Two-component polyurethane waterproof coating and preparation method thereof

A two-component polyurethane, two-component polyurethane technology, applied in the field of coatings, can solve the problem of low acid and alkali resistance, achieve good mixing performance, reduce costs, and low prices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] 1) Weigh the following materials in proportion:

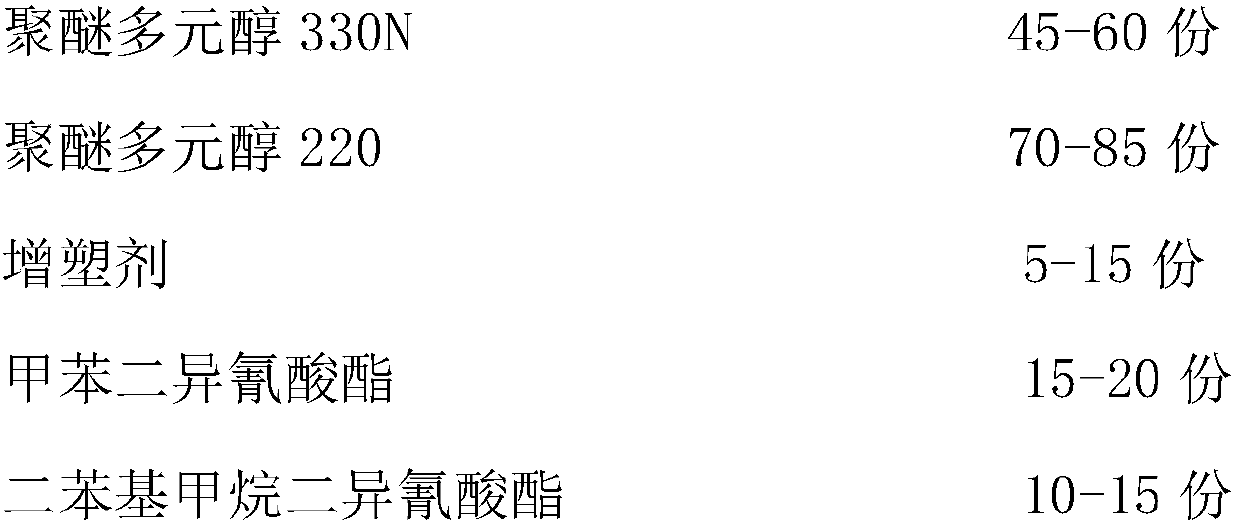

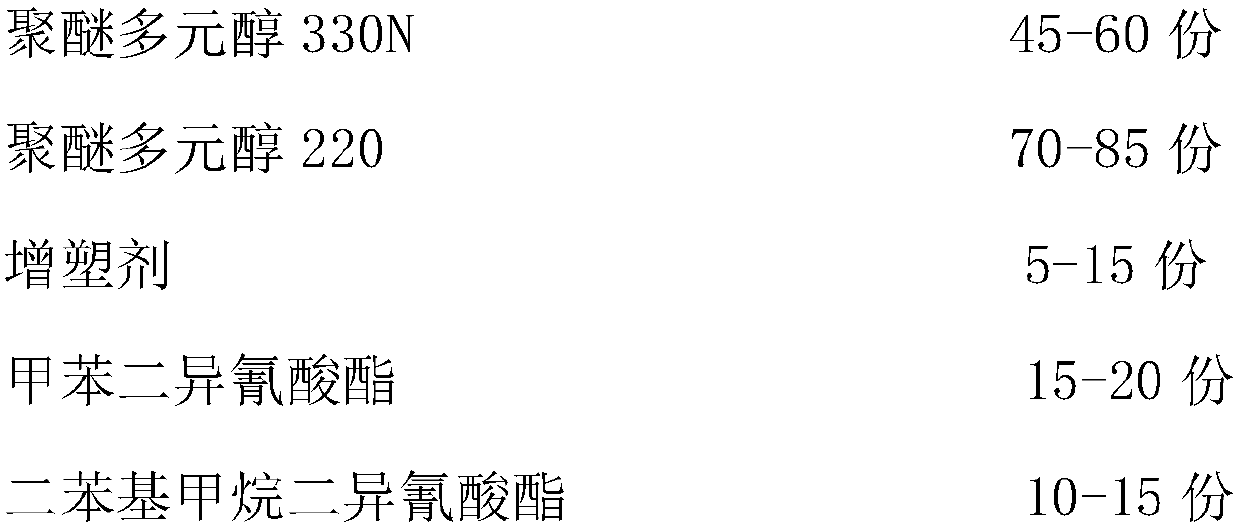

[0022] A component:

[0023]

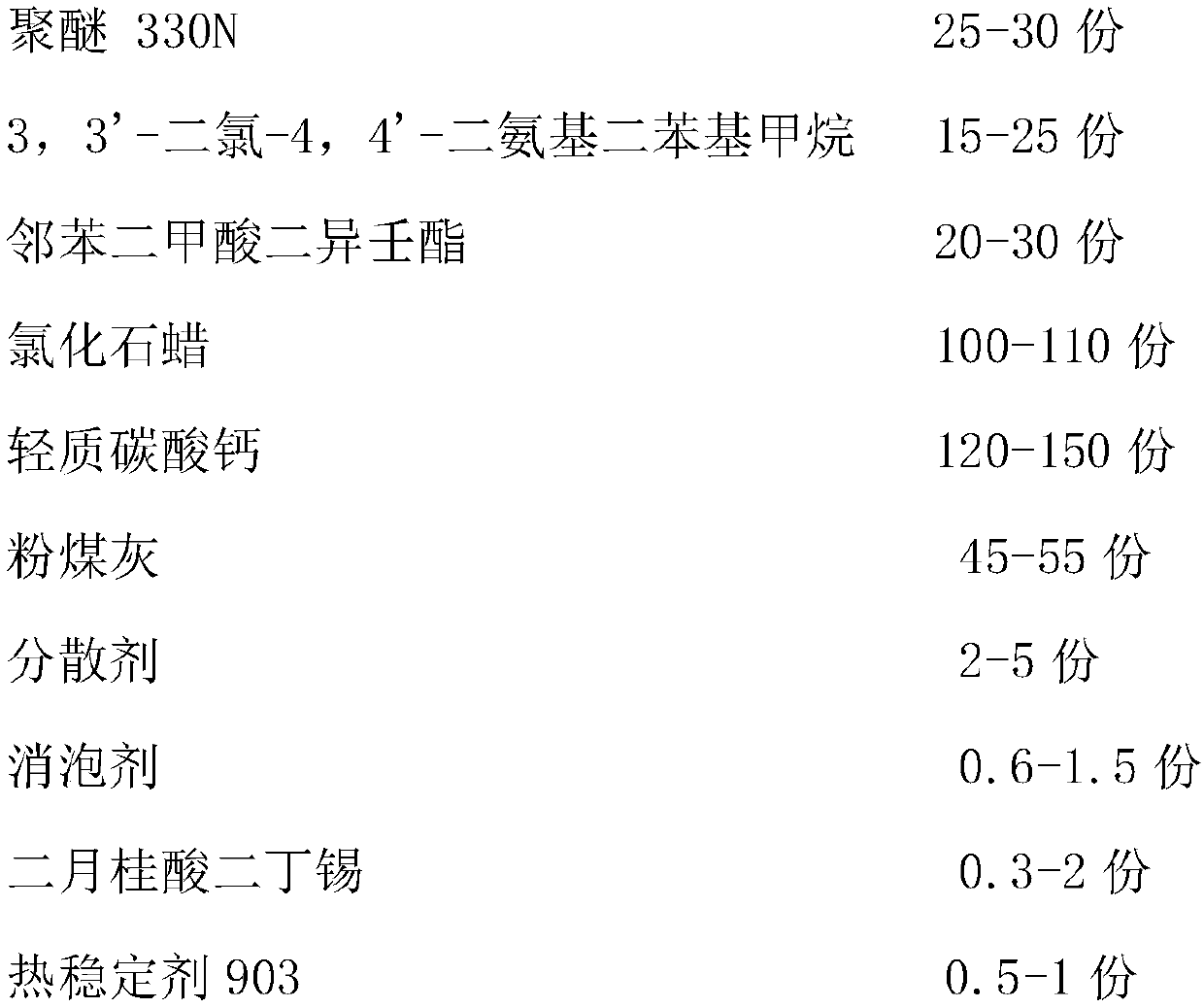

[0024] B component:

[0025]

[0026] Each component is composed of components in parts by weight;

[0027] 2) Preparation of component A: Mix polyether polyol 330N, polyether polyol 220 and plasticizer, heat up to 120°C while stirring, vacuum dehydrate for 1 hour, cool down to 70°C after the moisture content is less than 0.05% , add toluene diisocyanate and diphenylmethane diisocyanate, react at 82°C for 2 hours, and discharge to obtain a polyurethane prepolymer;

[0028] 3) Preparation of component B of curing agent: polyether 330N, 3,3'-dichloro-4,4'-diaminodiphenylmethane, chlorinated paraffin, 1200 mesh light calcium carbonate and fly ash, Stir and disperse evenly, heat to 120°C, vacuum dehydrate for 1 hour, add diisononyl phthalate, dibutyltin dilaurate, polydimethylsiloxane defoamer, heat stabilizer 903 and polyacrylic acid after cooling down Dispersant, mix and disperse, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com