Method for poly-generation and large-scale coupling production based on semi coke and magnesium

A technology for blue carbon and blue carbon tail gas, which is applied in the field of large-scale coupling production based on blue carbon and magnesium polyproduction, can solve the problems of large coke consumption, large emission and high cost, reduce coke consumption and power consumption, and reduce tail gas. quantity, the effect of protecting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

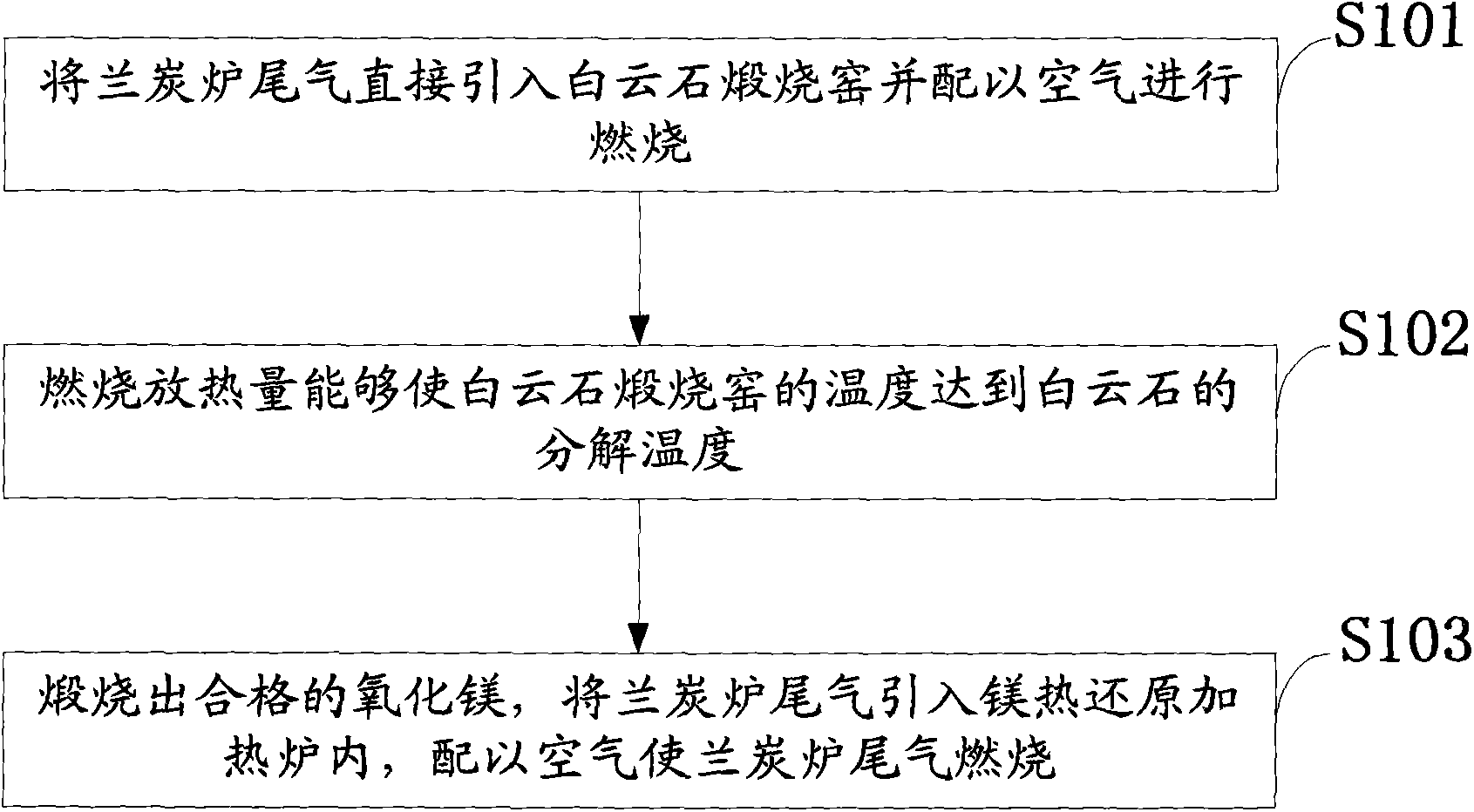

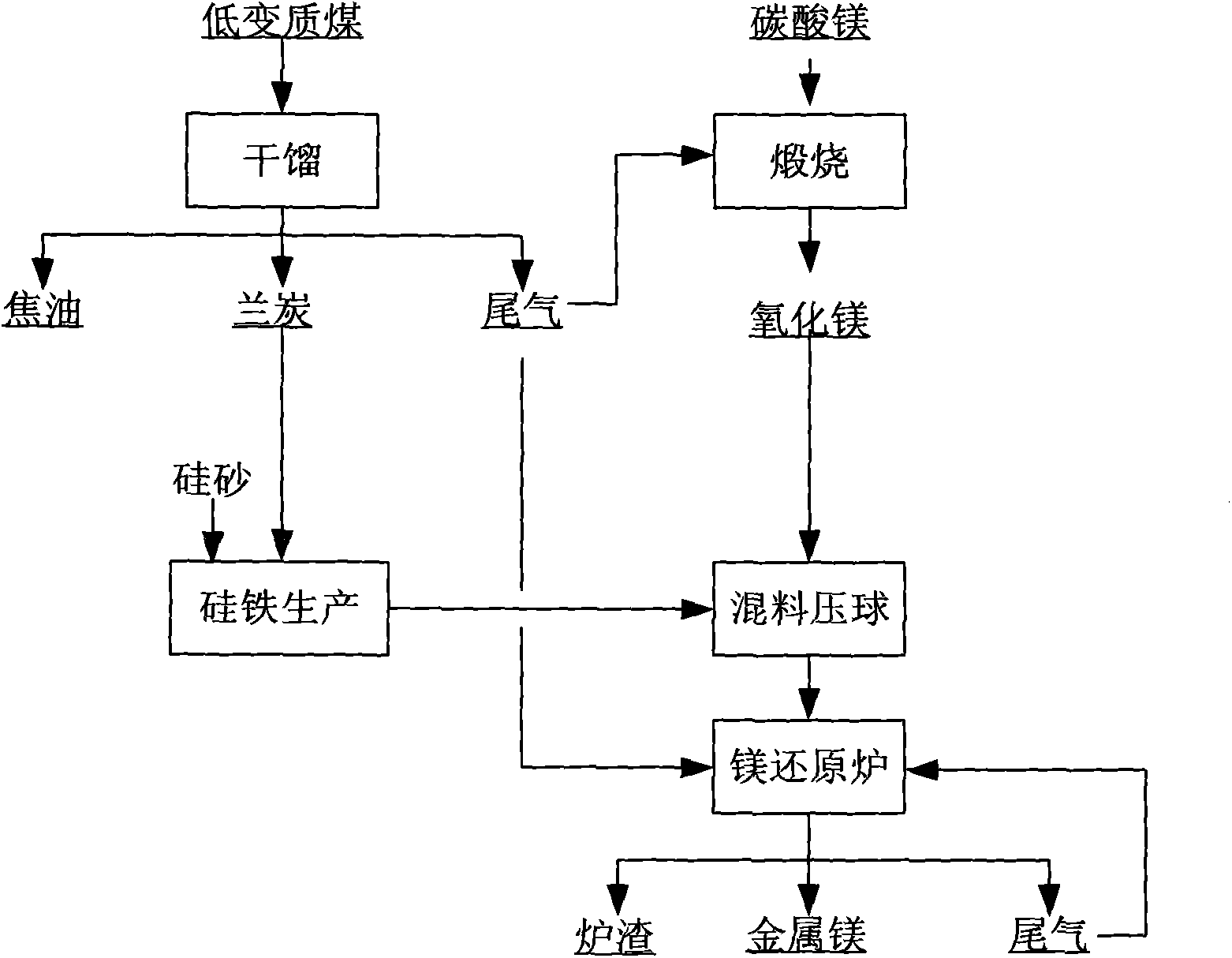

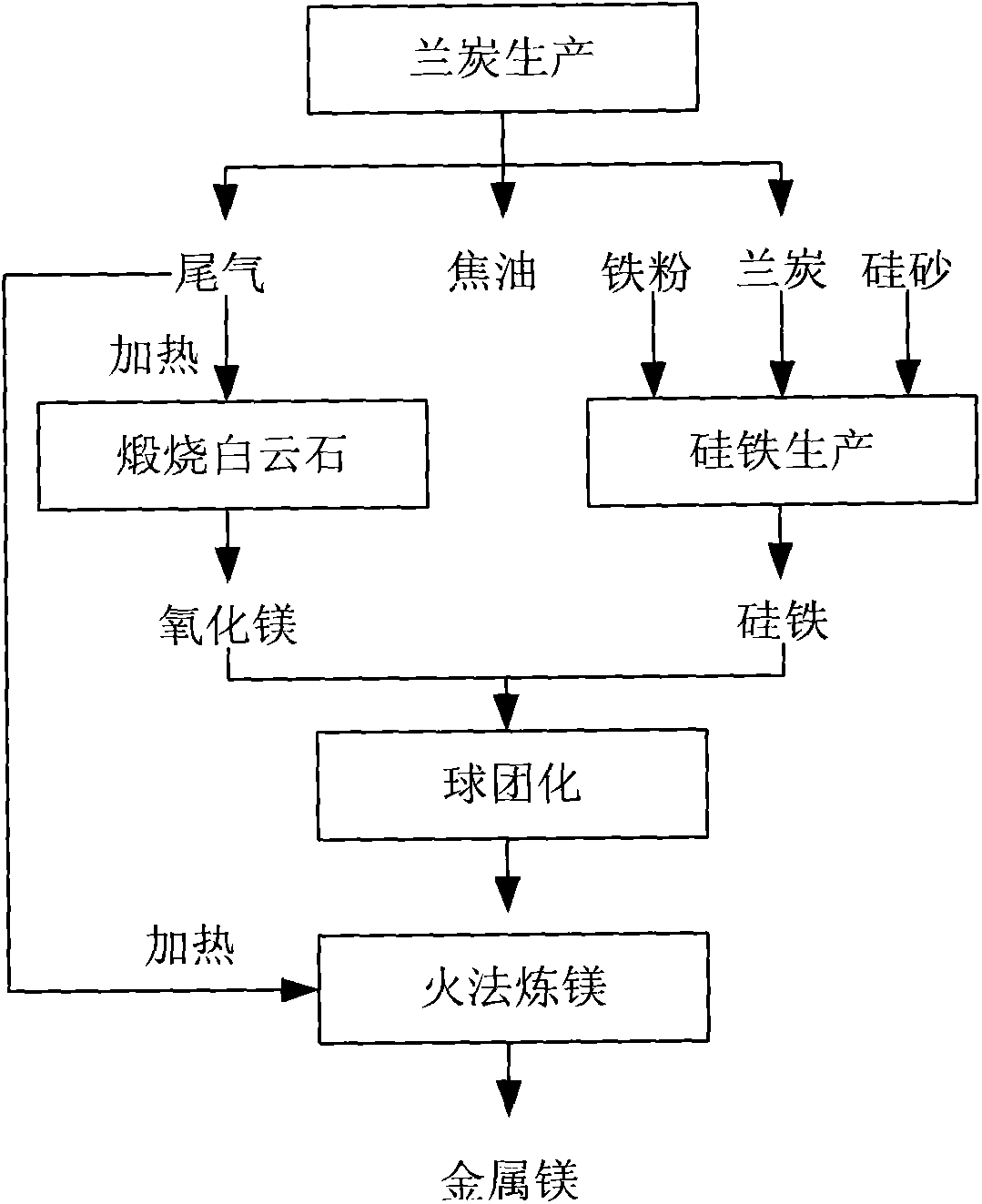

Method used

Image

Examples

Embodiment 1

[0040] When the output of the semi-coke furnace is 50,000 tons / year, it can use the tail gas of the semi-coke furnace as a heat source to produce 1,000 tons / year of magnesium metal. When the output of the semi-coke furnace is 300,000 tons / year, it uses semi-coke Furnace tail gas can be used as a heat source to produce 7,500 tons of magnesium metal per year. According to the above two sets of data, it can be concluded that after the production scale of the semi-coke furnace is expanded, the production capacity of the supporting metal magnesium will increase. When 50,000 tons per year At the carbon scale, the supporting magnesium production capacity is 200 tons of magnesium / 10,000 tons of semi-coke, while at the scale of 300,000 tons / year of semi-coke, the supporting magnesium production capacity is 250 tons of magnesium / 10,000 tons of semi-coke. Magnesium capacity was also expanded and energy consumption was reduced while magnesium production expanded.

[0041] The present inve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com