Vermicular graphite cast iron piston rings for internal combustion engines

A technology of compacted graphite cast iron and piston rings, which is applied in the field of compacted graphite cast iron piston rings for internal combustion engines, can solve problems such as uneven contact surface wear, achieve the effects of solving uneven wear, improving overall performance, and reducing scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

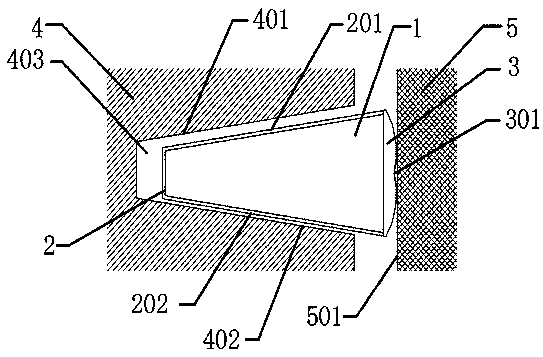

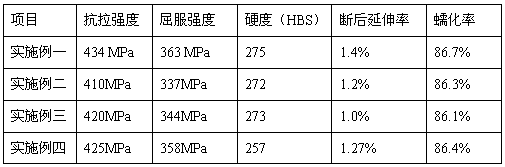

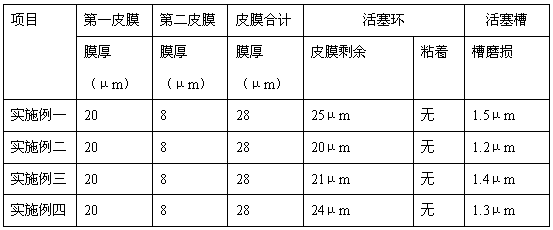

[0031] Such as figure 1 As shown, a vermicular graphite cast iron piston ring for an internal combustion engine includes a piston ring body 1, the upper surface, the lower surface of the piston ring body 1 and the side facing the piston ring groove are covered with a layer of anti-adhesive film 2, the piston ring body 1 and A wear-resistant layer 3 is provided on the side in contact with the cylinder. The anti-adhesive film 2 includes a first film and a second film. The first film covers the second film, and the second film covers the piston ring body. 1, the wear-resistant layer 3 extends along the side of the piston ring body 1 in contact with the cylinder 5 to form a first tongue and a second tongue, the outer peripheral surface of the first tongue forms a bulging cylinder shape, And an opening is formed on the side of the piston ring body 1 in contact with the cylinder, the outer peripheral surface of the second tongue is formed in a bulging cylindrical shape, and an openi...

Embodiment 2

[0045] This embodiment is the same as Embodiment 1, except that the compacted graphite cast iron is composed of the following components by weight percentage: 3.4% carbon, 2.1% silicon, 0.3% molybdenum, 0.3% manganese, niobium 0.2% of chromium, 0.01% of tin, 0.01% of antimony, 0.1% of vanadium, 0.25% of titanium, the total content of phosphorus and sulfur is not more than 0.06%, and the balance is iron and its unavoidable impurities , the preparation method of described vermicular graphite cast iron comprises the following steps:

[0046] Step 1. Raw material preparation and molten iron smelting. When molten iron is smelted, put the raw material iron into the converter to heat and melt. Add decarburizer, desulfurizer and deoxidizer to the pool to decarburize, desulfurize and deoxidize the molten iron in the pool;

[0047] Step 2. After the decarburization, desulfurization and deoxidation processes are completed, the temperature of the molten pool is raised to 1440°C, and then f...

Embodiment 3

[0056] This embodiment is the same as embodiment one and embodiment two, and its difference is that described vermicular graphite cast iron is made up of following composition by weight percentage: carbon is 3.8%, silicon is 2.6%, molybdenum is 0.1%, manganese is 0.2%, niobium 0.3%, chromium 0.1%, tin 0.03%, antimony 0.28%, vanadium 0.18%, titanium 0.15%, the total content of phosphorus and sulfur does not exceed 0.06%, and the balance is iron and its Unavoidable impurities, the preparation method of the compacted graphite cast iron comprises the following steps:

[0057] Step 1. Raw material preparation and molten iron smelting. When molten iron is smelted, put the raw material iron into the converter to heat and melt. Add decarburizer, desulfurizer and deoxidizer to the pool to decarburize, desulfurize and deoxidize the molten iron in the pool;

[0058] Step 2. After the decarburization, desulfurization and deoxidation processes are completed, the temperature of the molten ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com