Device and method for splicing interferometry of cylindricity errors

A cylindricity error and interferometric measurement technology, applied in measurement devices, optical devices, instruments, etc., can solve the problems of low resolution of measurement results, low sampling efficiency, and the accuracy is affected by many environmental factors, and achieves high measurement accuracy. Effects of low measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

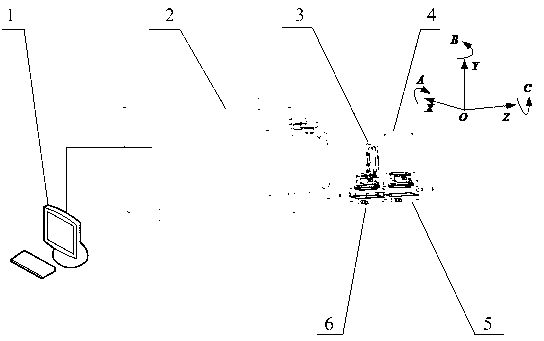

Embodiment 1

Embodiment 2

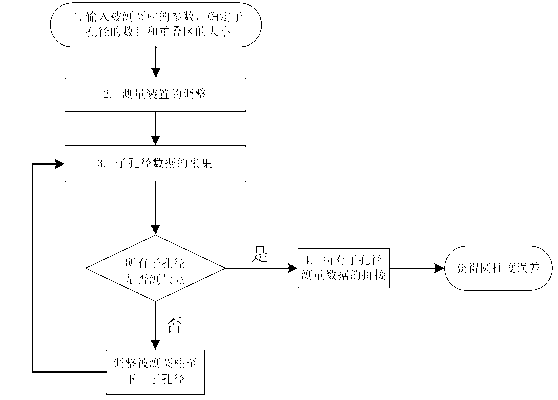

[0037] Example 2: See figure 2 The measurement method of a cylindrical error of the cylindrical error of the present invention is measured by the device of the embodiment one. The measurement step is:

[0038] (1) Determination of the number of sub -pore diameter and the overlapping area parameters: Enter the diameter and height parameters of the tested cylinder 4, according to the effective diameter and F number of the holographic lens (CGH) 3 (that is, the rear focal length and diameter of the diameter (that is, the rear focal length and diameter of the diameterThe ratio of) determine the number of sub -hole diameters of the tested cylindrical 4, the number of sub -pore diameters is 1, 2, 3, and ┅ , Overlapping number, overlapping number is 1, 2, 3, ┅ It

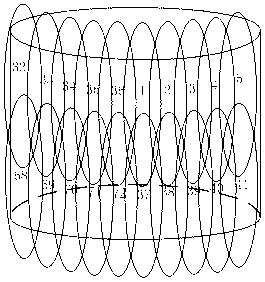

[0039] Circular pore pilot division method: see image 3 and Figure 4 Take the diameter of the cylindrical cylinder for 100mm, the height of 100mm as an example.Facial errors, therefore, according to the principle of 1 / 4 that...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Caliber | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com