Method for reducing, quenching and tempering molten steel slags in reducing atmosphere

A quenching and tempering treatment and steel slag technology, which is applied in the field of reduction and tempering treatment of molten steel slag under reducing atmosphere, can solve the problems of low gelling activity, slow hydration speed, and harm to the volume stability of cement concrete, so as to optimize mineral composition and improve The effect of gelling activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

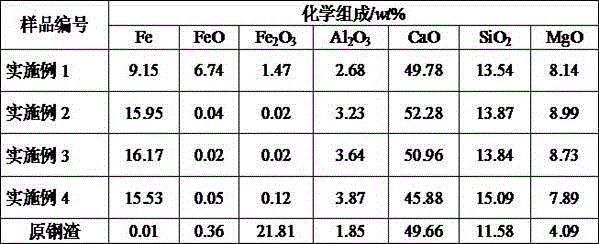

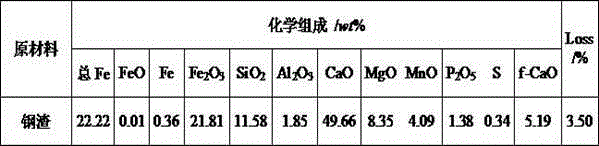

Embodiment 1

[0020] After the raw materials are crushed and ground, 93% converter steel slag and 7% graphite are selected as reducing component adjustment materials according to the weight percentage, and an appropriate amount of water is added to mix evenly, and slowly pressed by a YAW-300B cement press to make Φ12cm×2cm For the material cake, the maximum pressure is 100kN and maintained for 30s. The pressed cakes are layered and placed in a high-purity MgO ceramic crucible or molybdenum crucible, and placed in a high-temperature electric furnace with a reducing atmosphere to perform a high-temperature simulation reconstruction test. During the test, the high-temperature electric furnace was first vacuum degassed and filled with nitrogen, and then protected in the atmosphere (N 2 ) to 1400°C, and kept at the highest set temperature for 120 minutes, then cooled to room temperature in the furnace under the protection of the atmosphere, and then taken out. For the obtained samples, YB / T140-...

Embodiment 2

[0023] After crushing and grinding the raw materials, select 90% converter steel slag and 10% bituminous coal as reducing component adjustment materials according to the weight percentage, add appropriate amount of water and mix evenly, and slowly press it with a YAW-300B cement press to make Φ12cm×2cm For the material cake, the maximum pressure is 100kN and maintained for 30s. The pressed cakes are layered and placed in a high-purity MgO ceramic crucible or molybdenum crucible, and placed in a high-temperature electric furnace with a reducing atmosphere to perform a high-temperature simulation reconstruction test. During the test, the high-temperature electric furnace was first vacuum degassed and filled with nitrogen, and then protected in the atmosphere (N 2 ) to 1400°C, and kept at the highest set temperature for 120 minutes, then cooled to room temperature in the furnace under the protection of the atmosphere, and then taken out. For the obtained samples, YB / T140-2009 "M...

Embodiment 3

[0026] After the raw materials are crushed and ground, 85% converter steel slag and 15% bituminous coal are selected as the reducing component adjustment materials according to the weight percentage, and an appropriate amount of water is added to mix evenly, and slowly pressed by a YAW-300B cement press to make Φ12cm×2cm For the material cake, the maximum pressure is 100kN and maintained for 30s. The pressed cakes are layered and placed in a high-purity MgO ceramic crucible or molybdenum crucible, and placed in a high-temperature electric furnace with a reducing atmosphere to perform a high-temperature simulation reconstruction test. During the test, the high-temperature electric furnace was first vacuum degassed and filled with nitrogen, and then protected in the atmosphere (N 2 ) to 1400°C, and kept at the highest set temperature for 240 minutes, then cooled to room temperature in the furnace under the protection of the atmosphere, and then taken out. For the obtained sampl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com