steel plate

A steel plate and chemical composition technology, applied in furnaces, heat treatment equipment, manufacturing tools, etc., can solve the problems of mechanical property deviation, inability to obtain sufficient reaction force characteristics and collision characteristics, and achieve the effect of stable yield strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

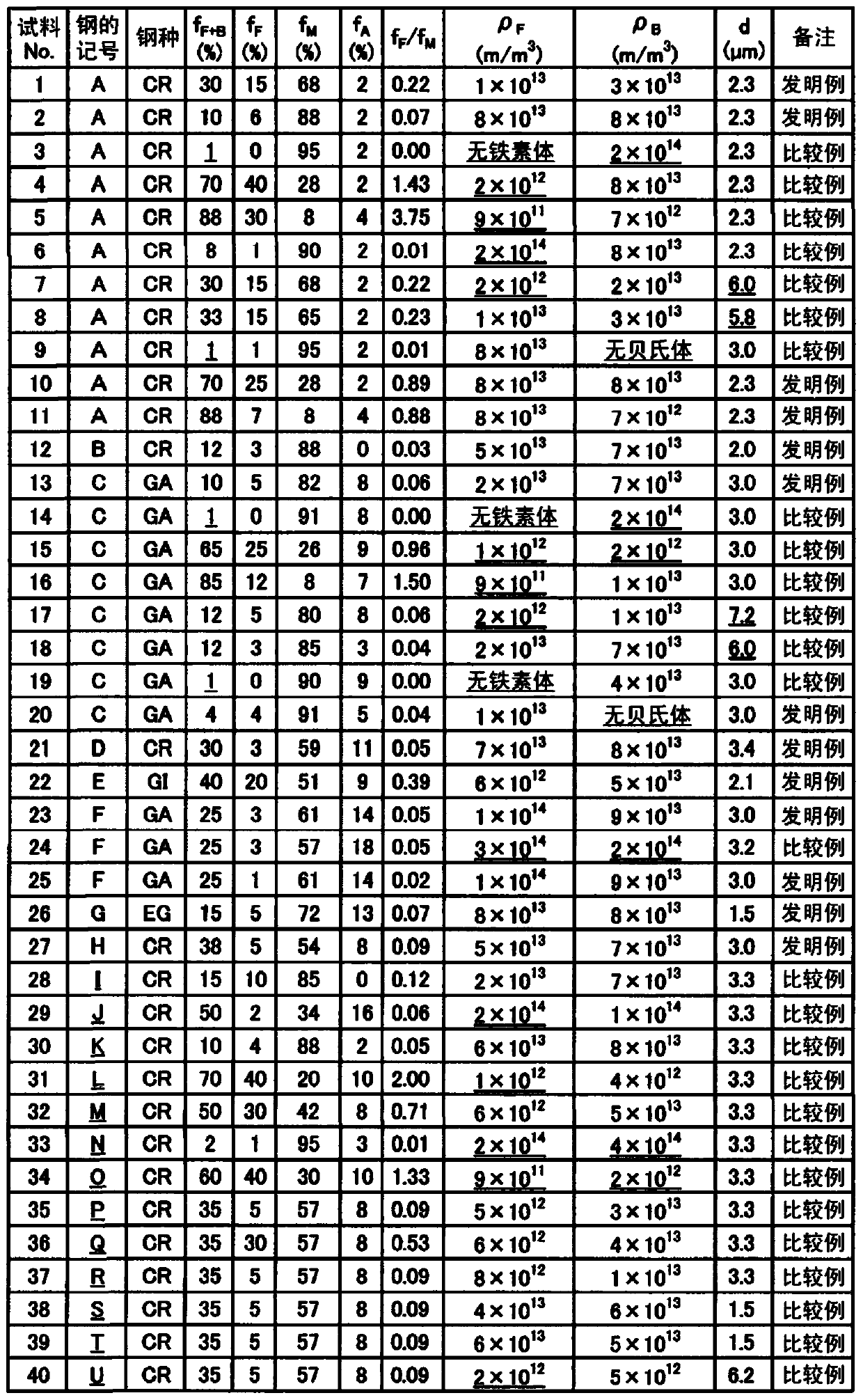

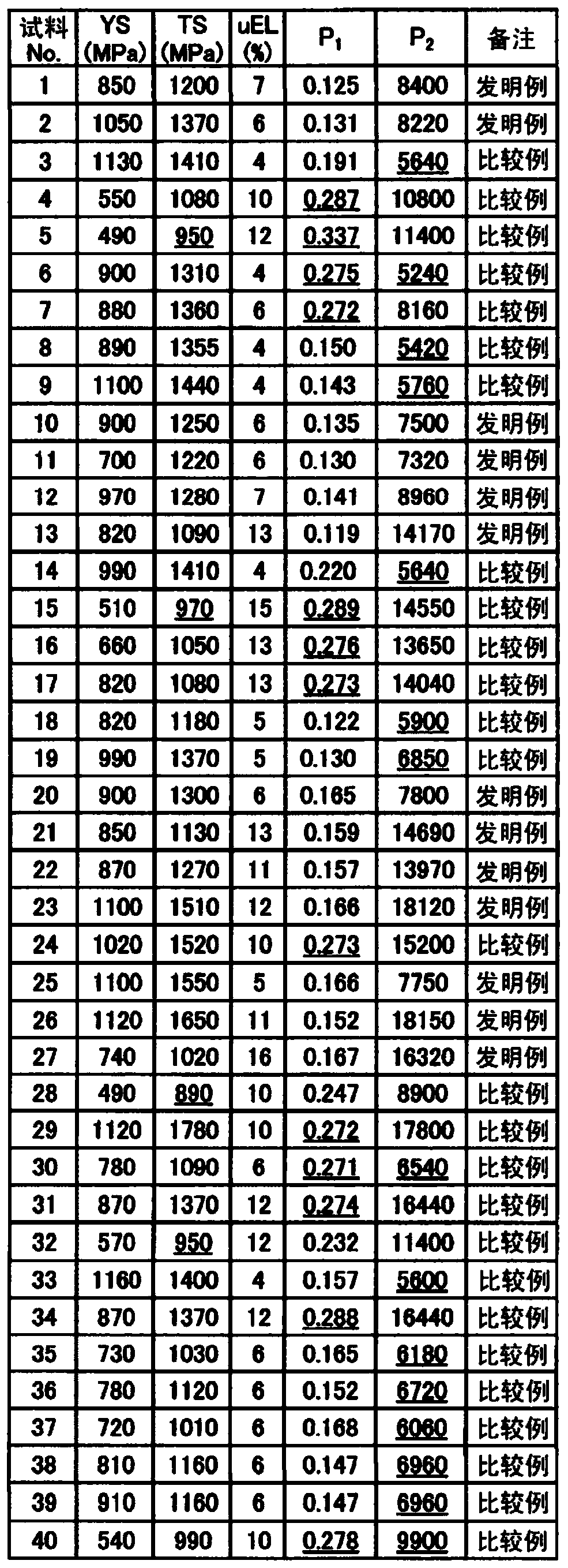

[0117] Embodiments of the present invention will be described below. The conditions of the examples are examples of conditions employed to confirm the feasibility and effects of the present invention, and the present invention is not limited to the examples of conditions. In the present invention, various conditions can be adopted as long as the object of the present invention can be achieved without departing from the gist of the present invention.

[0118] (1st test)

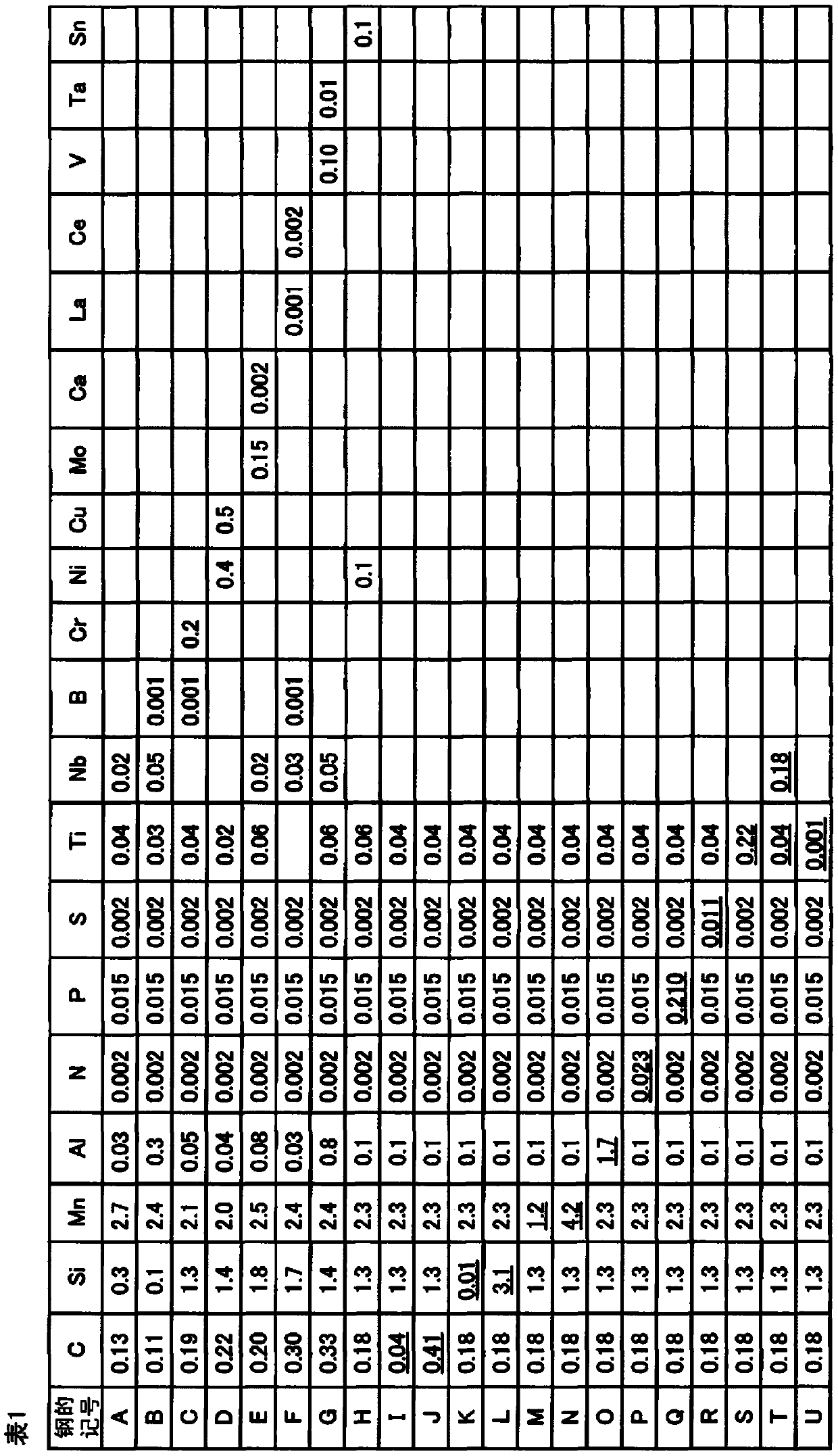

[0119] In the first test, steel having the chemical composition shown in Table 1 was melted to produce a steel slab, and the steel slab was heated to 1200°C to 1250°C for hot rolling. In hot rolling, rough rolling and finish rolling were performed. The empty column in Table 1 indicates that the content of this element is lower than the detection limit, and the rest is Fe and impurities. Underlines in Table 1 indicate that the values deviate from the range of the present invention.

[0120]

[0121] Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com