Outer packing material for high-punching-depth battery device

A battery device and outer packaging technology, which is applied to electronic equipment, rolling mill control devices, battery pack components, etc., can solve the problems of small elongation at break and inability to obtain formability, and achieve the effect of excellent formability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

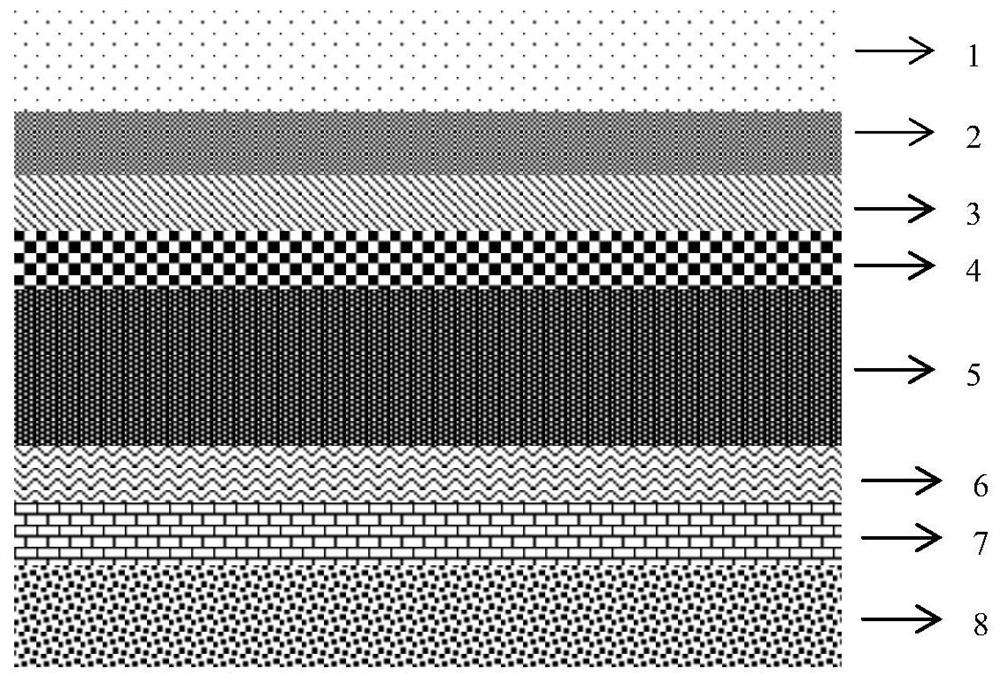

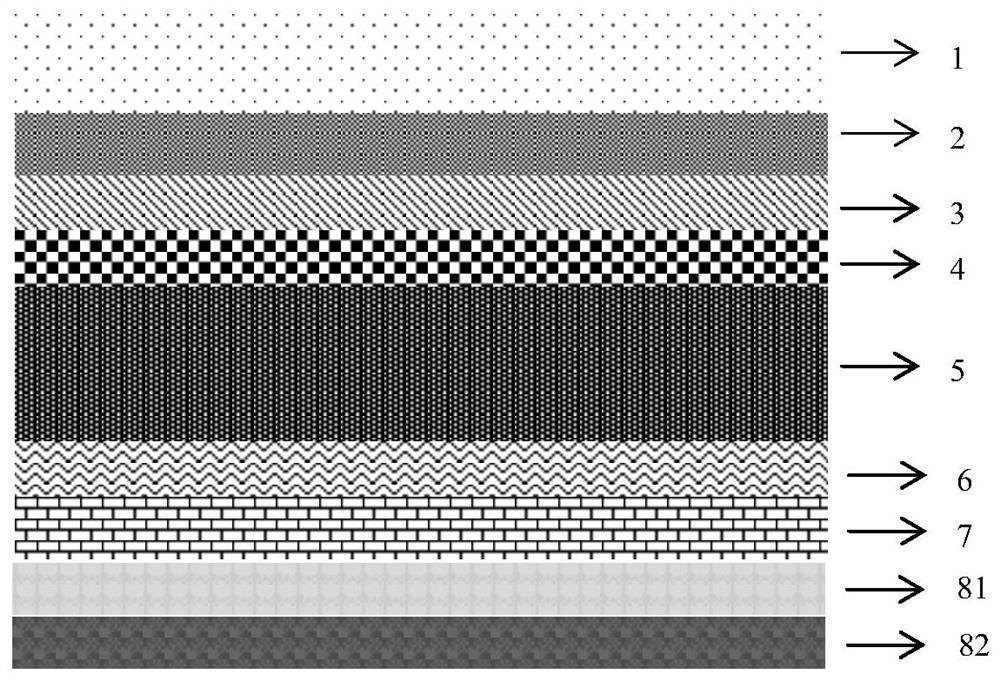

[0166] In the second embodiment of the present invention, the composite preparation method of the outer packaging material for high-drawing battery devices includes: deoiling treatment, corrosion resistance treatment, outer layer adhesive treatment, and inner thermal welding layer composite treatment.

[0167] 1. Deoiling treatment: deoiling with annealing treatment above 150°C, plasma, corona method or lye; wherein, the method of alkali deoiling is to immerse the metal in lye at 50-65°C, after a certain After the treatment of time, wash 2 times with deionized water, then dry, the surface wettability of the metal intermetallic layer 5 obtained deoiling treatment is 65mN / m, preferably more than 70mN / m, or the titrated contact angle angle of distilled water 15 degrees or less, preferably 10 degrees or less. If the wettability or surface water contact angle of the intermediate metal layer 5 exceeds a given range, it indicates that the rolling oil in the manufacturing stage may st...

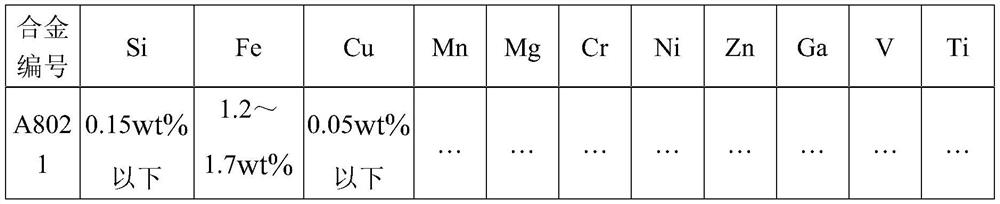

Embodiment 1

[0235] The aluminum alloy foil described in Table 5 was used to form a composite film. The Si content in the aluminum alloy foil was 0.04 wt%, the Cu content was 0.005 wt%, the Zn content was 0.008 wt%, and the Ti content was 0.015 wt%. The total of Cube orientation, Cu orientation, S orientation, Bs orientation, and R orientation ratio is 72 wt%, the total of Cube orientation and Cu orientation ratio is 32%, and the Cube orientation ratio is 10%. The average crystal particle size is 9.1 μm.

[0236] After the aluminum alloy foil is annealed and degreased, the surface contact angle is 15°, the thickness is 40μm, and the two sides are chemically treated in advance to form a corrosion-resistant layer.

[0237] The outer layer lamination method is as follows: Corona treatment is performed on the surface of the outer base material resin layer and the outer layer adhesive layer in contact. The aluminum alloy foil layer is laminated on the resin layer of the outer base material by ...

Embodiment 2

[0242] The aluminum alloy foil described in Table 5 was used to form a composite film. The Si content in the aluminum alloy foil was 0.016 wt%, the Cu content was 0.013 wt%, the Zn content was 0.004 wt%, and the Ti content was 0.004 wt%. The total ratio of Cube orientation, Cu orientation, S orientation, Bs orientation, and R orientation is 77 wt%, the total ratio of Cube orientation and Cu orientation is 47%, and the ratio of Cube orientation is 14%. The average particle size of crystals is 6μm.

[0243] After the aluminum alloy foil is annealed and degreased, the surface contact angle is 15°, the thickness is 40μm, and the two sides are chemically treated in advance to form a corrosion-resistant layer.

[0244] The outer layer lamination method is the same as in Example 1.

[0245] The inner layer stacking method is the same as that in Example 1.

[0246] Simultaneously, Slip coating was performed on the surface of the substrate layer. Slip coating is to apply a 10% eruca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

| Hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com