Method for manufacturing well pipe

A manufacturing method and well pipe technology, which are applied in manufacturing tools, ceramic molding machines, etc., can solve problems such as affecting the service life of the water output of machine wells, failure to implement national standards, etc., and achieve the effects of good elasticity, little splash, and clean exterior.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

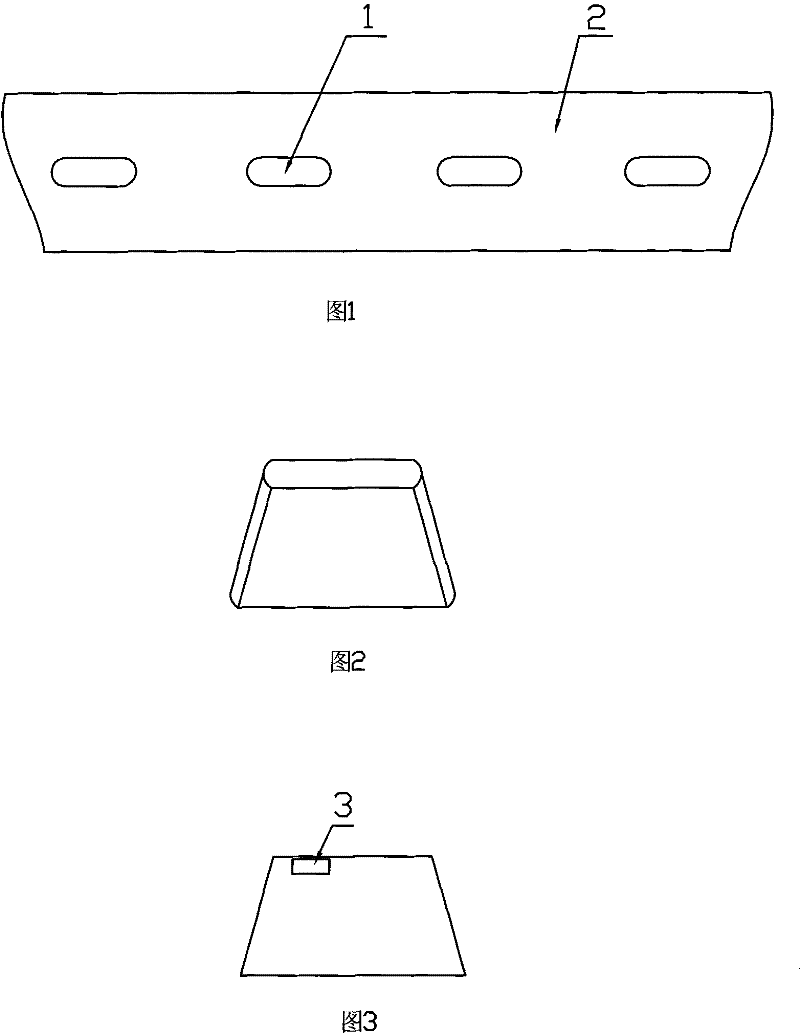

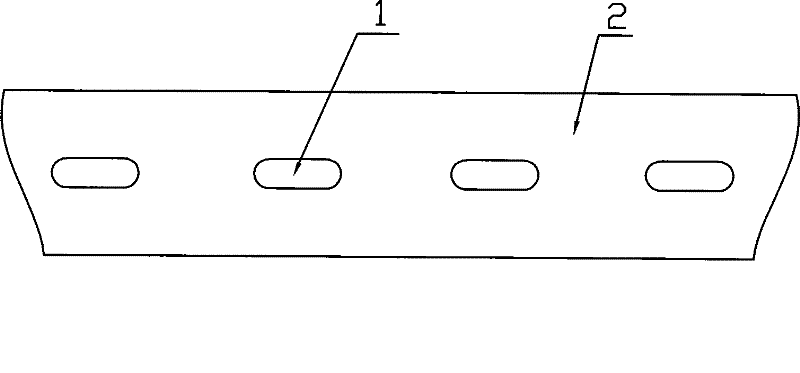

Image

Examples

Embodiment Construction

[0020] The well pipe mold of the present invention is controlled by a speed-regulating motor to rotate, and the rotation speed of the well pipe mold is adjusted by the motor, which is a prior art. The well pipe mold is an existing two-half mold mold.

[0021] The manufacturing method of the well pipe of the present invention comprises two kinds, and a kind of well pipe that is used to make the well pipe that does not perforate on the pipe wall such as the well wall pipe, the method steps are as follows:

[0022] (1) Start the motor, the well pipe mold starts to rotate, control the speed at 130-180 rpm, put the concrete mixture into the well pipe mold evenly through the openings at both ends of the well pipe mold, and as the well pipe mold rotates, The concrete mixture will evenly stick to the inner wall of the mold under the action of centrifugal force, and stop feeding when the required wall thickness is reached. The wall thickness varies according to the specifications of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com