Multi-layer conveying belt tea leaf fragrance extraction machine and control method

A tea aroma machine and conveyor belt technology, applied in the direction of conveyor control device, conveyor, conveyor objects, etc., can solve the problems of tea quality assurance, fragile tea, affecting tea baking quality, etc., to ensure uniformity, Achieving the effect of uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0071] Below in conjunction with embodiment technical solution of the present invention is made more specific description:

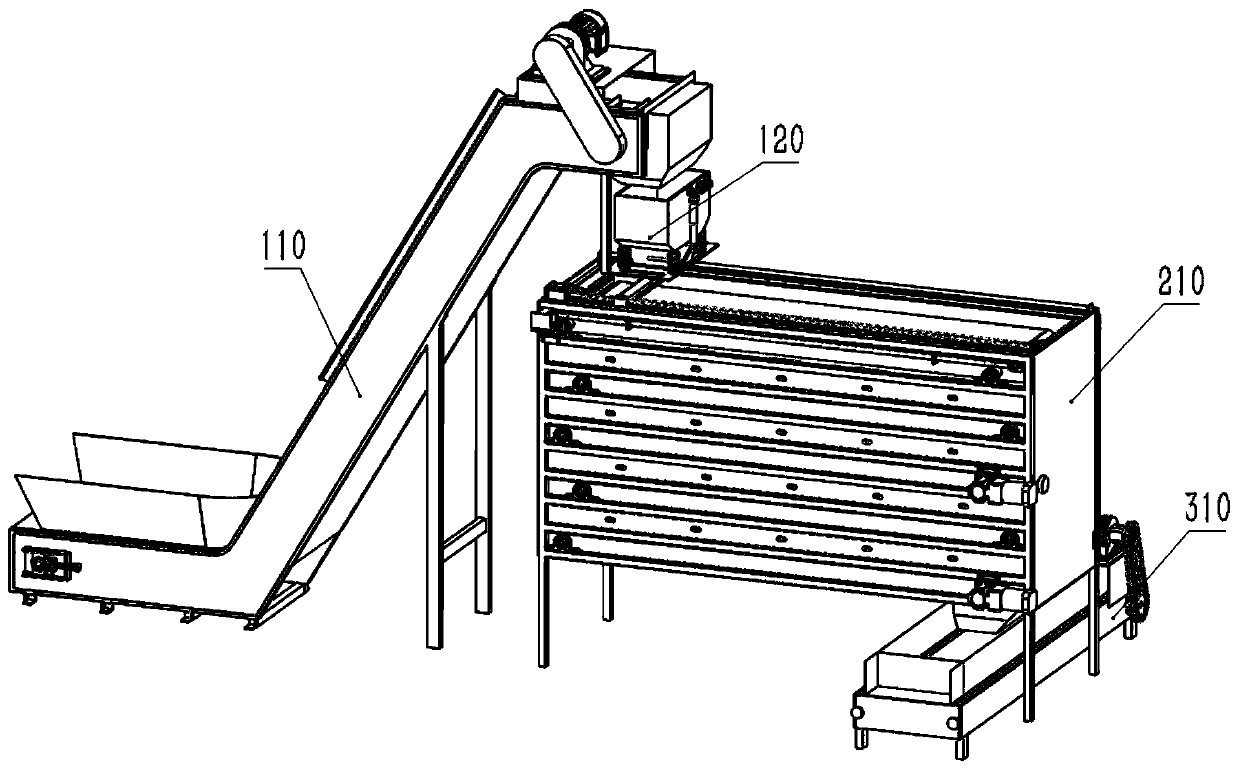

[0072] like figure 1 Shown: a tea aroma enhancing machine with multi-layer conveyor belts, including a PLC control unit, an automatic tea feeding unit, an aroma enhancing baking unit and an automatic tea discharge unit.

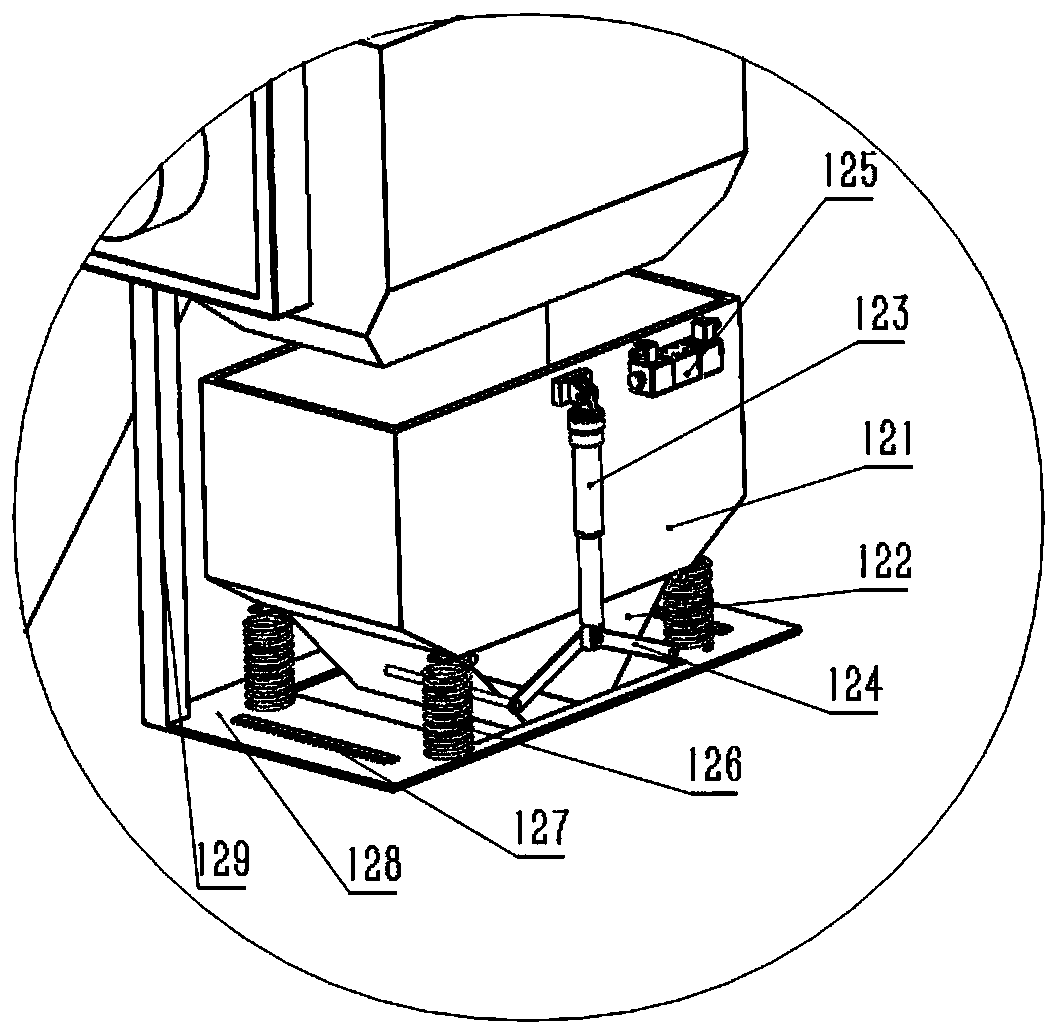

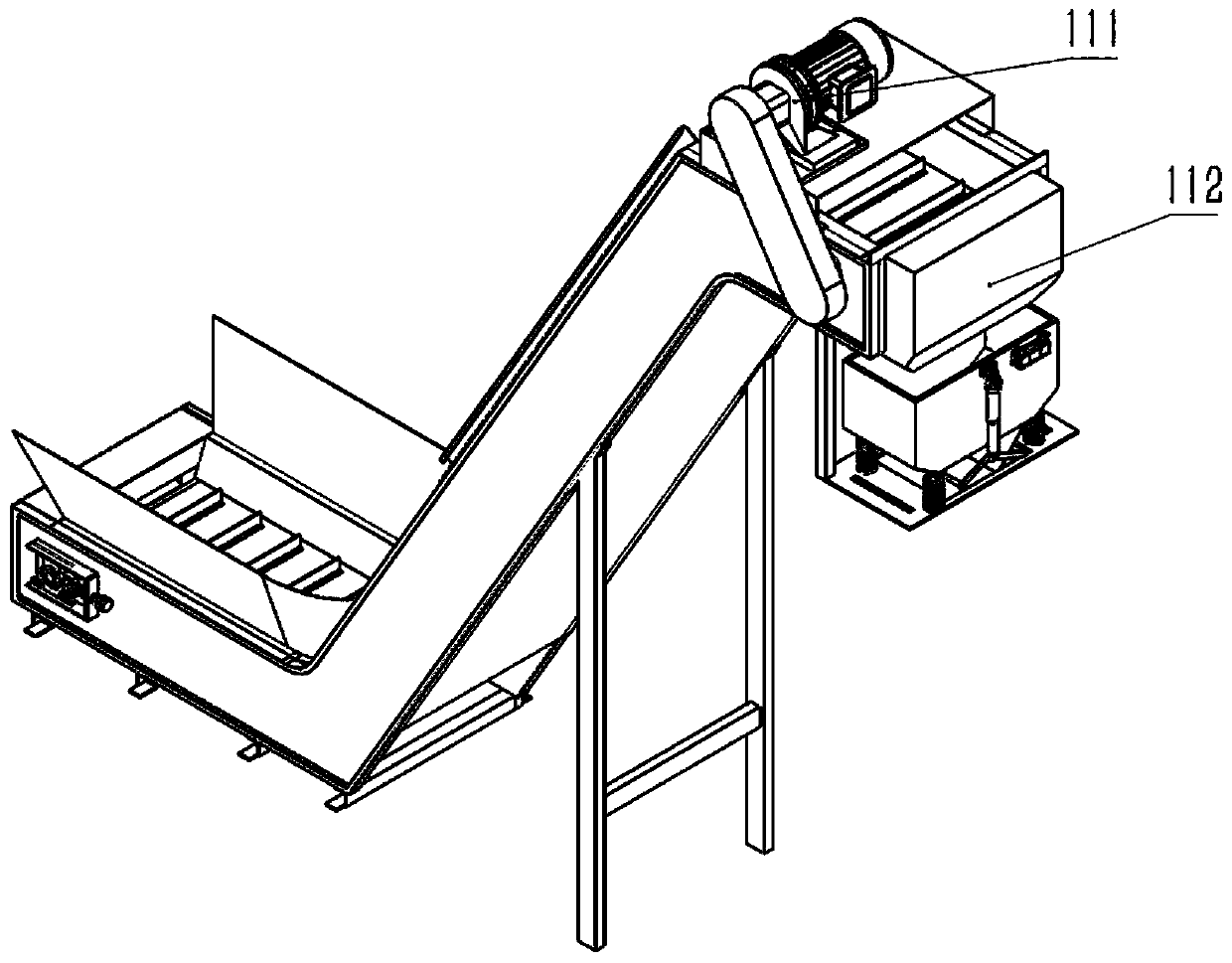

[0073] The automatic tea feeding unit includes a vertical elevator 110 for transporting tea leaves and an automatic tea weighing device 120, and the automatic tea weighing device 120 is installed directly below the discharge port 112 of the vertical elevator. It is used for accurate feeding of tea leaves; the automatic tea discharge unit includes a horizontal conveyor 310 for conveying the output of the aroma-improving and roasting unit;

[0074] The fragrance-increasing baking unit 210 includes a transfer conveyor belt 217, a horizontal leaf homogenizer, a longitudinal leaf homogenizer, and a multi-layer conveyor belt baking unit; the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com