Pijiang metal refining method and device

A metal and alkali metal technology, applied in the field of Pidgeon metal refining process and equipment, can solve problems such as waste of raw materials, reduction of thermal efficiency of reduction tank, hidden dangers of production safety, etc., to reduce hidden dangers of production accidents, shorten loading and unloading time, and enhance creep The effect of variable resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

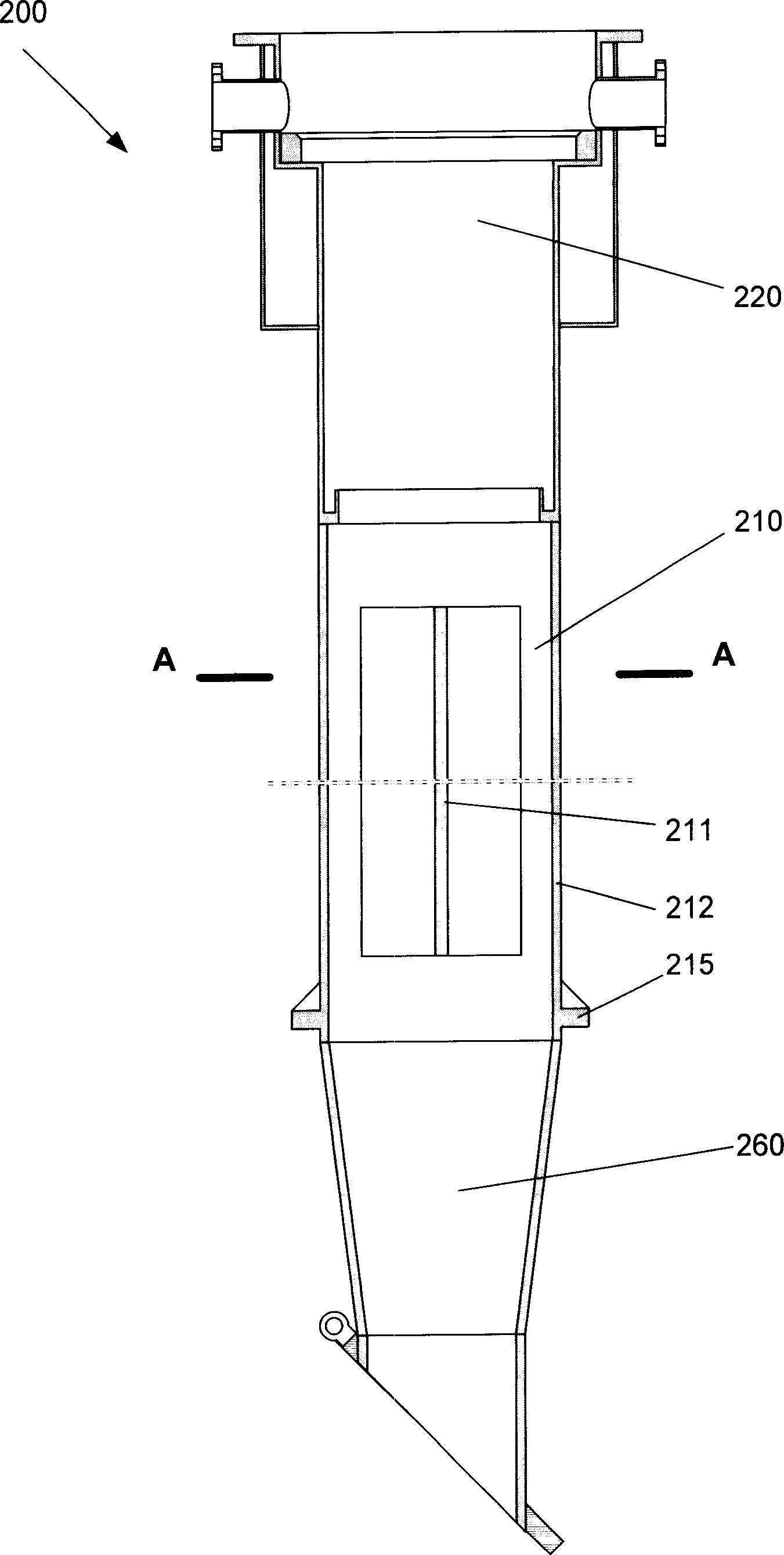

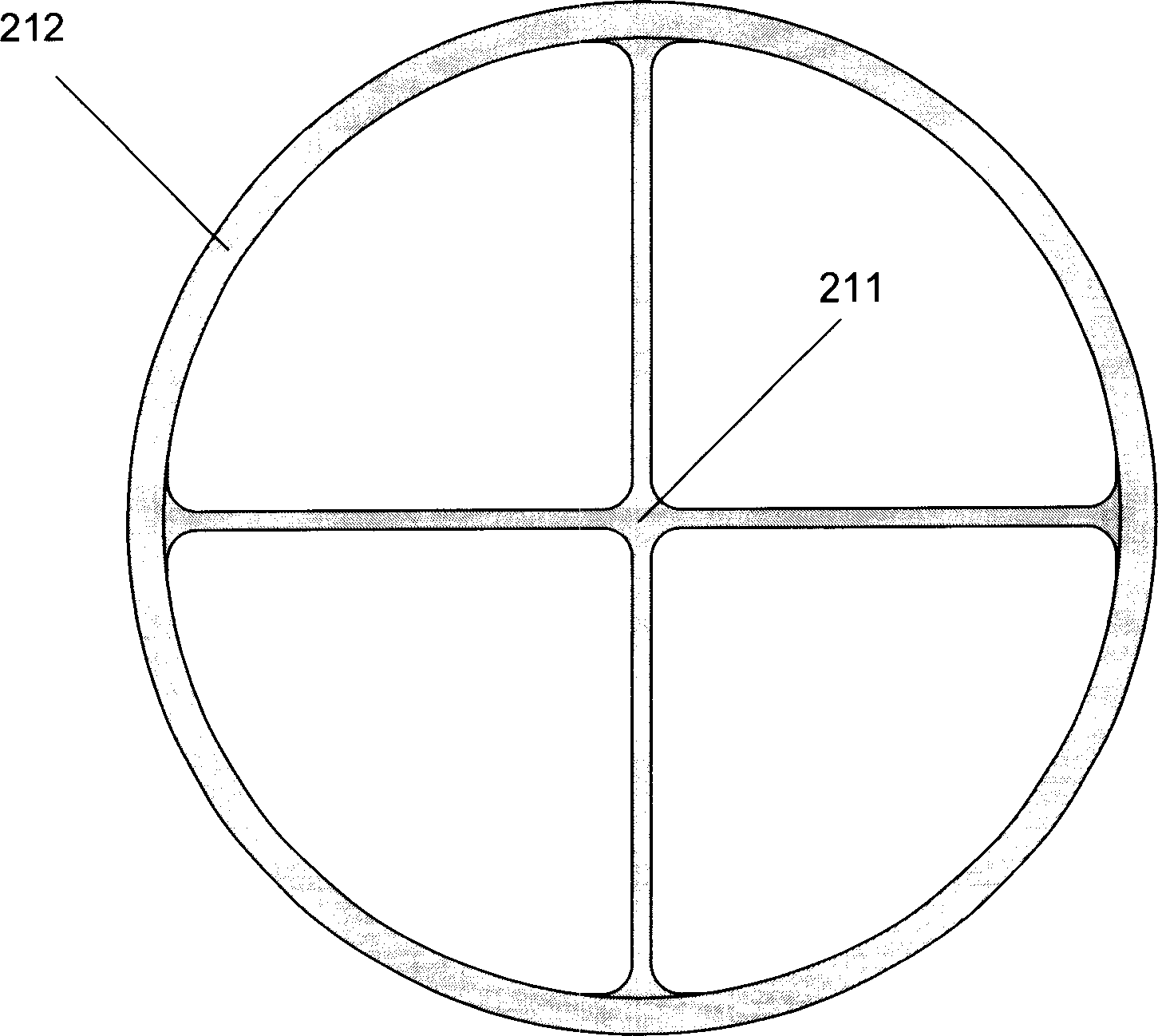

[0039] The present invention overcomes a series of existing defects of the Pidgeon magnesium smelting process by providing a novel vertical reduction tank and a reduction furnace built on the basis thereof, such as: long reduction period, short life of the reduction tank, difficulty in loading and unloading materials, inability to Monitoring of reduction processes, inability to recover alkali metals, etc. However, the present invention does not change the chemical reaction principle and basic technological process based on the Pidgeon magnesium smelting method.

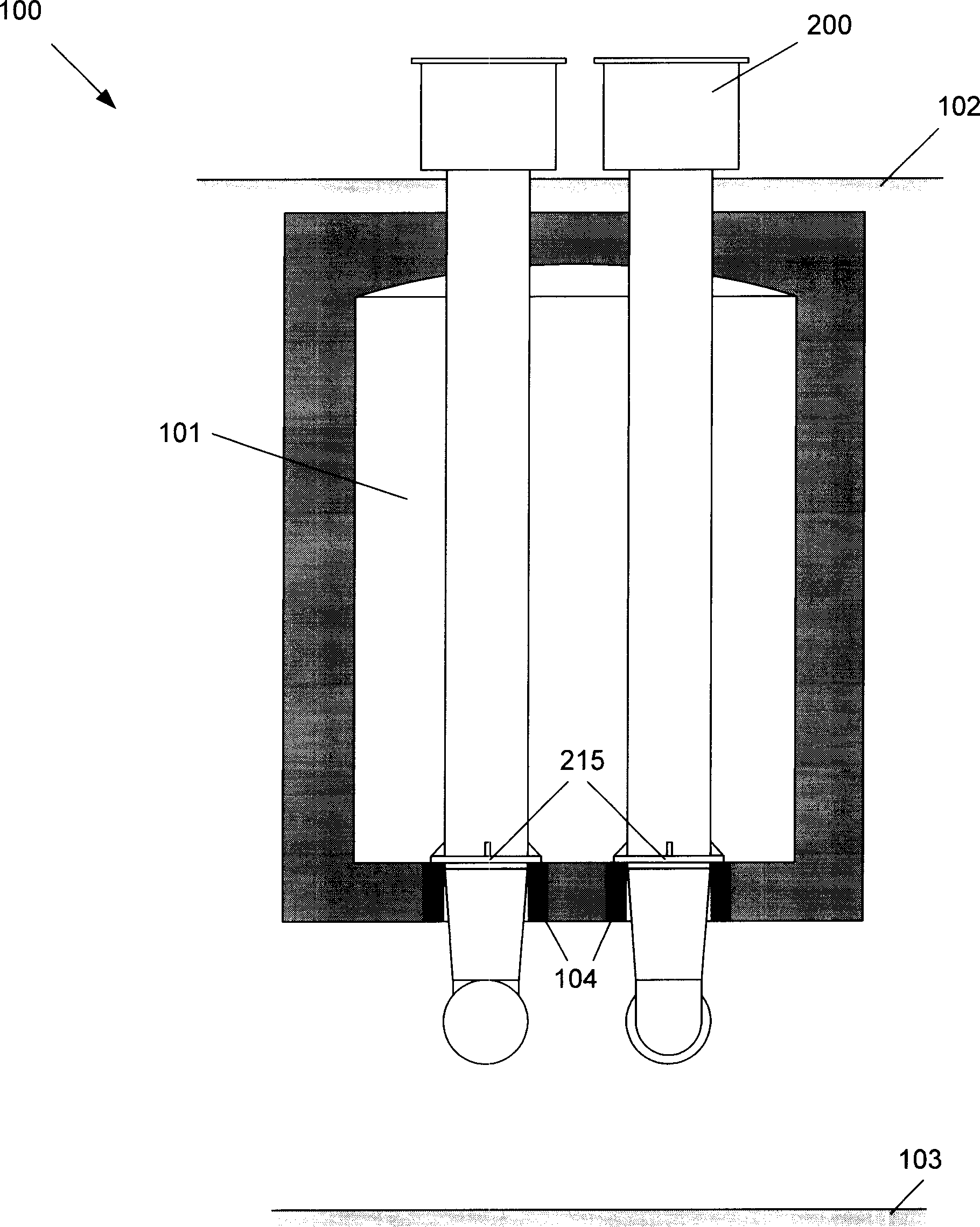

[0040] figure 1Shown is a schematic sectional view of a vertical reduction furnace (100) built using the reduction tank of the present invention (one embodiment). The reduction furnace (100) consists of a furnace body (101), a plurality of vertical reduction tanks (200) installed therein, an upper working platform (102) and a lower working platform (103). The heating of the furnace body (101) can be accomplished by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com