Strip steel rolling system, floating type surface cleaning roller for metal belt material and usage method of floating surface cleaning roller for metal belt material

A metal strip and surface cleaning technology, which is applied in metal rolling, metal rolling, metal processing equipment, etc., can solve the problems of scratching the strip surface, affecting tension control, strip deviation, etc., and achieves long service life, Easy replacement and light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

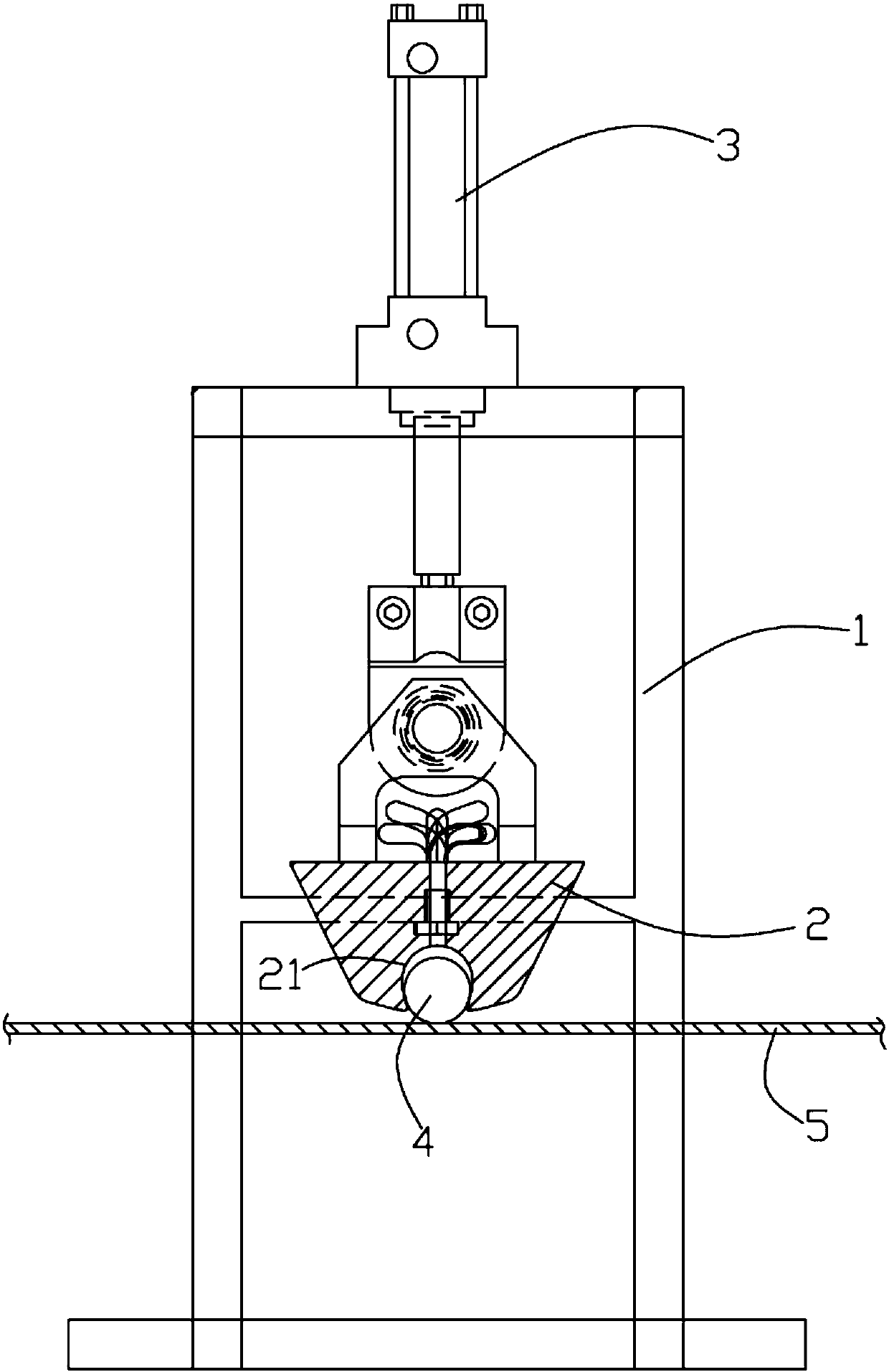

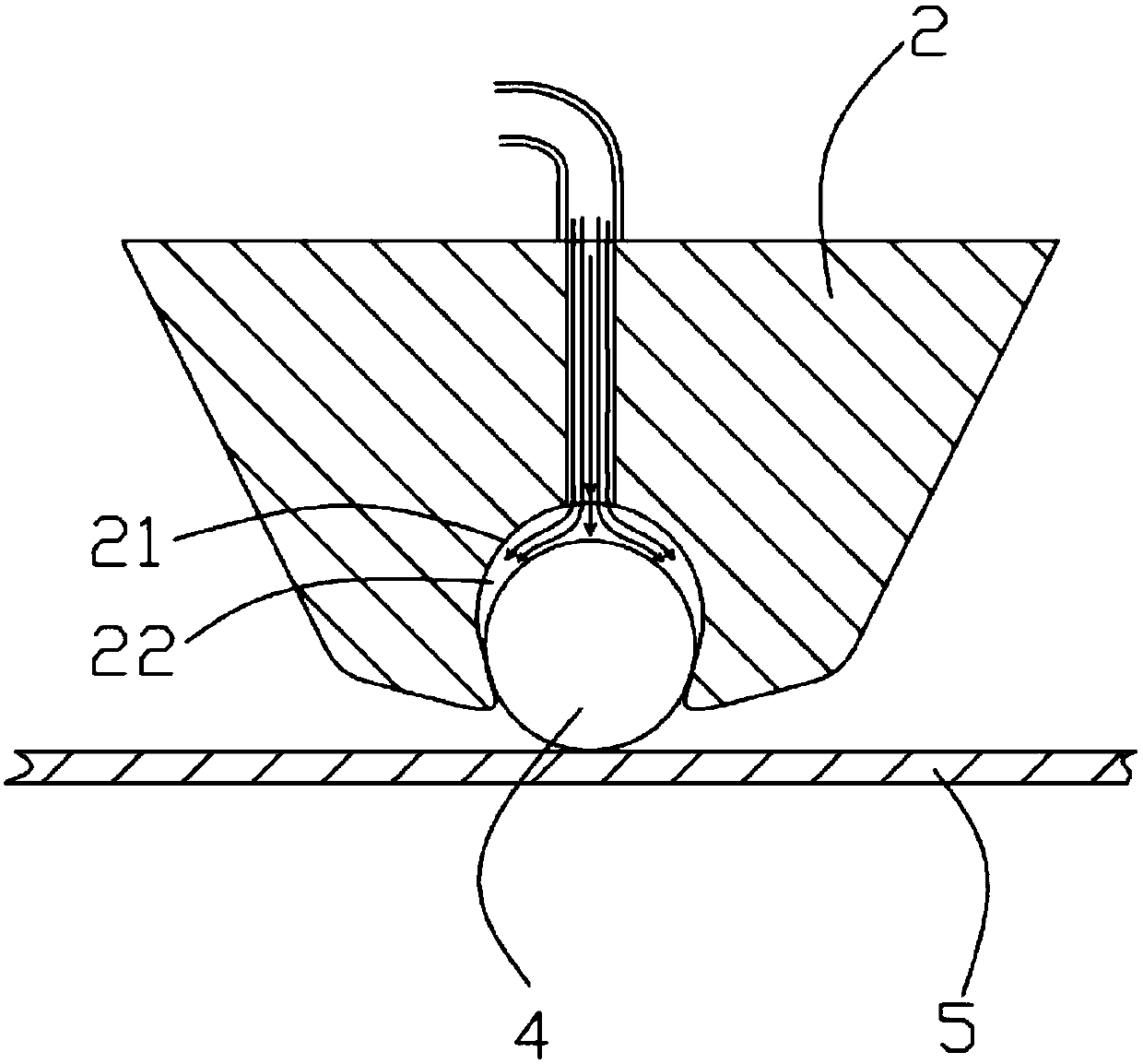

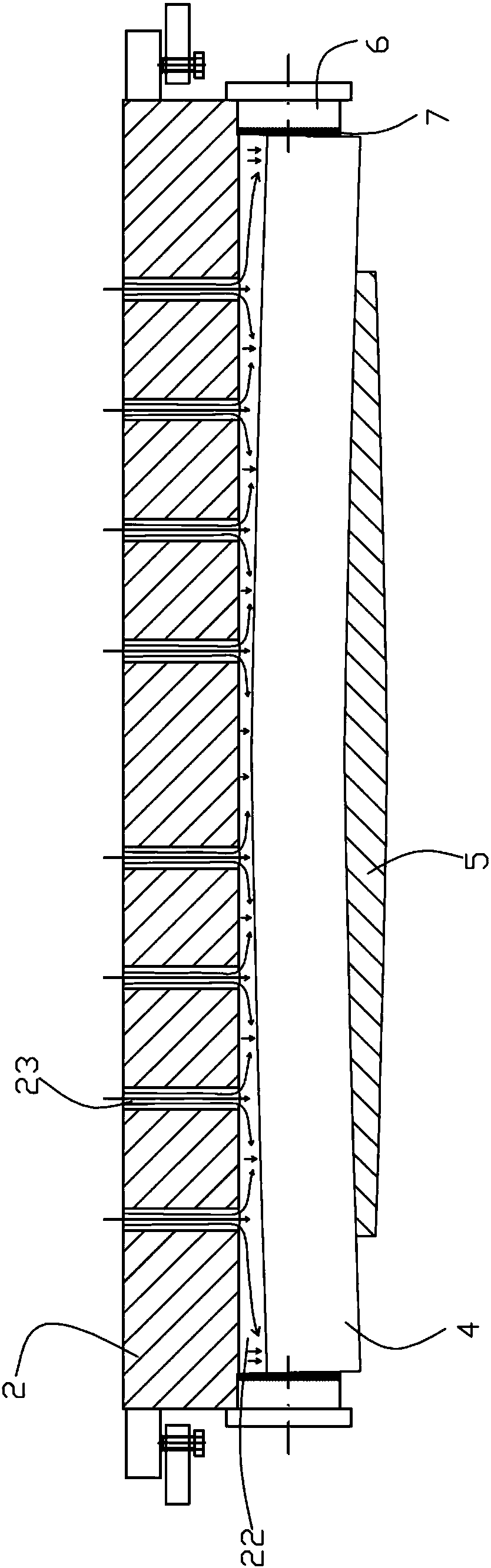

[0029] Such as Figure 1-Figure 3 , the embodiment of the present invention provides a floating metal strip surface cleaning roller, including a roller seat 2 and a flexible floating roller 4, and the roller seat 2 is connected with a driving mechanism for driving it close to or away from the metal strip running channel; generally Specifically, the above-mentioned flexible floating roller 4 is arranged above the running channel of the metal strip to clean the upper surface of the metal strip 5, and the above-mentioned driving mechanism 3 can drive the roller base 2 up and down, thereby driving the floating roller 4 up and down. Further preferably, the bottom of the above-mentioned roller seat 2 is provided with a floating groove 21 with the notch facing downwards, the floating roller 4 is vertically limited and set in the floating groove 21 and the bottom end is located outside the floating groove 21 so as to be compatible with the floating groove 21. The surface of the metal ...

Embodiment 2

[0044] Such as Figure 1-Figure 3 , the embodiment of the present invention describes the method of using the floating metal strip surface cleaning roller provided in the first embodiment above. 4. The bottom end is close to the upper surface of the metal strip 5; inflating the air cavity 22, the floating roller 4 deforms under pressure and contacts the metal strip 5. Other corresponding operation steps, such as the adjustment of the stop block, etc. will not be detailed here one by one.

Embodiment 3

[0046] The embodiment of the present invention relates to a strip rolling system, including a rolling mill, a coiler, and a cleaning device arranged between the rolling mill and the coiler. The cleaning device preferably includes the The floating metal strip surface cleaning roller, the specific structure of the floating metal strip surface cleaning roller will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com