Method for recycling cadmium from metallurgical cadmium-contained dust and device for recycling cadmium from cadmium-ammonia solution

An ammonia solution and soot technology, applied in the improvement of process efficiency, photography process, instruments and other directions, can solve the problems of "long process, difficult separation of zinc and cadmium, large consumption of zinc powder, etc., and achieve the effect of reducing the burden.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

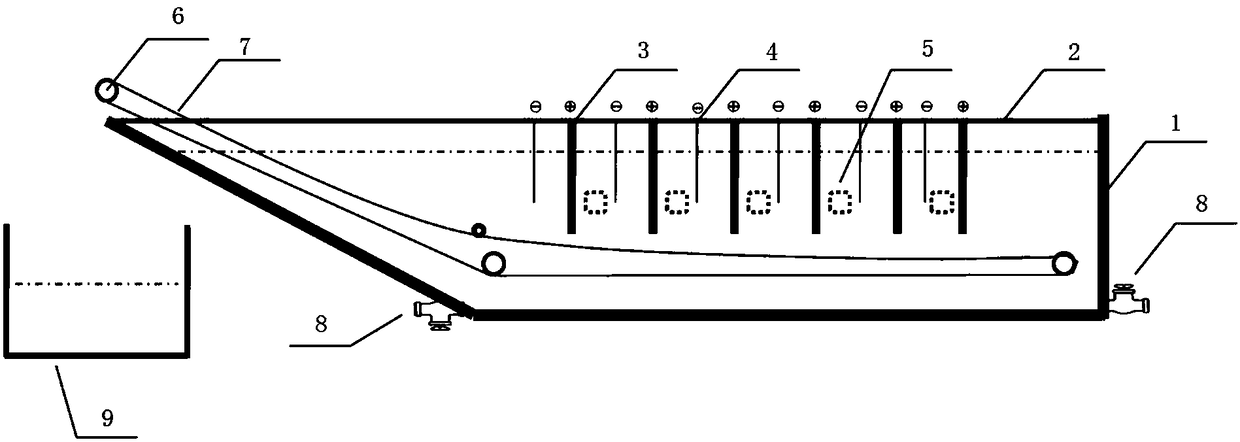

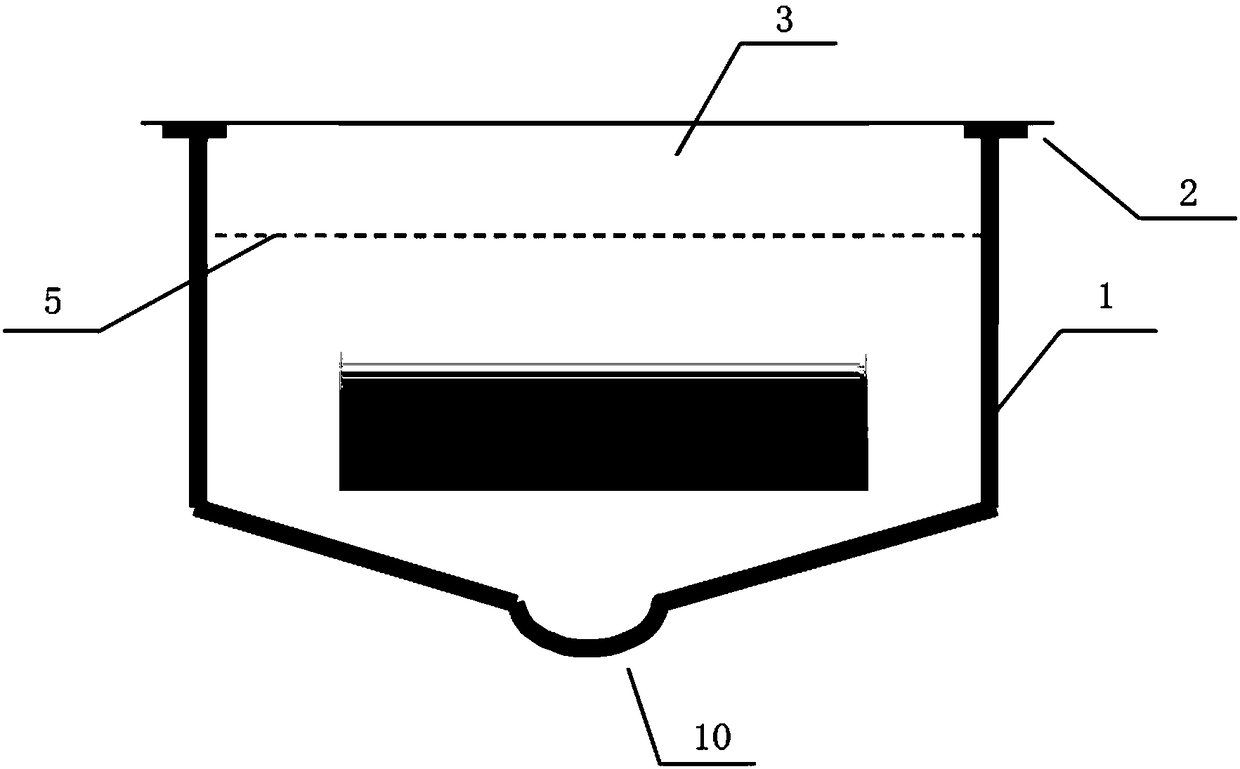

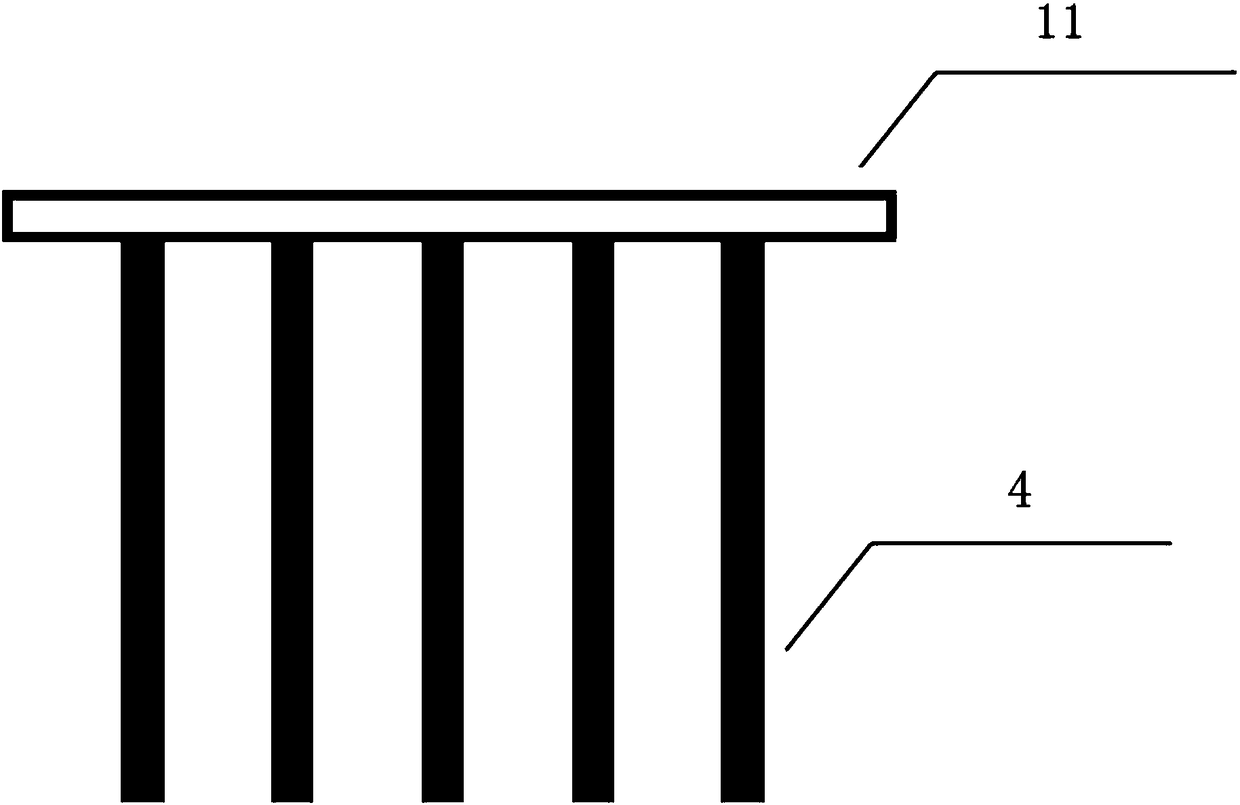

[0043] First, the cadmium-containing metallurgical fume is subjected to ammonia circulation leaching, and the circulation leaching process is ended when the lead / cadmium molar ratio in the solution is less than 0.01. After leaching, the liquid and solid are separated to obtain a cadmium-ammonia solution. Add an appropriate amount of vulcanizing agent to separate the sulfidation and precipitation of impurity ions in the cadmium-ammonia solution. The impurity-removed solution is placed in the key device for cadmium extraction enhanced by ultrasonic enhancement and electric displacement to efficiently extract cadmium to obtain high-grade sponge cadmium and zinc-ammonia solution. Sponge cadmium can be directly used for briquette distillation or casting-electrolytic refining to obtain high-purity cadmium, and the zinc-ammonia solution can be directly returned to the electric zinc system to produce electric zinc.

[0044] Specifically include: take 500g of cadmium-containing dust (...

Embodiment 2

[0046] The cadmium-containing metallurgical fumes are subjected to ammonia circulation leaching, and the circulation leaching process is ended when the lead / cadmium molar ratio in the solution is less than 0.01. After leaching, the liquid and solid are separated to obtain a cadmium-ammonia solution. Add an appropriate amount of vulcanizing agent to separate the sulfidation and precipitation of impurity ions in the cadmium-ammonia solution. The impurity-removed solution is placed in the key device for cadmium extraction enhanced by ultrasonic enhancement and electric displacement to efficiently extract cadmium to obtain high-grade sponge cadmium and zinc-ammonia solution. Sponge cadmium can be directly used for briquette distillation or casting-electrolytic refining to obtain high-purity cadmium, and the zinc-ammonia solution can be directly returned to the electric zinc system to produce electric zinc.

[0047] Specifically include: take 2000g of cadmium-containing dust from ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com