Method for preparing high-strength artificial marble by exciting and activating low-calorific-value coal ash slag

An artificial marble, low calorific value technology, used in chemical instruments and methods, manufacturing tools, clay preparation devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

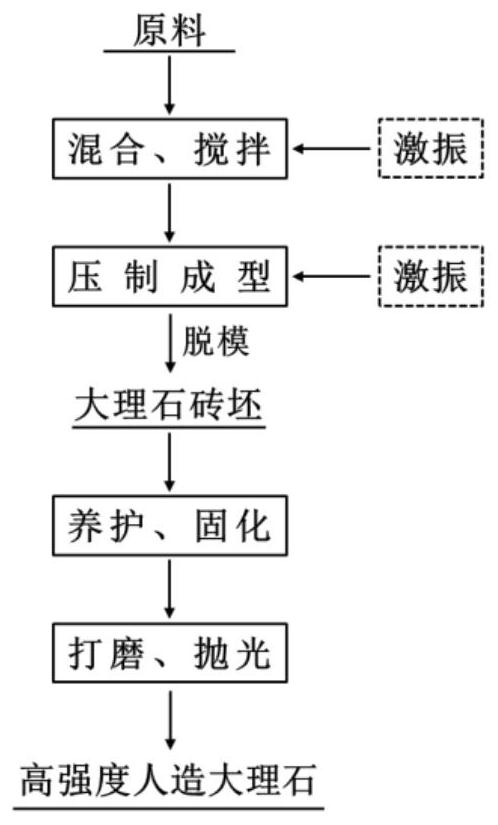

Method used

Image

Examples

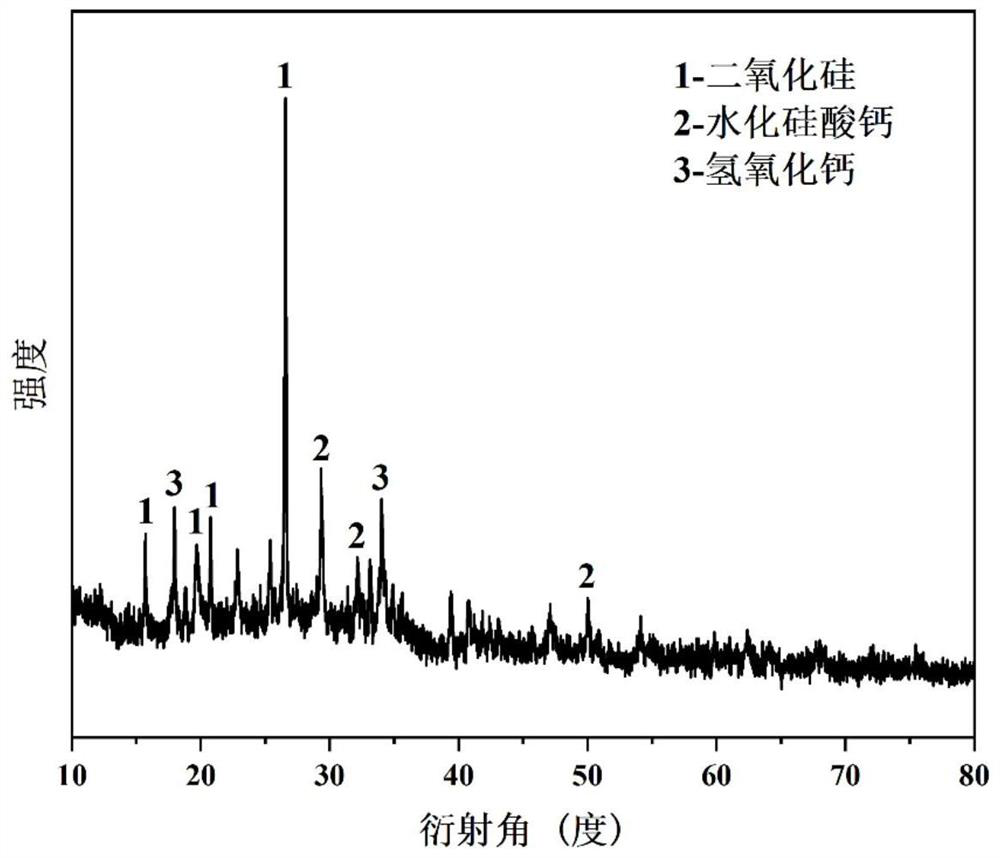

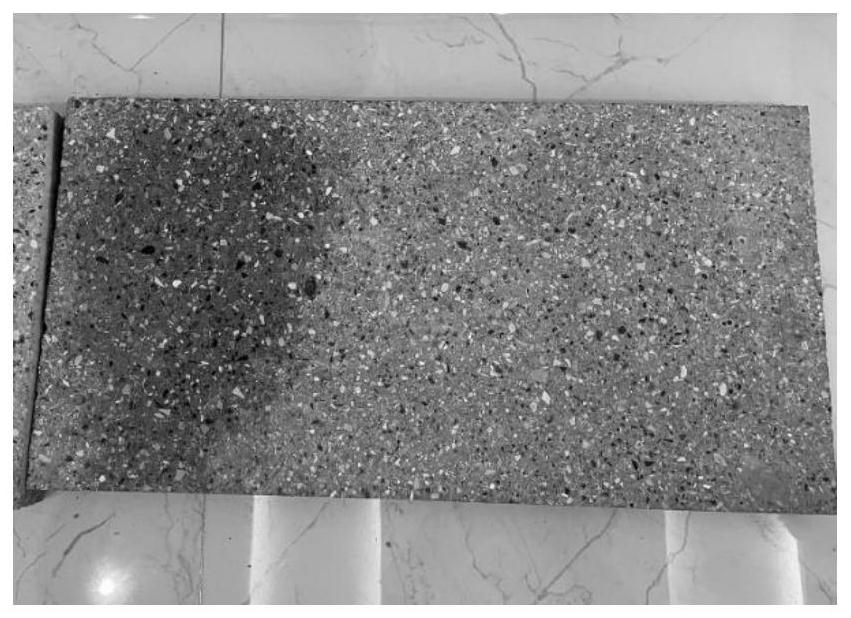

Embodiment 1

[0030] Firstly, the low-calorific-value coal fly ash is ball-milled into powder in a ball mill, and the low-calorific-value coal slag is screened through a 100-mesh sieve, and the low-calorific-value coal slag is selected with a particle size between 1-8mm. 15% cement, 30% low calorific value coal fly ash and 55% low calorific value coal slag are respectively weighed according to mass percentage. Transfer the above raw materials to the mixer, add water according to 30% of the weight of the gelled material, apply a 150Hz excitation frequency to the silo through the high-frequency pneumatic vibrator installed on the outer wall of the silo, and the air inlet pressure is 0.3MPa, vibrate and stir 180s. The material after the vibration activation is transferred to the 600mm×300mm rectangular stainless steel mold of the brick press, and the material is continuously vibrated by the high-frequency pneumatic vibrator. The vibration frequency is 43Hz, so that the material reaches a state...

Embodiment 2

[0033] Firstly, the low-calorific-value coal fly ash is ball-milled into powder in a ball mill, and the low-calorific-value coal slag is screened through a 100-mesh sieve, and the low-calorific-value coal slag is selected with a particle size between 1-8mm. 18% cement, 17% low calorific value coal fly ash and 65% low calorific value coal slag are respectively weighed according to mass percentage. Transfer the above raw materials to the mixer, add water according to 35% of the weight of the gelled material, apply a 400Hz excitation frequency to the silo through the high-frequency pneumatic vibrator installed on the outer wall of the silo, and the air inlet pressure is 0.45MPa, vibrate and stir 240s. The material after vibration activation is transferred to the 600mm×300mm rectangular stainless steel mold of the brick press, and the material is continuously vibrated by the high-frequency pneumatic vibrator. The frequency of the vibration is 44Hz, so that the material reaches a s...

Embodiment 3

[0035] Firstly, the low calorific value coal slag is screened to select the low calorific value coal slag with a particle size between 1-8mm. 20% cement and 80% low calorific value coal slag are respectively weighed according to mass percentage. Transfer the above raw materials to the mixer, add water according to 40% of the weight of the gelled material, apply a 400Hz excitation frequency to the silo through the high-frequency pneumatic vibrator installed on the outer wall of the silo, and the air inlet pressure is 0.6MPa, vibrate and stir 300s. The material after vibration activation is transferred to the 600mm×300mm rectangular stainless steel mold of the brick press, and the material is continuously vibrated by the high-frequency pneumatic vibrator. The vibration frequency is 45Hz, so that the material reaches a state of high-speed movement, thereby To make the material disperse more evenly and densely, apply a pressure of 4kN to the material while vibrating, and the vibr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com