Cooler of static chuck of extreme ultraviolet photolithographic mask platform

A technology of extreme ultraviolet lithography and electrostatic chuck, applied in the field of coolers, can solve problems such as thermal distortion of mask plates, and achieve the effects of reducing thermal deformation, flexible and simple operation, and high control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

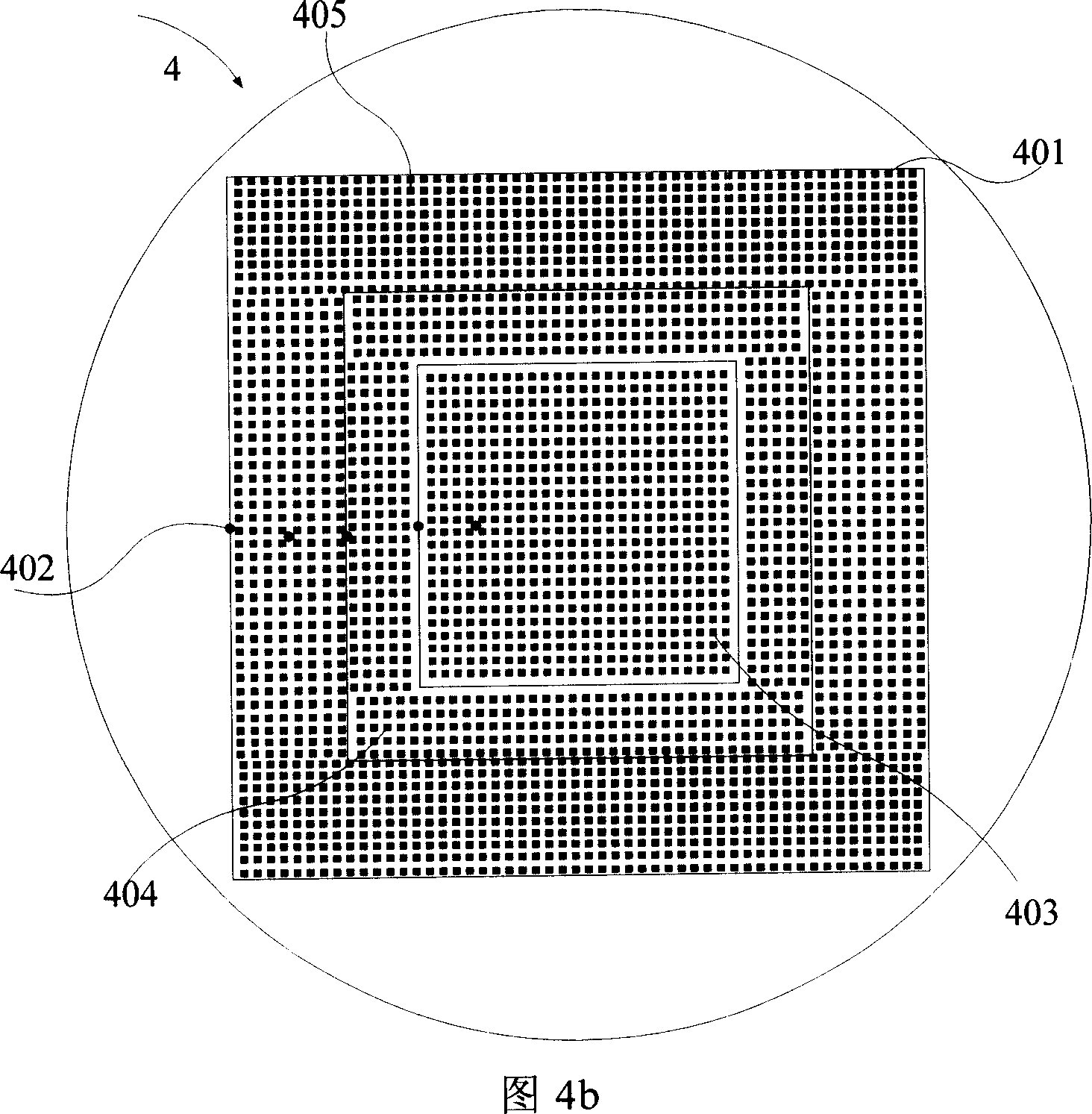

[0040] FIG. 3 is a schematic diagram of the thermoelectric cooler unit 3 in the array thermoelectric cooler, and FIG. 3 shows a cooler unit with m×n=1×4 thermocouple pairs.

[0041] As shown in Figure 3, the thermocouple pair 401 connects the N-type semiconductor 304 and the P-type semiconductor 305 through the conductive metal 303 to form a thermoelectric cooler unit 3. At this time, the cold end insulating heat conducting plate 302 will absorb heat to produce a cooling effect, while the heat sink 306 will release heat, thereby generating a temperature difference between the two ends. When the material and temperature of the hot end of the thermoelectric cooler are fixed, the temperature of the cold end is only related to the magnitude of the incoming current and the properties of the material, so the cooling temperature of the cold end can be changed by changing the magnitude of the incoming current.

[0042] Fig. 4 is a schematic diagram of a specific embodiment of the arra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com