Boiler for use in a steam generating device

A steam boiler, steam technology, applied in the direction of steam generation, steam generation method, lighting and heating equipment, etc., can solve the problems of not being able to freely choose the position of holes, steam interruption, etc., to improve reliability and durability, reduce heat The effect of the shock effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

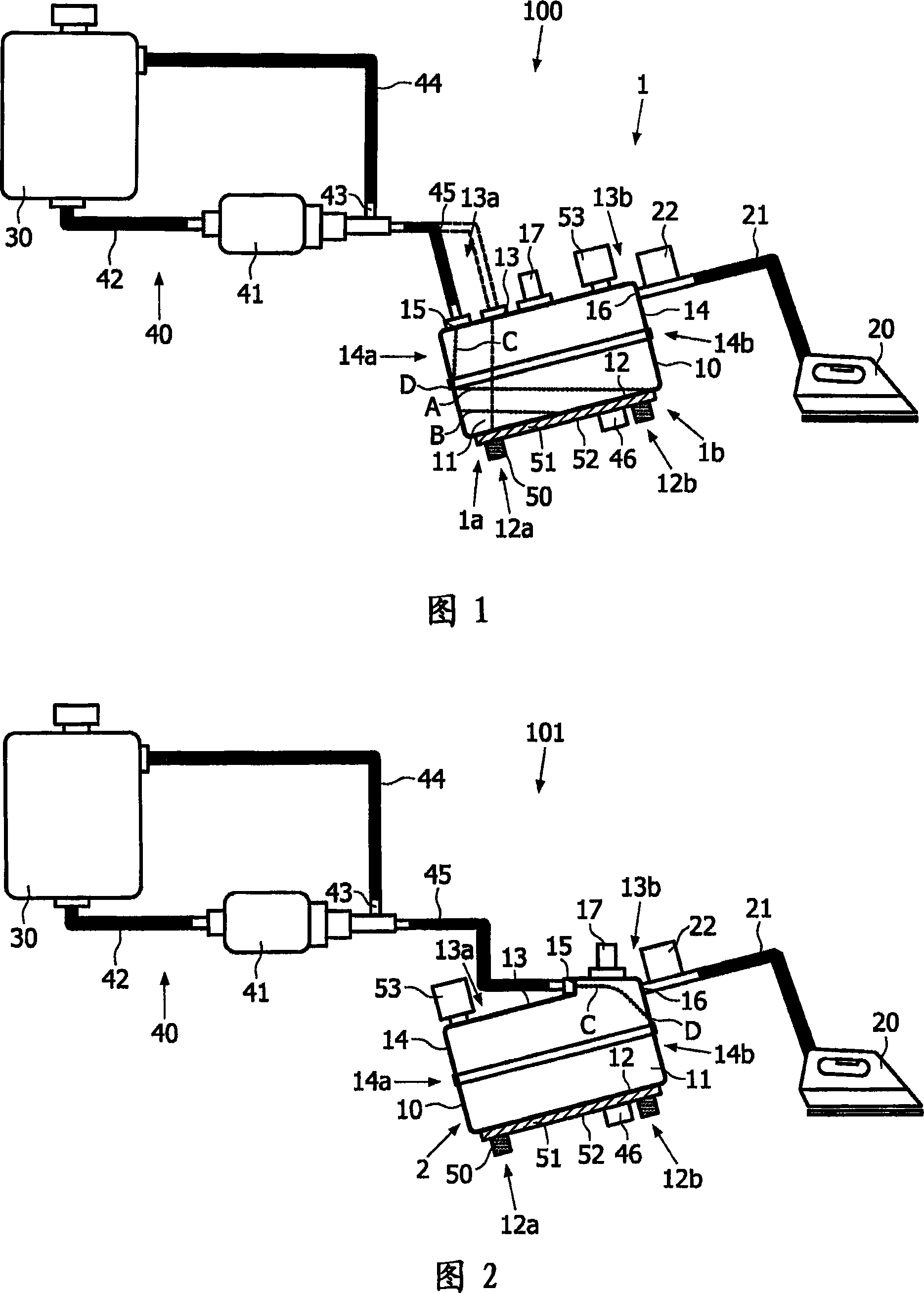

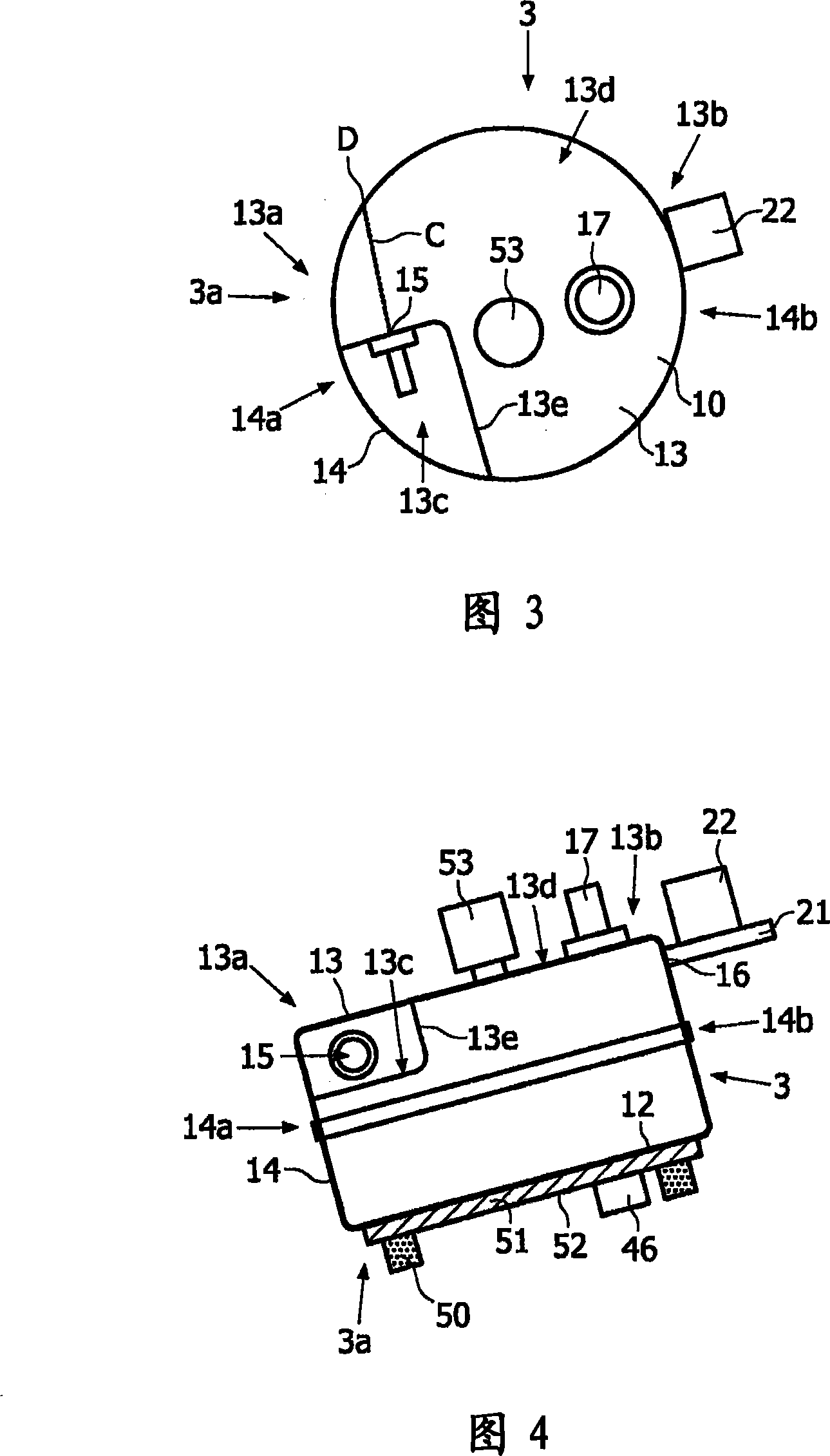

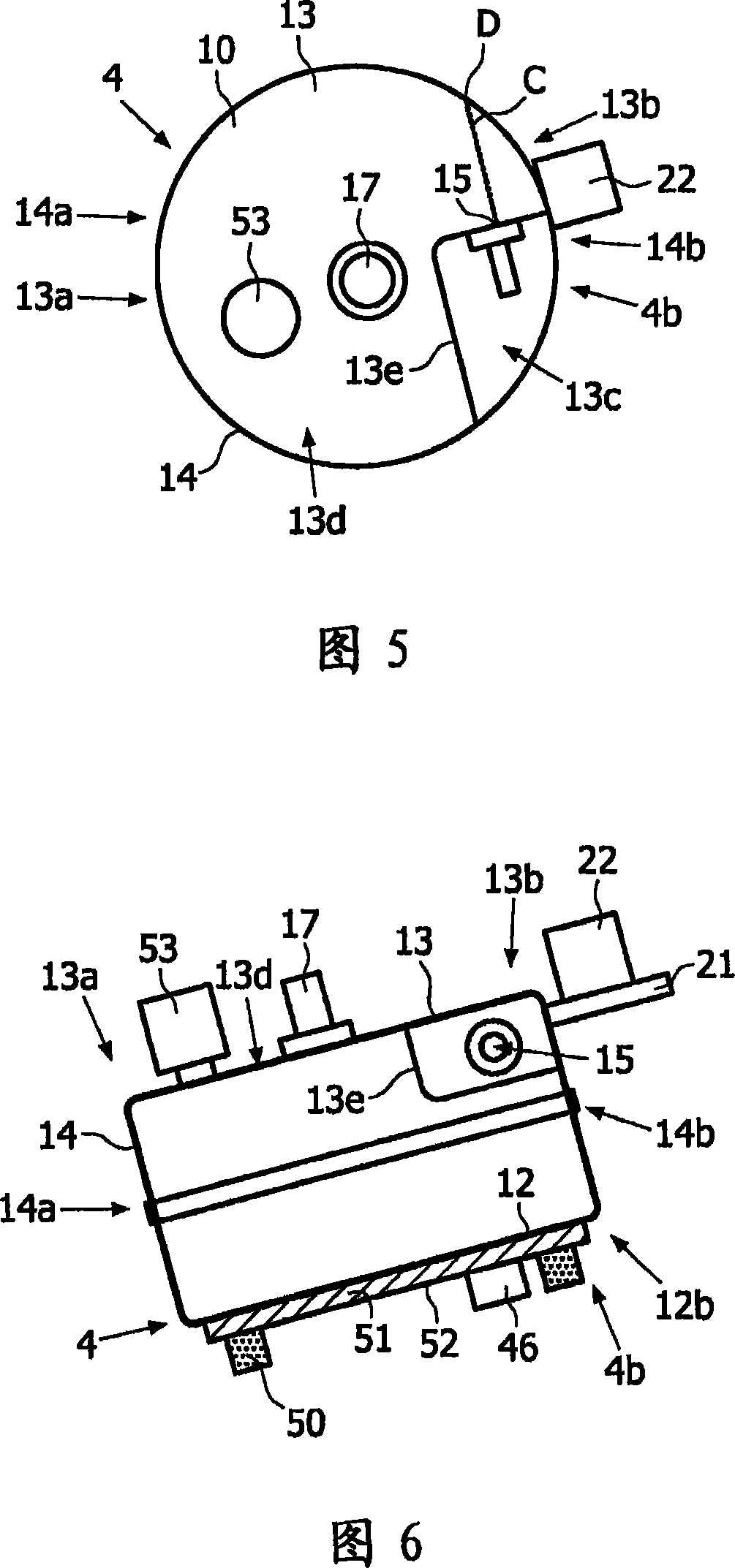

[0030] Fig. 1 schematically shows a steam ironing device 100, comprising a steam boiler 1 according to a first preferred embodiment of the present invention, which is also referred to as a first steam boiler 1 hereinafter. The main function of boiler 1 is to heat water into steam. Typically, the boiler 1 is mounted in a plastic housing (not shown).

[0031] The boiler 1 comprises a boiler housing 10 enclosing a boiler space 11 in which the process of converting water into steam takes place during operation of the boiler 1 . The boiler housing 10 is preferably made of stainless steel and is shaped like a cylinder including a bottom wall 12 and a top wall 13 . In the example shown, both the bottom wall 12 and the top wall 13 comprise planar sheets. Furthermore, the boiler housing 10 comprises an annular wall 14 extending between the bottom wall 12 and the top wall 13 . In the preferred embodiment of the boiler 1, the annular wall 14 has a circular shape, but this does not cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com