Diaphragms for combustion chamber pressure sensors

A technology of sensors and combustion chambers, applied in the direction of combustion ignition, combustion methods, measuring fluid pressure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

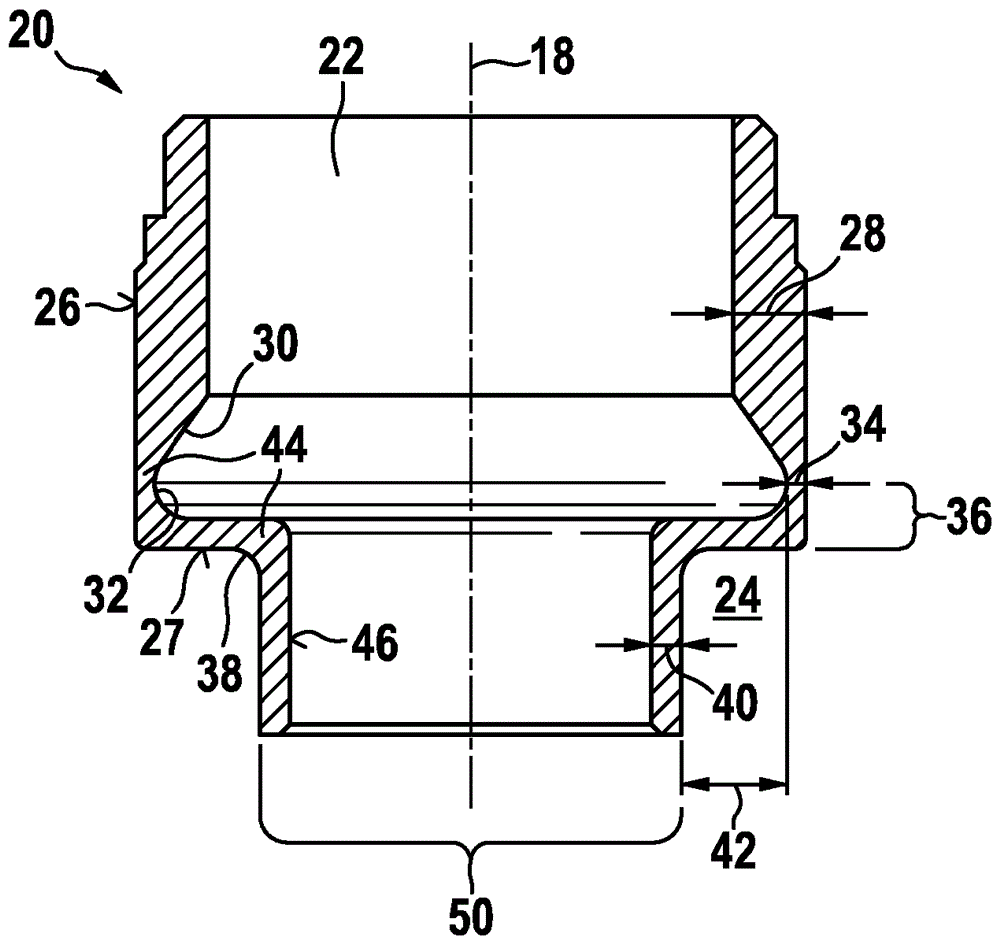

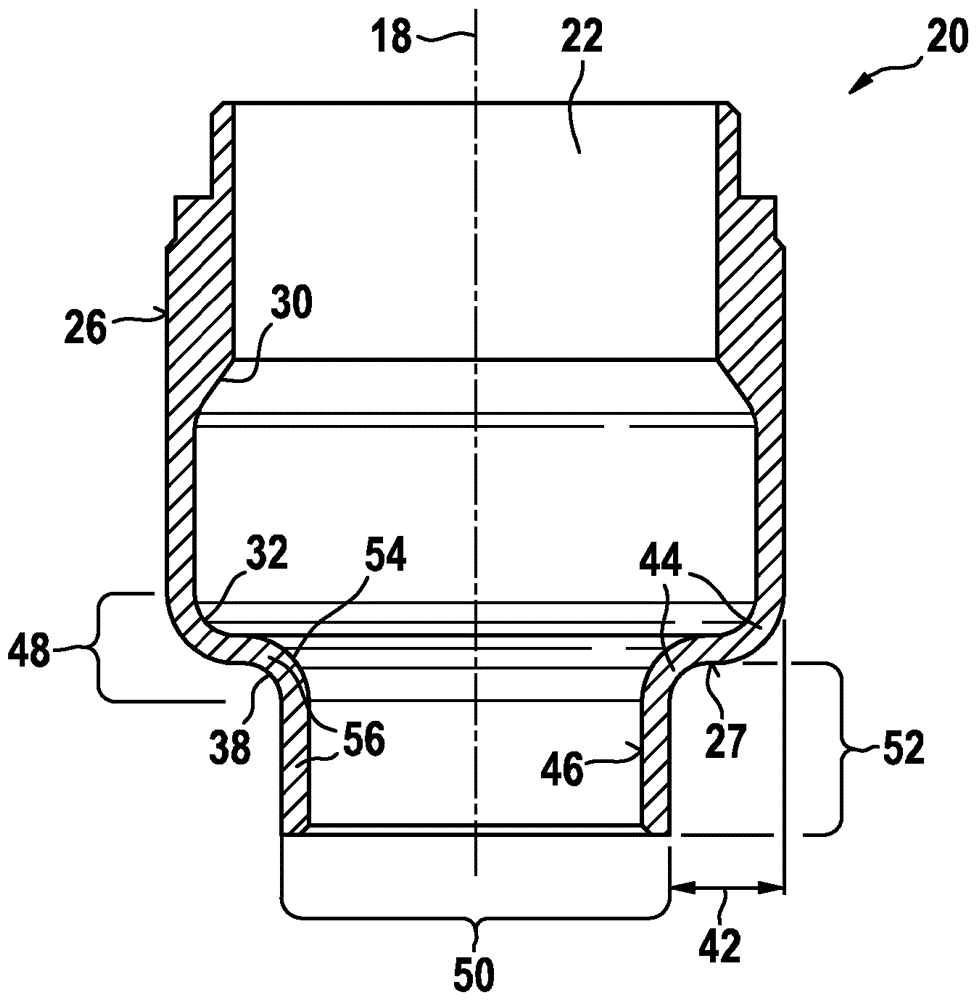

[0016] figure 1 with 2 The sensor membrane according to the prior art is shown.

[0017] From figure 1 with 2 It can be seen that the sensor diaphragm 19 is symmetrically configured with respect to its symmetry axis 18 and has a diaphragm cover 26. From figure 2 It can be seen from the cross-sectional view that the sensor diaphragm 19 according to the prior art is constructed with a first wall thickness 28.

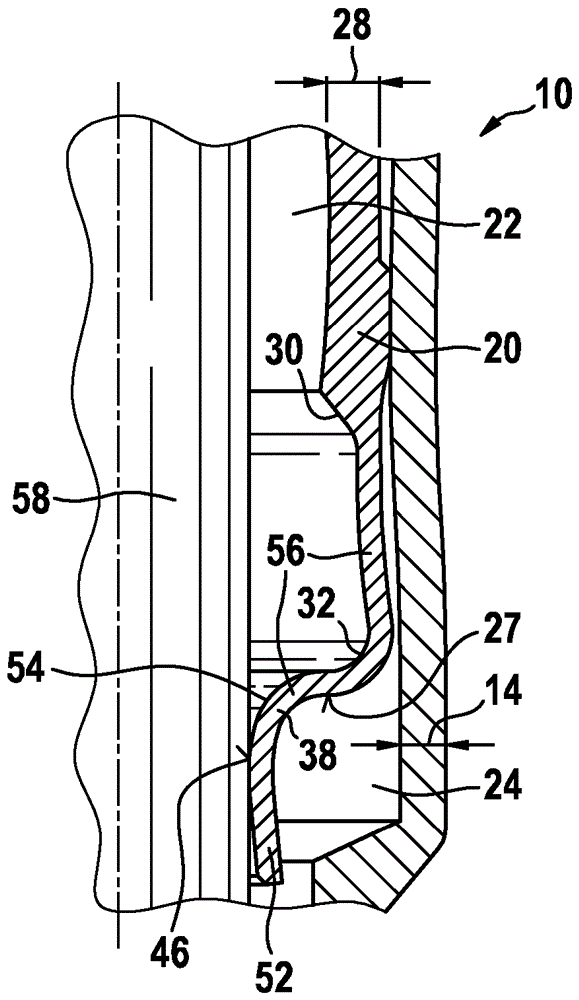

[0018] image 3 A longitudinal section of an embodiment of the combustion chamber pressure sensor according to the invention is shown. The combustion chamber pressure sensor includes a housing 10 in which a pressure rod 58 facing the pressure chamber 24 is accommodated. The pressure rod 58 receives the pressure from the pressure chamber 24 and converts the effect of the pressure into a movement along the axis 18. A cavity 22 is formed between the pressing rod 58 and the housing 10. Furthermore, a measuring sensor mechanism 59 is arranged along the axis 18 behind the pressu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com