Automobile brake disc and manufacturing method thereof

A technology of automobile brakes and raw material iron, applied in the direction of brake discs, mechanical equipment, brake types, etc., to achieve the effects of improving heat dissipation, reducing costs, and high performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The embodiments of the present invention are described in detail below, and these embodiments are only used to explain the present invention, but not to be construed as limiting the present invention.

[0027] refer to figure 2 , the present invention is achieved through the following technical solutions:

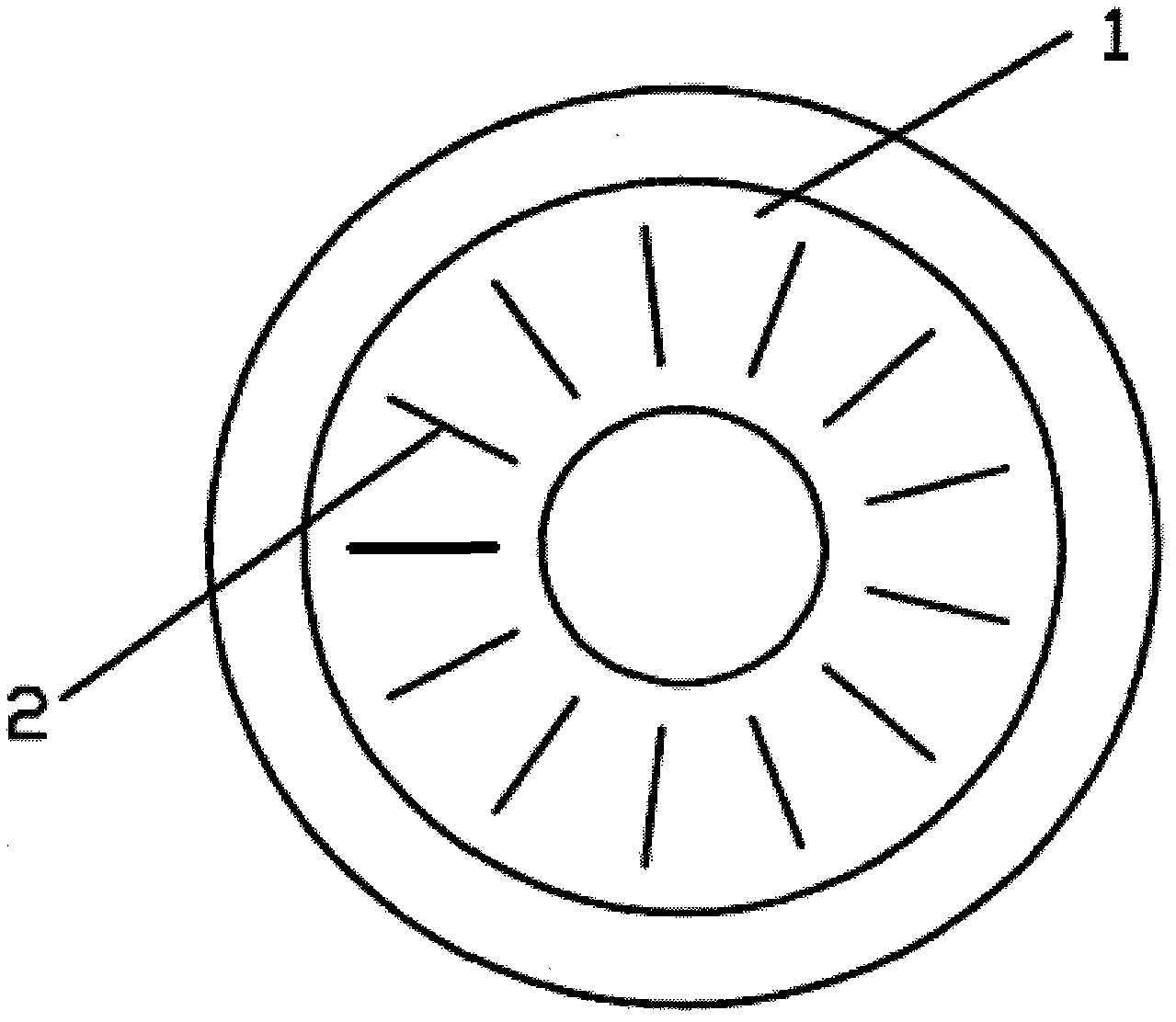

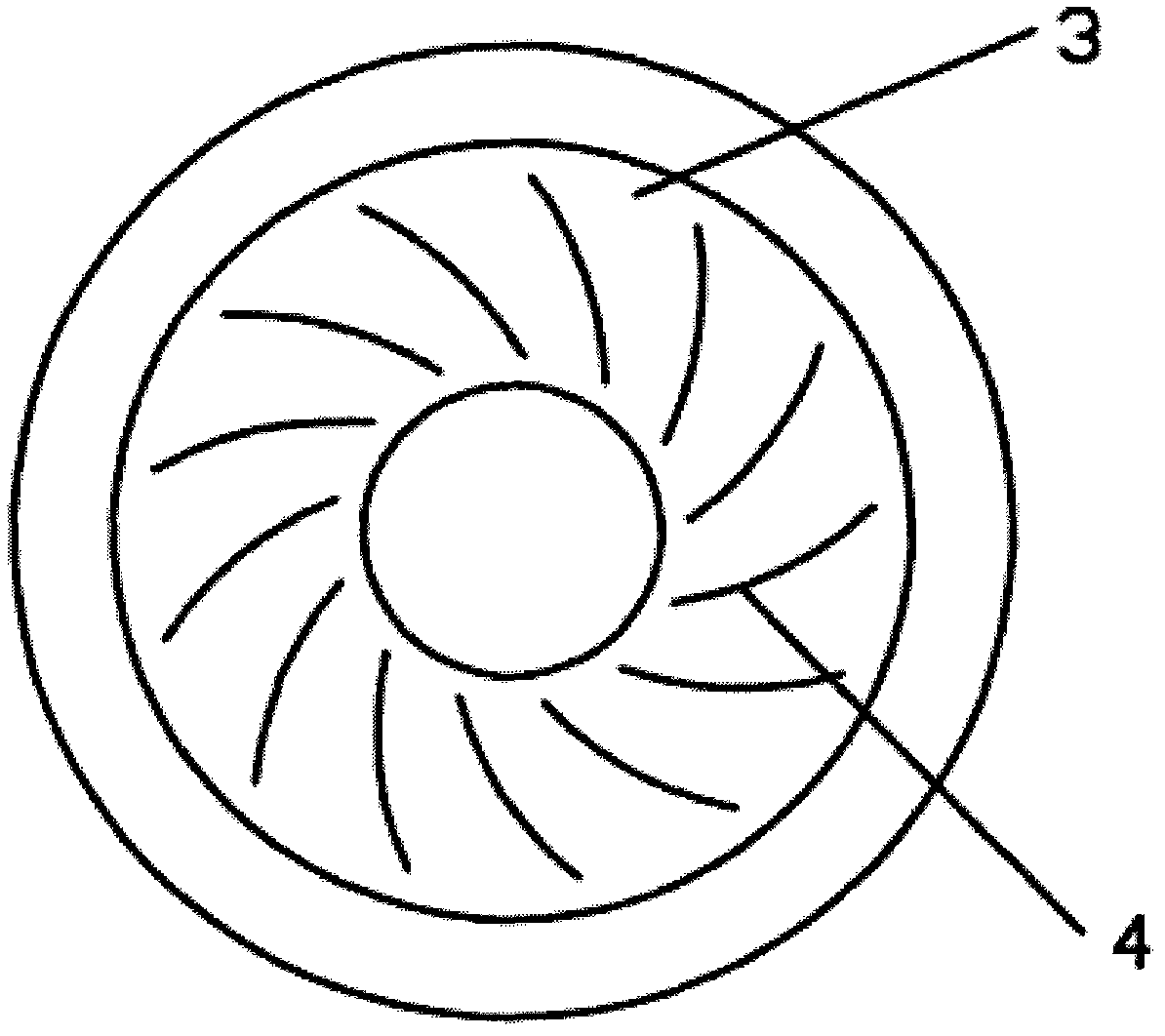

[0028] An automobile brake disc, the appearance of the brake disc 3 is the same as that of the prior art brake disc 1, and the flow direction of the internal fins 4 of the brake disc is spirally twisted from the center to the edge; the spiral twist is adopted Kimedean spiral structure.

[0029] The material of the automobile brake disc is vermicular graphite cast iron; the outer surface of the brake disc is treated with boronizing.

[0030] A kind of preparation method of automobile brake disc:

[0031] 1) Select raw iron; the weight percent of each element in the raw iron is 3.6-3.8% carbon, less than 1.2% silicon, less than 0.04% sulfur, 0.3-0.9% manganese, 0.0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com