Cavity type structured nano imprinting template and imprinting forming method therefor

一种纳米压印、模板的技术,应用在纳米技术、图纹面的照相制版工艺、光学等方向,能够解决很难、压力上升、压印结构缺陷等问题,达到保证脱模质量、消除溶解/吸附的的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

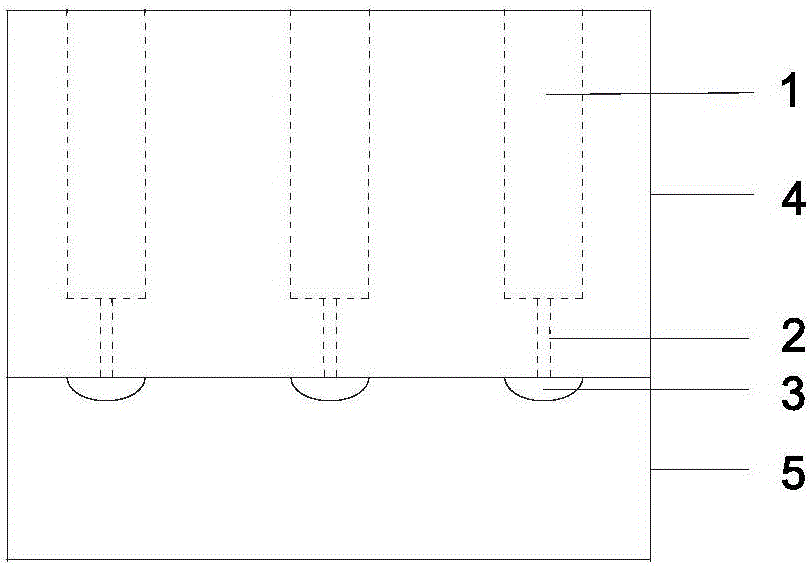

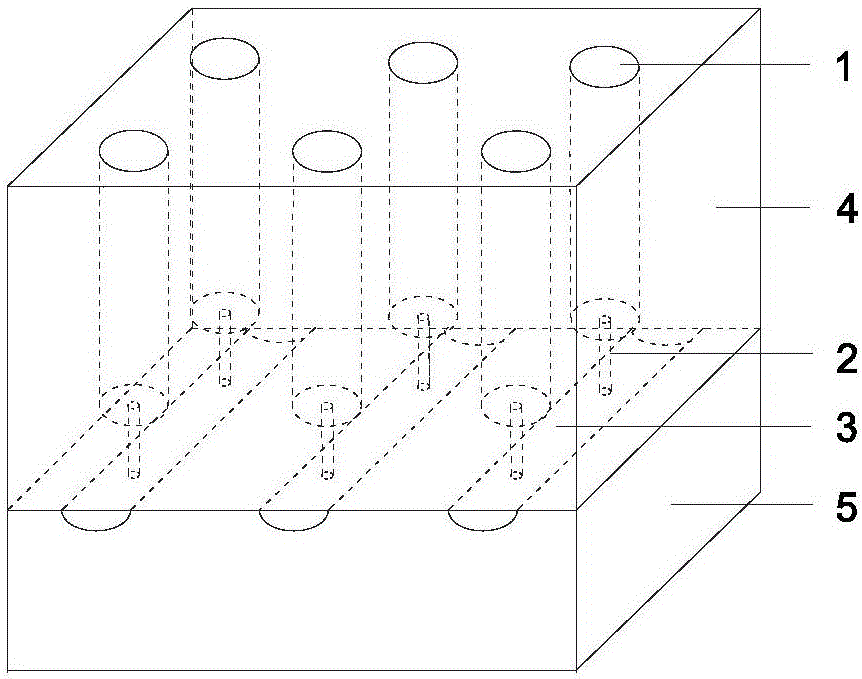

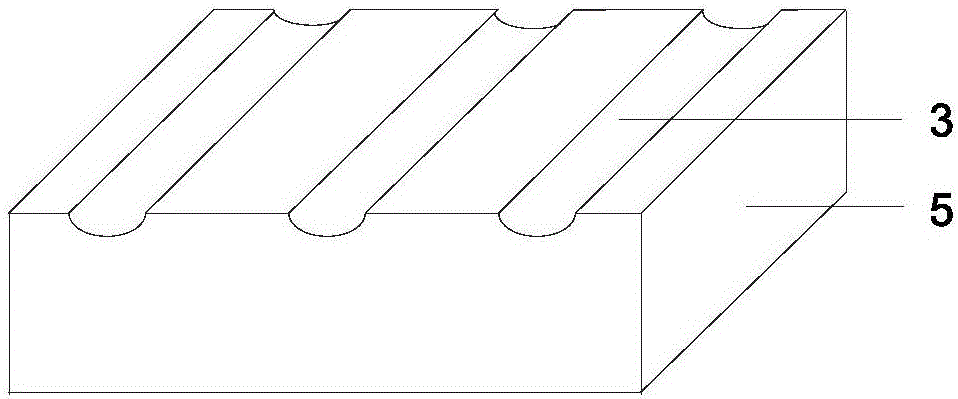

[0057] Such as Figures 1 to 3 As shown, the cavity structure nanoimprint template of the present invention has an integrated structure, including two parts of an upper template 4 and a lower template 5 welded together;

[0058] The upper template is evenly provided with a certain number of stepped holes, the above-mentioned stepped holes are thick at the top and thin at the bottom, and run through the upper and lower surfaces of the upper template; the upper part 1 of the stepped hole has a diameter of 10 microns and a hole depth of 100 microns. The diameter of the lower part 2 is 100nm;

[0059] The number of the above-mentioned stepped holes and the relative positions between the stepped holes correspond to the number of structural protrusions required to be embossed and the relative positions between the structural protrusions; the dimensions of the upper parts of the stepped holes are respectively One-to-one corresponding to the size of the structural protrusions to be e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com