Large area reverse roller impression method for micro-structure of flexible base macroelectron manufacture

A microstructure and large-area technology, applied in the direction of microstructure technology, microstructure devices, chemical instruments and methods, etc., can solve problems such as stress concentration of flexible substrates and microstructures, damage to flexible substrates, complex processes, etc., to avoid additional processes , Eliminate film retention and reduce stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

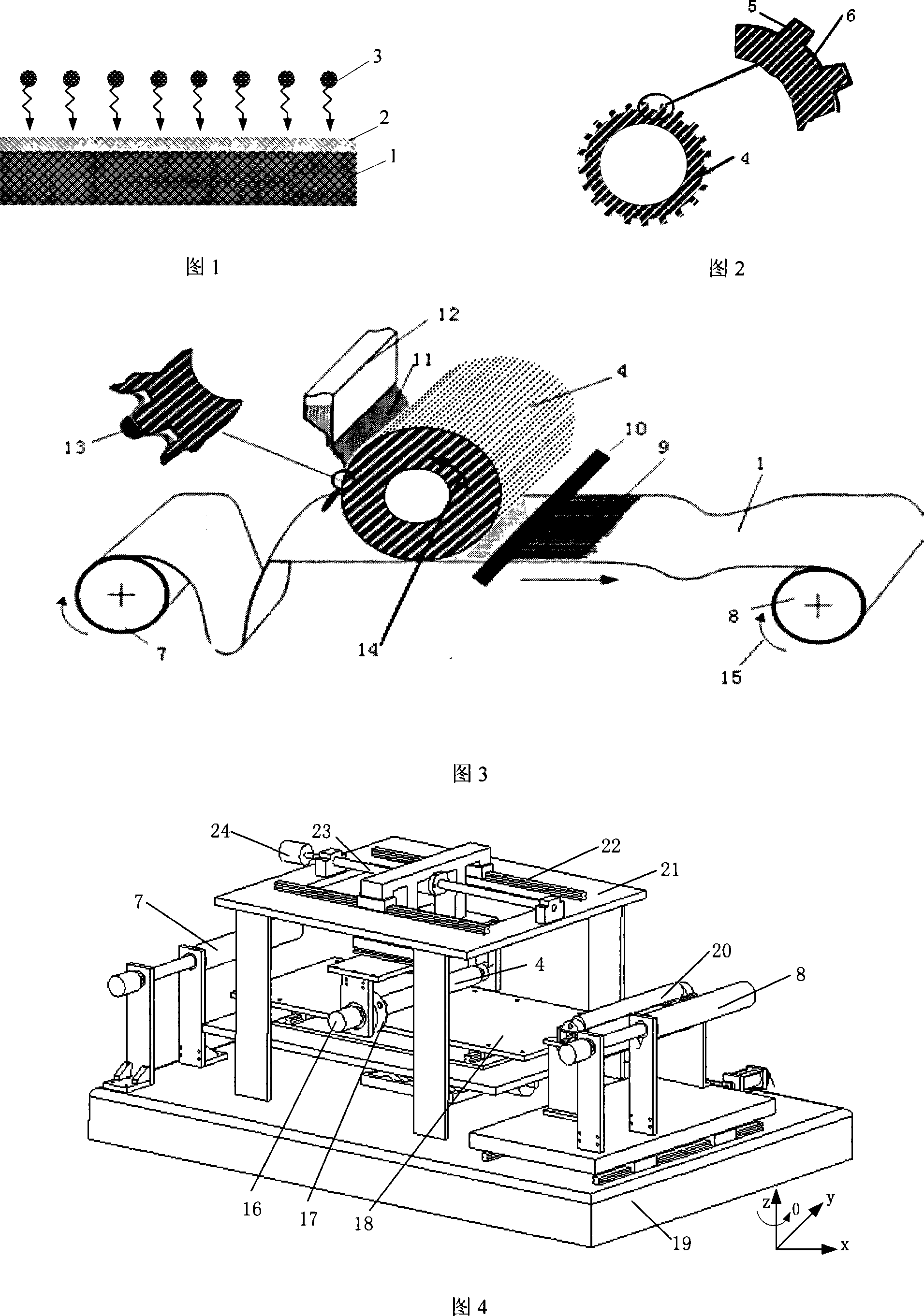

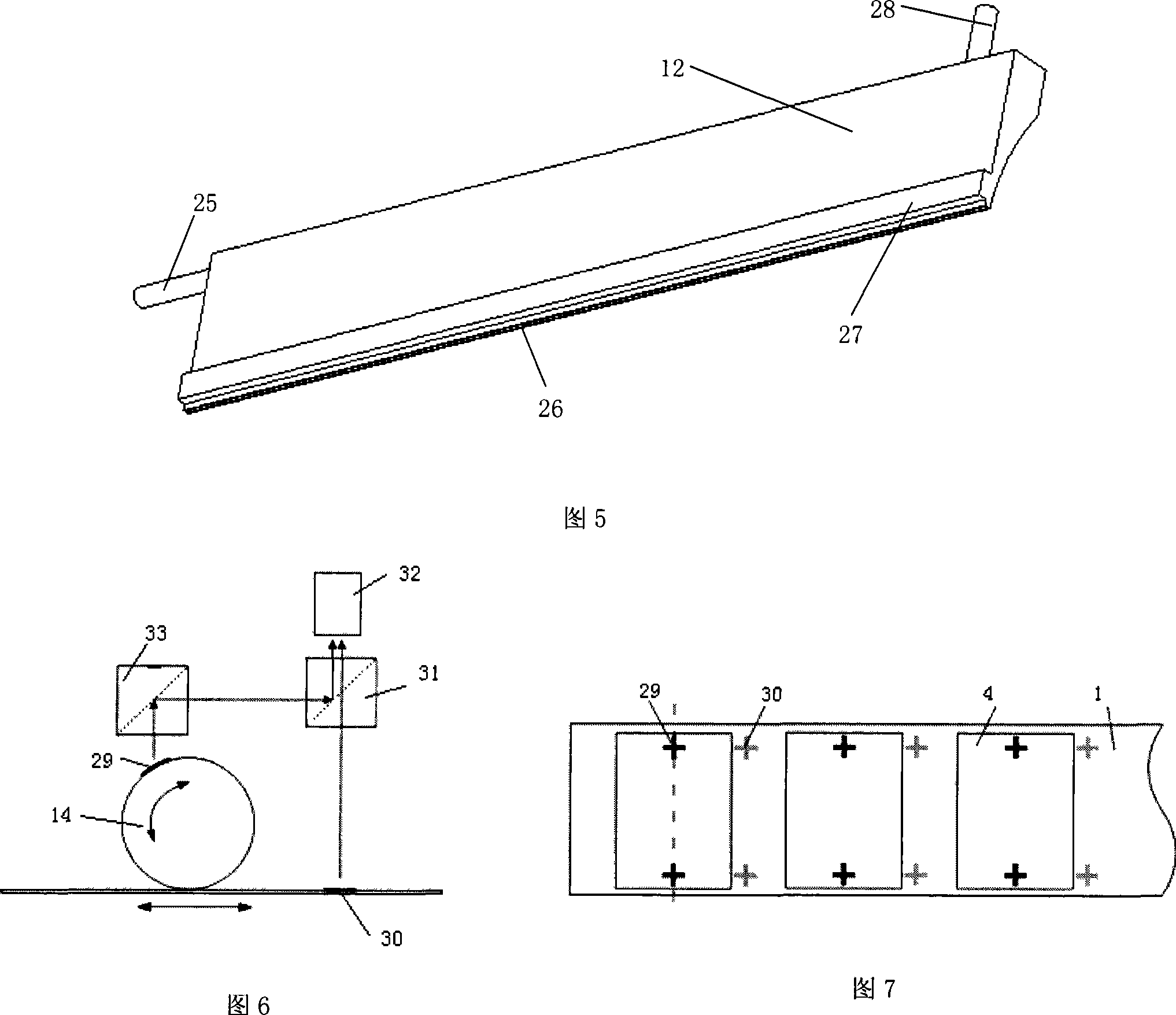

[0025] Referring to the accompanying drawings, Fig. 1 to Fig. 7 respectively show the flow chart of the large-area reverse embossing process of microstructures in the manufacture of flexible macroelectronics.

[0026] The basic working principle of the present invention is: coating the electronic material on the surface of the mold engraved with the microstructure, completing the patterning of the electronic material, and then transferring the patterned electronic material on the surface of the mold to the flexible substrate by continuous rolling. on the material. Add a photocuring agent to the electronic functional material, and use a cold ultraviolet light source for curing after reverse imprinting. The mold roller rotates at a constant speed while moving in translation, and the linear speed of the rotation matches the translation speed, so as to realize no friction between the microstructure on the mold and the microstructure to be replicated. When printing multilayer circ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com