Patents

Literature

39results about How to "Small pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

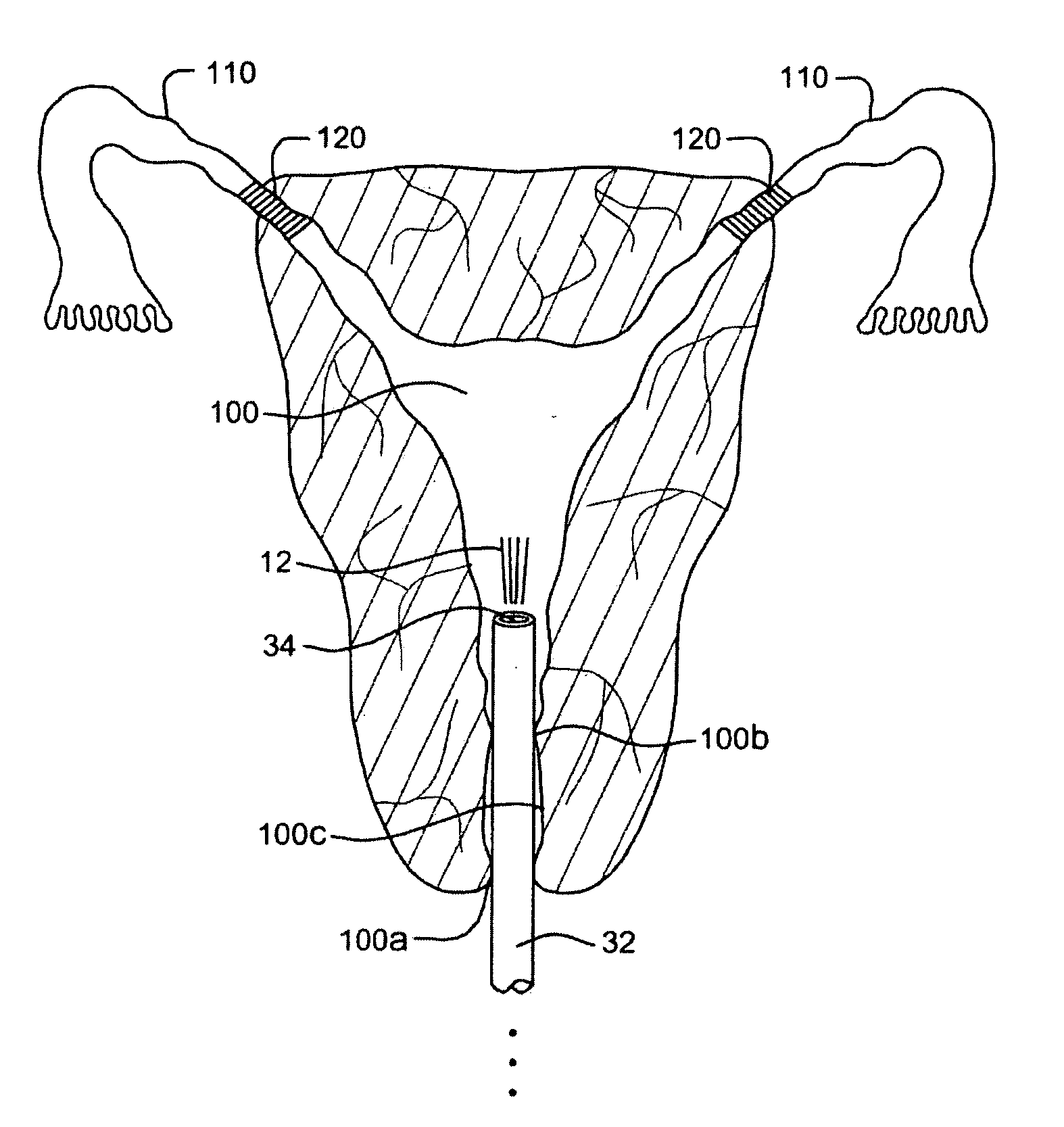

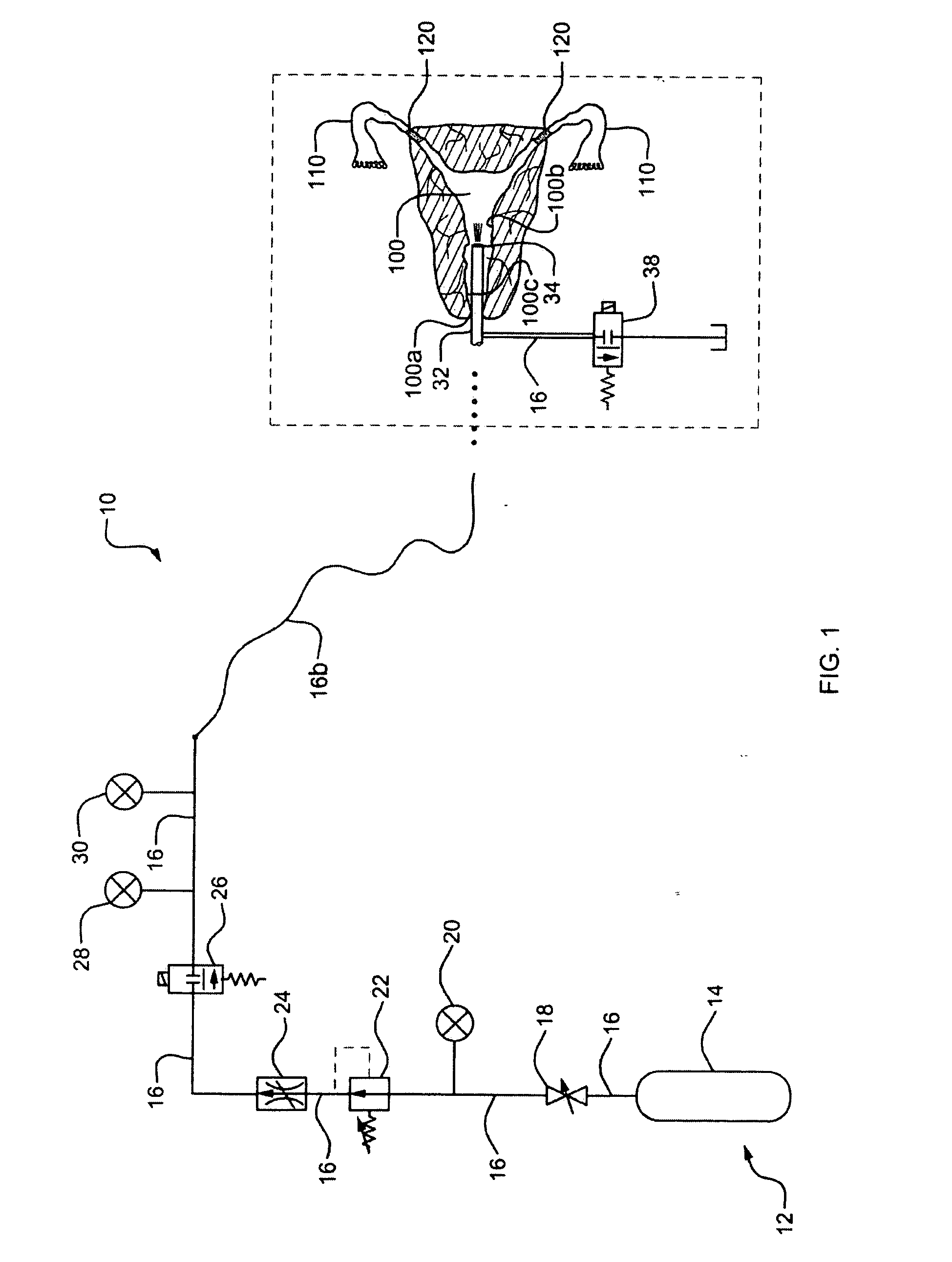

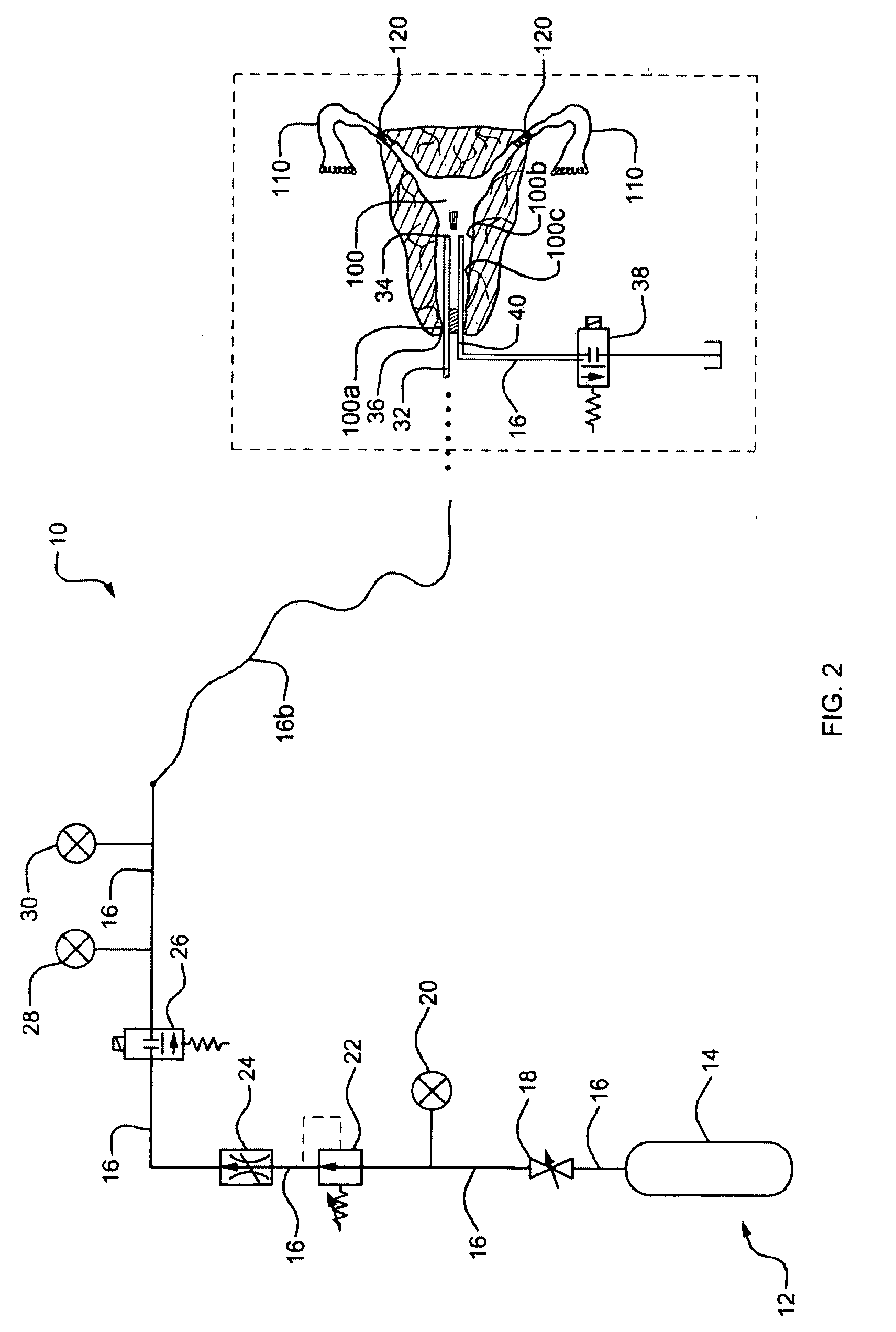

Method and apparatus for verifying occlusion of fallopian tubes

InactiveUS20080167664A1Constant pressureSmall pressureFallopian occludersMedical devicesCarbon dioxidePressure sensor

A device for verifying occlusion of the fallopian tube in a female subject includes an elongate gas delivery member having a lumen disposed therein, the elongate gas delivery member adapted for sealing engagement with the subject's uterus. The device includes a pressurized insufflation gas source coupled to the elongate gas delivery member, the insufflation gas source being in communication with the lumen of the elongate gas delivery member. The insufflation gas may includes for example, carbon dioxide. In one aspect, the device includes a pressure sensor or gauge to measure intra-uterine pressure to verify occlusion of the fallopian tube(s). In another aspect, the flow rate of insufflation gas into the uterus may be measured using a flow meter to verify occlusion of the fallopian tube(s).

Owner:CYTYC CORP

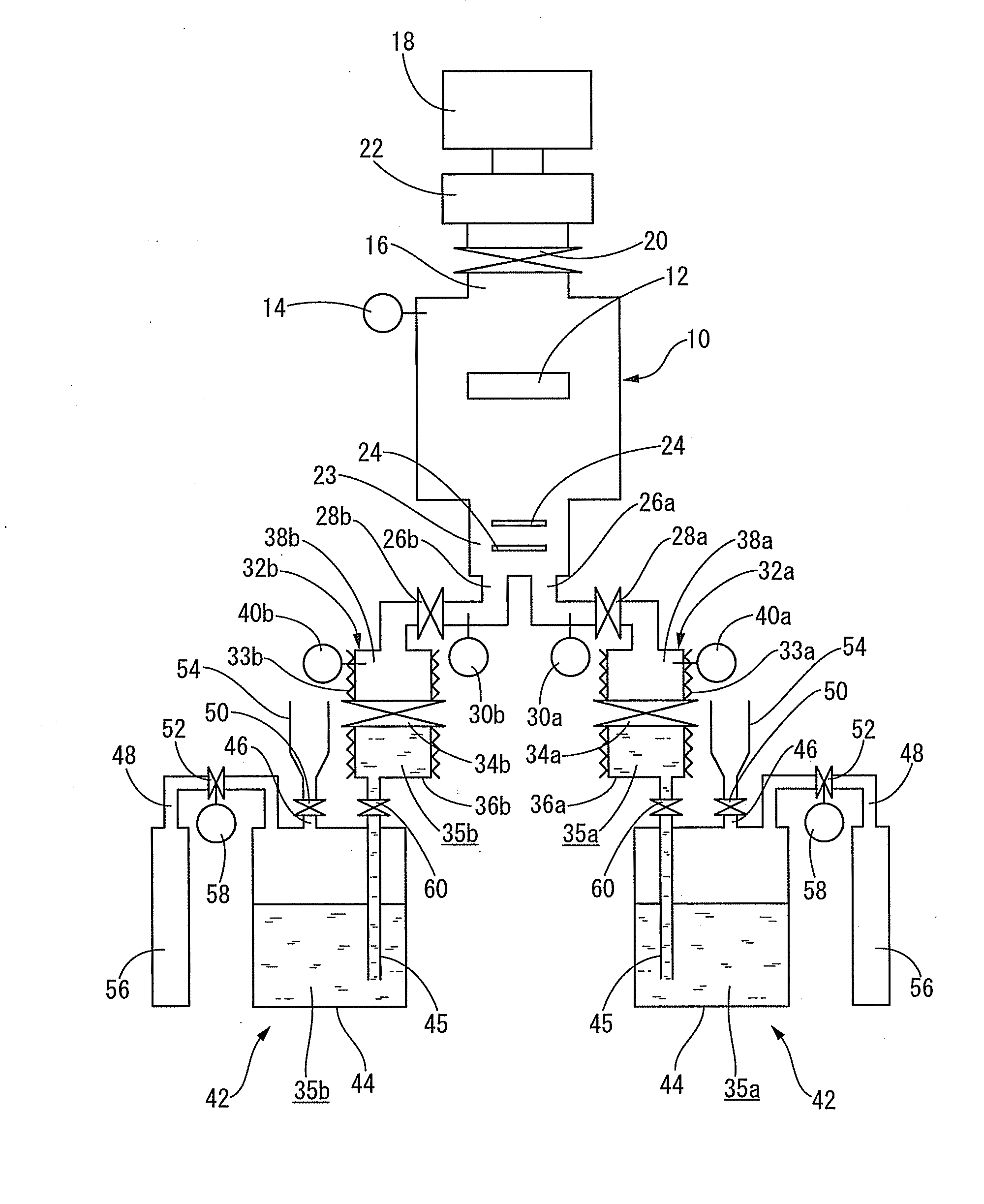

Method of forming organic polymer thin film and an apparatus for forming the organic polymer thin film

ActiveUS20110091650A1Small pressureHigh film formation efficiencyVacuum evaporation coatingSputtering coatingPolymer thin filmsOptoelectronics

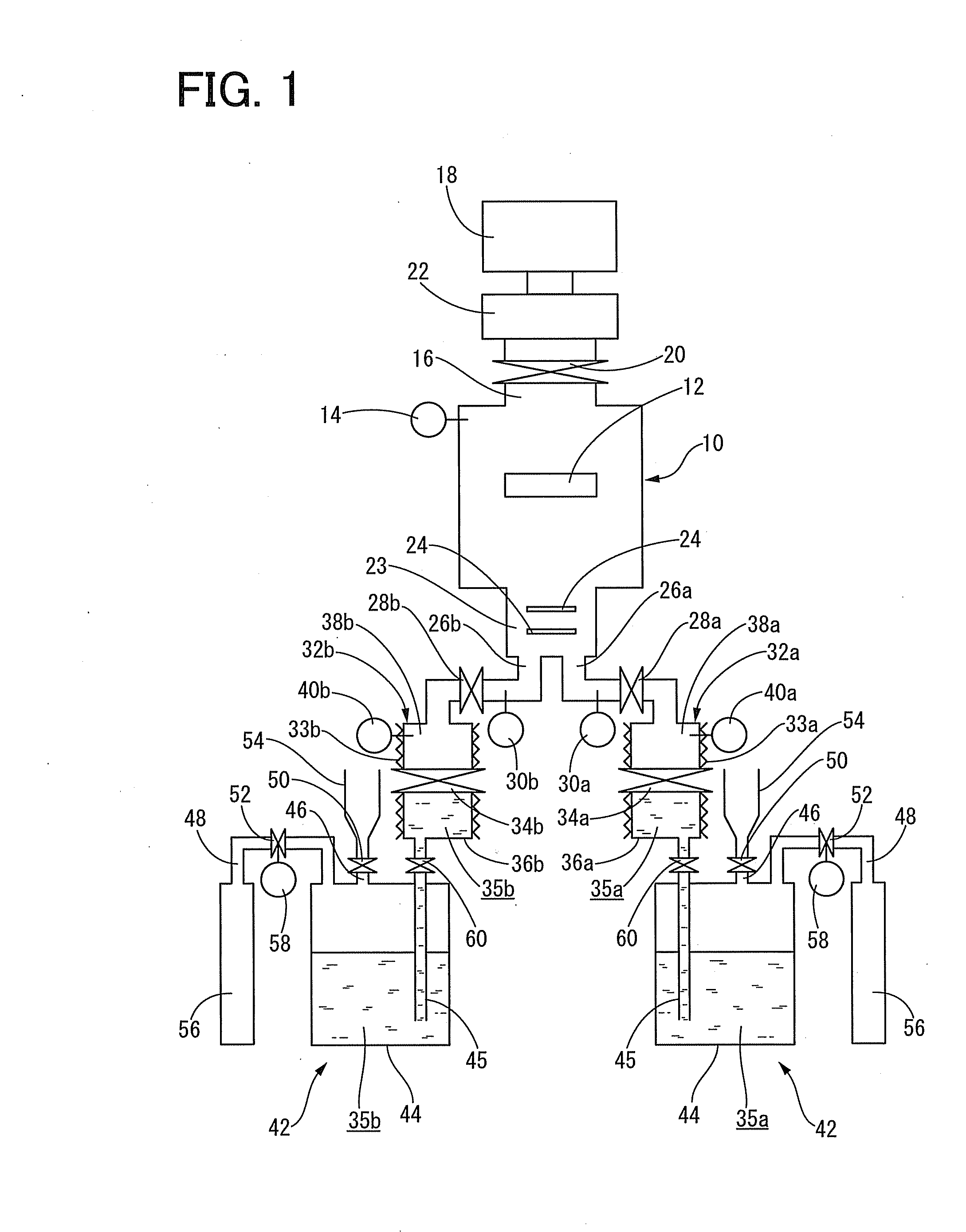

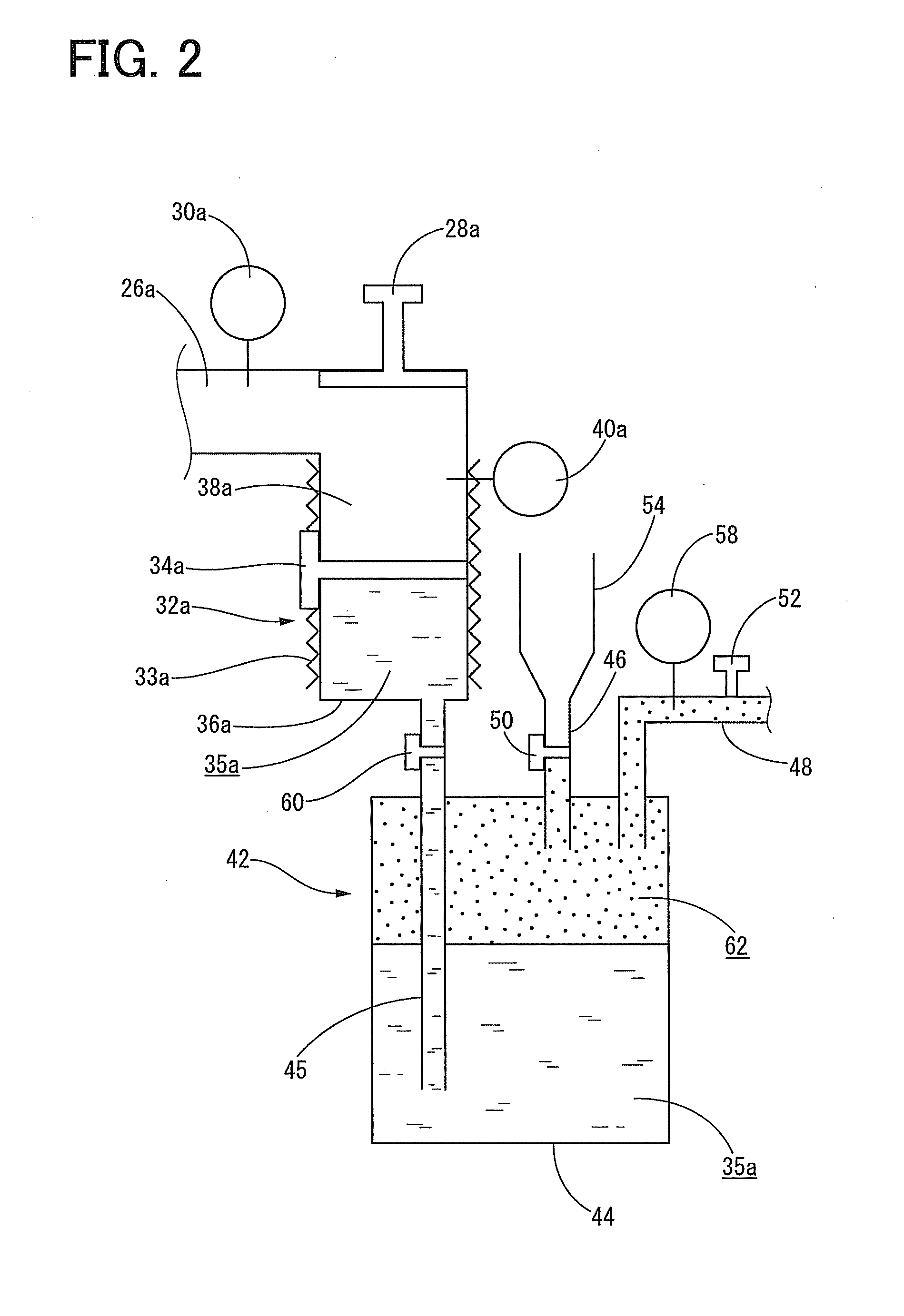

A technique for forming an organic polymer thin film on a surface of a substrate with high film formation efficiency and excellent reproducibility and stability is provided. When a vacuum deposition polymerization for forming an organic polymer thin film is performed on a surface of a substrate 12 repeatedly, in which a plurality of kinds of monomers evaporated in a plurality of evaporation source containers 32a, 32b in vacuum state are introduced into a deposition chamber 10 in a vacuum state and polymerized on a surface of the substrate 12 arranged in the deposition chamber 10, each of the monomers in a liquid form is present in the evaporation source containers 32a, 32b in a constant amount every time, at the beginning of the evaporation operation of monomers.

Owner:KOJIMA PRESS IND CO LTD +1

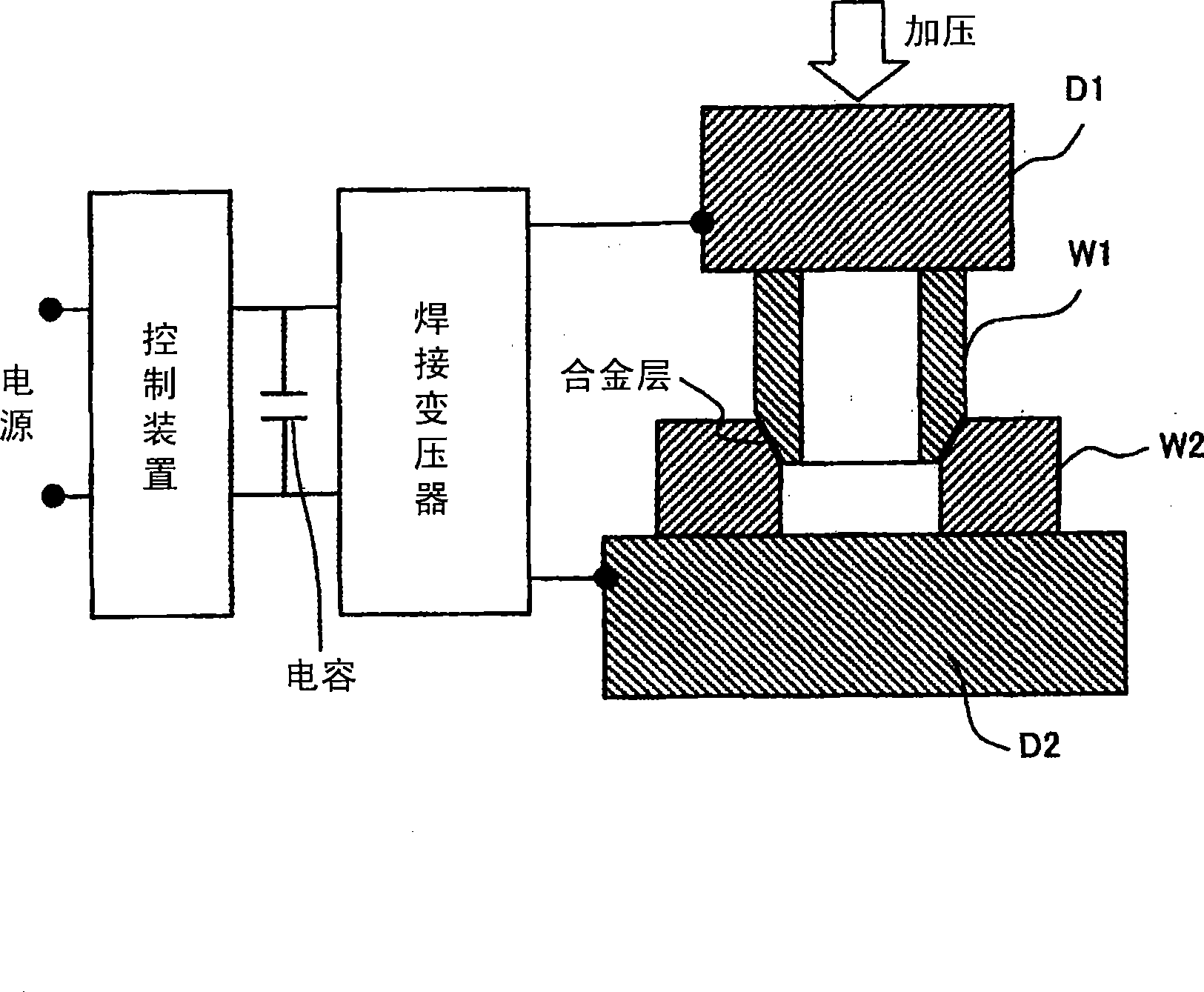

High-pressure fuel supply pump and the manufacturing method

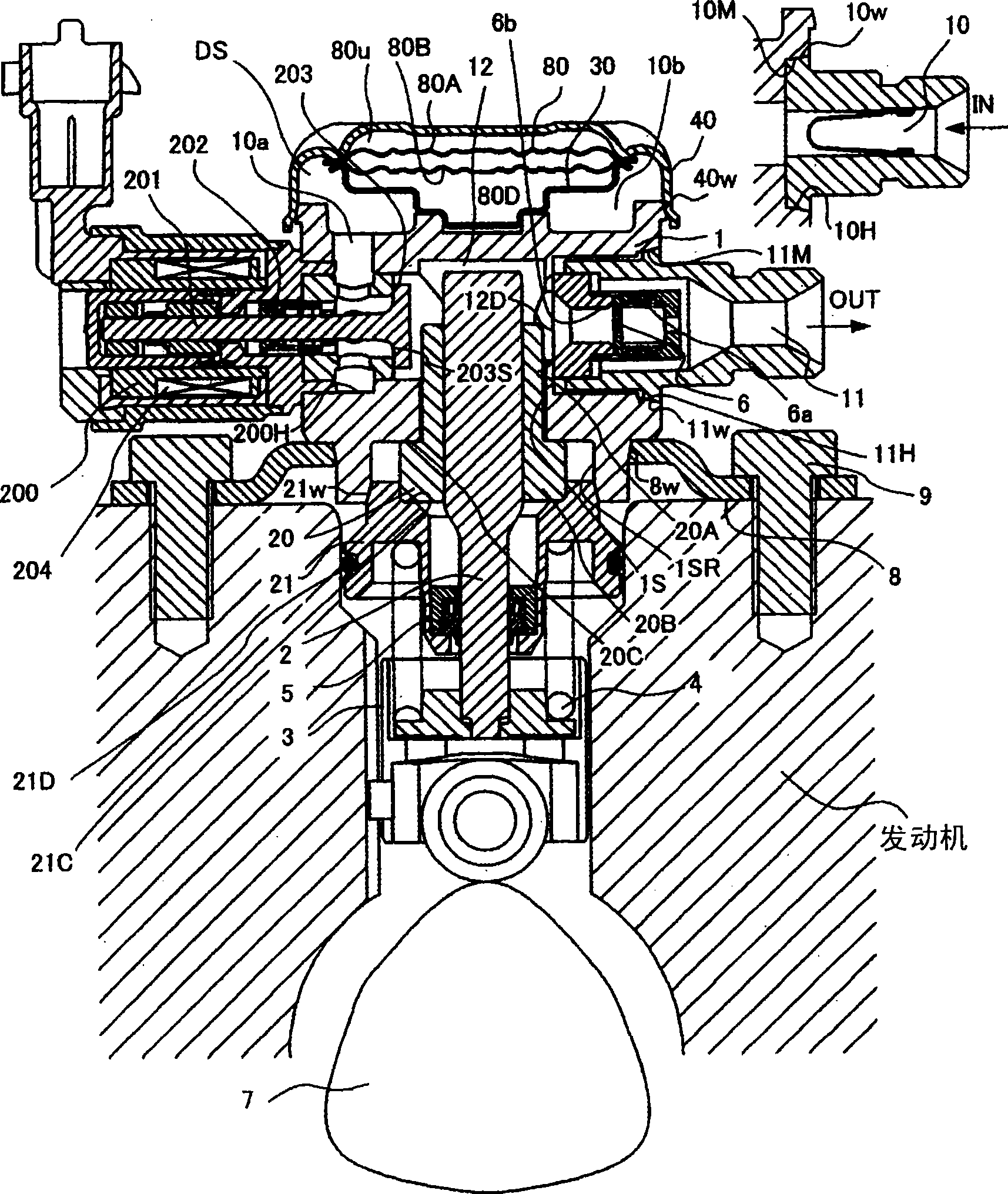

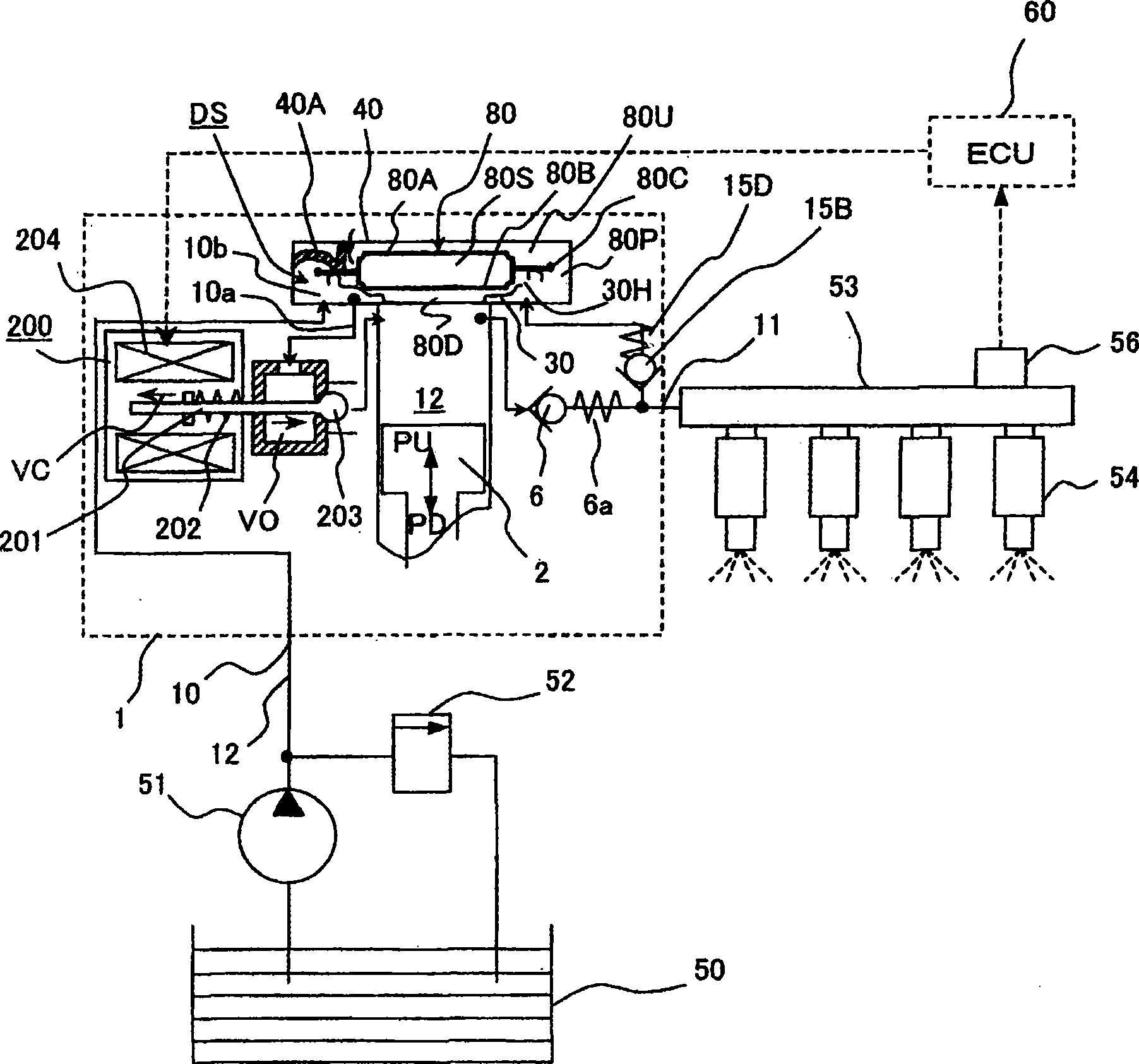

InactiveCN101424235ARealize the joint functionRealize the sealing functionTubular articlesHollow articlesInlet valveMetallic materials

An object of this invention is to provide such a welded structure of and welding method for two metallic parts fitted together at a tubular section in a high-pressure fuel supply pump, that enables rapid joining of both metallic parts by staking (press-fitting included), screw fastening, and / or laser welding, offers high welding strength and sufficient fluid sealability, and keeps the metallic materials free from thermal changes in composition. While an electric current is supplied to any one of the welding connection surfaces formed between a pump housing and cylinder in a high-pressure fuel supply pump, between the pump housing and an installation flange, between the pump housing and an intake or discharge joint, between the pump housing and a pulsation-absorbing damper cover, between the pump housing and a relief valve mechanism, and between the pump housing and an electromagnetically driven intake valve mechanism, the particular two sections are pressed against each other to generate, along the connection surface, a plastic flow not causing melting or fusion due to heat, and form a diffusion-weld region at the connection surface by using the plastic flow and the application of the pressure.

Owner:HITACHI LTD

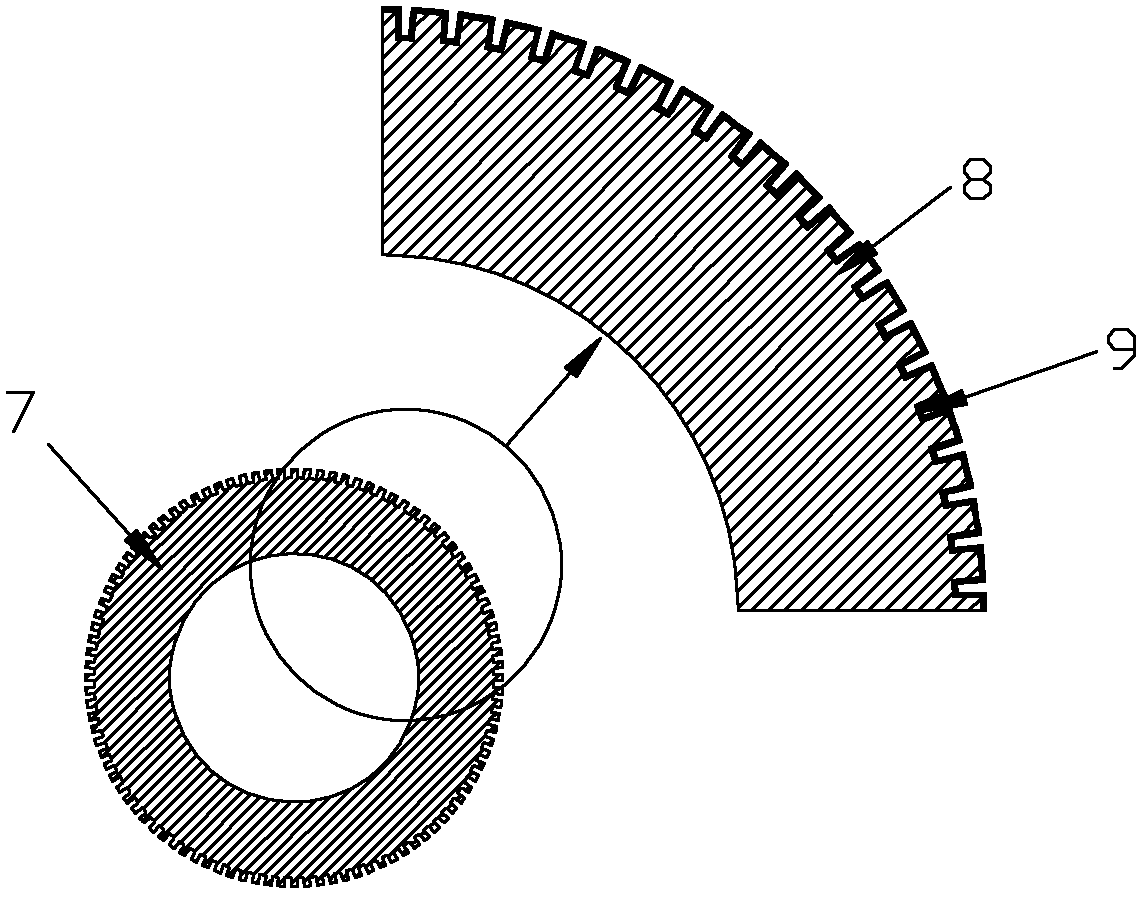

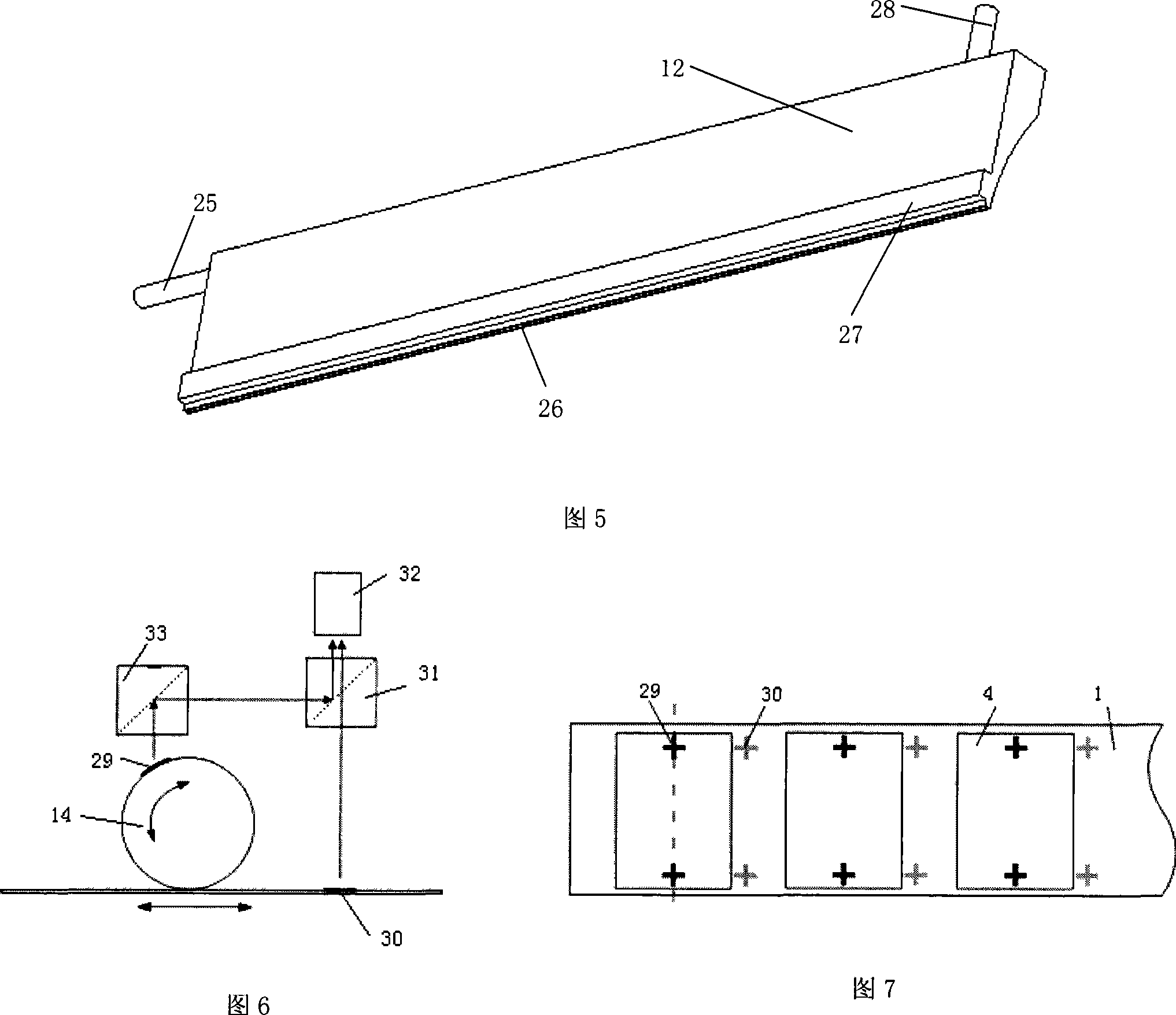

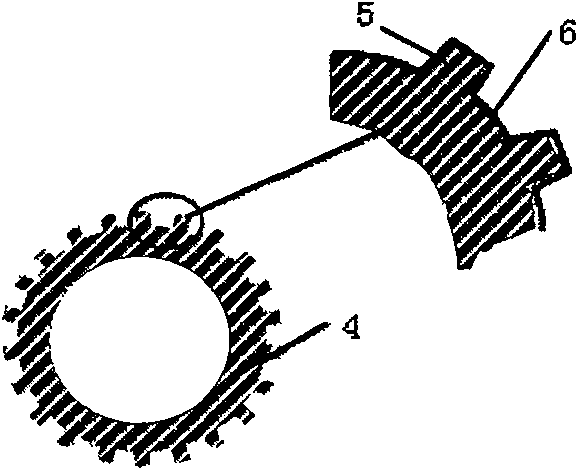

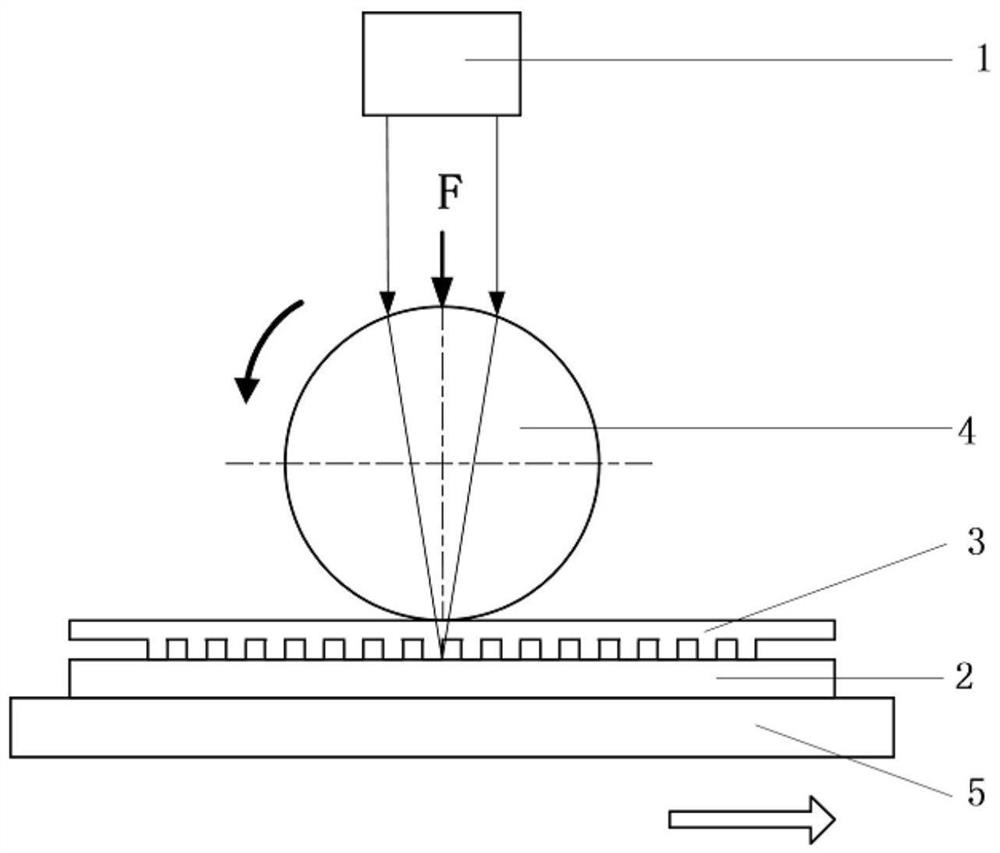

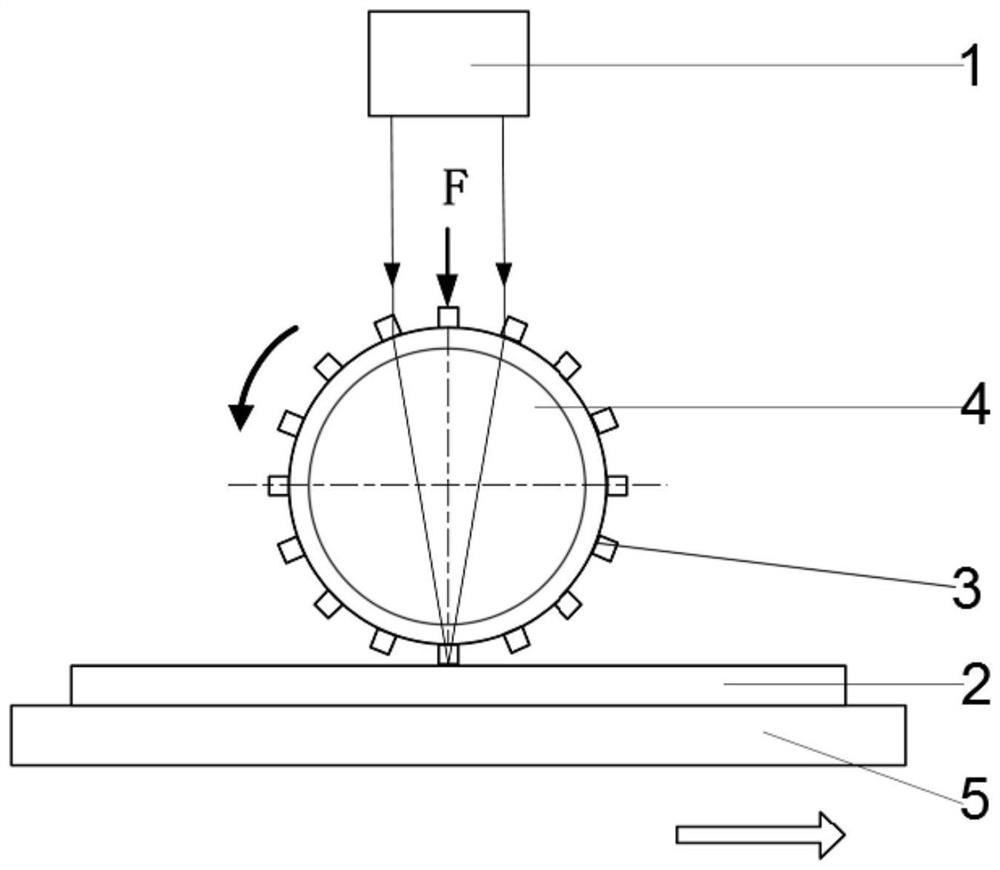

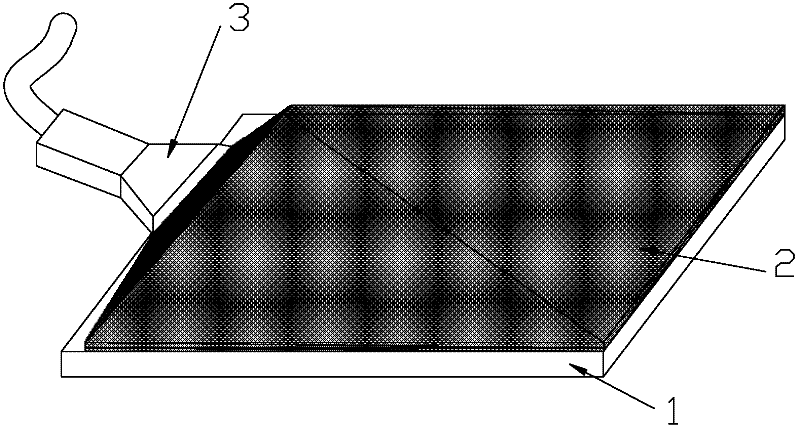

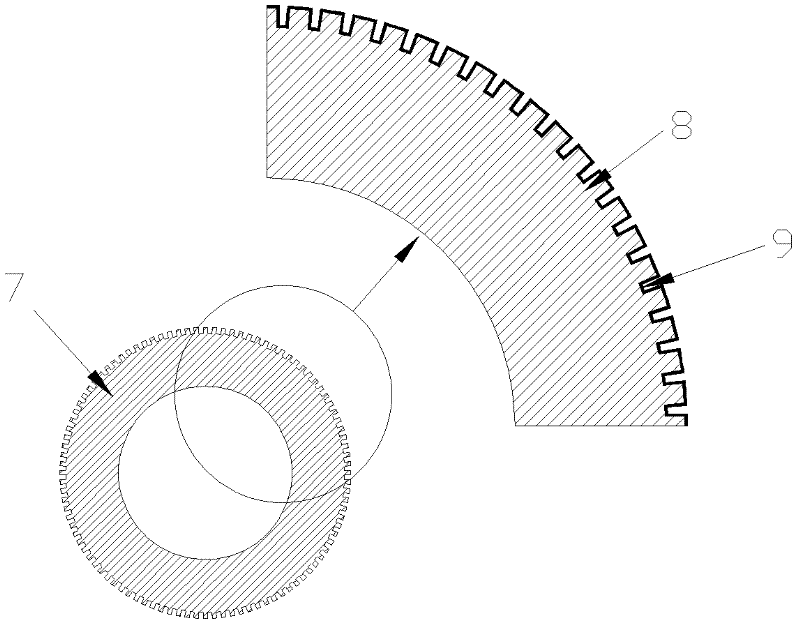

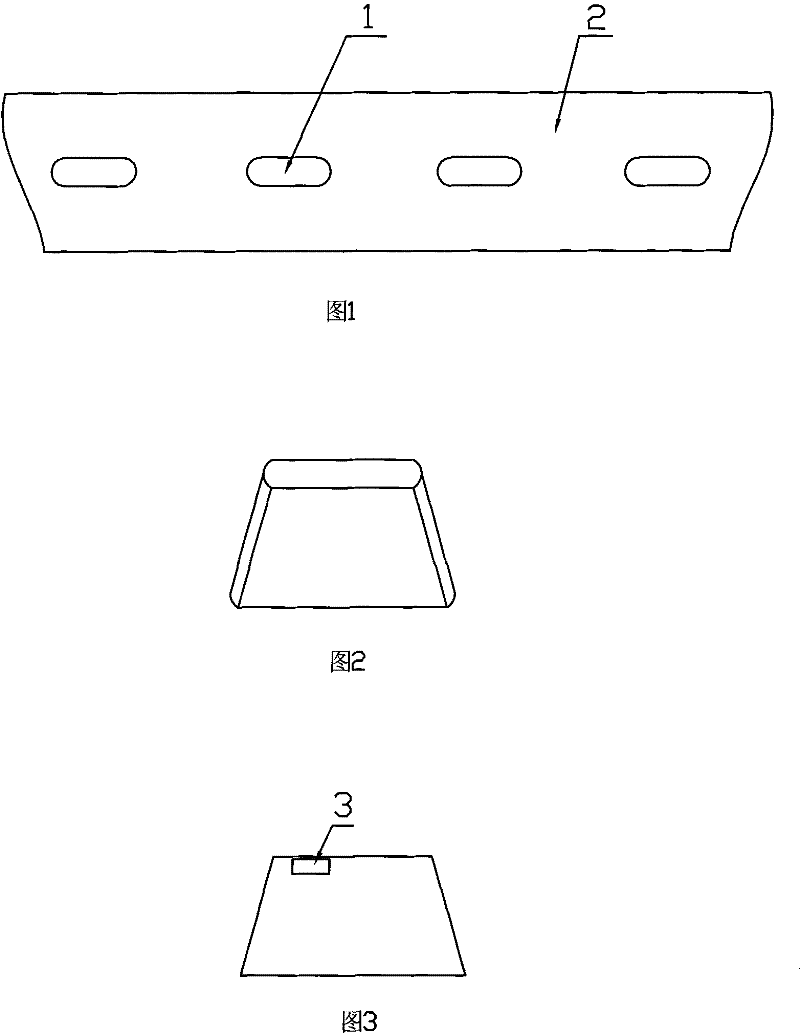

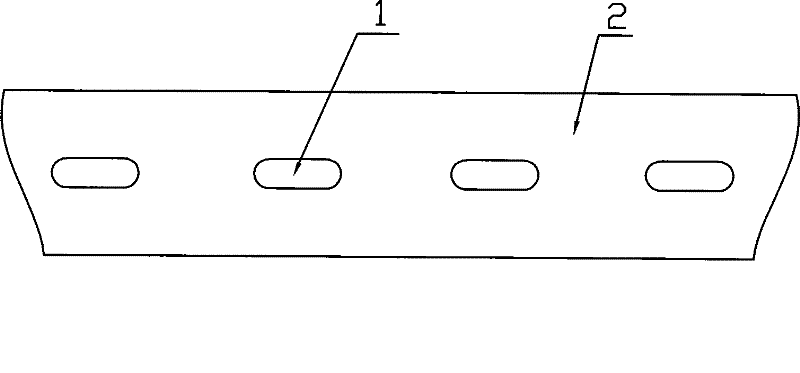

Method for forming grating for machine tool measurement in two-step solidifying rolling pressing forming manner

ActiveCN102193310ALow costIncrease productivityDiffraction gratingsPhotomechanical exposure apparatusStress concentrationGrating

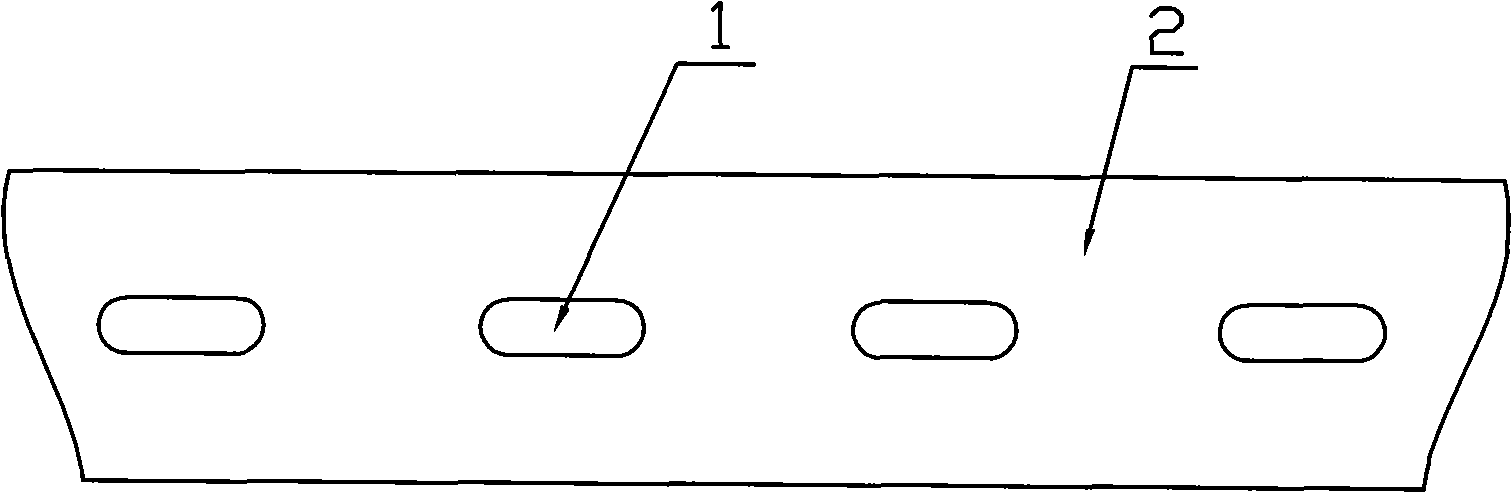

The invention relates to a method for forming a grating for machine tool measurement in a two-step solidifying rolling pressing forming manner, which comprises the following steps: 1) coating an ultraviolet light solidifying adhesive layer on a grating blank substrate; 2) manufacturing a rolling mould having a prototype grating structure on the surface of a cylindrical mould, making an alignment mark, and polishing and performing low surface energy treatment on the surface of the rolling mould; 3) coating a flexible film on the adhesive layer on the grating blank substrate, carrying out primary exposure and peeling the film; 4) comparing the alignment mark on the grating blank substrate with an acquired alignment mark image on the surface of the rolling mould, adjusting and calibrating; 5) gluing the rolling mould with the grating, applying a pressing force, and compounding the prototype grating structure on the surface of rolling mould on the adhesive layer on the surface of the substrate; 6) carrying out exposure on the compounded ultraviolet light solidifying adhesive layer; and 7) collecting and packaging the grating. According to the method, the required pressing force is small, and thus, the substrate deformation and stress concentration are avoided. The method has high production efficiency and can be used for realizing the mass production of the grating for large-area and altitude machine tool measurement.

Owner:XI AN JIAOTONG UNIV

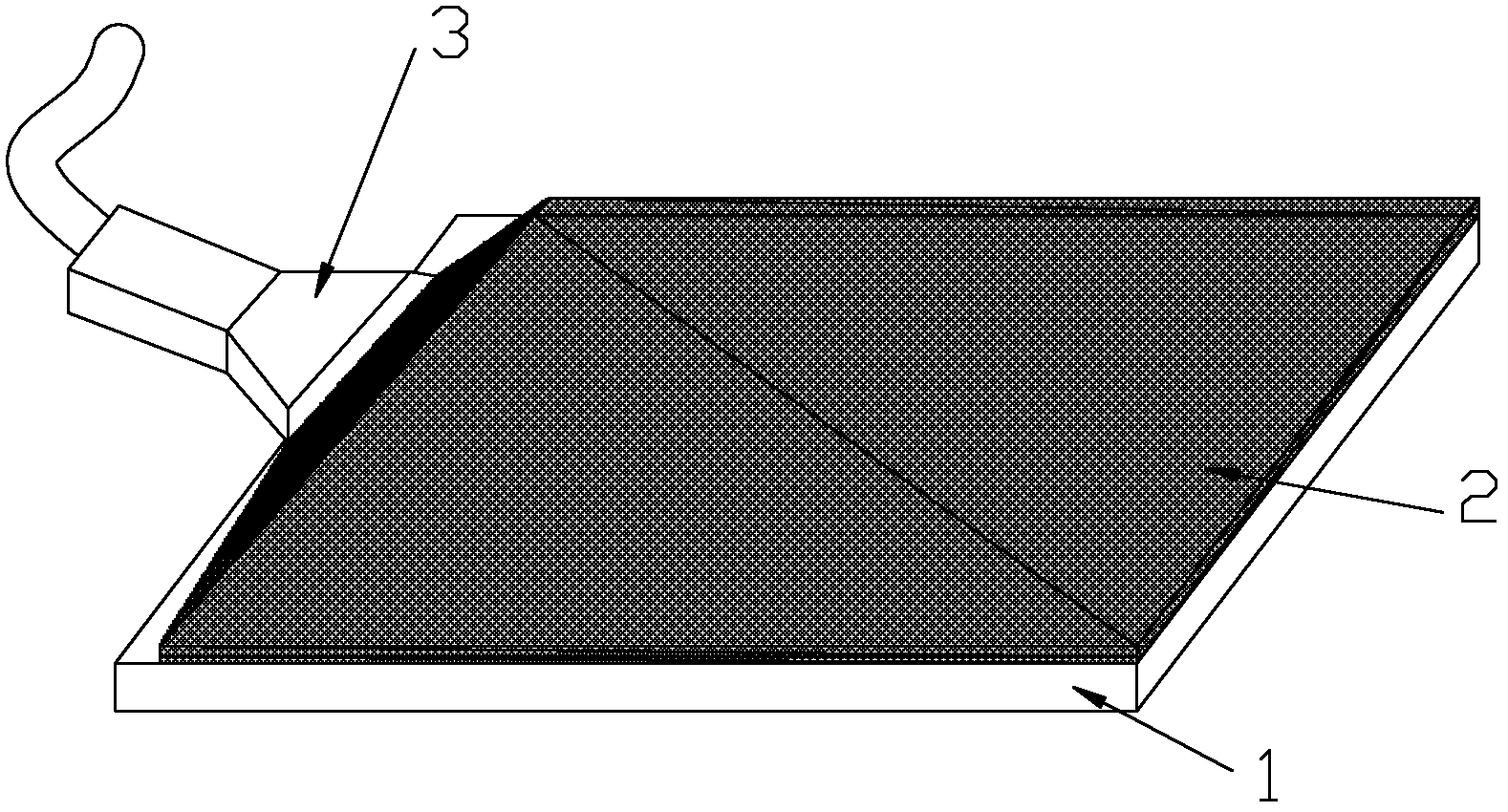

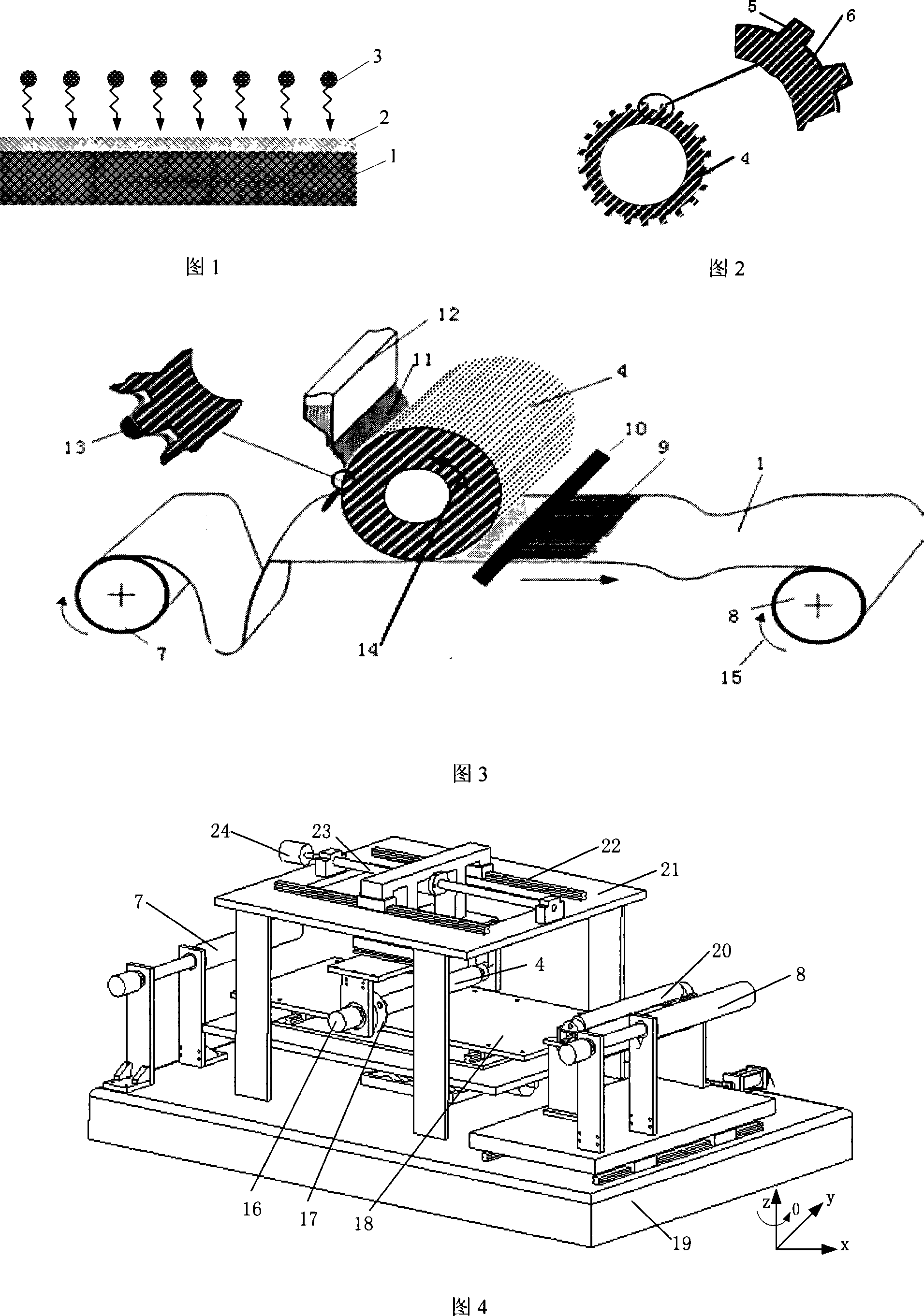

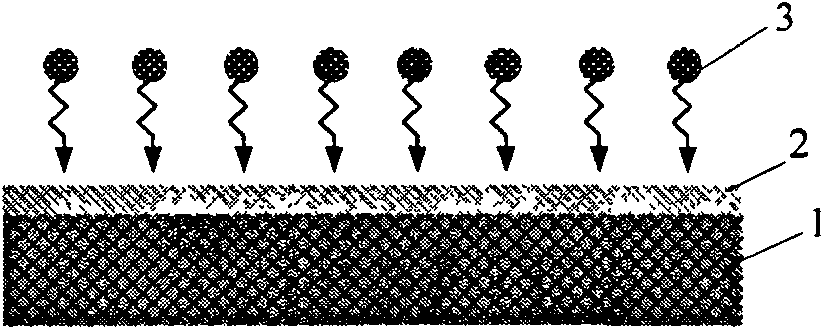

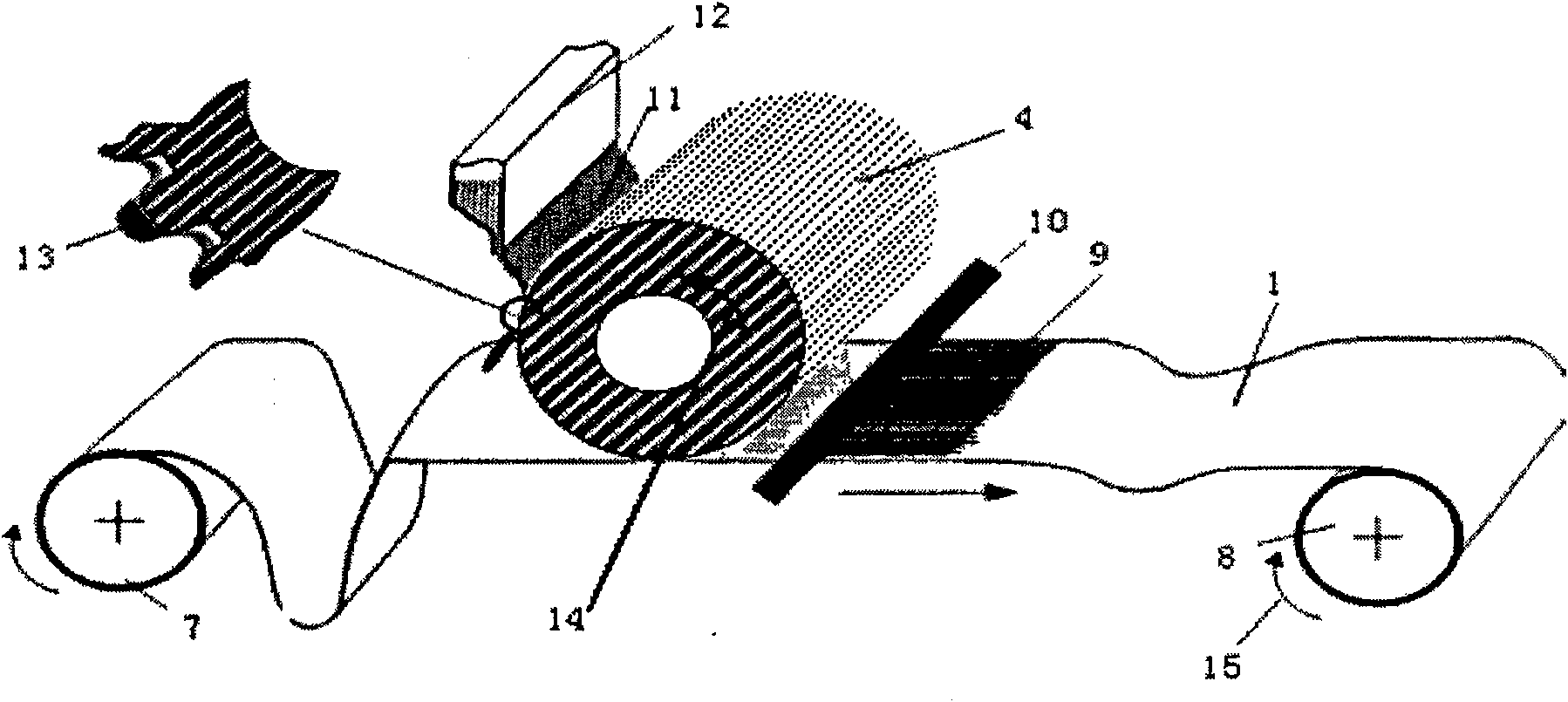

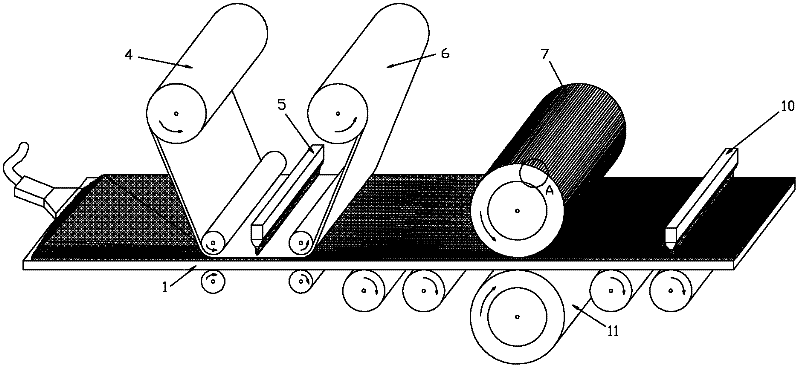

Large area reverse roller impression method for micro-structure of flexible base macroelectron manufacture

InactiveCN101168438AReduce in-plane deformationSmall thermal deformationSemi-permeable membranesSemiconductor/solid-state device manufacturingMicro structureStress concentration

The invention discloses a large-area reverse coil embossing shaping method for using flexible substrate and macro electron to produce middle micro structure. The invention uses reverse coil embossing technique, relative chromatograph aligning technique, and ultraviolet solidifying technique, to produce large-area three-dimension functional micro structure needed by macro electric appliance. The invention eliminates the left membrane in general embossing, to eliminate the additional process needed for treating left membrane. And the invention adds optical solidifier in electric functional material to solidify cold ultraviolet light source, thereby reducing the thermal deformation of flexible material. The invention has wide application in the productions of macro electron system as expandable large-size display, electric paper, OLED, film RFID, flexible solar sail, portable X-ray imager, portable radar, space solar power system, antenna device, and electromechanical intelligent cover adhered on the surface of arbitrary three-dimension structure.

Owner:XI AN JIAOTONG UNIV

Large area reverse roller impression method for micro-structure of flexible base macroelectron manufacture

InactiveCN100575243CReduce in-plane deformationSmall thermal deformationSemi-permeable membranesSemiconductor/solid-state device manufacturingUltraviolet lightsDisplay device

The invention discloses a large-area reverse coil embossing shaping method for using flexible substrate and macro electron to produce middle micro structure. The invention uses reverse coil embossing technique, relative chromatograph aligning technique, and ultraviolet solidifying technique, to produce large-area three-dimension functional micro structure needed by macro electric appliance. The invention eliminates the left membrane in general embossing, to eliminate the additional process needed for treating left membrane. And the invention adds optical solidifier in electric functional material to solidify cold ultraviolet light source, thereby reducing the thermal deformation of flexible material. The invention has wide application in the productions of macro electron system as expandable large-size display, electric paper, OLED, film RFID, flexible solar sail, portable X-ray imager, portable radar, space solar power system, antenna device, and electromechanical intelligent cover adhered on the surface of arbitrary three-dimension structure.

Owner:XI AN JIAOTONG UNIV

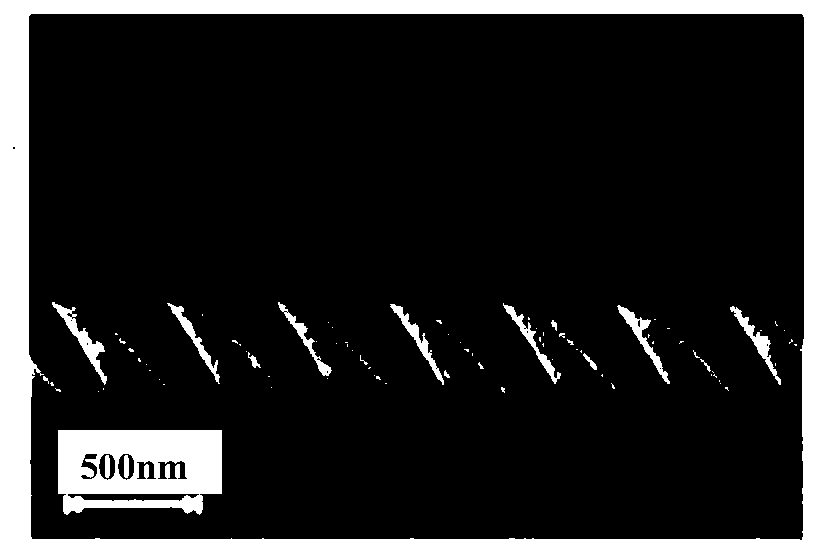

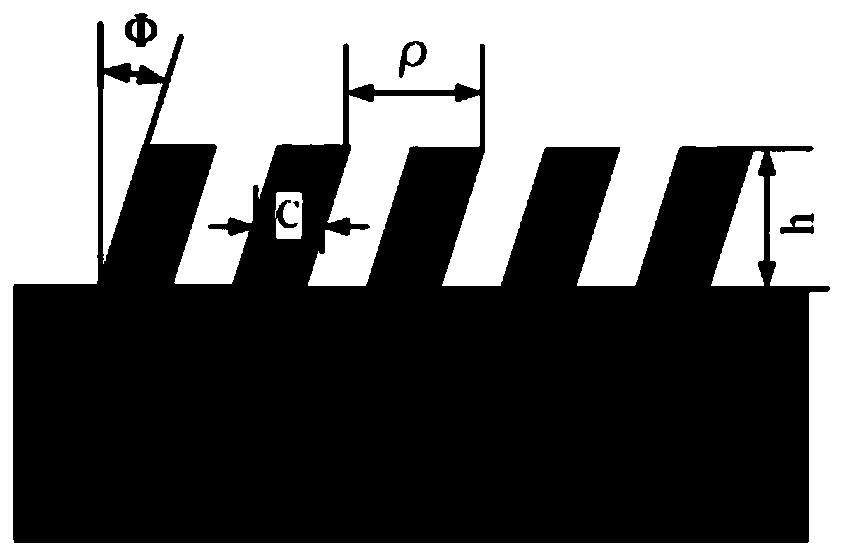

Method and equipment for batch production of AR diffracted optical waveguides

ActiveCN110927873AEnable Unconstrained ManufacturingRealize mass productionAdditive manufacturing apparatusPhotomechanical apparatusGratingEngineering

The invention provides a method and equipment for batch production of AR diffracted optical waveguides. According to the invention, low-cost batch production of large-area AR diffractive optical waveguides (surface embossment tilted gratings) in any shape can be realized, two-photon polymerization micro-nano 3D printing is adopted to achieve manufacturing of the tilted grating large-area mother set in any shape (on one hand, the problem of manufacturing of the tilted grating mother set in any shape is solved, on the other hand, direct manufacturing of the large-size wafer-level mother set canbe achieved, and the advantages of being low in manufacturing cost and high in production efficiency are further achieved). By adopting a composite nanoimprint lithography technology (combining with an imprint special suitable for an inclined grating imprint process and a composite soft mold), the problem that an inclined grating with a large inclination angle and a large groove depth cannot be manufactured due to the fact that demolding cannot be conducted is solved, and unconstrained (geometrical shape and size) manufacturing of the inclined grating is achieved.

Owner:QINGDAO 5D INTELLIGENT ADDITIVE MFG TECH CO LTD

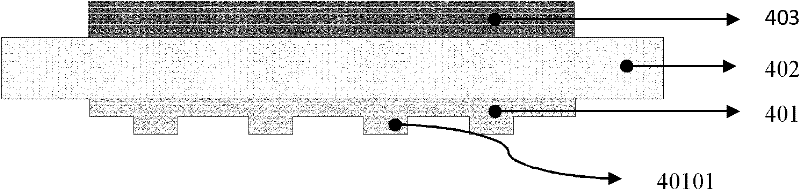

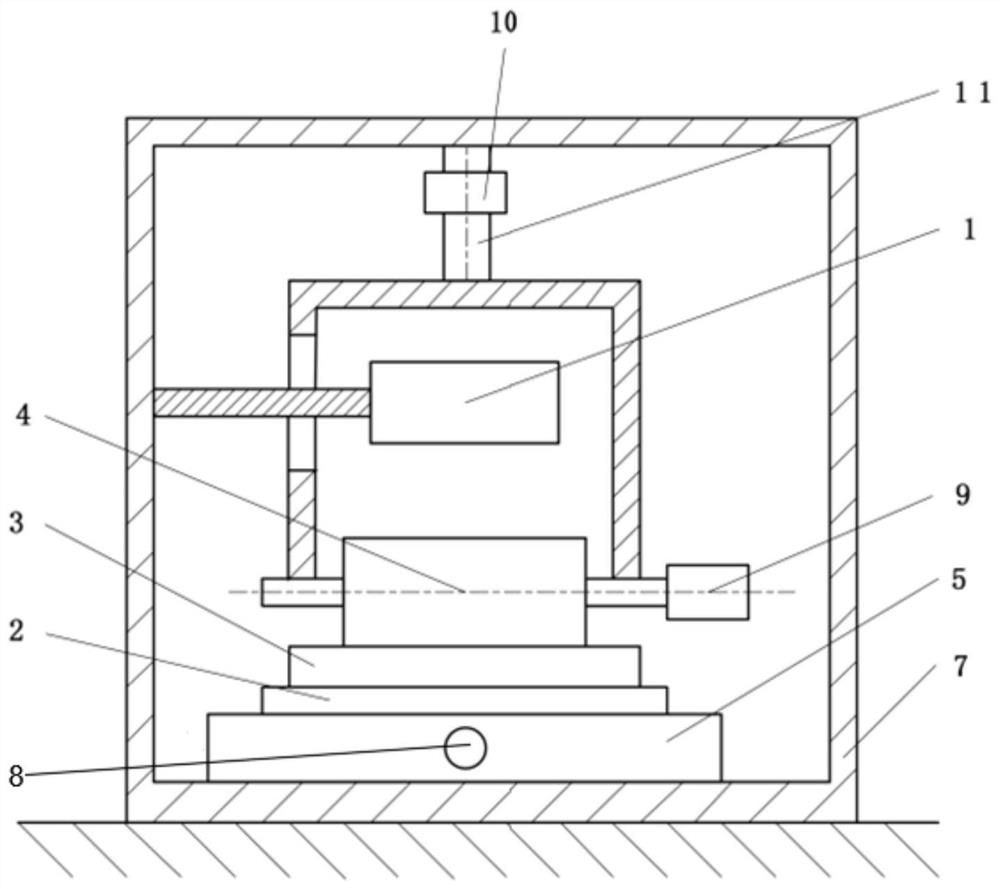

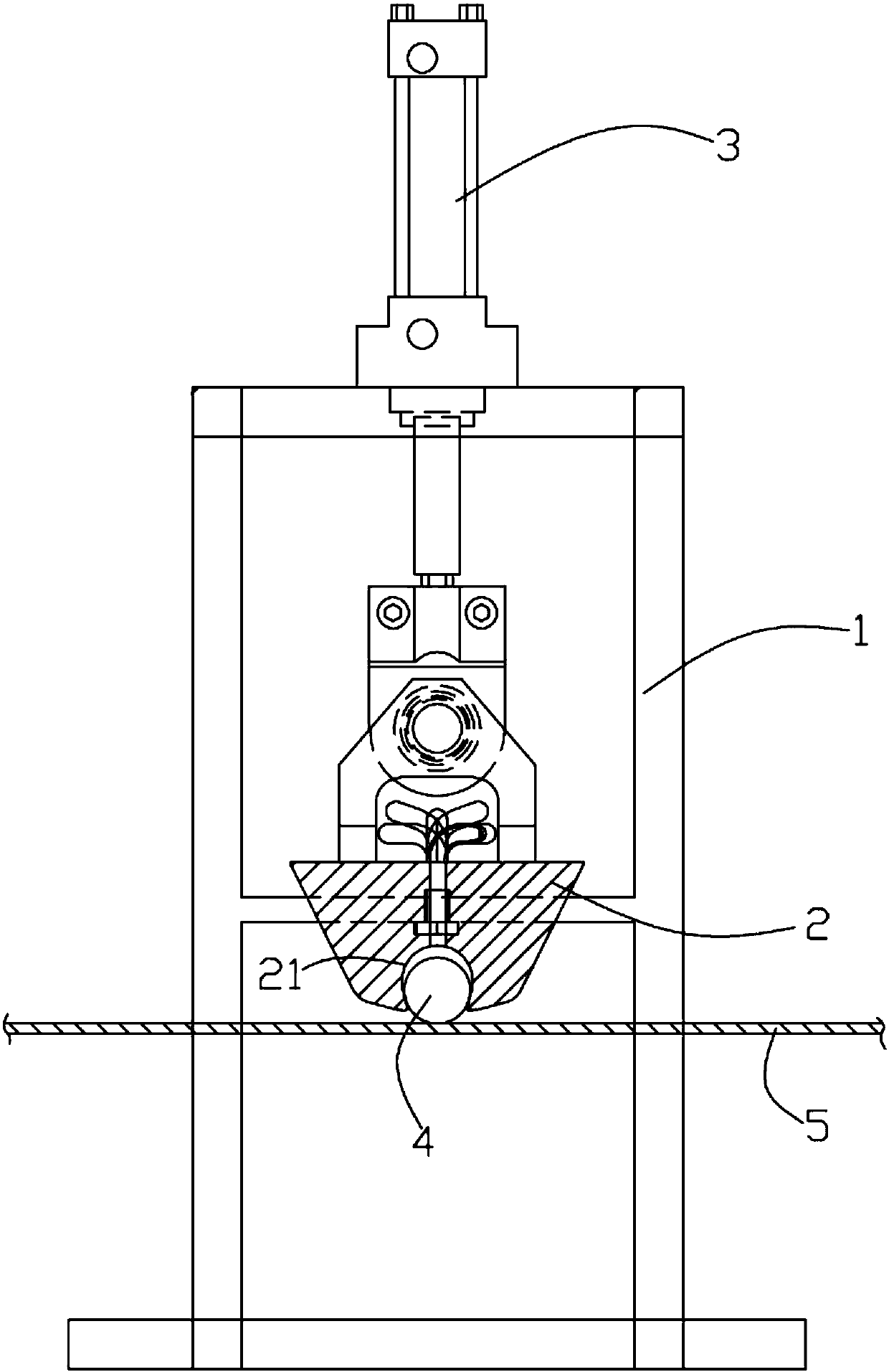

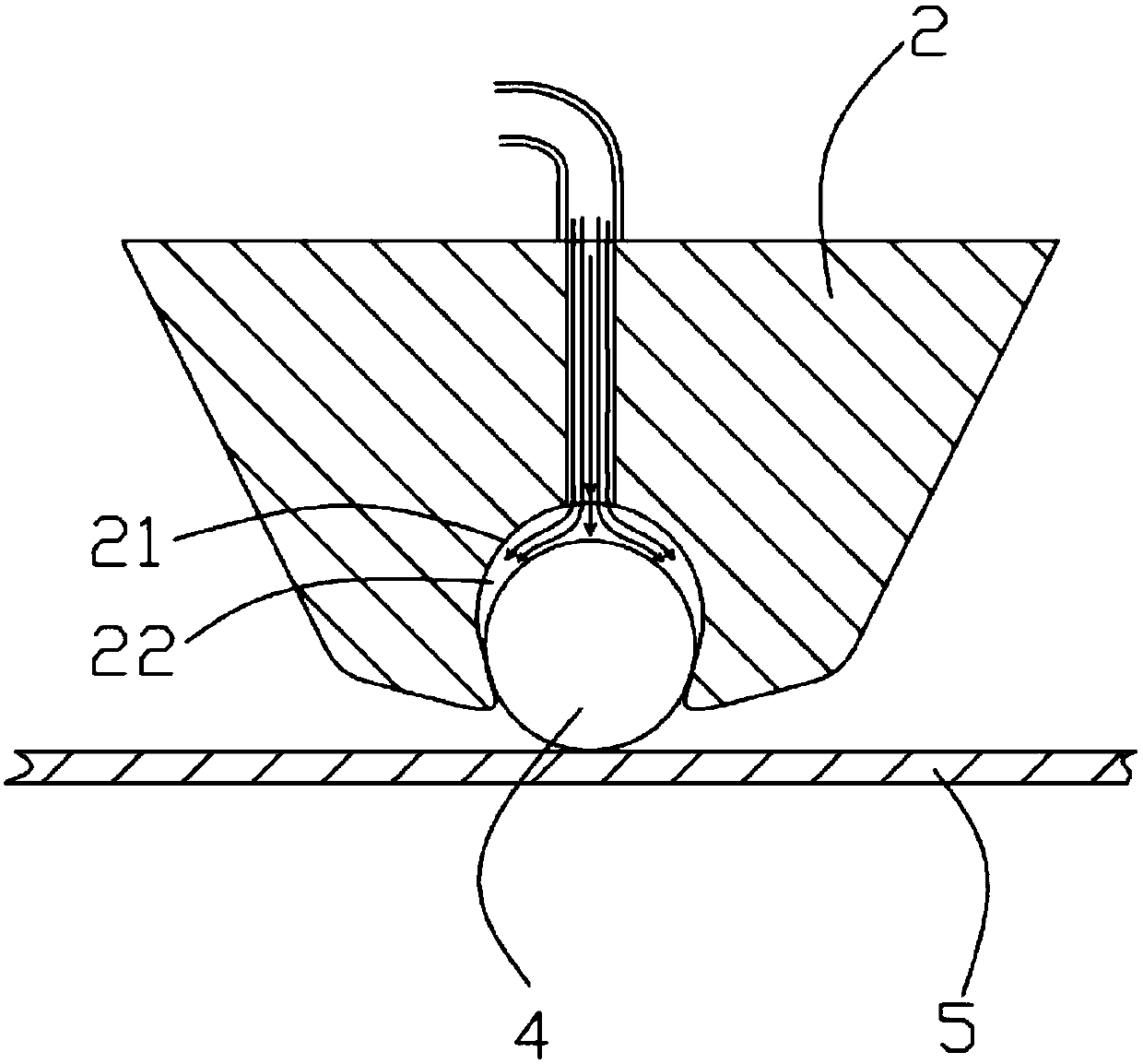

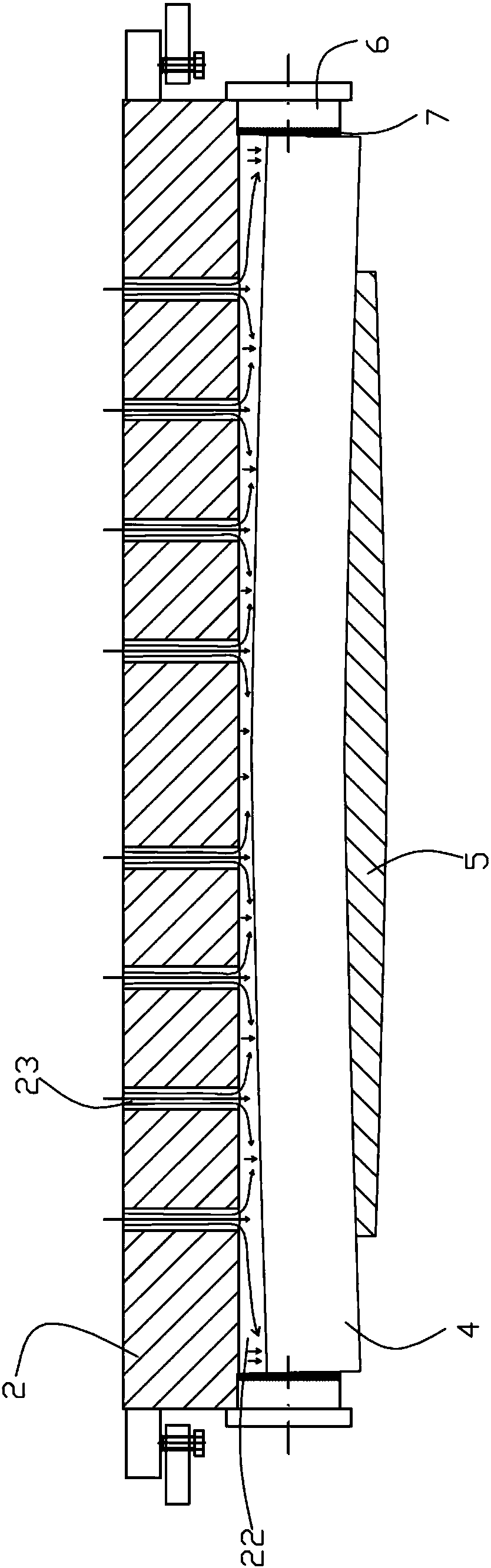

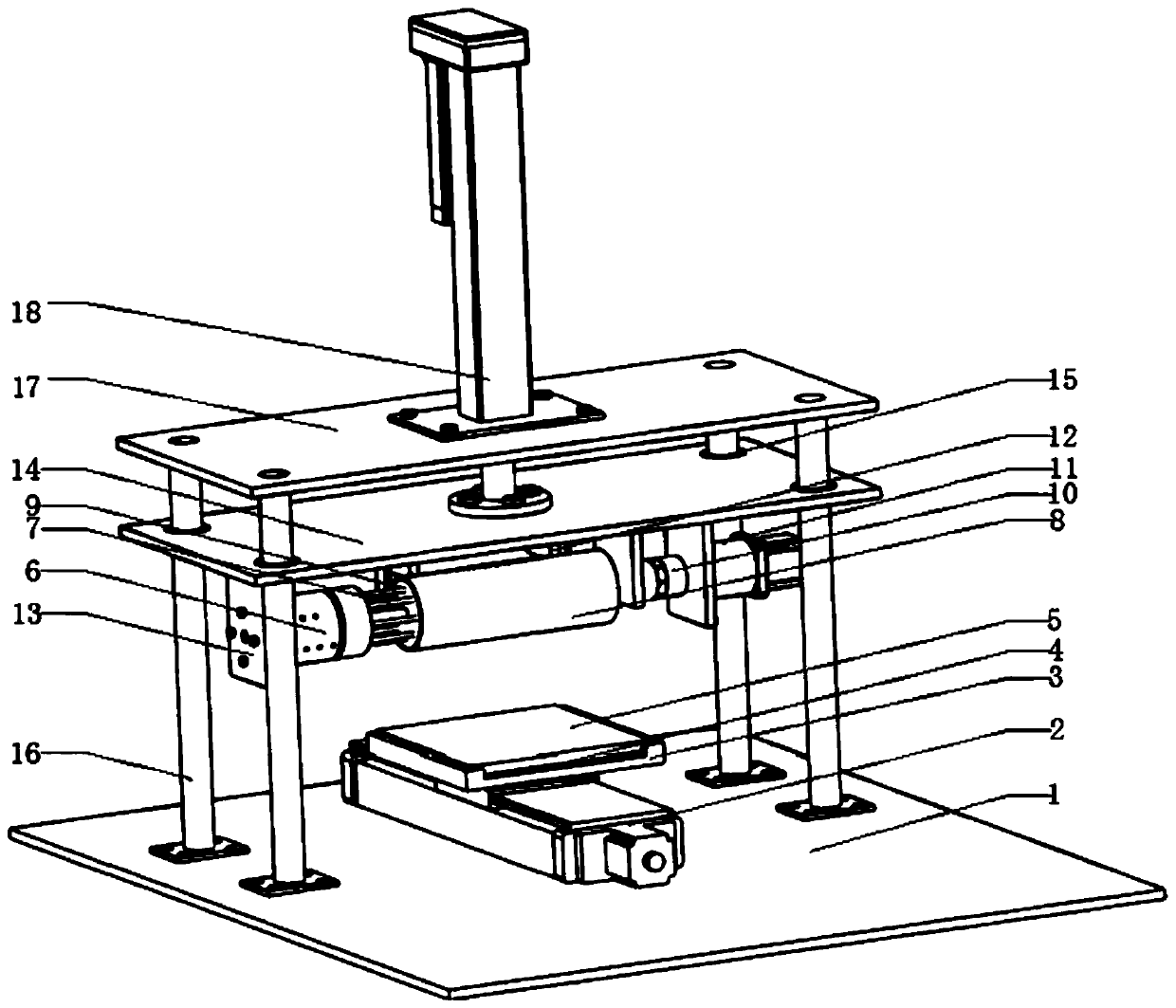

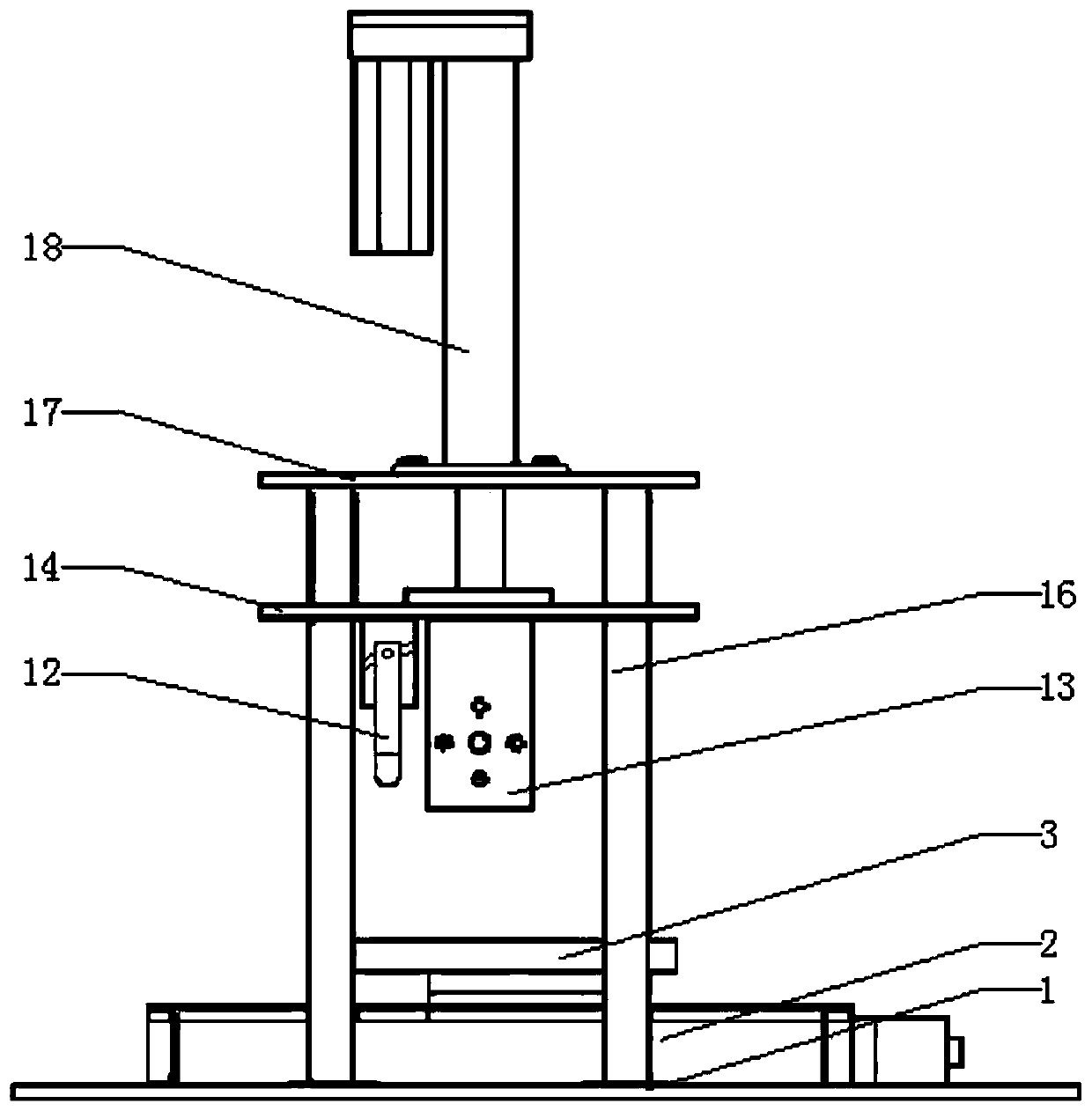

Device and method for nanoimprinting of full wafer

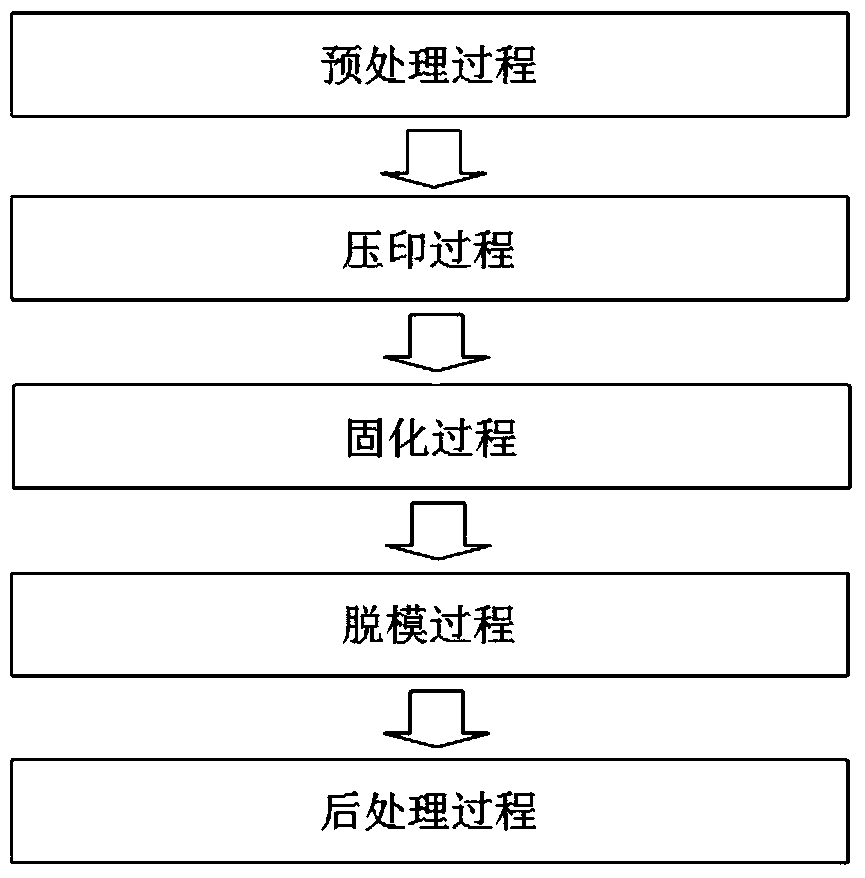

ActiveCN102096315BNo tensile deformationReduce local deformationPhotomechanical apparatusResistUltraviolet lights

The invention relates to a device and a method for nanoimprinting of a full wafer, comprising a working platform, a full wafer coated with an etchant resist, a nozzle for demoulding, a template, an imprinting head, a pressure pipeline, a vacuum pipeline and an ultraviolet light source, wherein the template is fixed on the bottom surface of the imprinting head; the side surface on the lower part of the template is equipped with the nozzle for demoulding; the pressure pipeline and the vacuum pipeline are connected to air inlet holes which are arranged on two side surfaces of the working platform of the imprinting head; the full wafer coated with the etchant resist is fixed on a wafer working platform; and the ultraviolet light source is arranged over the imprinting head. The method providedby the invention comprises the following steps of: 1) pre-treating process; 2) imprinting process; 3) curing process; and 4) demoulding process. The device and the method for nanoimprinting of the full wafer provided by the invention have the characteristics that the structure is simple, the cost is low, the production efficiency is high, the accuracy is high, the imprinting area is large, and the suitability for the batch production and the imprinting of the full uneven wafer can be obtained. The device and the method can be applied to the large-scale manufacturing of high-density disc, micro-optic device and micro-fluidic device and the like, and the device and the method are particularly suitable for the imaging of the full wafer of a photonic crystal LED (Light Emitting Diode).

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

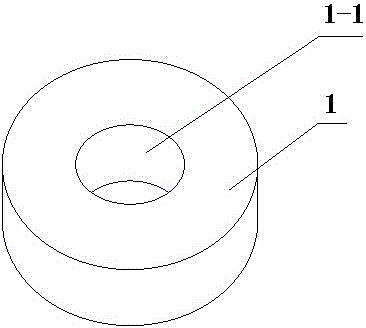

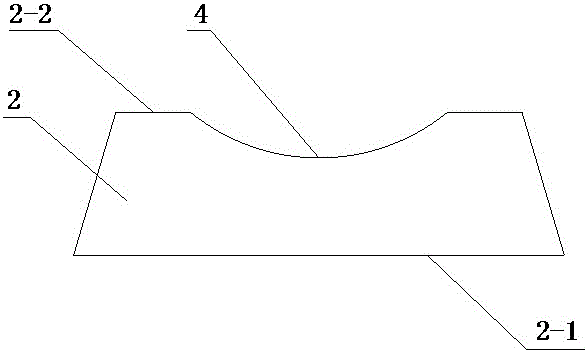

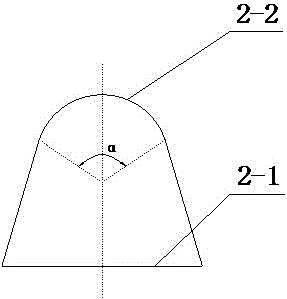

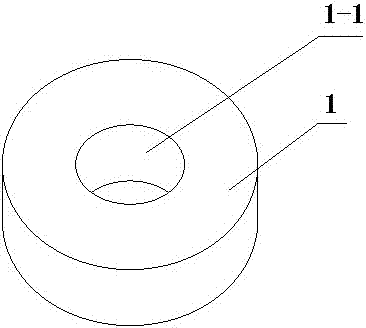

Combined type body posture pad for operation

InactiveCN106063756ASimple postoperative careImprove satisfactionOperating tablesMedical transportPhysical medicine and rehabilitationBody posture

The invention provides a combined type body posture pad for operation, and belongs to a body posture fixing device. The combined type body posture pad for operation comprises a head fixing member, a cervical vertebra holder and a shoulder pad, wherein the head fixing member, the cervical vertebra holder and the shoulder pad are made of polyurethane gel, the head fixing member if of a circular shape, the hollow part of the head fixing member corresponds to a cranium occipitalia, the bottom of the cervical vertebra holder is planer, the top of the cervical vertebra holder is of a cambered surface, a concave holding surface is arranged on the top center of the cervical vertebra holder, and the shoulder pad is cylindrical. An aseptic cover is arranged on the external of each of the head fixing member, the cervical vertebra holder and the shoulder pad. The combined type body posture pad, when used in a body posture placing process for an anterior cervical operation, has the advantages of being convenient for use, being firm for fixing a neck portion and being light in skin compression. The comfort level and operation convenience for a surgeon are improved.

Owner:漯河医学高等专科学校第一附属医院

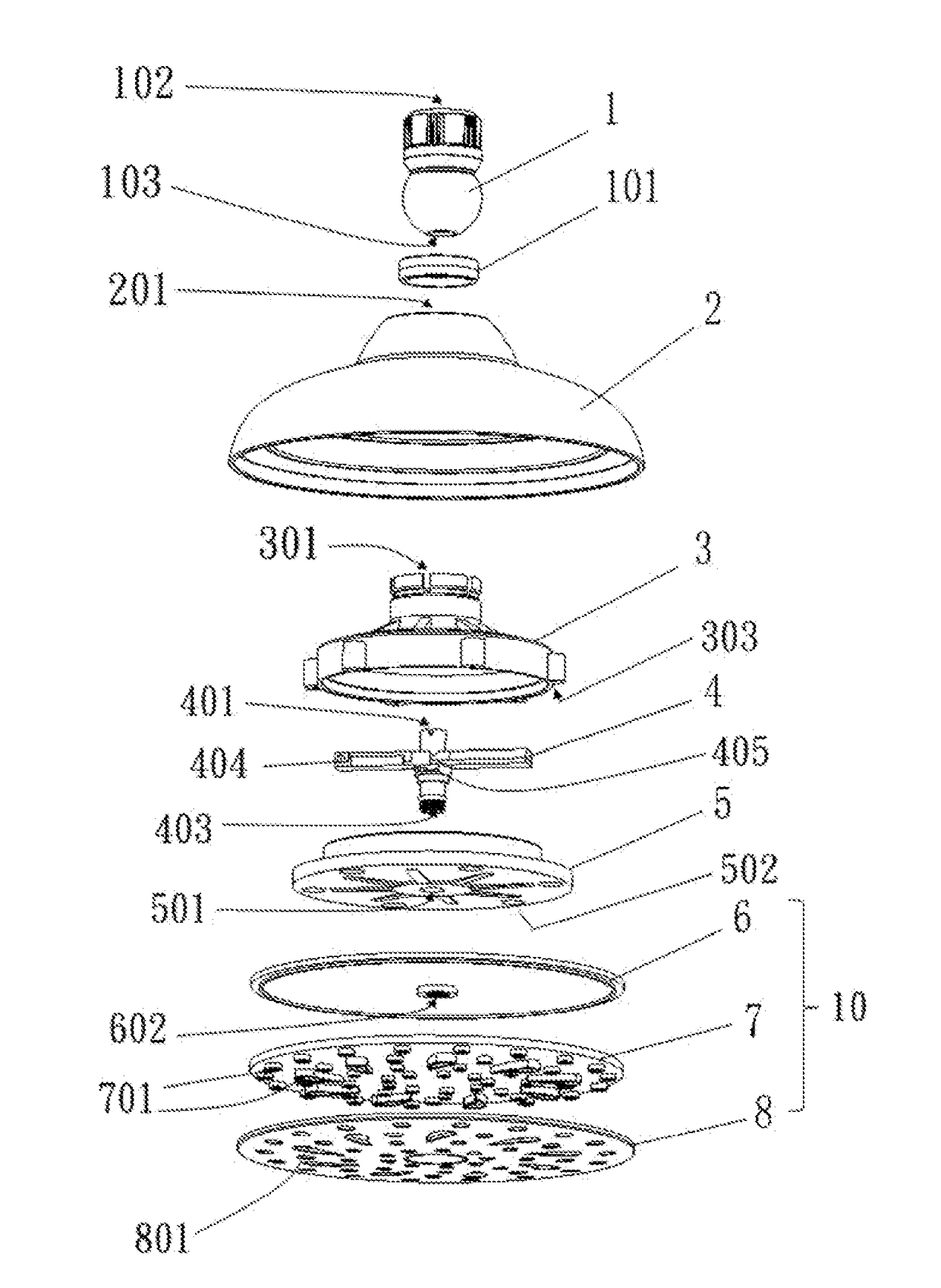

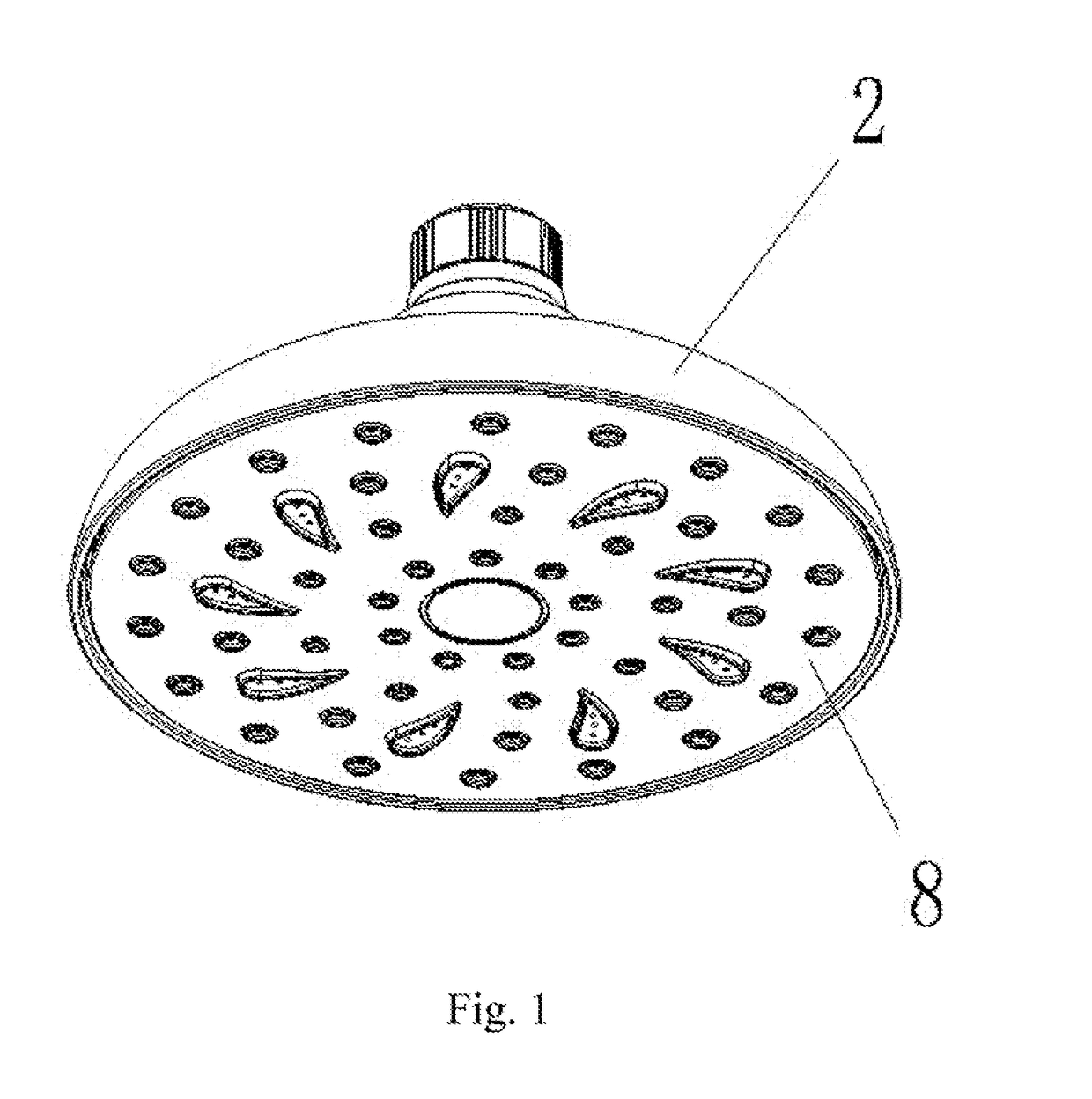

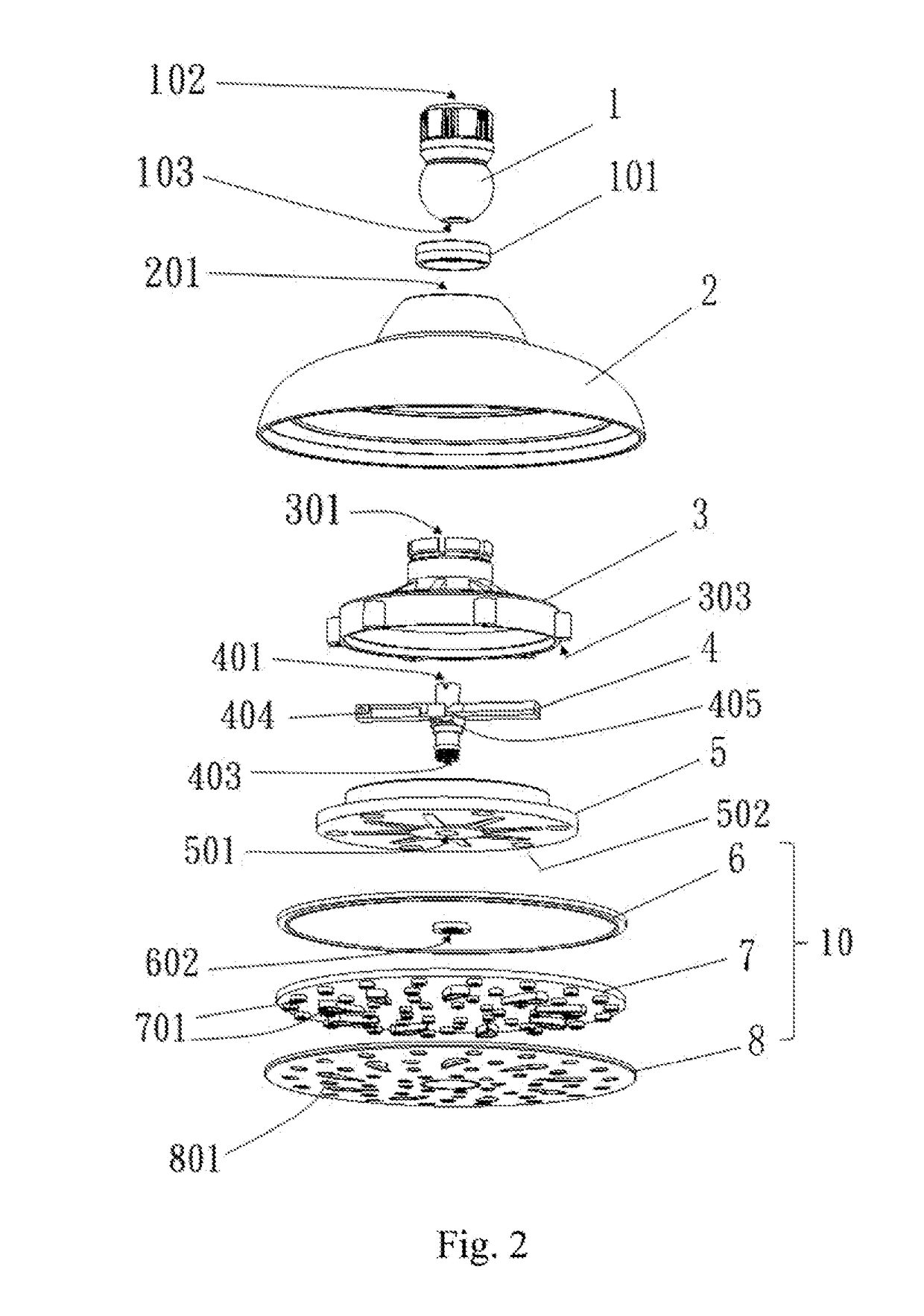

Shower head with a rotary bottom cover assembly

InactiveUS20170087565A1Long life spanSmall pressureMovable spraying apparatusSpray nozzlesEngineeringStructural engineering

A shower head with rotary bottom cover assembly includes a water passage member with a third inlet and an outlet chamber communicating with each other, a rotator mounted inside the outlet chamber and having a first rotator inlet, a first outlet and a diverting channel, a rotator cover, a bottom cover assembly. The first rotator inlet is mounted inside the third inlet of the water passage member and communicates with a center portion of the diverting channel. The diverting channel has two second outlets formed on two ends thereof and oppositely located. The rotator cover hermetically covers and seals the outlet chamber and has a hole for an outlet hose to be mounted through. A top of the outlet hose is connected with the center portion of the diverting channel. A bottom of the outlet hose engages the bottom cover assembly. The water head is structurally simple and has massaging effect.

Owner:RUNNER XIAMEN CORP

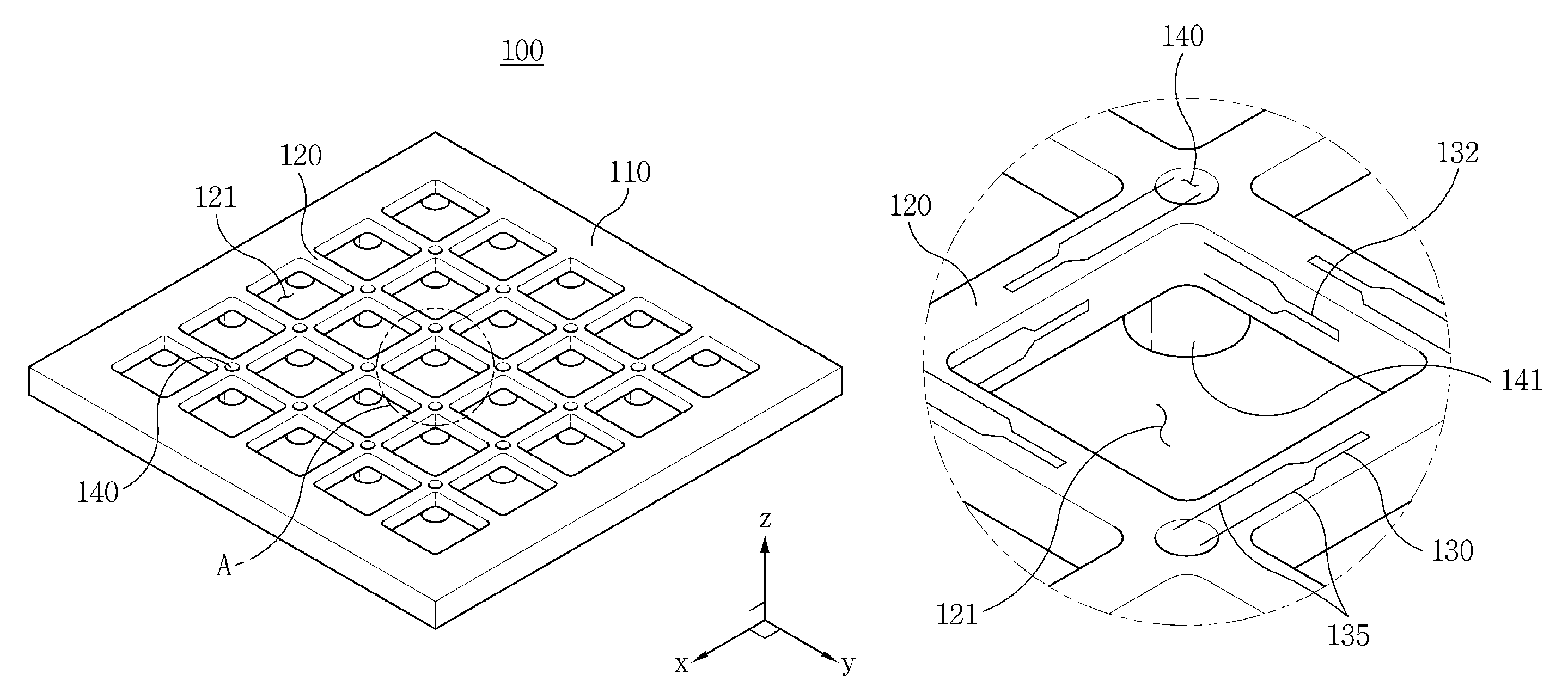

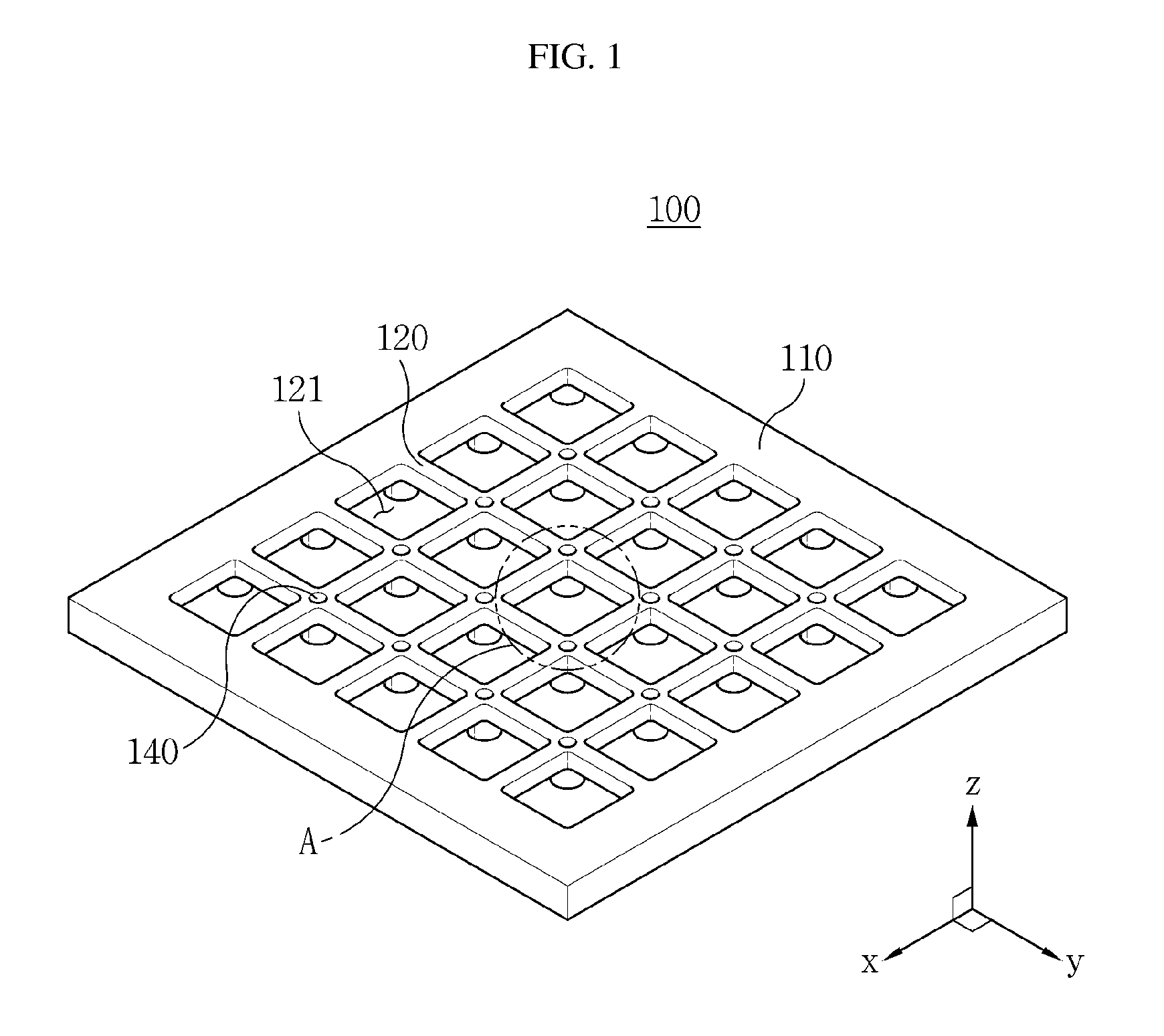

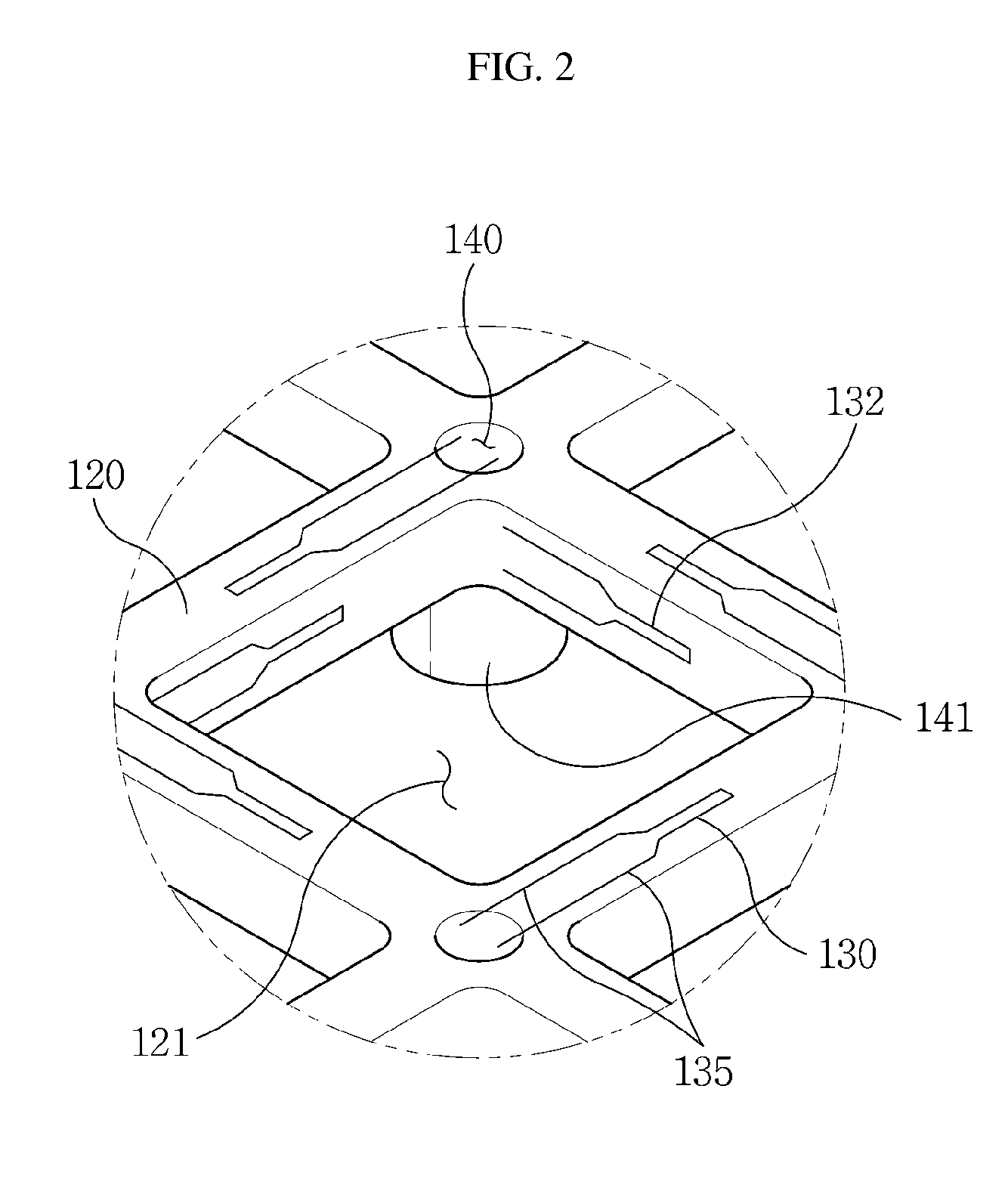

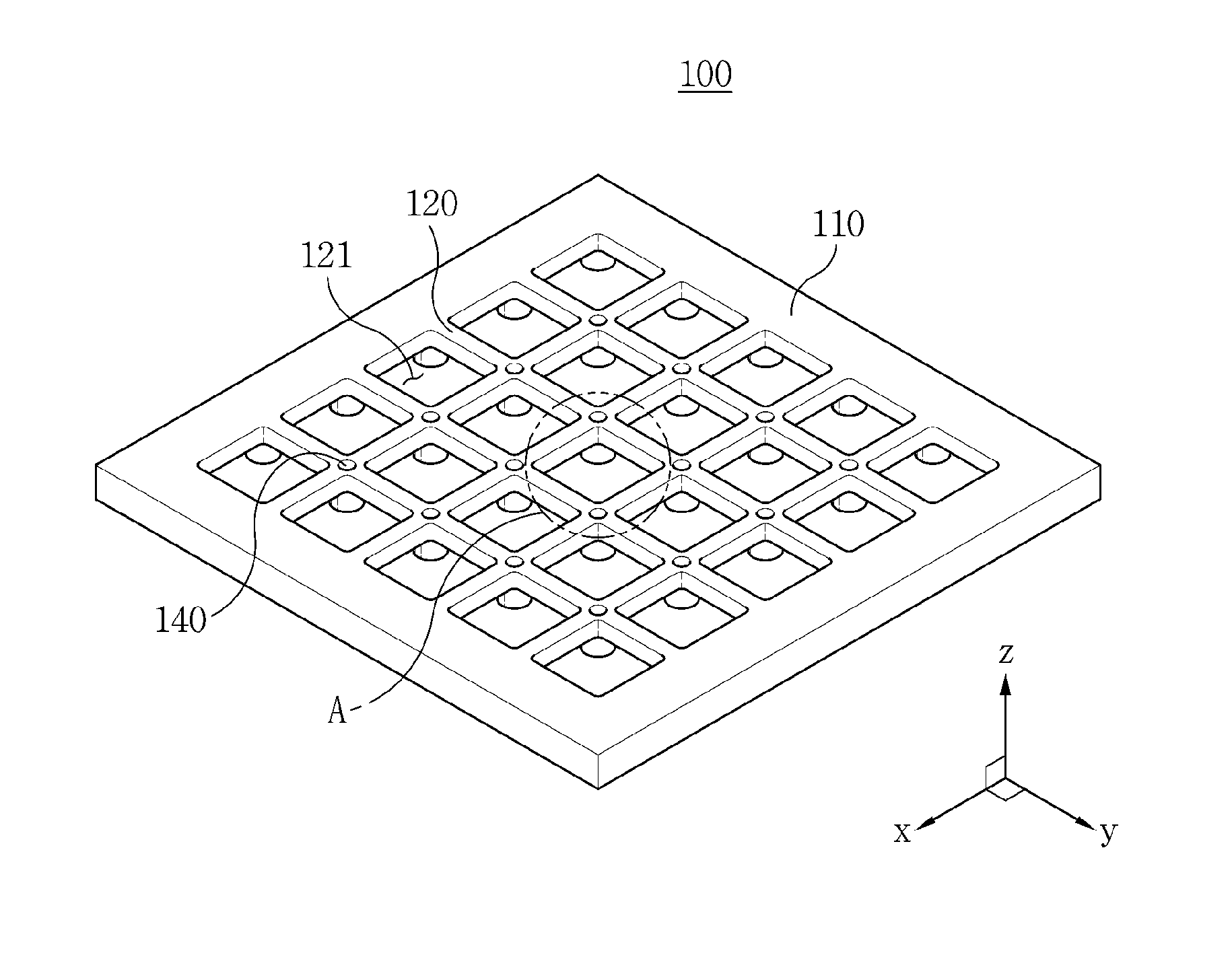

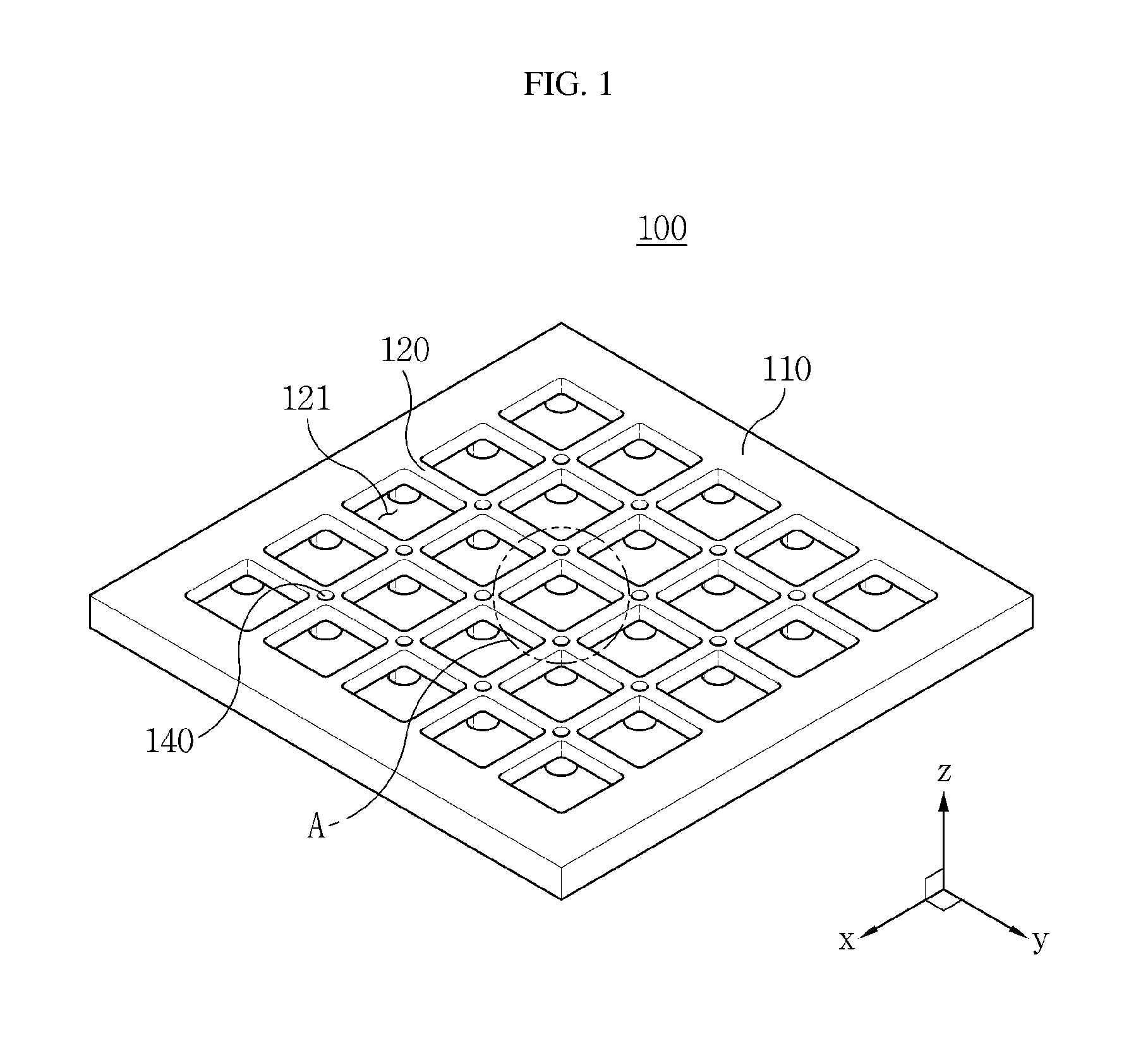

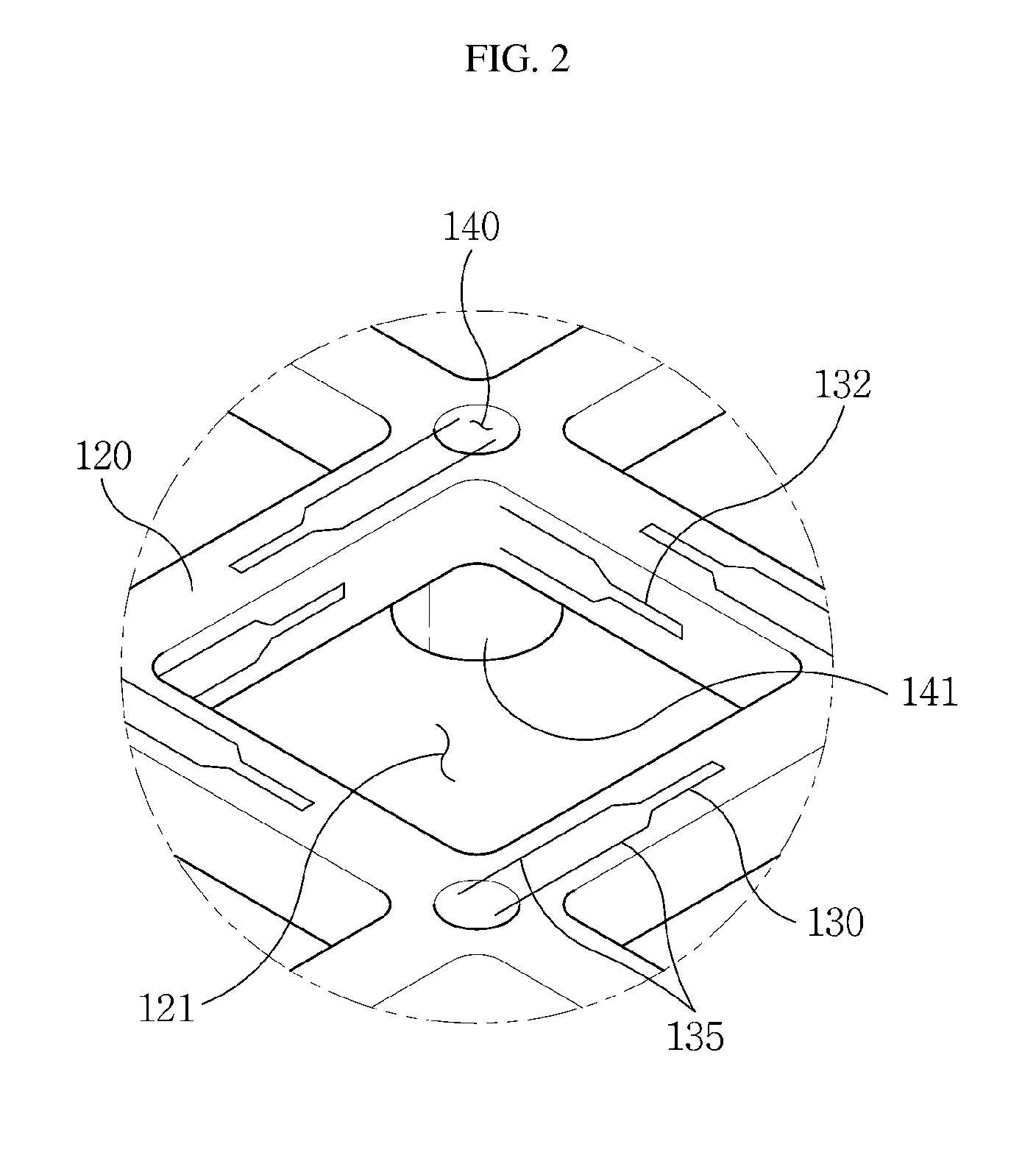

Deformation measurement sensor for measuring pressure and shearing force and structure therefor

ActiveUS9441941B2Accurate measurementSmall sizeForce measurement using piezo-resistive materialsElectrical/magnetic solid deformation measurementEngineeringStrain gauge

A deformation measurement sensor for measuring pressures and shearing forces according to the present invention includes: a plurality of beams shaped like a lattice; a strain gauge attached to each of the plurality of beams for measuring a deformation rate; a frame connected to the end of the lattice shape for surrounding the plurality of beams; and holes for arranging lines and formed in the intersections of the plurality of beams, whereby it is possible to precisely measure the deformation rate depending on the pressures or shearing forces exerted to a plurality of areas.

Owner:KOREA ELECTRONICS TECH INST

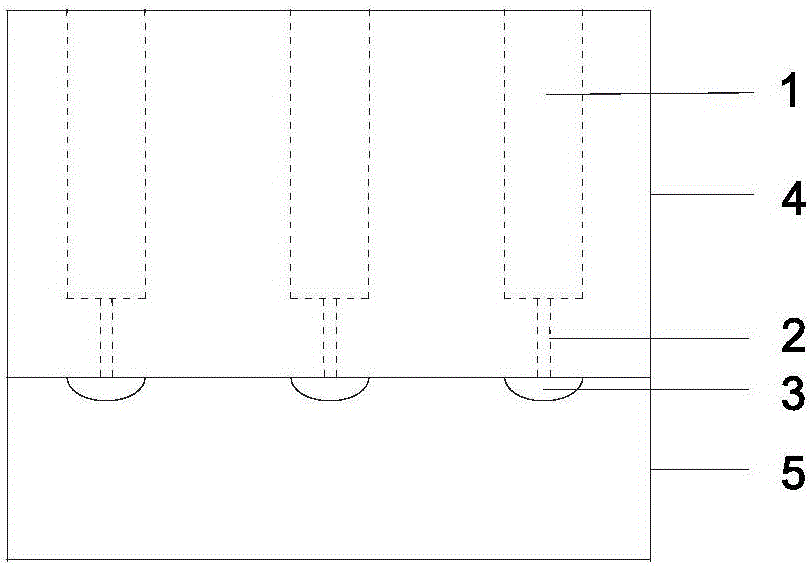

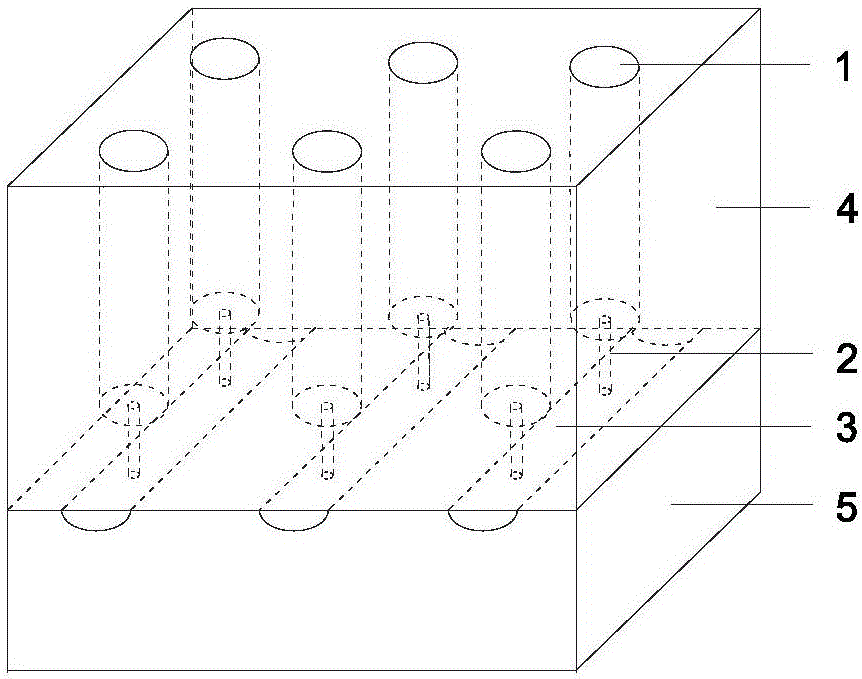

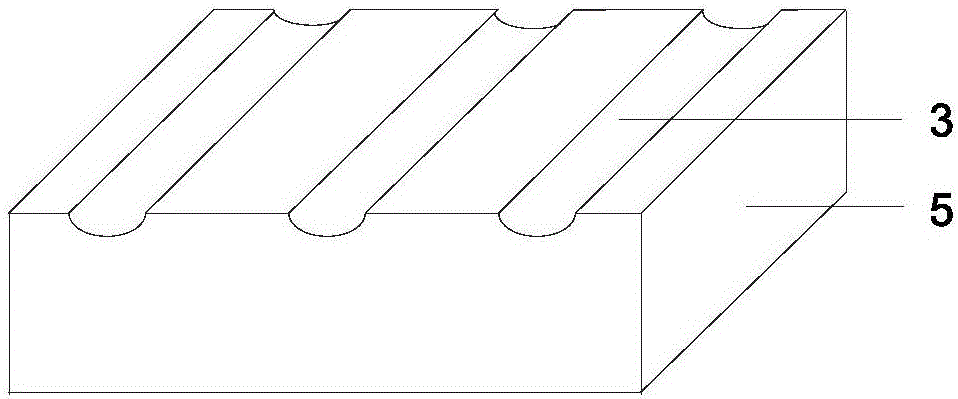

Cavity type structured nano imprinting template and imprinting forming method therefor

ActiveCN106371286AValid entryEffectively guaranteed entryPhotomechanical apparatusNanotechnologyAdhesiveEngineering

The invention discloses a cavity type structured nano imprinting template and an imprinting forming method therefor. The cavity type structured nano imprinting template adopts an integrated structure, and comprises an upper template and a lower template which are welded together, wherein multiple thorough stepped holes are uniformly formed in the upper template; multiple trenches are uniformly formed in the lower template; and the two ends of the trenches are connected with an external high-pressure water pump and a vacuum pump through pipelines. According to the cavity type structured nano imprinting template, a sealed hollow cavity is additionally formed in the template, so that negative pressure is formed by vacuumizing the cavity of the template in the imprinting process; and in a demolding process, cracks are generated on the interface of the template and imprinting adhesive through water pressure, and then the cracks extend to the overall combination interface to complete the demolding. Compared with the prior art, the cavity type structured nano imprinting template has the beneficial effects of simple and convenient operation, low required pressure for imprinting, good forming quality and the like, so that the cavity type structured nano imprinting template is suitable for forming a normal imprinting structure and particularly suitable for forming an imprinting structure with high aspect ratio.

Owner:SHANDONG UNIV OF SCI & TECH

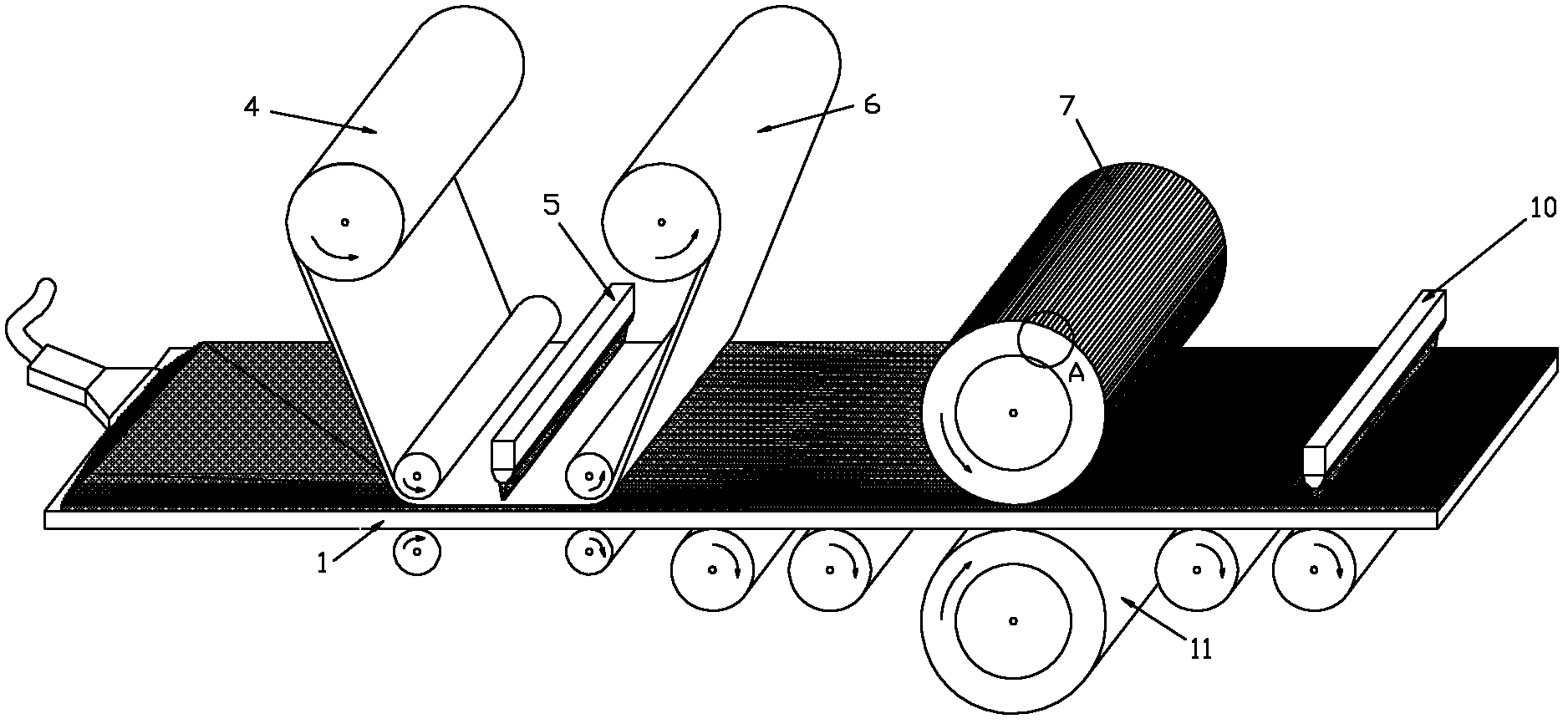

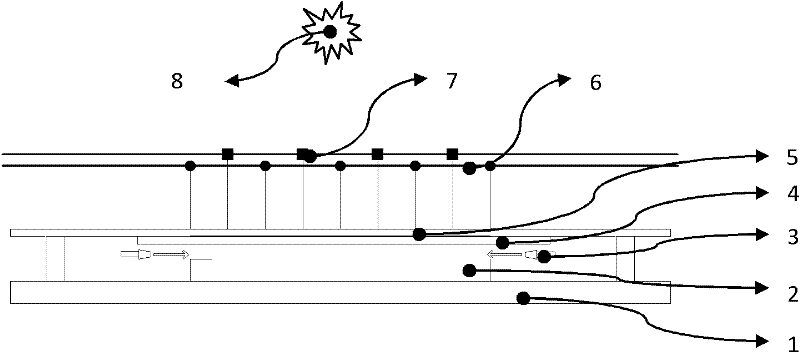

Laser heating roller type micro-imprinting device

The invention discloses a laser heating roller type micro-imprinting device. The laser heating roller type micro-imprinting device comprises a frame, a supporting and conveying mechanism, a laser device, a transparent mold, a transparent roller and a rolling gap adjusting mechanism; the transparent roller is rotatably arranged at the lower end of the rolling gap adjusting mechanism; the laser device is arranged above the transparent roller; a central rotating shaft of the transparent roller and the conveying direction of the supporting and conveying mechanism are perpendicular to each other; the transparent roller acts on the surface of the transparent mold; a rolling gap is formed between the transparent mold and the supporting and conveying mechanism; materials are placed at the rollinggap; and laser beams emitted by the laser device sequentially pass through the transparent roller and the transparent mold to act on the materials. According to the laser heating roller type micro-imprinting device, impressing force is reduced through the near-linear contact between the transparent roller, the transparent mold and the materials, the molding stability and the molding precision of the materials are improved by adopting a laser non-contact mode to heat micro-forming areas on the surfaces of the materials; and a traditional rolling process is combined with a plane impressing process, and the imprinting efficiency is improved.

Owner:NANJING VOCATIONAL UNIV OF IND TECH

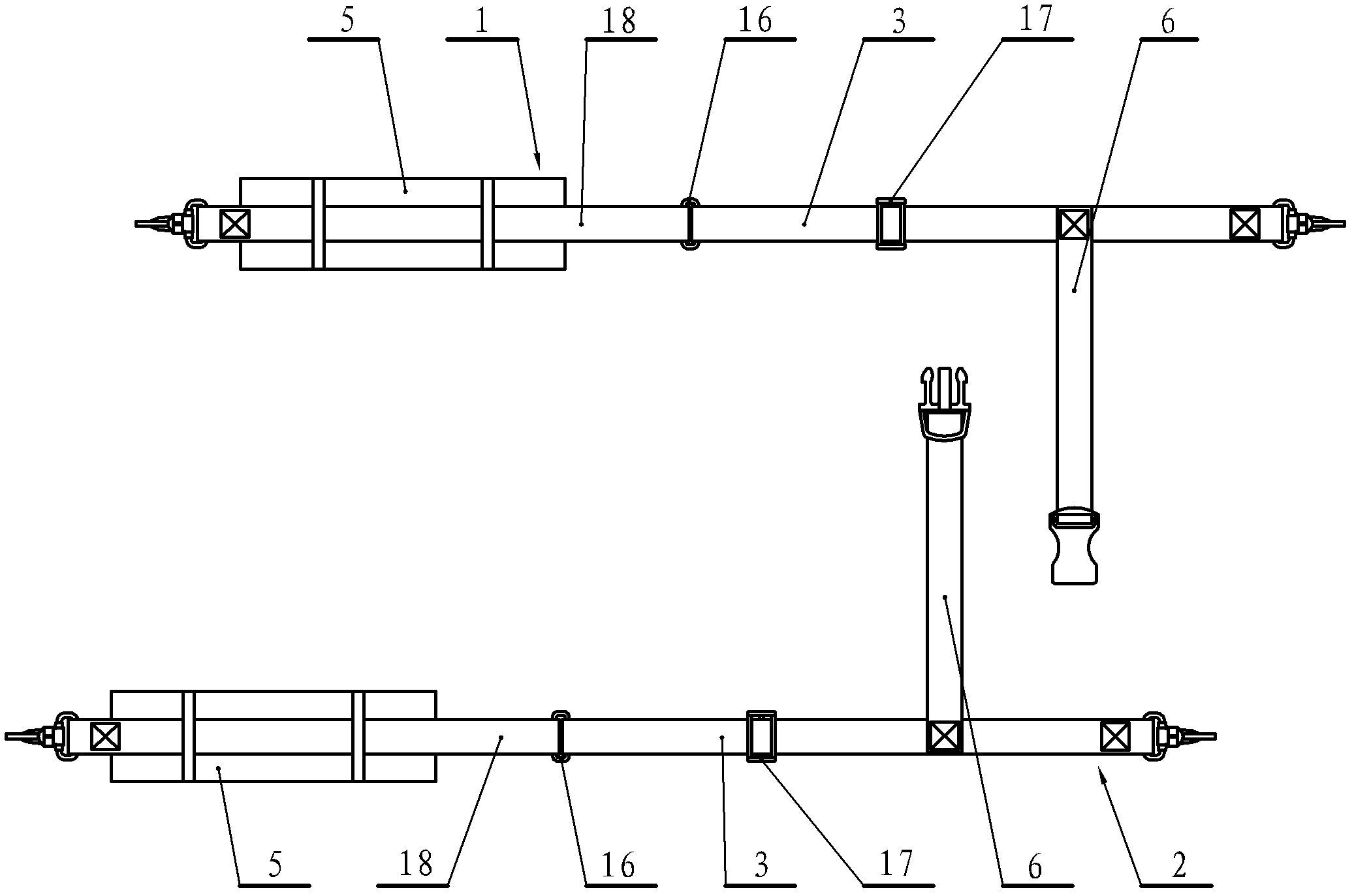

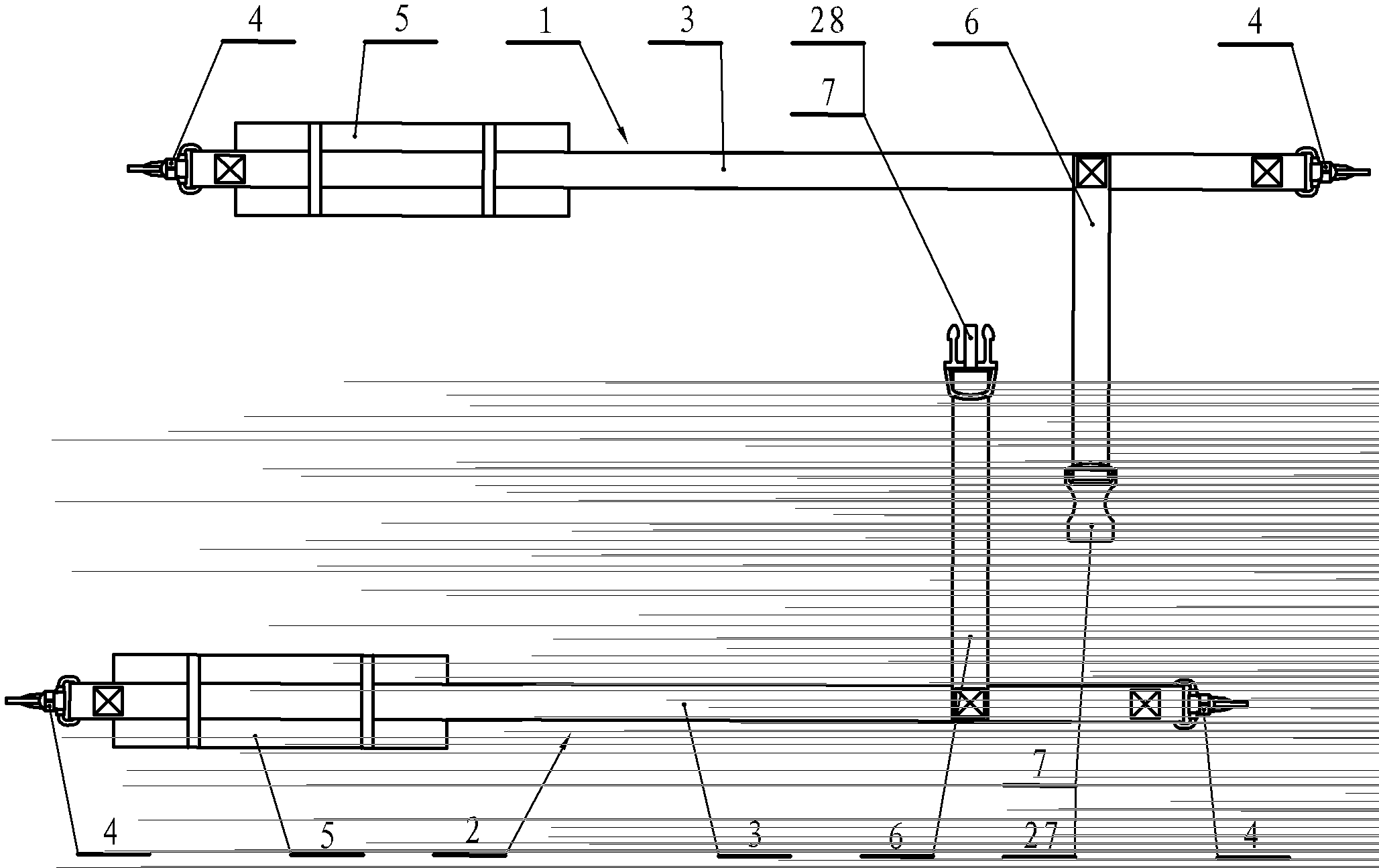

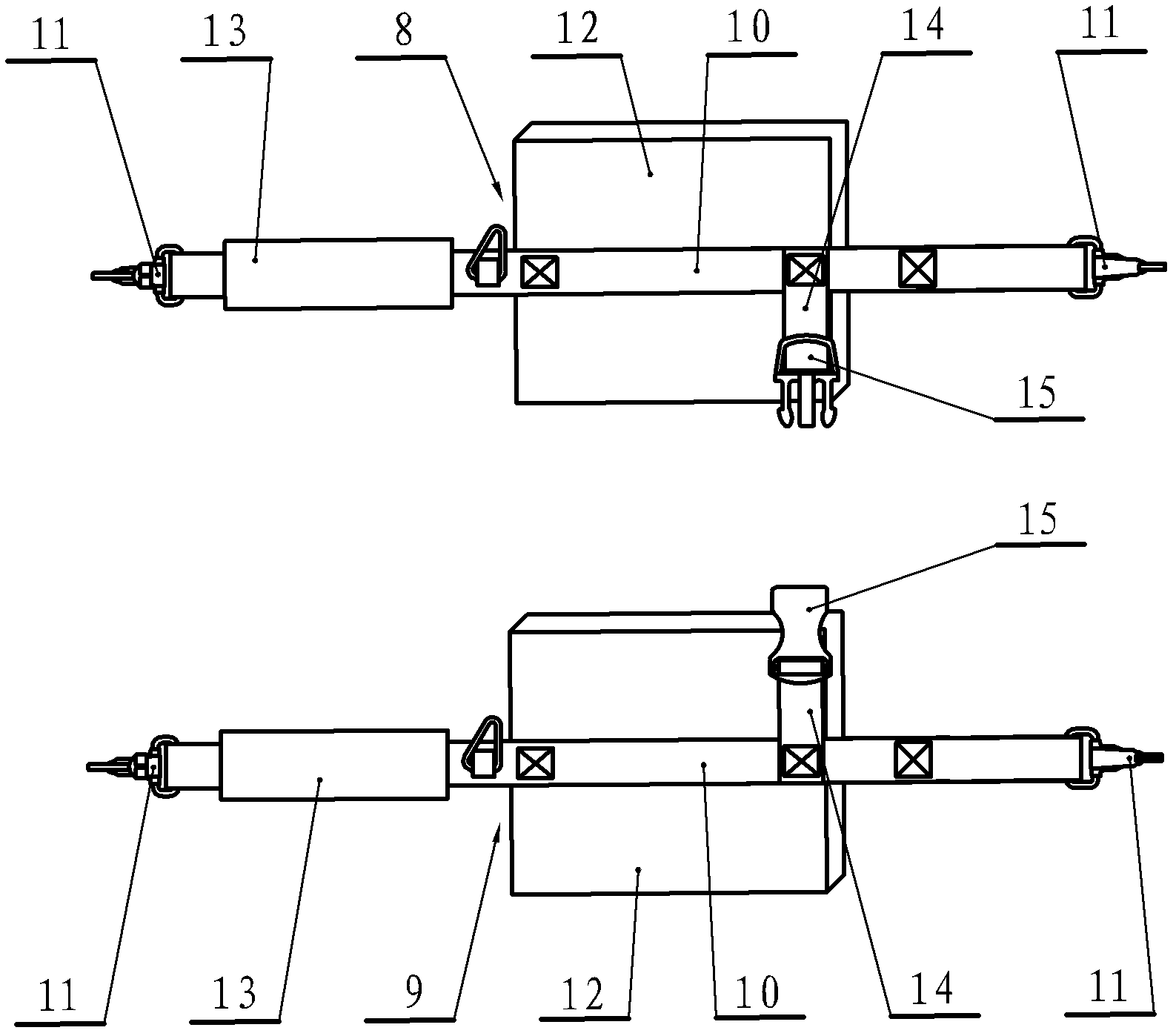

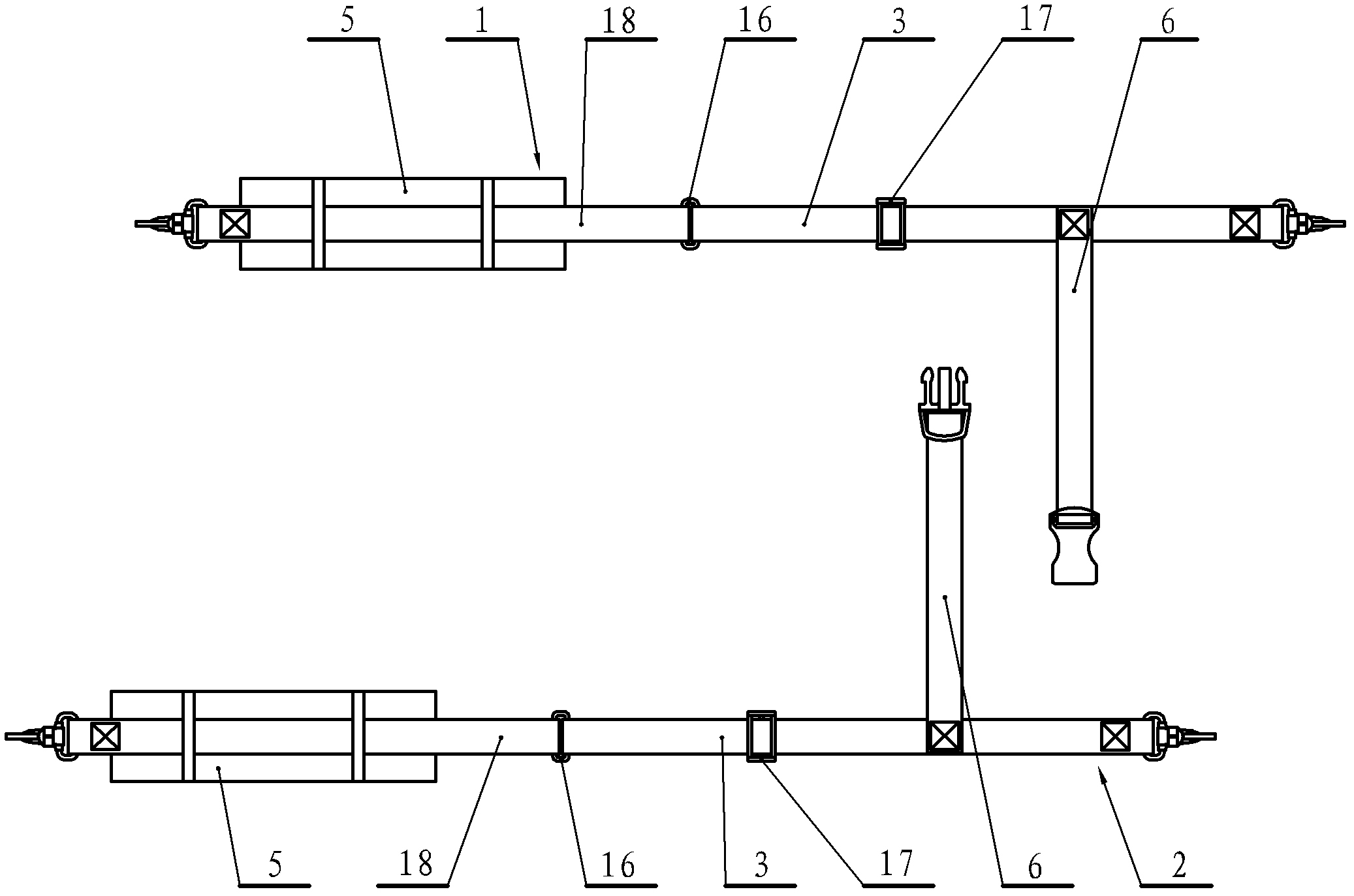

Multifunctional combined carrying system

The invention relates to a multifunctional combined carrying system, which is respectively provided with a first combination strap and a second combination strap. Each of the first combination strap and the second combination strap comprises a strap, load connecting mechanisms, a shoulder pad, a waist belt and a waist belt plug connector. The waist belt plug connectors of the first combination strap and the second combination strap are fastened to each other. The multifunctional combined carrying system is further provided with a first bag hanging carrier and a second bag hanging carrier. Waist belt plug connectors of the first bag hanging carrier and the second bag hanging carrier can be mutually fastened to the waist belt plug connectors of the first combination strap and the second combination strap. The first combination strap and the second combination strap are suitable for double-shoulder carrying. One combination strap can be used with one bag hanging carrier for single-shoulder crossover carrying. The waist belts can be used around a waist for fastening the load. One bag hanging carrier can be used for carrying the load with a single hand. The multifunctional combined carrying system can be used for long-term carrying of any load, is suitable for hikes or journeys on vehicles under various difficult conditions, and is effective.

Owner:北京北机机电工业有限责任公司

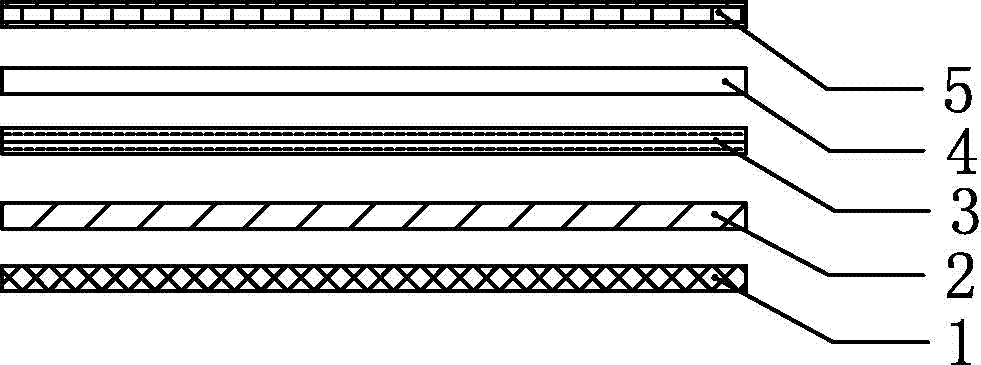

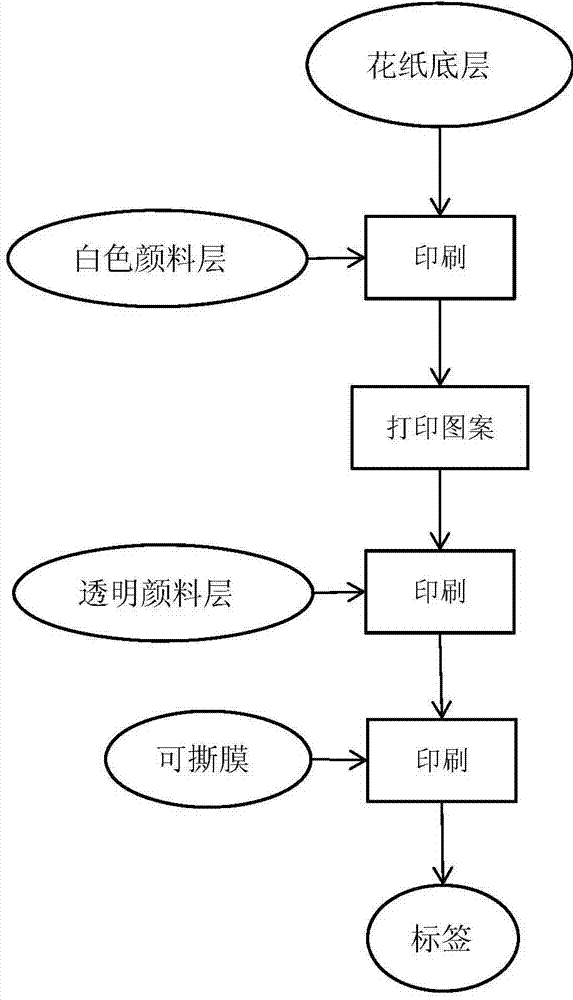

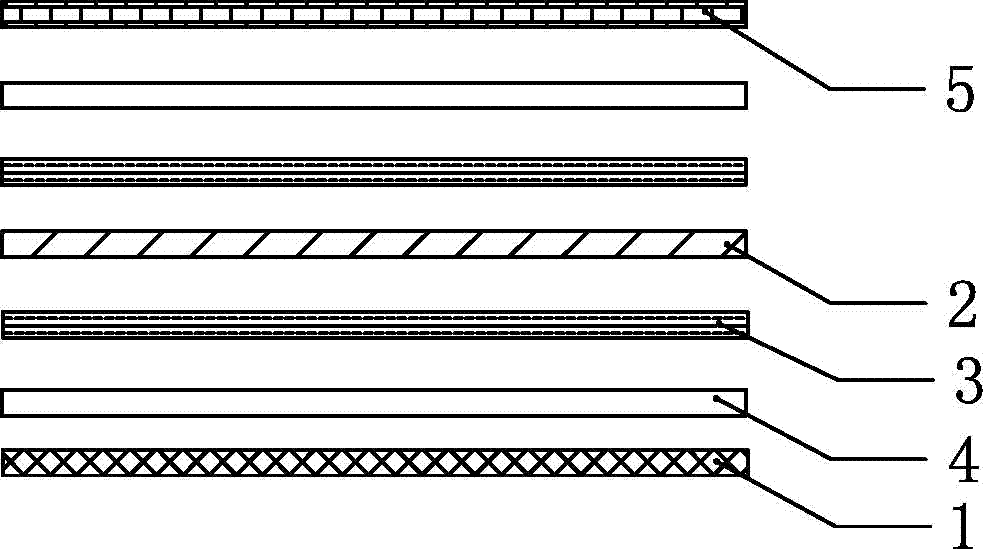

Glass bottle label and manufacturing method thereof

The invention discloses a glass bottle label and a manufacturing method thereof. The glass bottle label comprises a stained paper bottom layer and a patterned layer positioned on the stained paper bottom layer, the patterned layer comprises a white pigment layer, patterns and a transparent pigment layer, the patterns are positioned between the white pigment layer and the transparent pigment layer, and the outermost layer of the label is a tearable film. The manufacturing method includes: printing the white pigment layer or the transparent pigment layer on the stained paper bottom layer, printing the patterns on the white pigment layer or the transparent pigment layer, printing the transparent pigment layer, and finally printing the tearable film on the outermost layer of the label to obtain the glass bottle label. The glass bottle label overcomes defects of high cost, many printing procedures, incapability of seeing patterns in bottles and poor beautifulness, and is low in cost, few in printing procedure, capable of seeing the patterns even in the bottles, good in beautifulness and high in three-dimensionality.

Owner:CHONGQING HAOSHENG GLASS

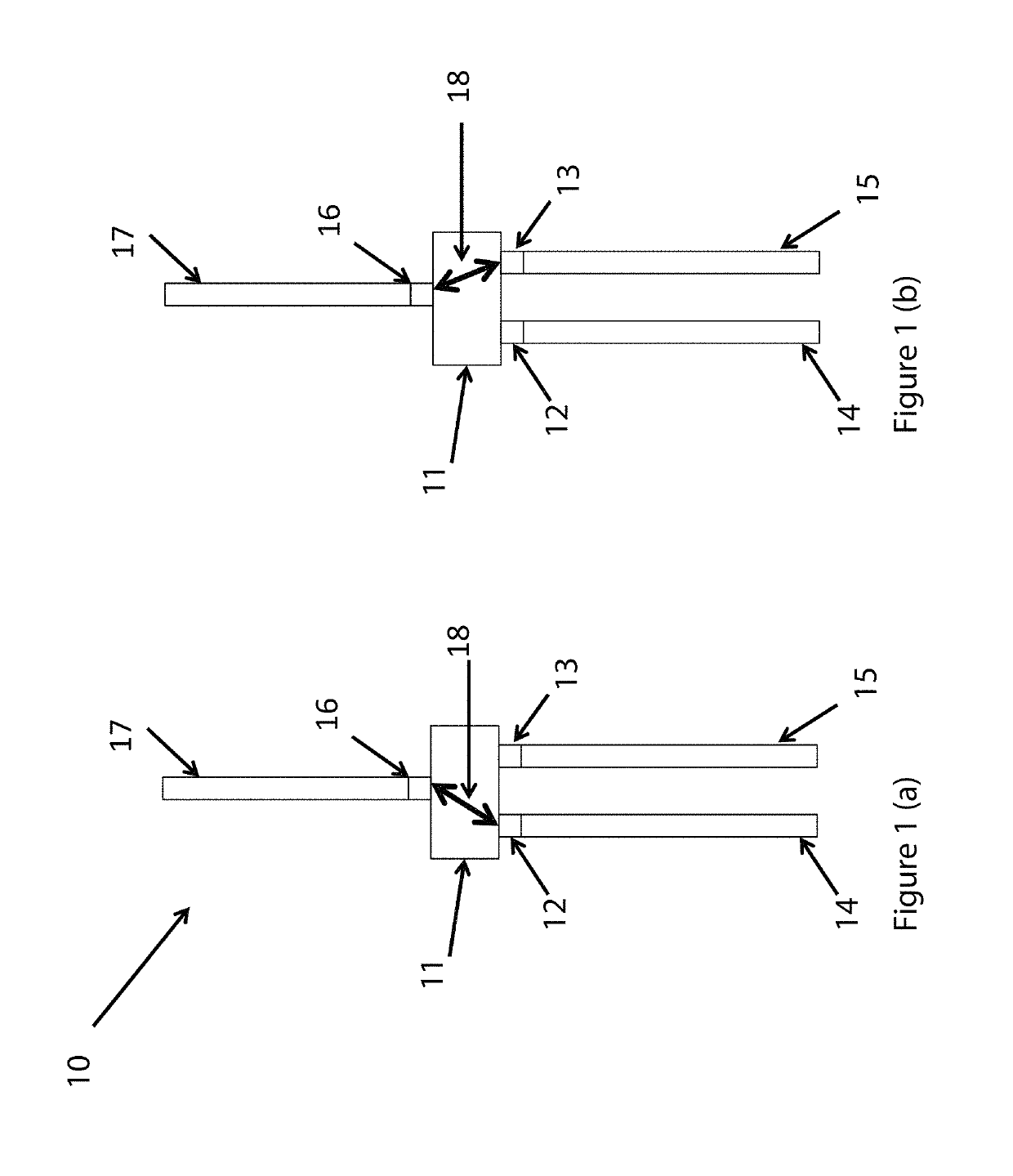

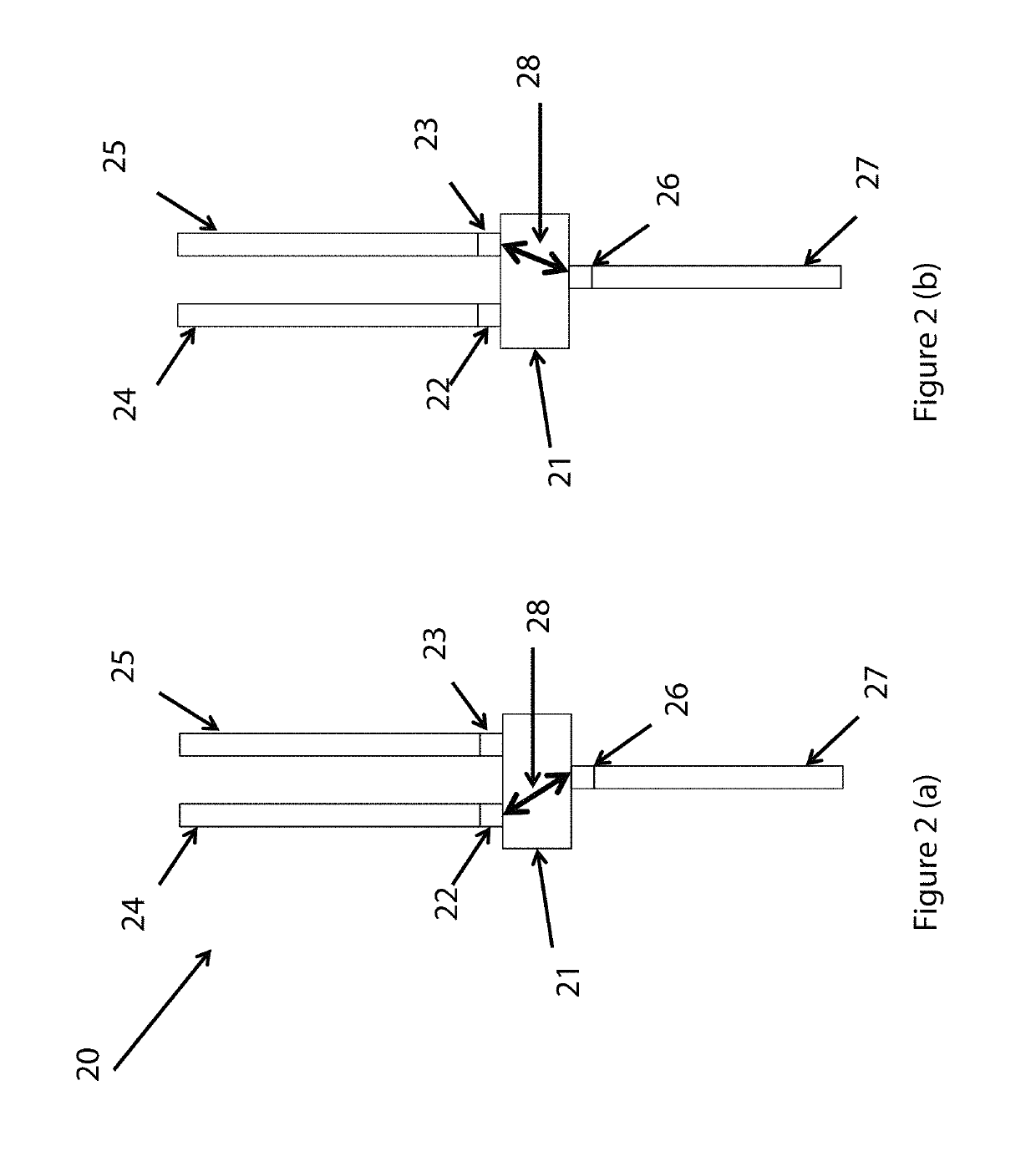

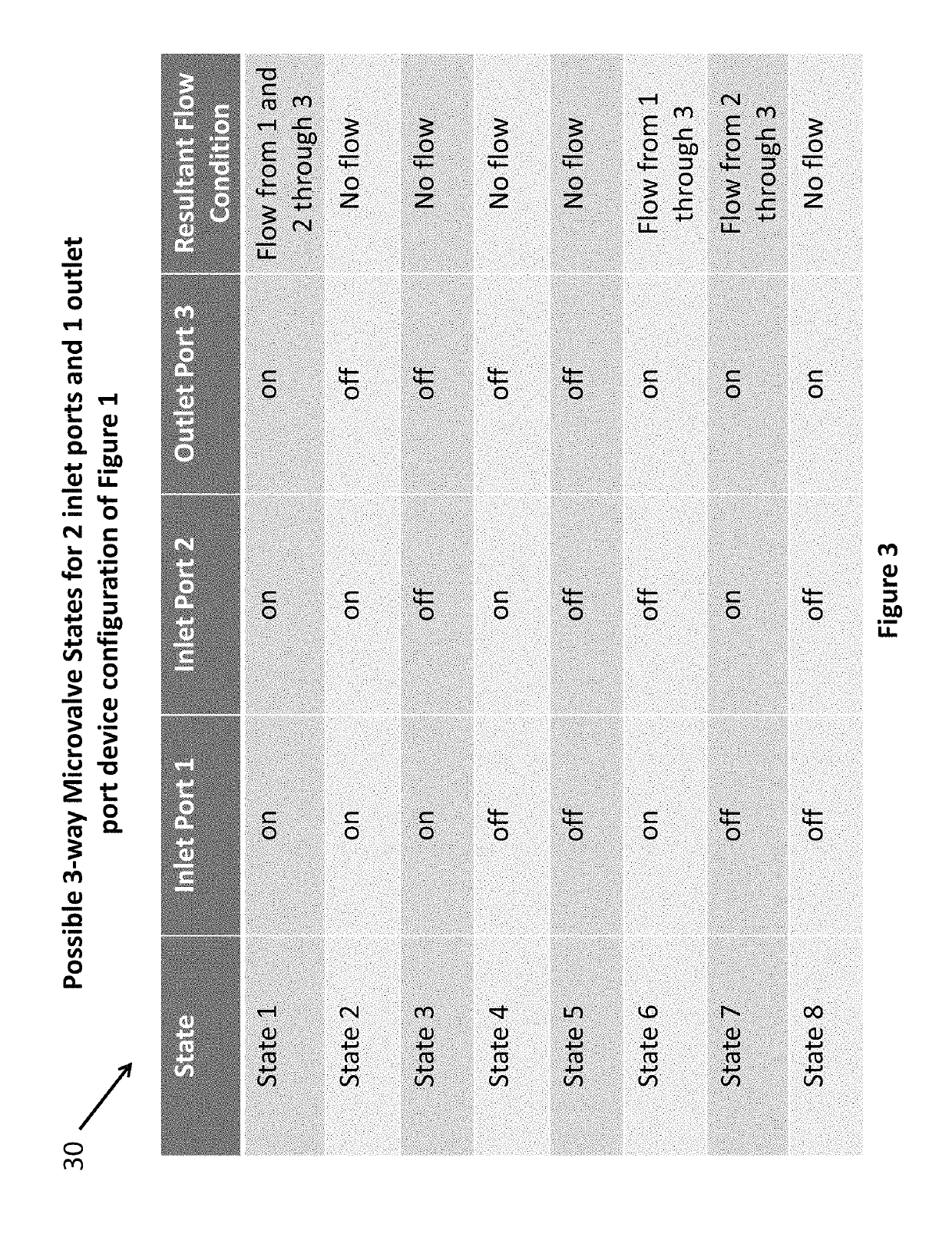

Three-way microvalve device and method of fabrication

Owner:FOR NAT RES INITIATIVES

Method for manufacturing well pipe

InactiveCN101486227AIntegrity guaranteedGuaranteed flatnessCeramic shaping apparatusUltimate tensile strengthMaterials science

Owner:HARBIN HUIZHONG ENVIRONMENTAL PROTECTION TECH DEV CO LTD

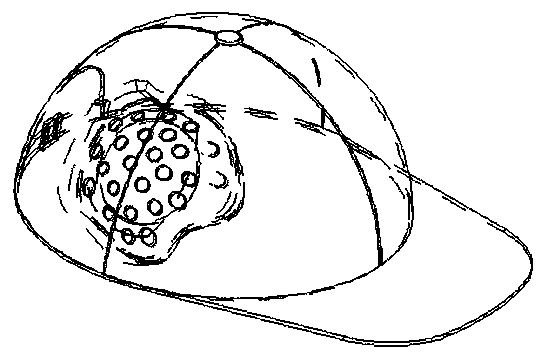

Personalized skull defect protection device and preparation method

PendingCN111544178ANot easy to dropImprove comfortAdditive manufacturing apparatusNon-surgical orthopedic devicesSkull boneImage extraction

The invention provides a personalized skull defect protection device and a preparation method. The protection device comprises a cap body and a 3D printing protection support matched with a damaged part of a patient, the 3D printing protection support is provided with a smooth contour edge and can cover a skull defect part of the patient, the outer side of the 3D printing protection support is wrapped with a connecting cover, and the side, away from the damaged part of the patient, of the connecting cover is connected with the inner side of the cap body. Due to the arrangement of the personalized 3D printing protection support, the defect part can be substantially protected. The preparation method comprises the following steps: reconstructing a three-dimensional computer image of the headof a patient according to three-dimensional data of the head of the patient to obtain a three-dimensional computer image of a defect part of the patient, extracting a curved surface of the three-dimensional computer image of the defect part, reconstructing a protection support computer three-dimensional model according to the curved surface, and printing a solid body of the protection support in a3D mode so that the protection support matched with the defect portion of the patient is obtained, recovery of head defects of the patient is facilitated, and comfort of the patient is improved.

Owner:HUNAN BOKE BIOTECH CO LTD

Deformation measurement sensor for measuring pressure and shearing force and structure therefor

ActiveUS20150143915A1Reduce in sizeSmall structureForce measurement using piezo-resistive materialsElectrical/magnetic solid deformation measurementStrain gaugeEngineering

A deformation measurement sensor for measuring pressures and shearing forces according to the present invention includes: a plurality of beams shaped like a lattice; a strain gauge attached to each of the plurality of beams for measuring a deformation rate; a frame connected to the end of the lattice shape for surrounding the plurality of beams; and holes for arranging lines and formed in the intersections of the plurality of beams, whereby it is possible to precisely measure the deformation rate depending on the pressures or shearing forces exerted to a plurality of areas.

Owner:KOREA ELECTRONICS TECH INST

Strip steel rolling system, floating type surface cleaning roller for metal belt material and usage method of floating surface cleaning roller for metal belt material

ActiveCN107774726AReduce hardnessOvercome cleaning blind spotsWork treatment devicesMetal rolling arrangementsEngineeringMetal

The invention relates to a floating type surface cleaning roller for a metal belt material, a strip steel rolling system adopting the floating type surface cleaning roller for the metal belt materialand a usage method of the floating type surface cleaning roller for the metal belt material. The cleaning roller comprises a roller seat and a flexible floating roller, wherein the roller seat is connected with a driving mechanism used for driving the roller seat to approach or be far away from a metal-belt-material running passage; the bottom of the roller seat is provided with a floating groove;the width of a groove opening of the floating groove is less than the diameter of the floating roller; the floating roller can be held in the floating groove and further the bottom end of the floating roller is located outside the floating groove, so as to be in contact with the surface of the metal belt material; a gas charging cavity is enclosed and formed by the floating roller and the groovewall of the floating groove; the roller seat is provided with a gas charging passage communicated with the gas charging cavity. The pressure of a gas in the gas charging cavity can uniformly act on the total length of the floating roller; the pressure and tension distribution in the width direction of the metal belt material is not influenced; when the surface of the metal belt material is uneven,the floating roller can generate different extrusion deformation along the axial direction of the floating roller; a cleaning blind area can be effectively overcome and the metal belt material is better cleaned.

Owner:WISDRI ENG & RES INC LTD

Method for forming grating for machine tool measurement in two-step solidifying roll-pressing forming method

ActiveCN102193310BLow costIncrease productivityDiffraction gratingsPhotomechanical exposure apparatusStress concentrationGrating

Owner:XI AN JIAOTONG UNIV

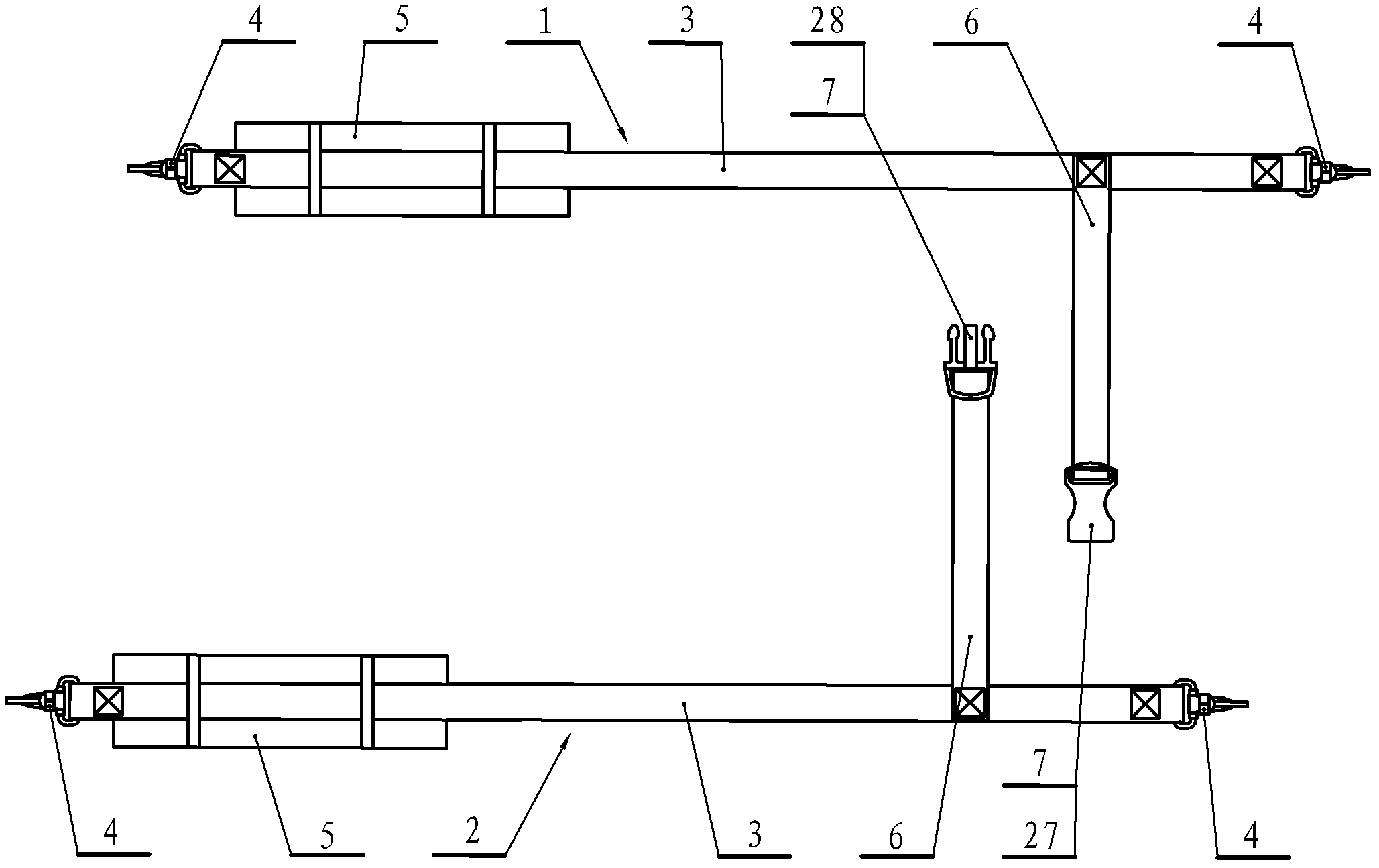

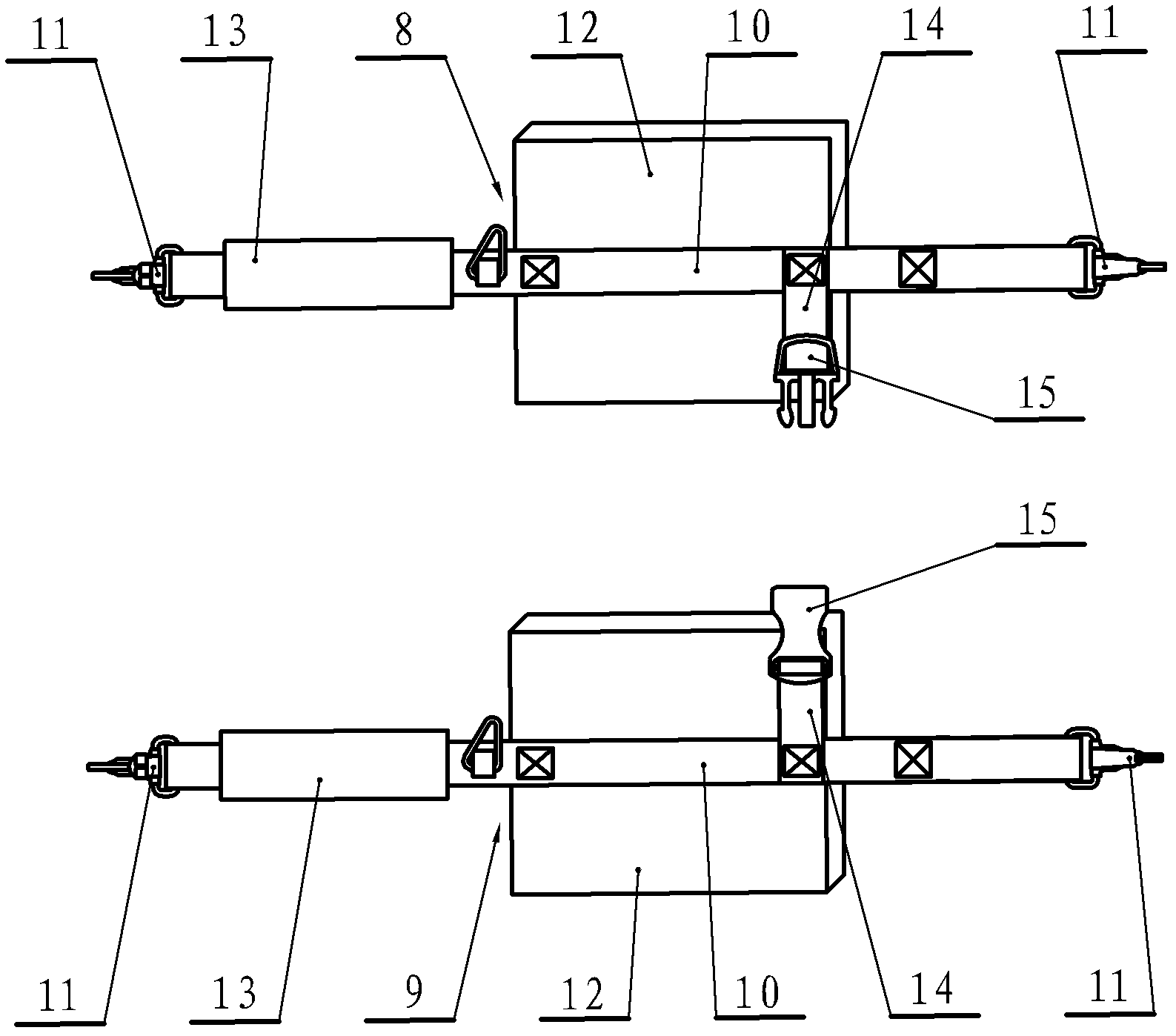

Multifunctional combined carrying system

The invention relates to a multifunctional combined carrying system, which is respectively provided with a first combination strap and a second combination strap. Each of the first combination strap and the second combination strap comprises a strap, load connecting mechanisms, a shoulder pad, a waist belt and a waist belt plug connector. The waist belt plug connectors of the first combination strap and the second combination strap are fastened to each other. The multifunctional combined carrying system is further provided with a first bag hanging carrier and a second bag hanging carrier. Waist belt plug connectors of the first bag hanging carrier and the second bag hanging carrier can be mutually fastened to the waist belt plug connectors of the first combination strap and the second combination strap. The first combination strap and the second combination strap are suitable for double-shoulder carrying. One combination strap can be used with one bag hanging carrier for single-shoulder crossover carrying. The waist belts can be used around a waist for fastening the load. One bag hanging carrier can be used for carrying the load with a single hand. The multifunctional combined carrying system can be used for long-term carrying of any load, is suitable for hikes or journeys on vehicles under various difficult conditions, and is effective.

Owner:北京北机机电工业有限责任公司

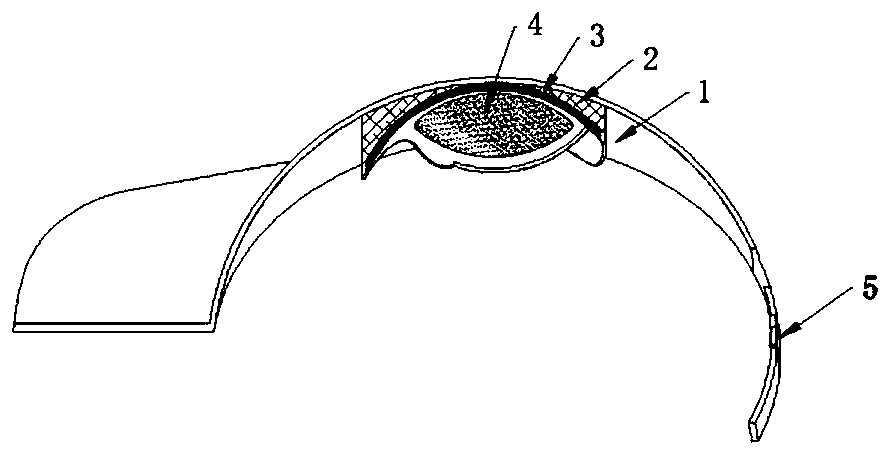

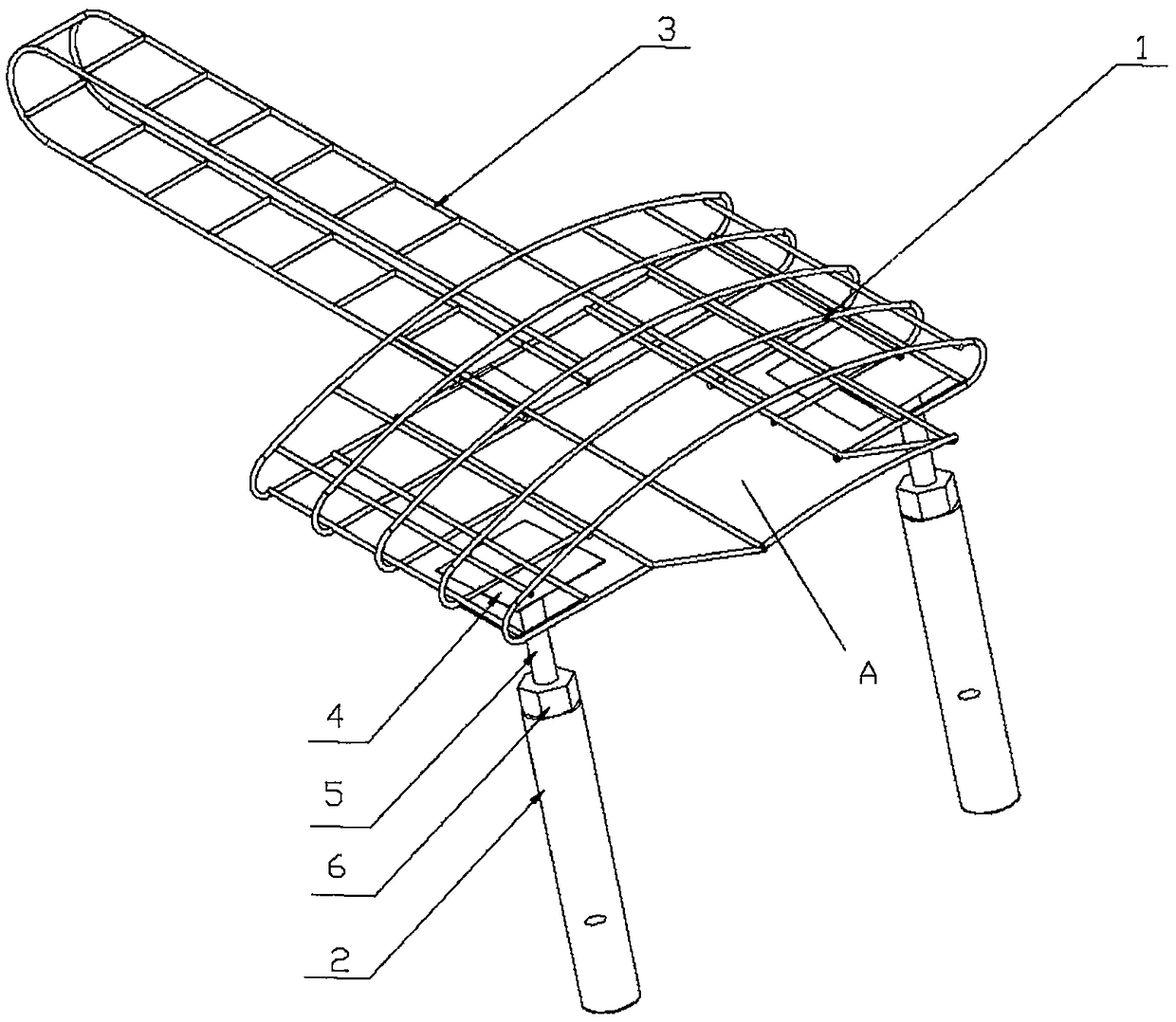

An ophthalmic surgery assisted breathing mask

ActiveCN105596172BStrong enduranceSmall pressureOperating tablesEye treatmentMedical equipmentMedicine

The invention relates to the field of medical equipment, in particular to an auxiliary breathing mask for assisting ophthalmologic operation. A main body of the auxiliary breathing mask comprises a rigid mesh mask welded through metal wires, wherein both sides of the mesh mask are provided with at least one support rod respectively; a narrow and long truss is fixed at the lower end of the mesh mask; a main body of the mesh mask is an arc-shaped framework; the upper part of the mesh mask is an arc-shaped mesh enclosure; the lower part of the mesh mask is hollow; metal sheets are welded on both sides of the bottom of the side face of the mesh mask; the metal sheets are connected integrally with the end part of the support rod. The auxiliary breathing mask is designed with a metal mesh structure, various size relations among a lower jaw, a neck and a chest are considered, and the height can be adjusted, so that not only the structure is more firm, the auxiliary breathing mask can adapt to patients of different bodily forms, and a safe and comfortable free breathing space is formed below the breathing mask for each patient.

Owner:闵晓珊

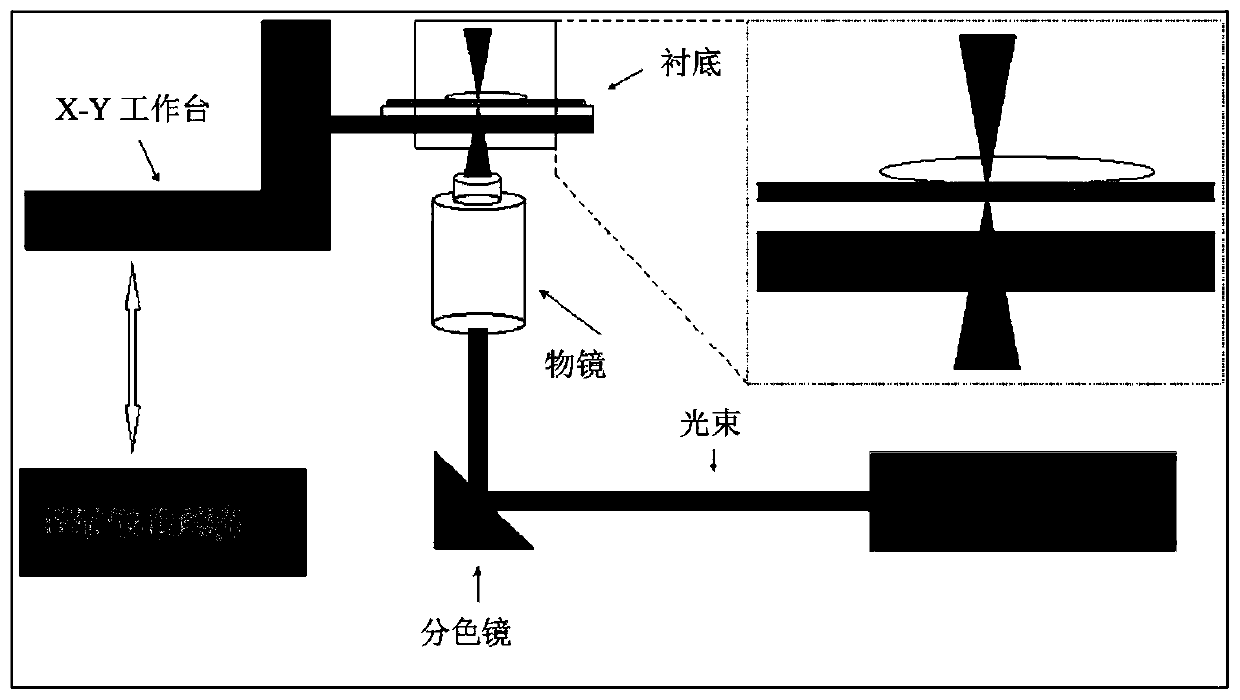

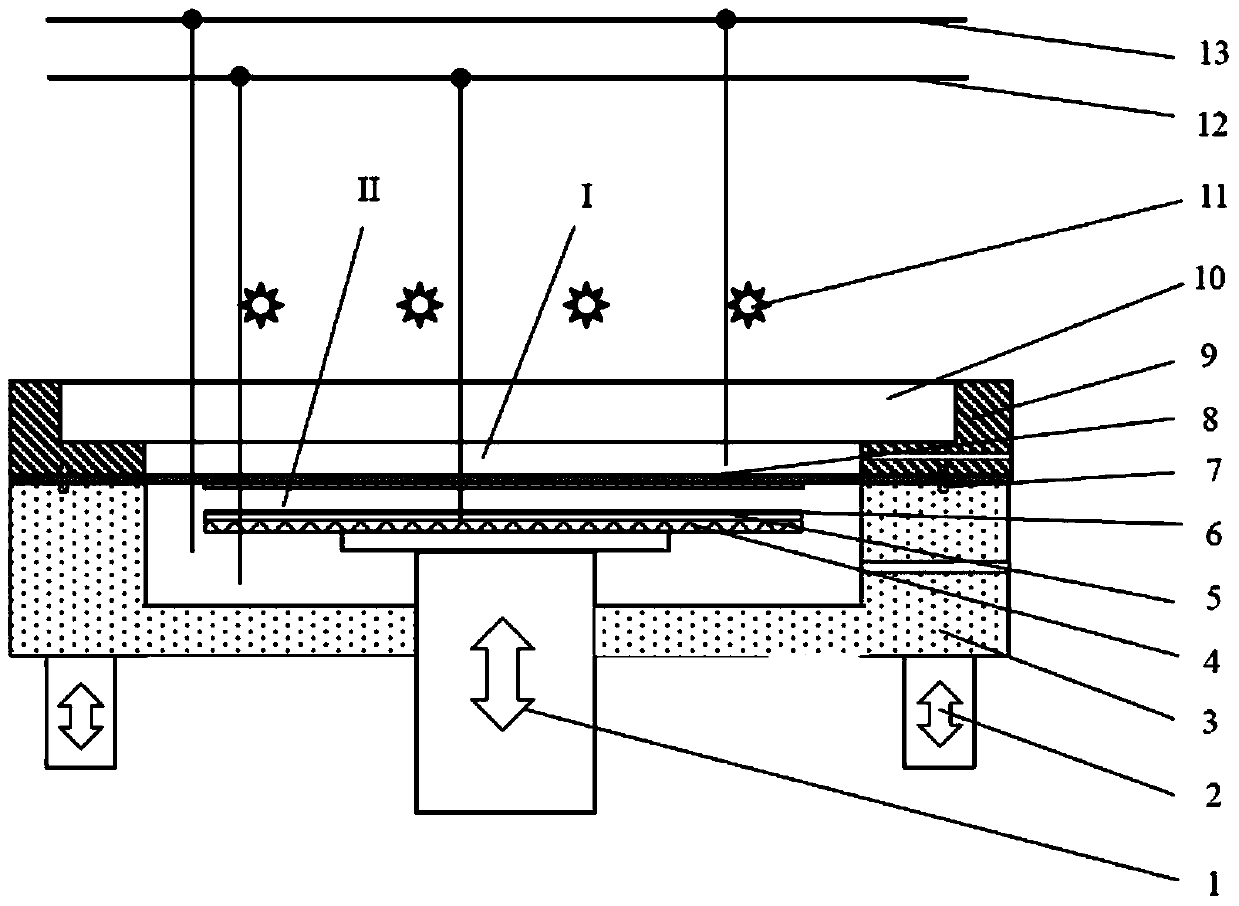

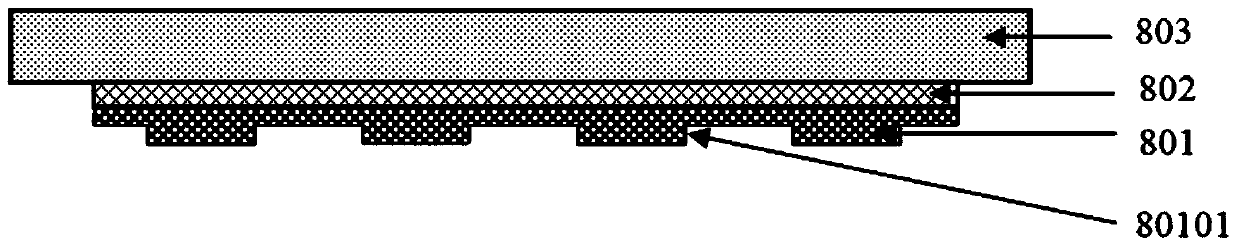

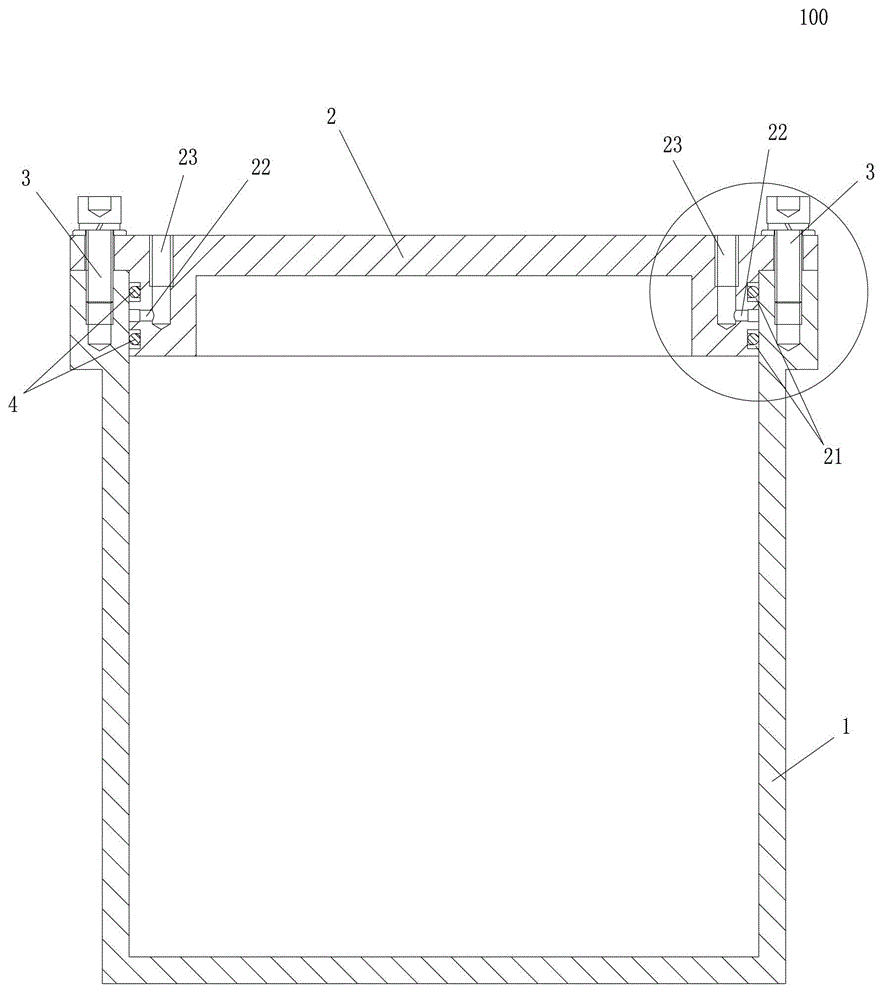

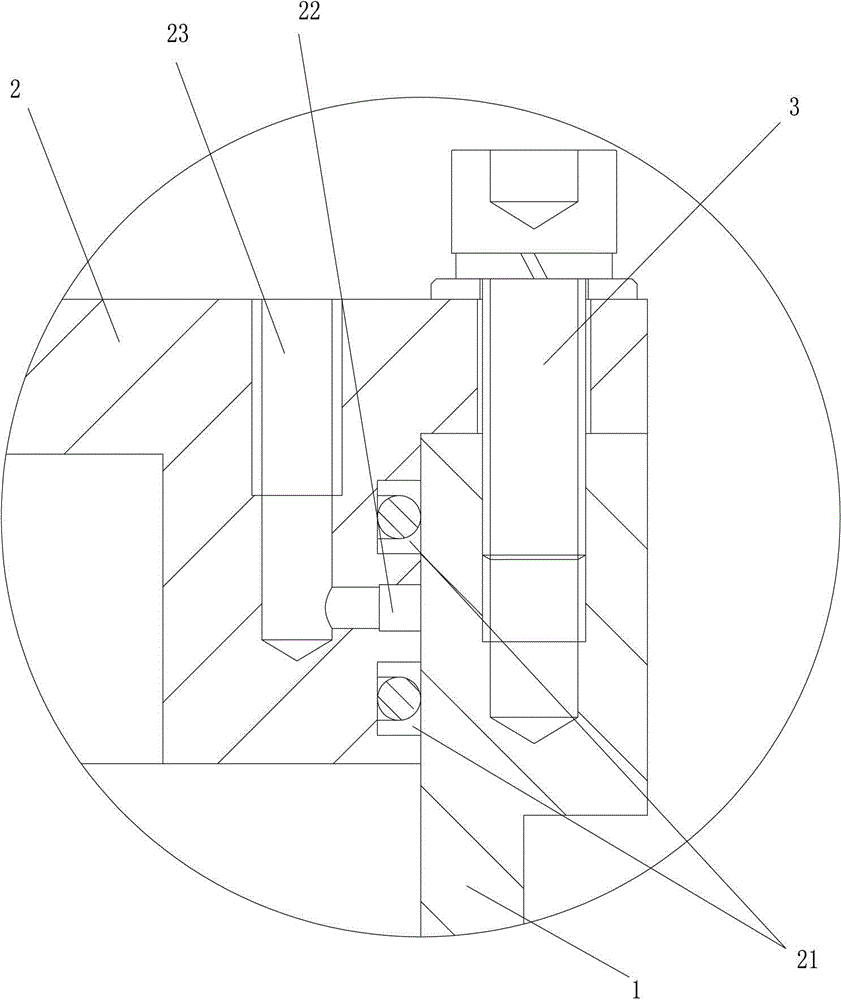

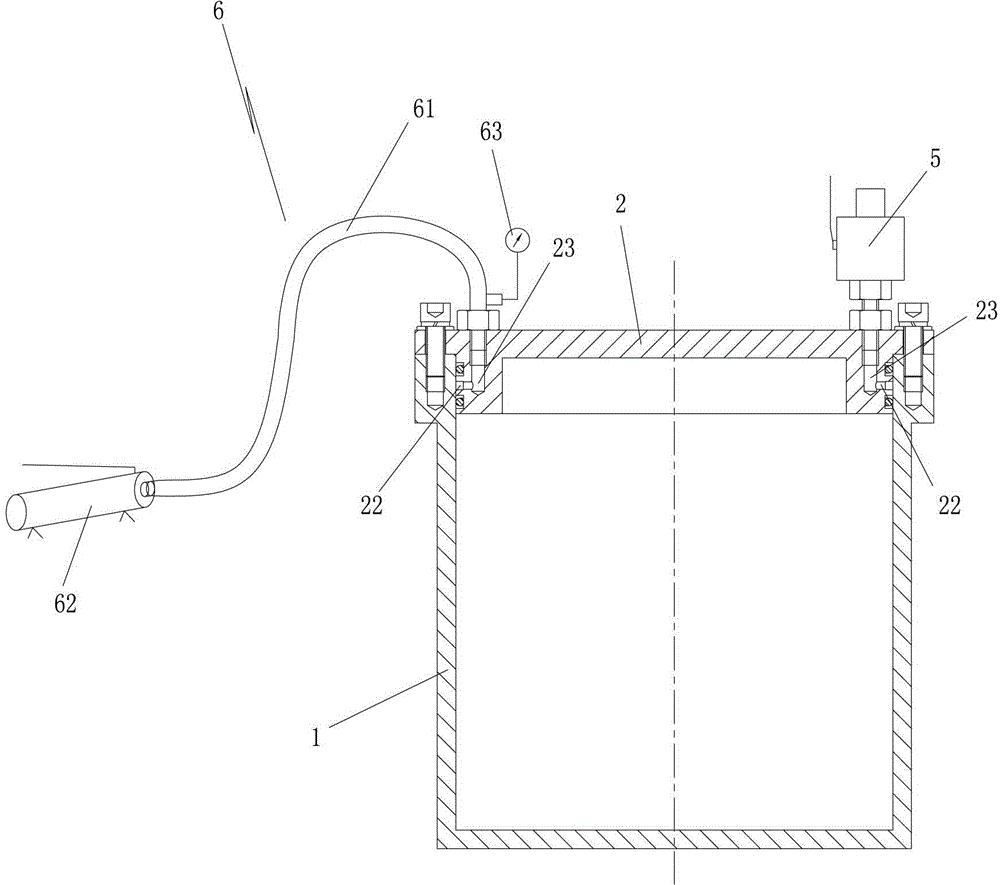

A device for nano-imprinting of a large-sized wafer and its imprinting method

A large-size wafer entire nanoimprinting device and an imprinting method therefor. The device comprises an upper cavity (9) and a lower cavity (3), the lower cavity (3) being driven by a first raising and lowering mechanism (2) to move up and down to come into contact with or be separated from the upper cavity (9), an elastic mould (8) used for imprinting being arranged on a bottom portion of the upper cavity (9), a wafer-bearing platform (4) being horizontally arranged within the lower cavity (3), a bottom portion of the wafer-bearing platform (4) being provided with a second raising and lowering mechanism (1), an upper cavity air inlet (902) movably connected to a pressure pipe (13) being arranged on a cavity wall of the upper cavity (9), a lower cavity air inlet (301) movably connected to both a vacuum pipe (12) and the pressure pipe (13) being arranged on a cavity wall of the lower cavity (3), a wafer-bearing platform air inlet in communication with the vacuum pipe (12) being arranged on the wafer-bearing platform (4), the device also comprising an exposure light source (11). The nanoimprinting device and the imprinting method therefor implement large-size, uneven substrate and fragile substrate large-area micro / nanostructure high-efficiency and low-cost batch manufacturing, and provide an industrial-grade solution for large-size wafer-level large-area micro / nanostructure manufacturing.

Owner:兰红波

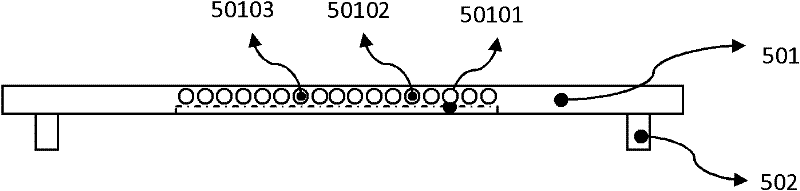

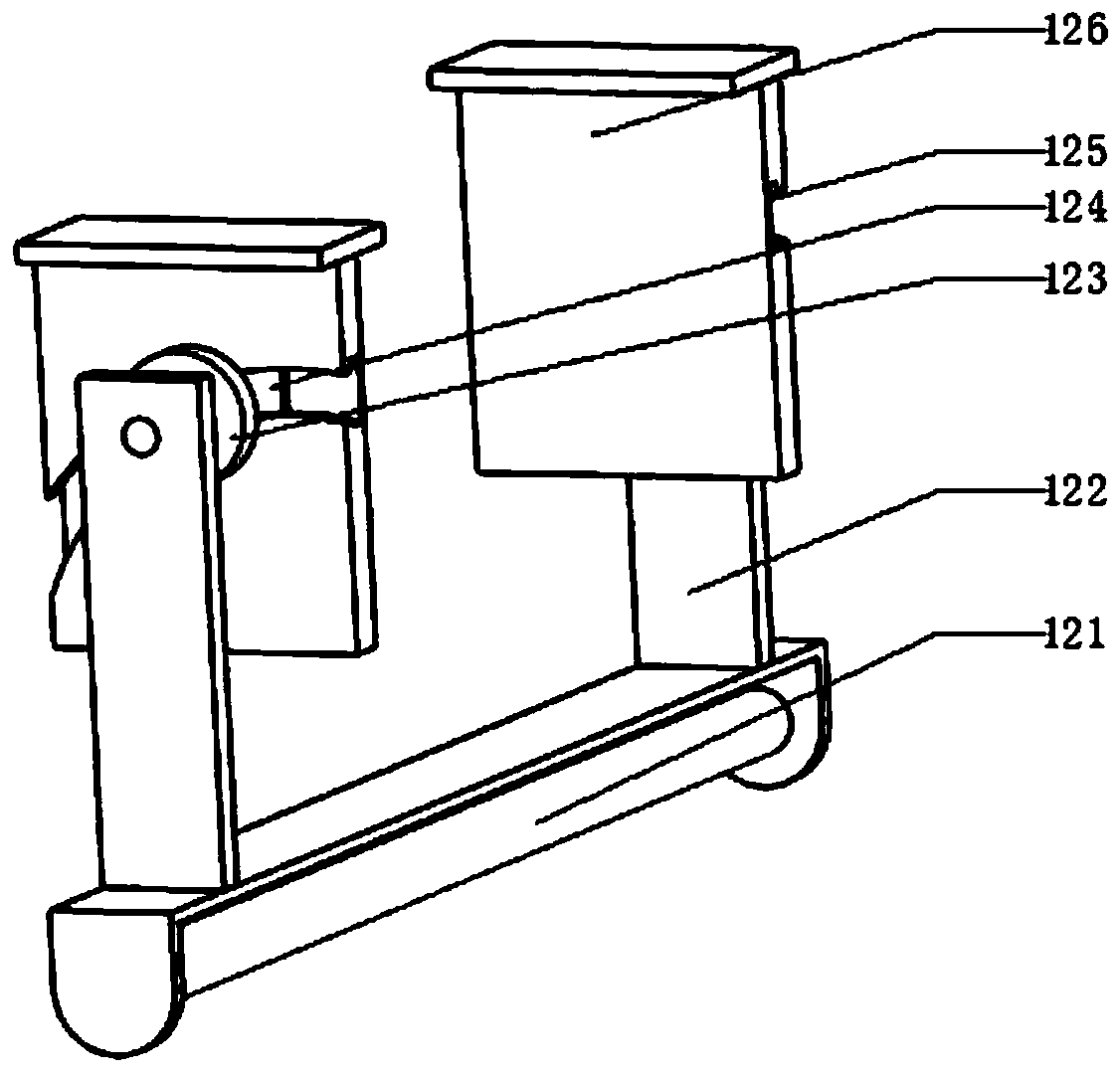

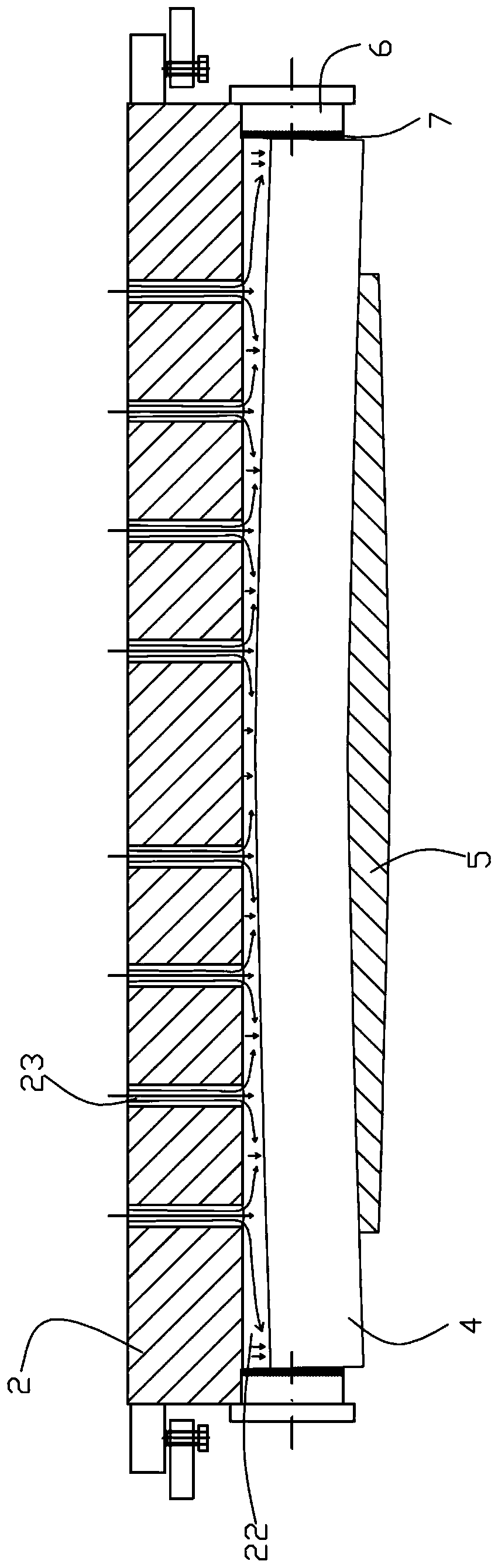

Composite nanoimprint lithography machine and working method

ActiveCN106918987BHigh precisionRealize large-area micro-nano patterningPhotomechanical apparatusNanotechnologyLithographic artistNanoimprint lithography

The invention discloses a composite nano-imprint photolithography machine and a working method, which solves the problems of large deformation of imprinted graphics, low imprinting precision, and poor imprinting quality. The close cooperation of the platform, under the joint and synergistic effect of positive and negative pressure, can efficiently and automatically complete large-area imprinting and uncovering demoulding, and realize large-area micro-nano patterning on ultra-large-sized rigid substrates. The technical solution is as follows: including a base, on which a workbench is fixed, and a vacuum suction cup is arranged on the movable table of the workbench, and the vacuum suction cup vacuum-adsorbs the base material, and the embossing material is evenly spread on the base material; An embossing module is provided in cooperation, the embossing module includes an embossing assembly and a curing assembly, the embossing assembly includes a roller, the outer surface of the roller is vacuum-adsorbed with a composite soft mold, and the outer surface of the roller is An elastic material layer is covered, and a flexible material layer is provided on the side of the composite soft mold in contact with the roller.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

A combined surgical body position cushion

InactiveCN106063756BSimple postoperative careImprove satisfactionOperating tablesMedical transportPhysical medicine and rehabilitationBody posture

Owner:漯河医学高等专科学校第一附属医院

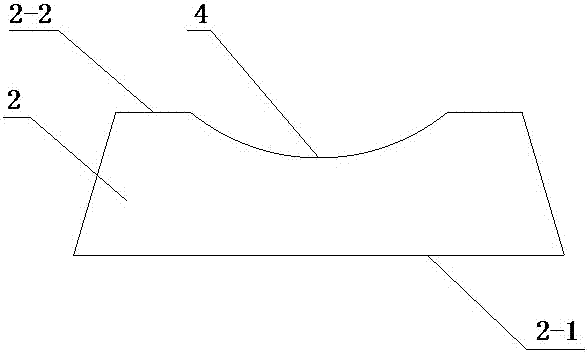

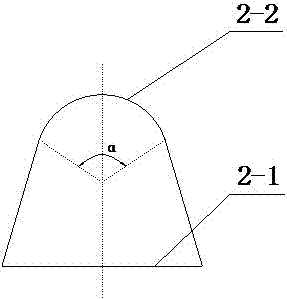

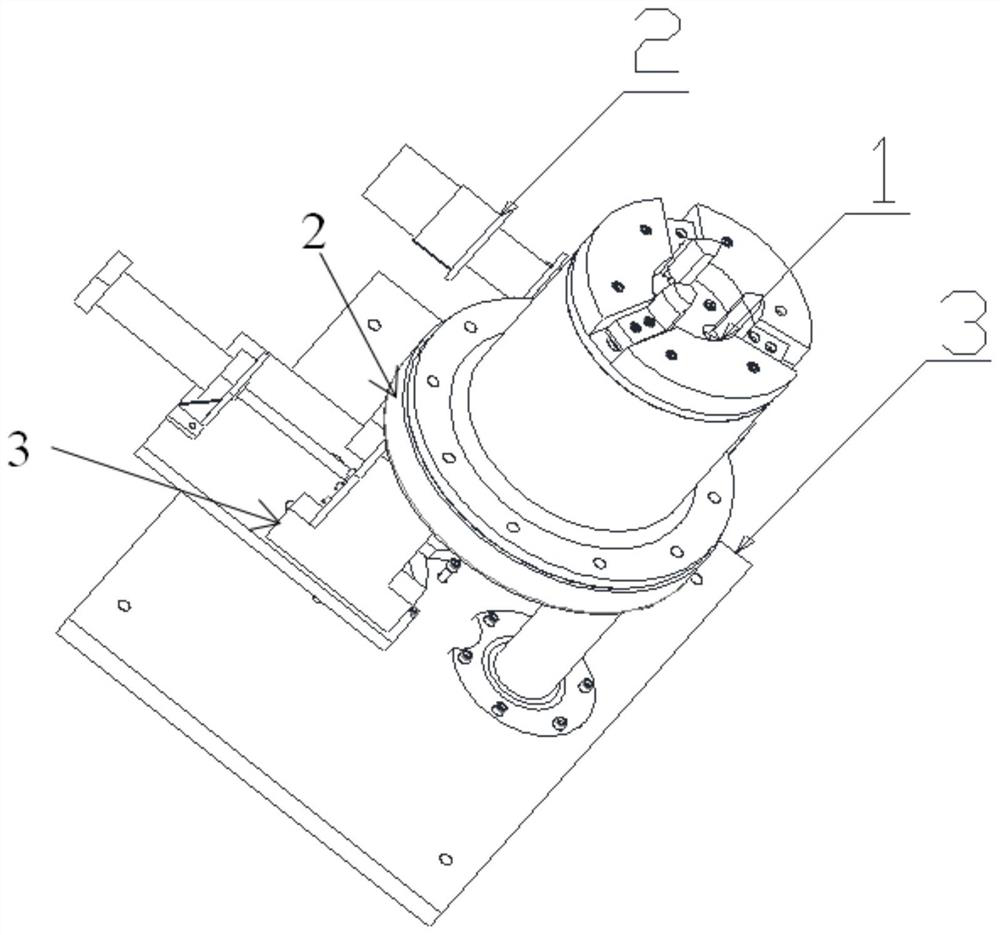

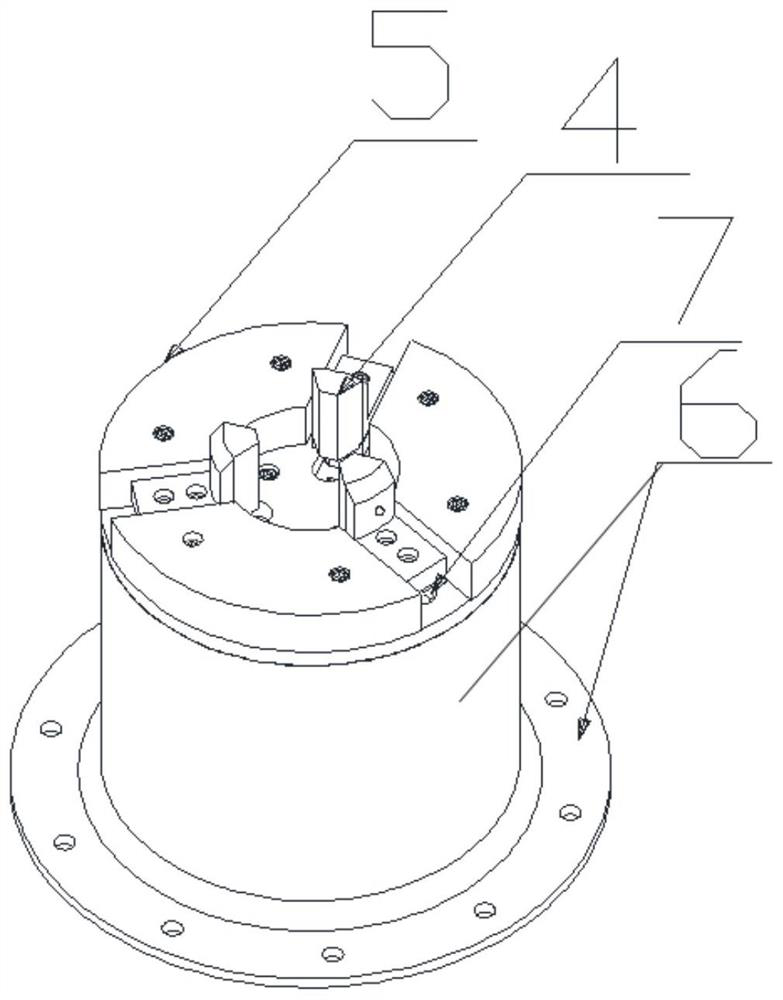

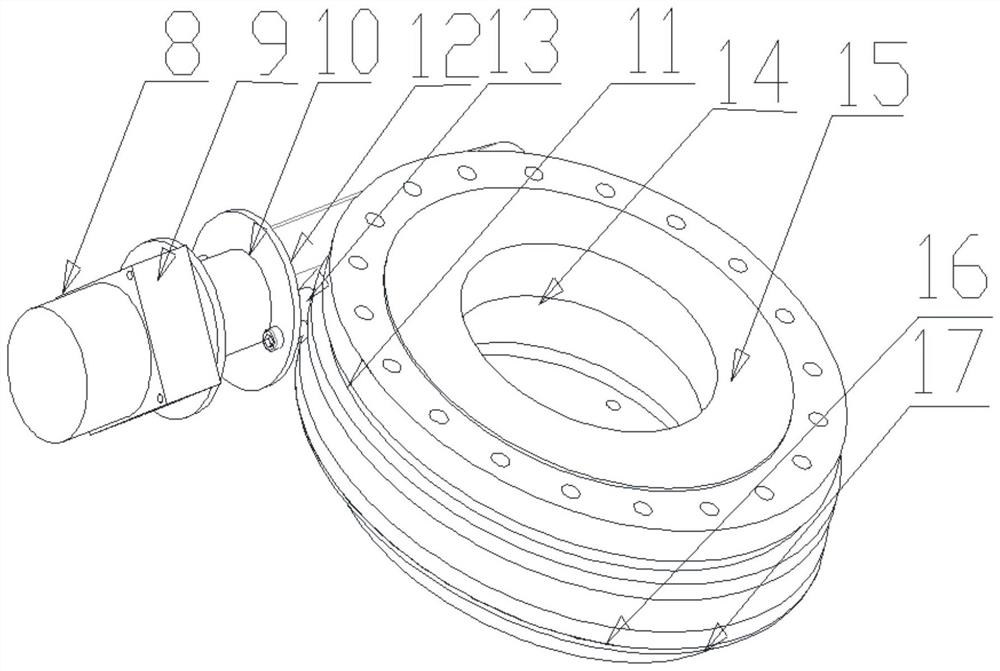

Positioning supporting device for wheel letter press and using method thereof

The invention discloses a positioning supporting device for a wheel letter press. The positioning supporting device comprises a fixed core mechanism for positioning a wheel hub, a rotating mechanism for driving the fixed core mechanism to rotate and a supporting mechanism, wherein the supporting mechanism is mounted on a lower beam of the letter press; one end of the rotating mechanism is connected on the supporting mechanism; and the fixed core mechanism is connected at the other end of the rotating mechanism. To realize function needs of the letter press, the positioning supporting device disclosed by the invention can meet positioning needs of different hub-hole wheels, also can drive the wheels to rotate to meet needs of letter pressing positions in the peripheral direction of the wheels. The positioning supporting device disclosed by the invention realizes that the wheel letter press adopts a single letter pressing mode, is small in needed pressing-printing force, is simple in structure, is compact and reasonable in configuration, is high in degree of automation, is less in investment, is low in operation and maintenance cost, is convenient in operation, is reliable in operation, improves production space, reduces production cost, and improves market competition of wheel products. The invention further discloses a using method of the positioning supporting device for the wheel letter press.

Owner:MAANSHAN MAGANG JINXI RAIL TRANSPORT EQUIP

Strip rolling system, floating metal strip surface cleaning roll and method of use

ActiveCN107774726BWon't scratchThe surface hardness of the roller body is lowWork treatment devicesMetal rolling arrangementsMetal stripsSurface cleaning

The invention relates to a floating type surface cleaning roller for a metal belt material, a strip steel rolling system adopting the floating type surface cleaning roller for the metal belt materialand a usage method of the floating type surface cleaning roller for the metal belt material. The cleaning roller comprises a roller seat and a flexible floating roller, wherein the roller seat is connected with a driving mechanism used for driving the roller seat to approach or be far away from a metal-belt-material running passage; the bottom of the roller seat is provided with a floating groove;the width of a groove opening of the floating groove is less than the diameter of the floating roller; the floating roller can be held in the floating groove and further the bottom end of the floating roller is located outside the floating groove, so as to be in contact with the surface of the metal belt material; a gas charging cavity is enclosed and formed by the floating roller and the groovewall of the floating groove; the roller seat is provided with a gas charging passage communicated with the gas charging cavity. The pressure of a gas in the gas charging cavity can uniformly act on the total length of the floating roller; the pressure and tension distribution in the width direction of the metal belt material is not influenced; when the surface of the metal belt material is uneven,the floating roller can generate different extrusion deformation along the axial direction of the floating roller; a cleaning blind area can be effectively overcome and the metal belt material is better cleaned.

Owner:WISDRI ENG & RES INC LTD

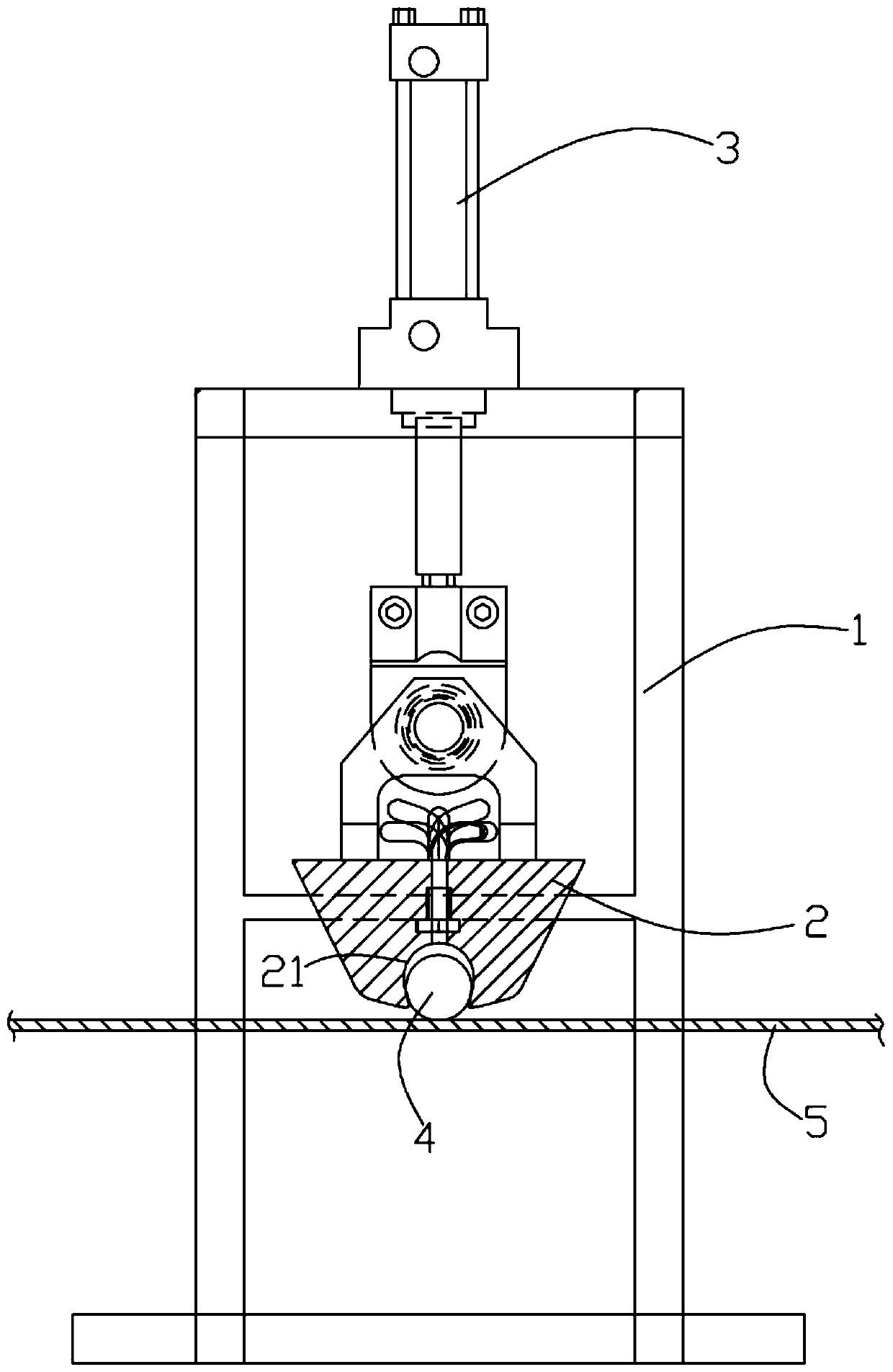

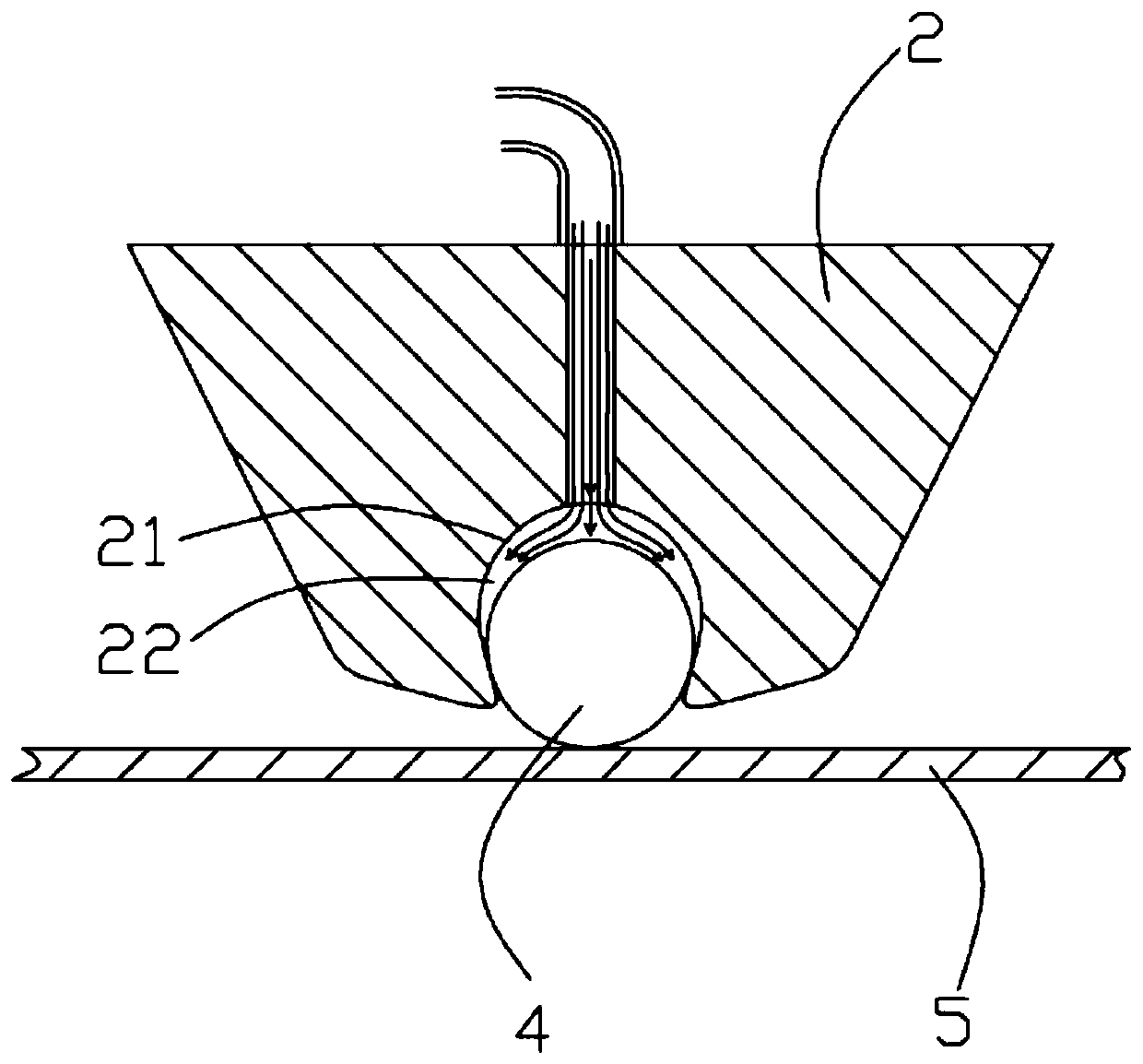

O-shaped sealing ring sealing pressure test method and its sealing device

InactiveCN102879156BSmall pressureEasy to operateMeasurement of fluid loss/gain rateEngineeringPressure vessel

The invention provides a sealing pressure test method for O-shaped seal rings and a sealing device for O-shaped seal rings. Two O-shaped ring grooves are arranged in a sealing surface on one side of a sealing bonding surface; an injection compressing ring groove communicated with the sealing bonding surface is parallelly arranged between the two O-shaped ring grooves; O-shaped seal rings are arranged in the O-shaped ring grooves; pressure is injected in the injection compressing ring grooves through pressurizing equipment, and pressure is maintained for a certain time, so that the sealing effect of the O-shaped seal rings on the two sides of the injection compressing ring grooves can be detected. According to the invention, the seal structure is changed, that is, one O-shaped seal ring is changed into two O-shaped seal rings, and the injection compressing ring groove is arranged between the two O-shaped seal rings, so that all that is needed is to slightly pressure the injection compressing ring groove regardless of a pressure vessel or a sealed cabin, furthermore, the operation is convenient, and the structure is simple.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Method for manufacturing well pipe

InactiveCN101486227BIntegrity guaranteedGuaranteed flatnessCeramic shaping apparatusUltimate tensile strengthMaterials science

Owner:HARBIN HUIZHONG ENVIRONMENTAL PROTECTION TECH DEV CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com