High-pressure fuel supply pump and the manufacturing method

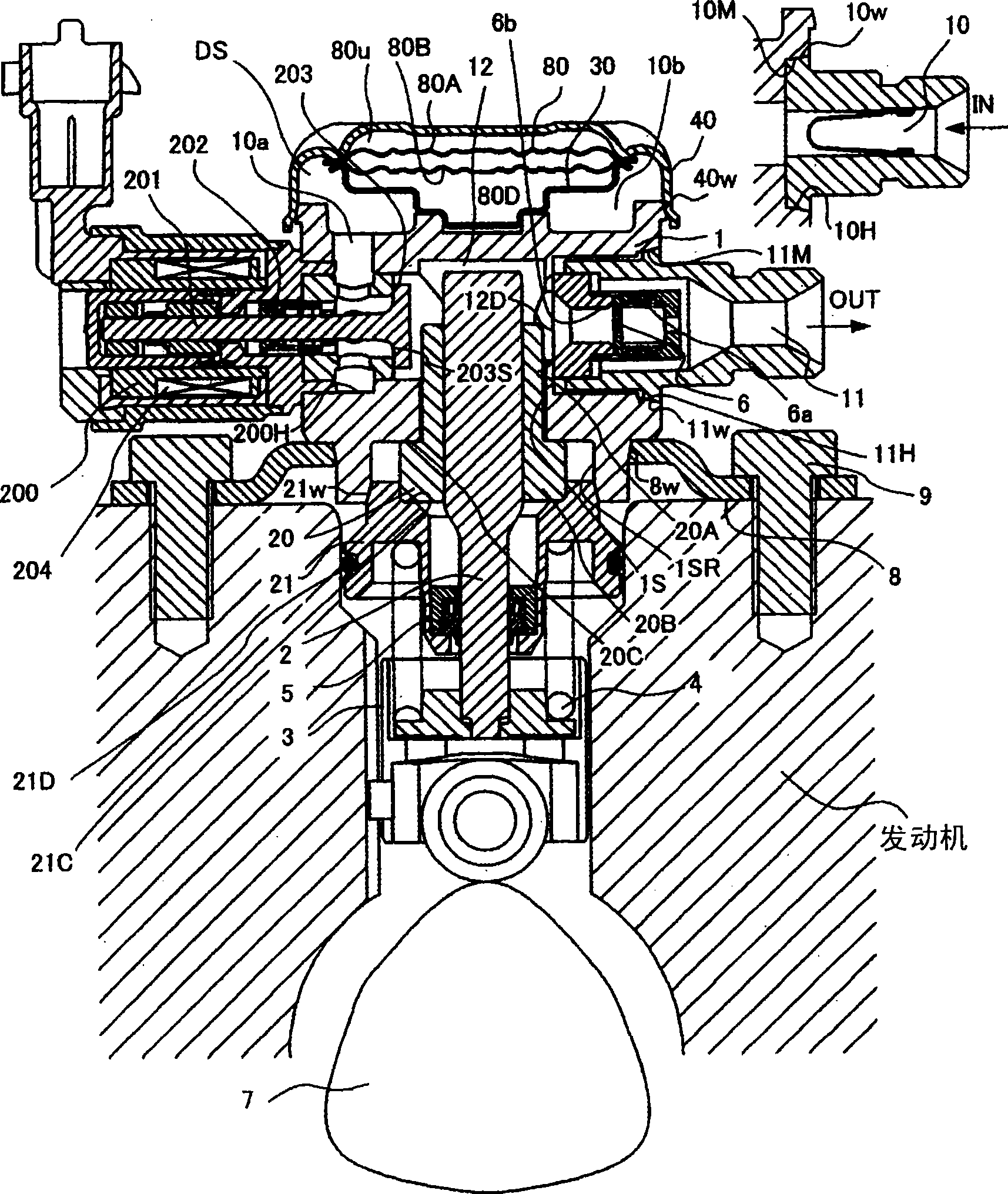

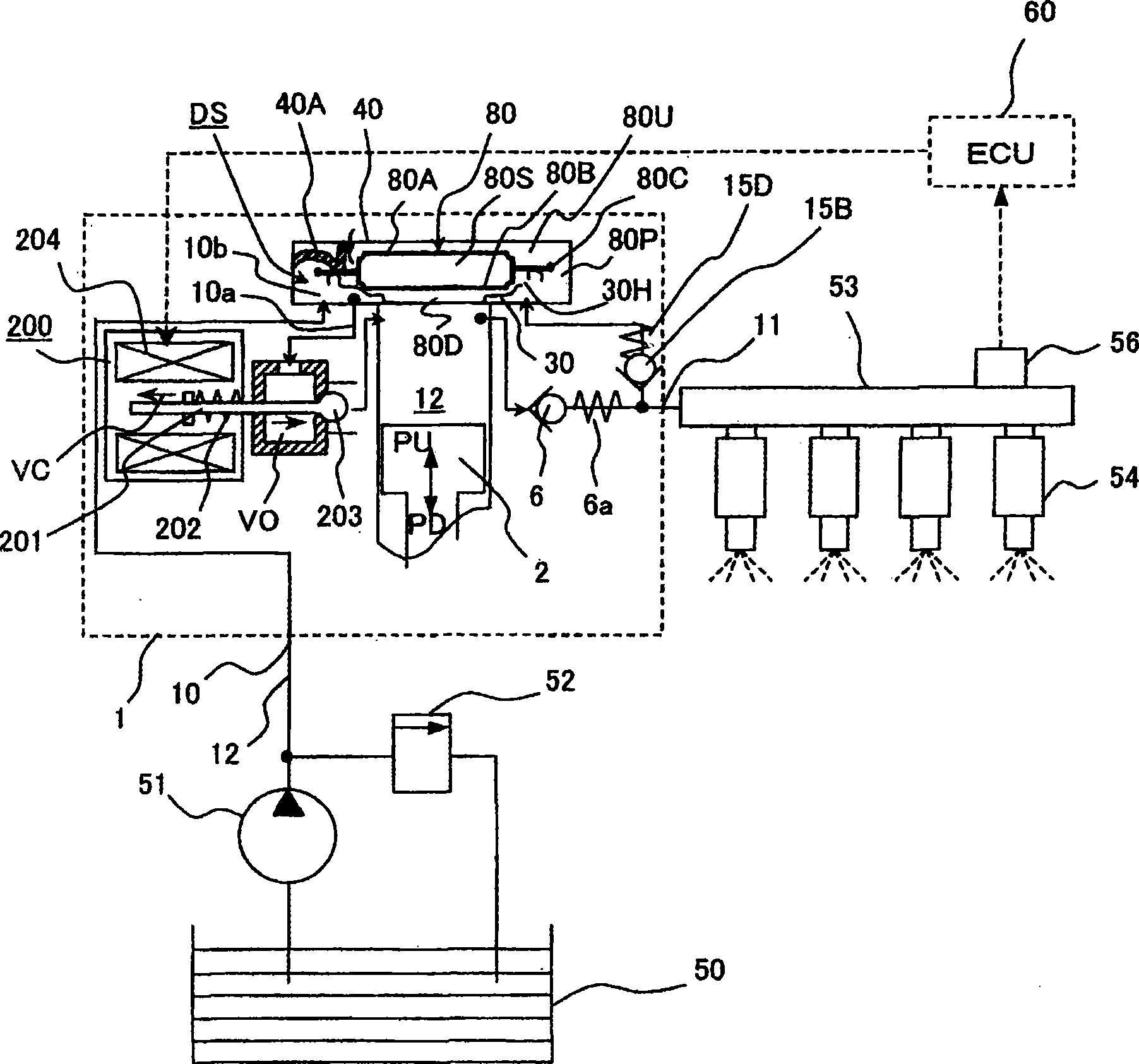

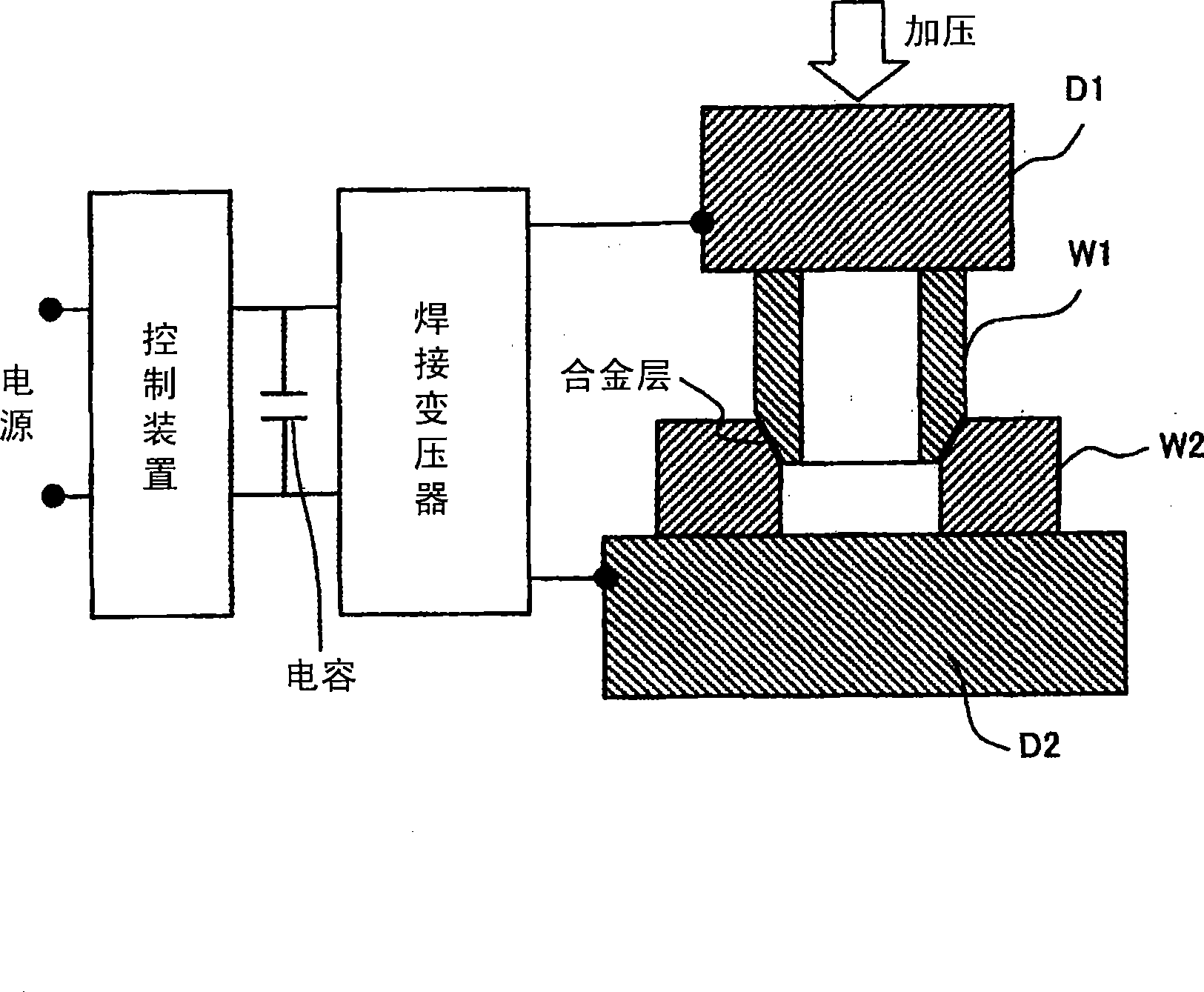

一种高压燃料、供给泵的技术,应用在燃料喷射泵、制造工具、燃料喷射装置等方向,能够解决尺寸变化、接合强度不充分、流体密封性不充分等问题,达到强固接合力、大焊接接合面积、实现密封功能的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0163] A joint structure of two members, a basic technology of joining a joint member and a non-joint member by welding, wherein the joint surface of the above two members has a conical joint surface, sandwiching the joint surface, formed along the joint The plastic flow area of the above two components on the surface.

Embodiment approach 2

[0165] A joint structure of two members is the basic technique described in Embodiment 1, wherein a diffusion bonded region of the two members is formed in a region including the joint surface sandwiched between plastic flow regions of the two members.

Embodiment approach 3

[0167] A joint structure of two members, which is the basic technique described in Embodiment 1, wherein at least one of the large-diameter side end or the small-diameter side end of the conical joint surface is provided with the large-diameter side end or the small-diameter side Any one of the annular cavity, the annular groove or the annular recess facing any one of the ends.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com