High magnesium and low rare earth austenitic vermicular graphite cast iron, its preparation method and application

A vermicular graphite cast iron and austenite technology, applied in the field of cast iron, can solve the problems of low linear expansion coefficient and low wear resistance of cast iron inserts, and achieve the improvement of wear resistance, increase creep rate, and increase creep rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

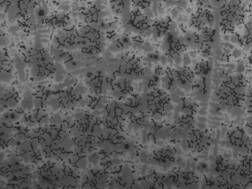

Image

Examples

Embodiment 1

[0043] A high-magnesium and low-rare-earth austenitic vermicular graphite cast iron is composed of the following chemical components according to mass percentage:

[0044] Carbon 2.8%, silicon 2.6%, manganese 1.5%, nickel 10%, copper 6%, chromium 1.0%, magnesium 0.1%, rare earth 0.007%, titanium 0.15%, sulfur ≤ 0.08%, phosphorus ≤ 0.15%, the rest is iron and unavoidable impurities.

[0045] The preparation method of high magnesium and low rare earth austenitic vermicular graphite cast iron comprises the steps of:

[0046] 1) Add recarburizer, pig iron, and scrap steel to an intermediate frequency induction furnace for smelting, wherein the recarburizer is placed at the bottom; after melting, add electrolytic nickel, electrolytic copper, ferrosilicon, ferrochrome, and ferromanganese to continue smelting, and there is molten iron Then add the returned iron filings;

[0047] 2) When the composition of the cast iron solution is qualified and the temperature reaches 1560°C, keep it...

Embodiment 2

[0056] A high-magnesium and low-rare-earth austenitic vermicular graphite cast iron is composed of the following chemical components according to mass percentage:

[0057] Carbon 3.1%, silicon 2.3%, manganese 1.5%, nickel 13%, copper 5%, chromium 1.5%, magnesium 0.09%, rare earth 0.005%, titanium 0.6%, sulfur ≤ 0.08%, phosphorus ≤ 0.15%, the rest is iron and unavoidable impurities.

[0058] The preparation method of high magnesium and low rare earth austenitic vermicular graphite cast iron comprises the steps of:

[0059] 1) Add recarburizer, pig iron, and scrap steel to an intermediate frequency induction furnace for smelting, wherein the recarburizer is placed at the bottom; after melting, add electrolytic nickel, electrolytic copper, ferrosilicon, ferrochrome, and ferromanganese to continue smelting, and there is molten iron Then add the returned iron filings;

[0060] 2) When the composition of the cast iron solution is qualified and the temperature reaches 1550°C, keep ...

Embodiment 3

[0069] A high-magnesium and low-rare-earth austenitic vermicular graphite cast iron is composed of the following chemical components according to mass percentage:

[0070] 2.9% carbon, 2.5% silicon, 01.3% manganese, 8% nickel, 7% copper, 2.5% chromium, 0.08% magnesium, rare earth ≤0.0038%, titanium 0.12%, sulfur ≤0.08%, phosphorus ≤0.15%, and the rest is iron and unavoidable impurities.

[0071] The preparation method of high magnesium and low rare earth austenitic vermicular graphite cast iron comprises the steps of:

[0072] 1) Add recarburizer, pig iron, and scrap steel to an intermediate frequency induction furnace for smelting, wherein the recarburizer is placed at the bottom; after melting, add electrolytic nickel, electrolytic copper, ferrosilicon, ferrochrome, and ferromanganese to continue smelting, and there is molten iron Then add the returned iron filings;

[0073] 2) When the composition of the cast iron solution is qualified and the temperature reaches 1600°C, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com