Normalizing process method for obtaining QT450-12 material

A process method and material technology, which is applied in the field of normalizing process to obtain QT450-12 material, can solve the problems of slow cooling speed of castings, reduced gas permeability of molding sand, slow cooling speed of large parts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

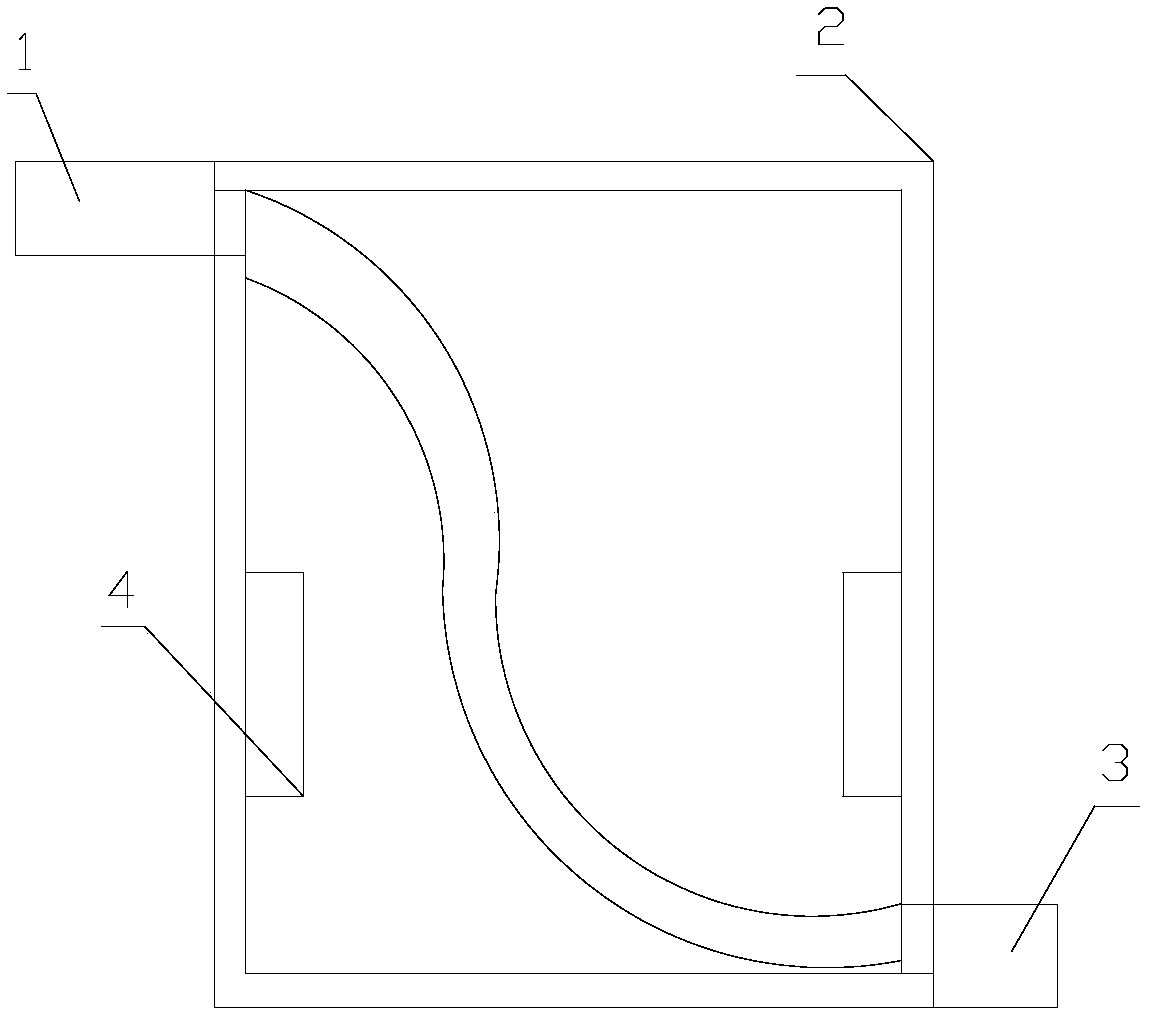

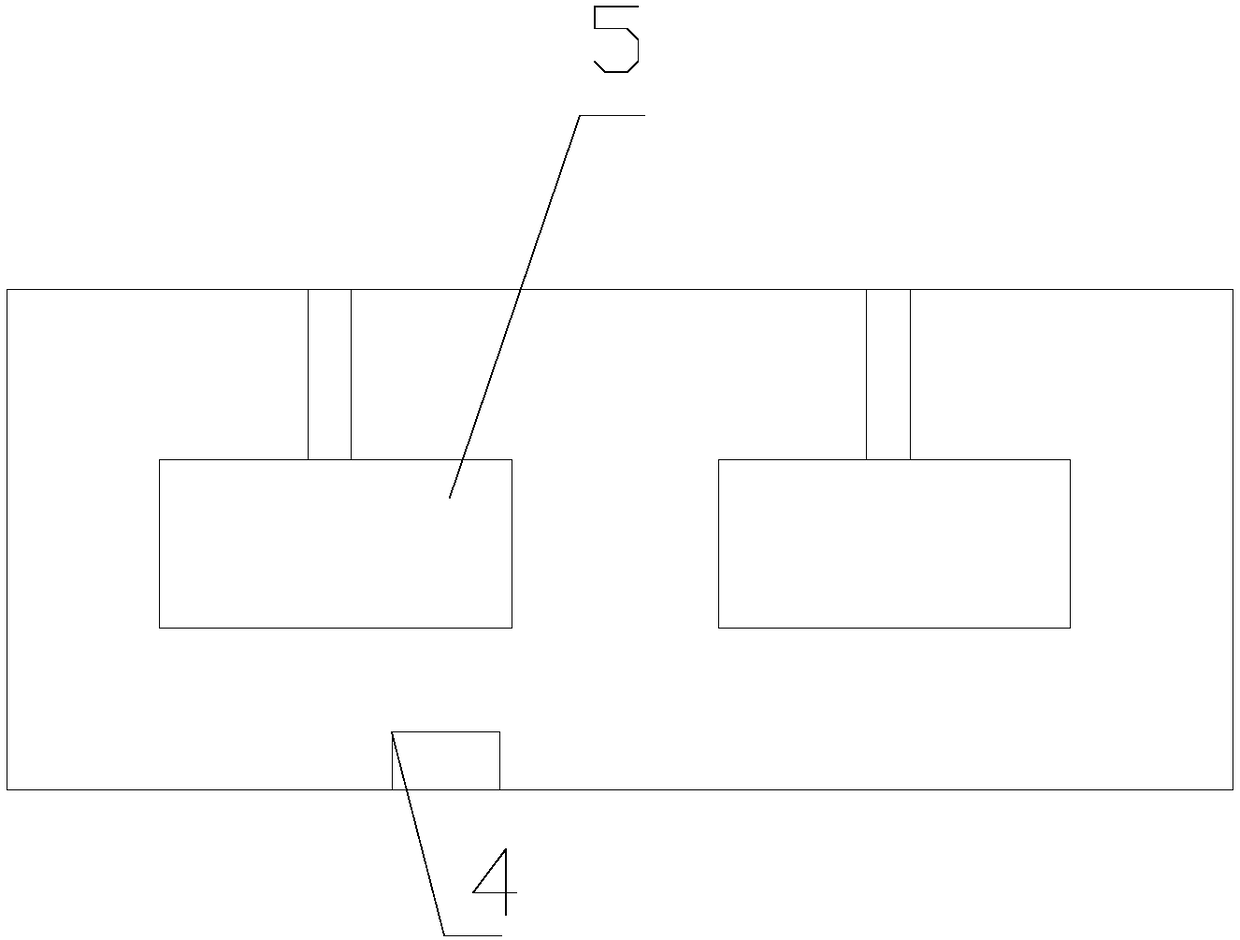

[0013] In order to make the technical means, creative features, goals and functions achieved by the present invention clearer and easier to understand, the present invention will be further elaborated below in conjunction with the accompanying drawings and specific implementation methods: a normalizing process method for obtaining QT450-12 material, casting The state is a mixed structure with ferrite as the matrix, its silicon content is 2.4%-2.8%, and its manganese content is ≤0.45%. After incomplete austenitization at 810°C-830°C, normalizing for 1.5 hours and air cooling; Get the proper pearlite content and QT450-12 material.

[0014] As a specific example, a mixed structure with a silicon content of 2.4%-2.8% and a manganese content of ≤0.45% is obtained through casting sampling. The casting must be uniform in texture, free of cracks and defects that affect product performance; on the processing surface of the casting, processing is allowed. Sand hole, air hole, slag hole ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com