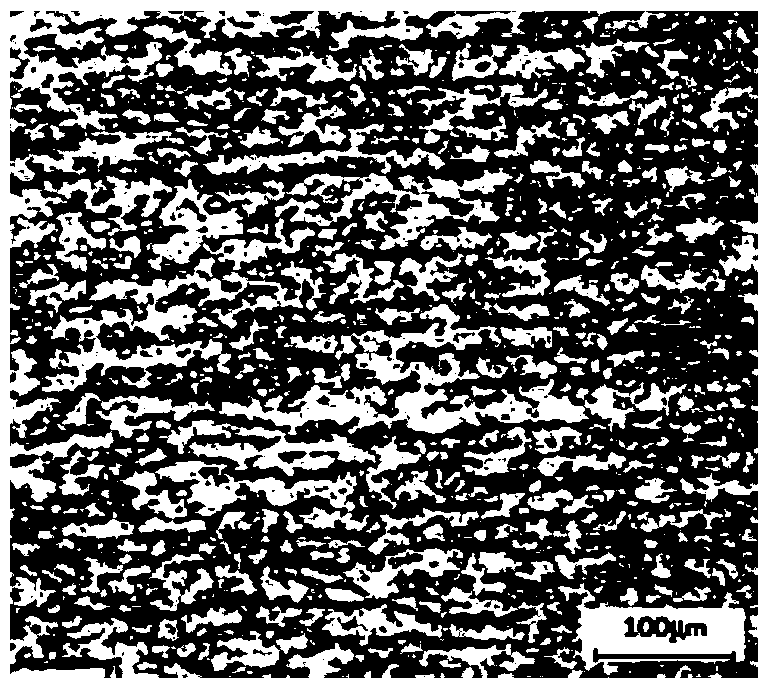

Embodiment 1

[0033] A wide and thick steel plate for normalizing rolled fine-grained pressure welded steel pipes. In terms of weight percentage, the chemical composition of the wide and thick steel plate is: C: 0.10%, Si: 0.25%, Mn: 1.40%, S: 0.007% , P: 0.008%, Nb: 0.025%, Ti: 0.025%, V: 0.025%, Als: 0.030%, and the rest are iron and unavoidable impurities.

[0034] The preparation method of above-mentioned wide and thick steel plate is:

[0035] 1) The slab size is 300mm (thickness) × 2200mm (width) heated to 1180-1200°C, heat preservation ≥ 200min, heating time ≥ 50min;

[0036] 2) The starting temperature of rough rolling in normalizing rolling is 1170°C, the finishing temperature is 1130°C, and the reduction rates in the last three passes of the rough rolling stage are 23%, 21% and 20% respectively;

[0037] 3) The starting temperature of normalizing rolling and finishing rolling is 890°C, the thickness of the intermediate billet is 4 times the thickness of the finished product, and ...

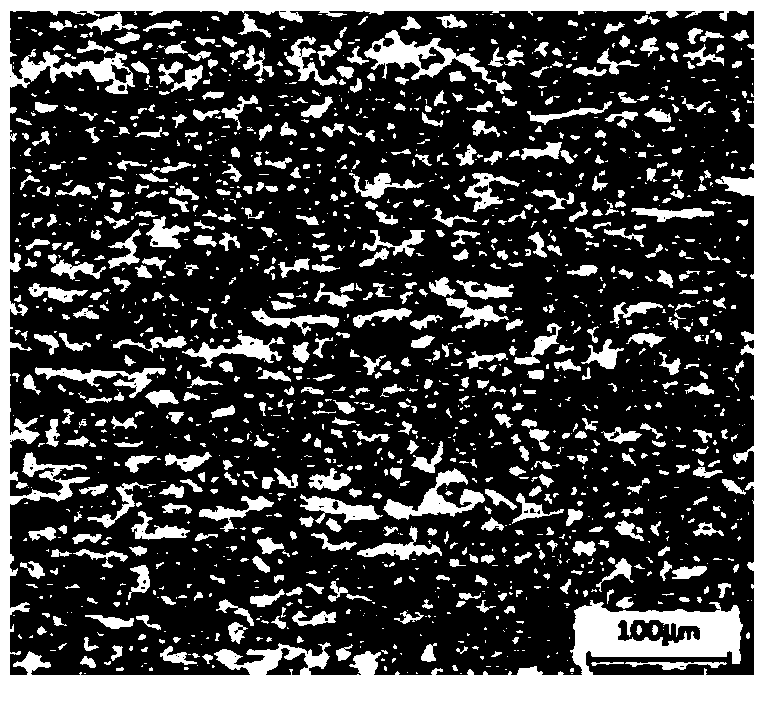

Embodiment 2

[0041] A wide and thick steel plate for normalizing rolled fine-grained pressure welded steel pipes. In terms of weight percentage, the chemical composition of the wide and thick steel plate is: C: 0.08%, Si: 0.20%, Mn: 1.20%, S: 0.010% , P: 0.012%, Nb: 0.025%, Ti: 0.020%, V: 0.020%, Als: 0.020%, and the rest are iron and unavoidable impurities.

[0042] The preparation method of above-mentioned wide and thick steel plate is:

[0043] 1) The slab size is 300mm (thickness) × 2200mm (width) heated to 1180-1200°C, heat preservation ≥ 200min, heating time ≥ 50min;

[0044] 2) The starting temperature of rough rolling in normalizing rolling is 1150°C, the finishing temperature is 1100°C, and the reduction rates in the last three passes of the rough rolling stage are 22%, 20% and 23% respectively;

[0045] 3) The starting temperature of normalizing rolling and finishing rolling is 850°C, the thickness of the intermediate billet is 3 times the thickness of the finished product, and ...

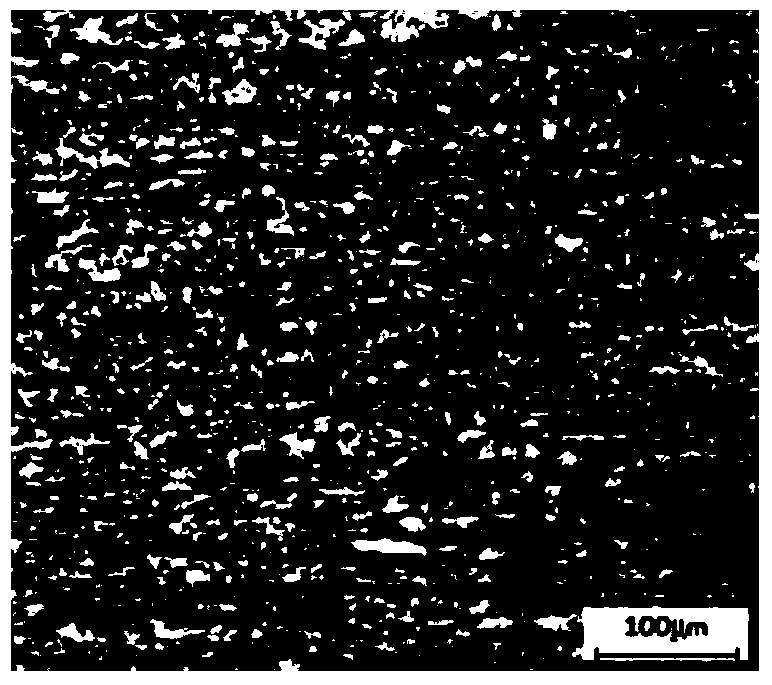

Embodiment 3

[0049] A wide and thick steel plate for normalizing rolled fine-grained pressure welded steel pipes, the chemical composition of the wide and thick steel plate is: C: 0.16%, Si: 0.60%, Mn: 1.70%, S: 0.020% , P: 0.025%, Nb: 0.050%, Ti: 0.050%, V: 0.050%, Als: 0.020%, and the rest are iron and unavoidable impurities.

[0050] The preparation method of above-mentioned wide and thick steel plate is:

[0051]1) The slab size is 300mm (thickness) × 2200mm (width) heated to 1180-1200°C, heat preservation ≥ 200min, heating time ≥ 50min;

[0052] 2) The starting temperature of rough rolling in normalizing rolling is 1200°C, the finishing temperature is 1160°C, and the reduction ratios in the last three passes of the rough rolling stage are 20%, 22% and 21% respectively;

[0053] 3) The starting temperature of normalizing rolling and finishing rolling is 920°C, the thickness of the intermediate billet is 6 times the thickness of the finished product, and the final forming rolling tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com