Production method of hot rolled ribbed steel bar

A technology of hot-rolled ribbed steel bars and production methods, which is applied in the production of Φ8mm~Φ10mm HRB400E coiled snails and the production of hot-rolled ribbed steel bars, which can solve the insufficient strength margin, rough and medium rolling equipment strength and motor performance requirements Higher, increased equipment maintenance costs and other issues, to achieve the effect of increased yield strength, stable yield strength, and high economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Below in conjunction with embodiment further illustrate content of the present invention.

[0011] The production method of a group of high wire Φ8 mm~Φ10mm HRB400E coiled snails. The rolling process is as follows: furnace temperature: 1080~1120℃, pre-finishing rolling 1030~1060℃, finishing rolling temperature: 850~870℃, silk spinning temperature: 850~870℃, fan air volume 100%, temperature in the insulation cover 640~660℃, 600~620℃ out of the heat preservation cover, 45~55s in the heat preservation cover, natural cooling. The chemical composition of the wire rod of the embodiment of the present invention is shown in Table 1, and the mechanical properties of the wire rod of the embodiment of the present invention are shown in Table 2.

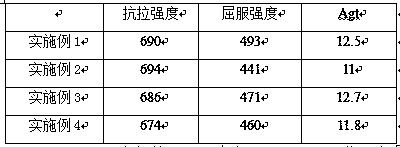

[0012] surface The chemical composition (Wt%) of embodiment wire rod

[0013]

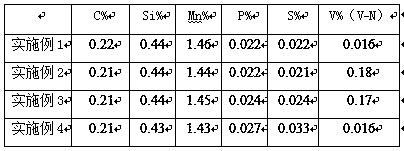

[0014] Table 2 Mechanical properties of example wire rods

[0015]

[0016] The yield strength of the high wire Φ8mm~Φ10mmHRB400E disc snails produ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com